Inkjet pigment ink

A pigment and inkjet technology, applied in the field of ink sets, printed matter, and inkjet inks, can solve the problems of difficulty in making inks with dispersion stability, difficulty in ensuring dispersion stability, etc., and achieve the effects of excellent weather resistance and excellent printability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

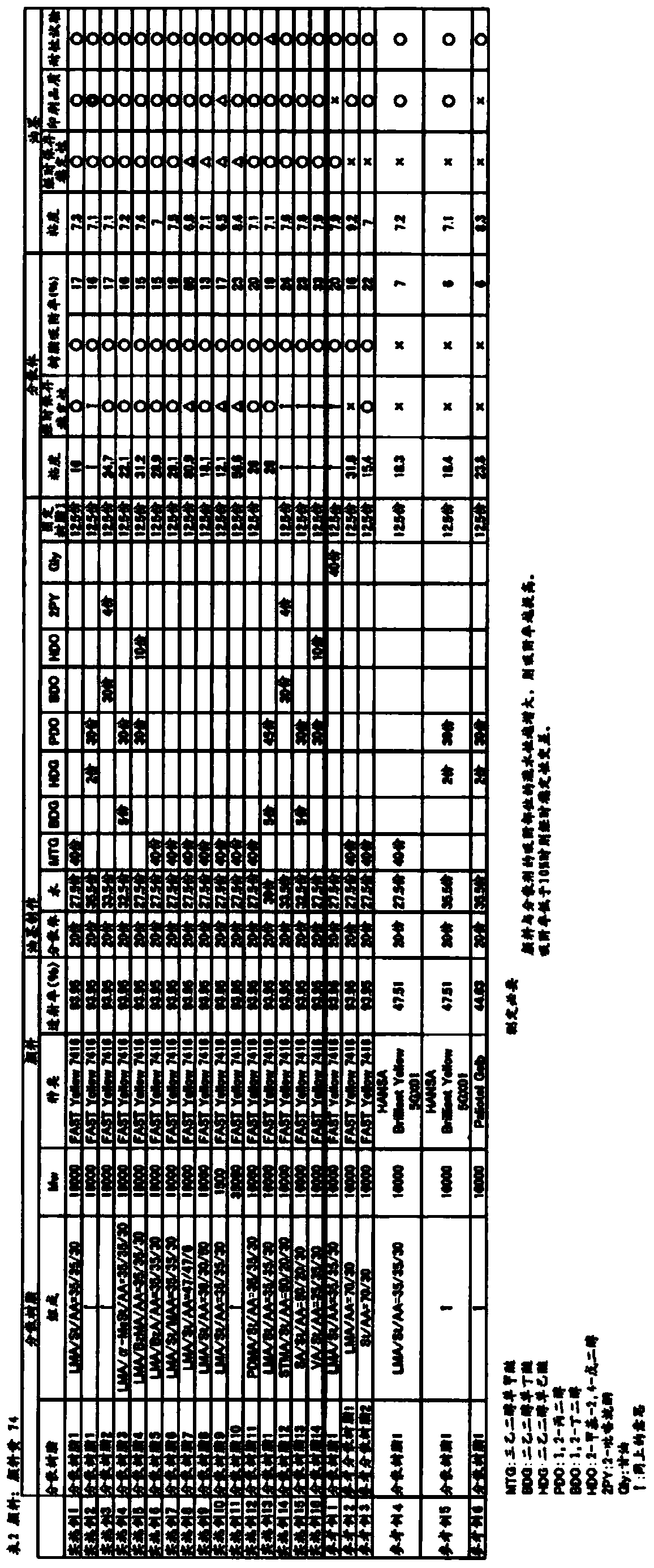

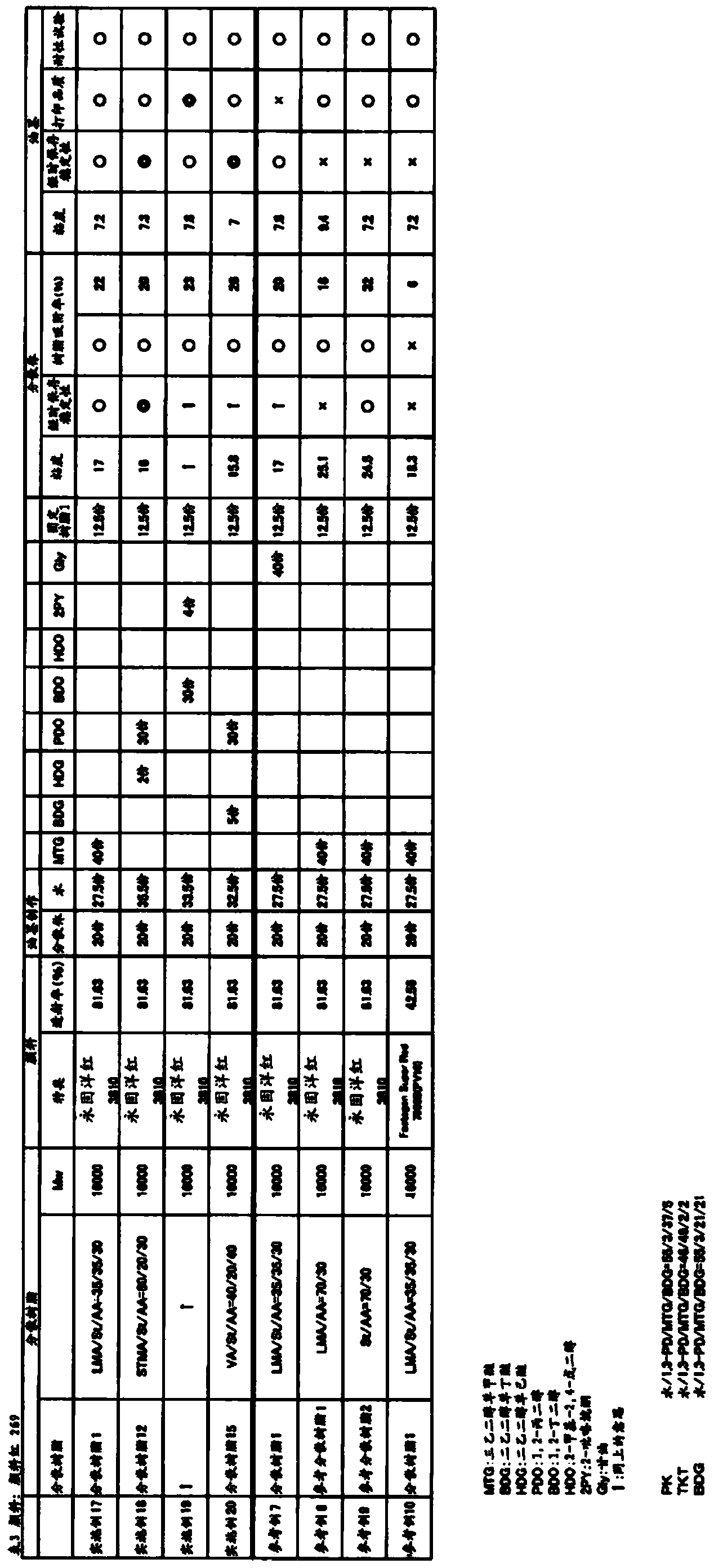

Examples

Embodiment

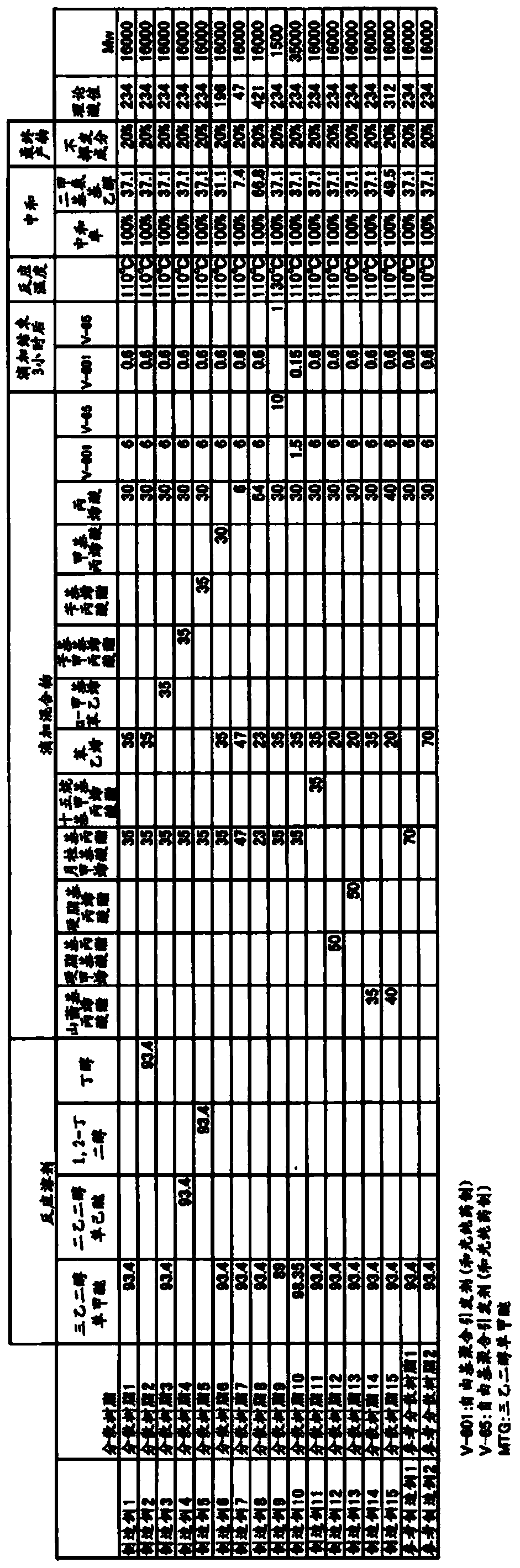

[0133] Hereinafter, the present invention will be described more concretely with reference to the embodiments, examples and comparative examples. In addition, in the following description, when using "part" and "%", it is a basis of weight unless otherwise indicated.

[0134]

manufacture example 1

[0135] (Production Example 1) Synthesis of Dispersion Resin 1

[0136]93.4 parts of triethylene glycol monomethyl ether were added to a reaction container equipped with a gas introduction tube, a thermometer, a condenser, and a stirrer, and nitrogen gas was used to replace it. The inside of the reaction vessel was heated to 110°C, and a mixture of 35.0 parts of lauryl methacrylate, 35.0 parts of styrene, 30.0 parts of acrylic acid, and 6.0 parts of V-601 (manufactured by Wako Pure Chemical Industries) was added dropwise over 2 hours to perform polymerization reaction. After completion of the dropwise addition, 0.6 parts of V-601 (manufactured by Wako Pure Chemical Industries, Ltd.) was added after further reacting at 110° C. for 1 hour, and a solution of dispersion resin 1 was obtained by further reacting at 110° C. for 1 hour. The weight-average molecular weight of Dispersion Resin 1 was about 16,000.

[0137] Furthermore, after cooling to room temperature, 37.1 parts of di...

manufacture example 2

[0138] (Production Example 2) Synthesis of Dispersion Resin 2

[0139] 93.4 parts of butanol was added to a reaction container equipped with a gas introduction tube, a thermometer, a condenser, and a stirrer, and nitrogen gas was used to replace it. The inside of the reaction vessel was heated to 110°C, and a mixture of 35.0 parts of lauryl methacrylate, 35.0 parts of styrene, 30.0 parts of acrylic acid, and 6.0 parts of V-601 (manufactured by Wako Pure Chemical Industries) was added dropwise over 2 hours to perform polymerization reaction. After completion of the dropwise addition, 0.6 parts of V-601 (manufactured by Wako Pure Chemical Industries, Ltd.) was added after further reacting at 110° C. for 1 hour, and a solution of dispersion resin 2 was obtained by further performing reaction at 110° C. for 1 hour. The weight average molecular weight of dispersion resin 2 was about 16,000.

[0140] Furthermore, after cooling to room temperature, 37.1 parts of dimethylaminoethano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com