Transparent polyvinyl chloride material, and preparation and application thereof

A polyvinyl chloride and ethylene technology, applied in the field of polyvinyl chloride hose materials, can solve the problems of lowering the plasticizing temperature and not ensuring the transparency of PVC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

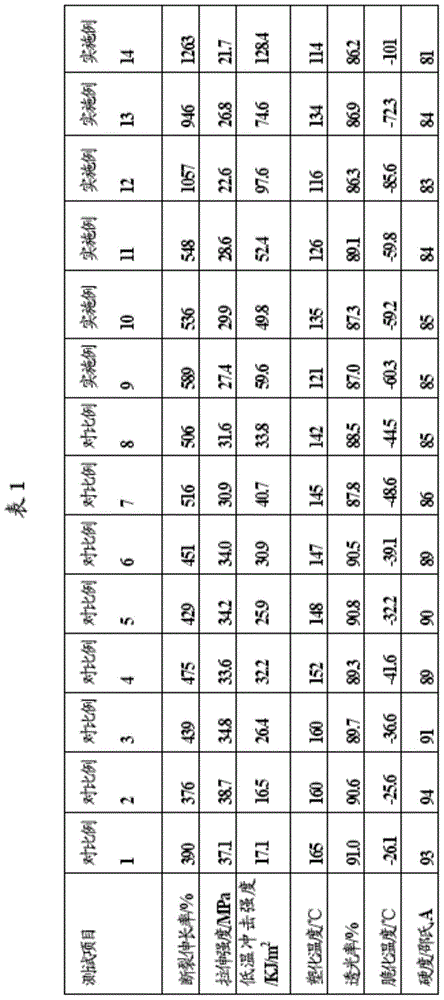

[0089] The present invention will be described in more detail below with examples. This embodiment all is only the description to the preferred embodiment of the present invention, does not have any limitation to the scope of the present invention

[0090] In each of the following examples, unless otherwise specified, the parts of each component are parts by weight.

[0091] In following each embodiment, adopt following method to test gained polyvinyl chloride material:

[0092] Light transmittance and haze test: measured according to GB / T2410-1980, sample thickness is 2.0mm;

[0093] Tensile strength: According to GB / T16421-1996, the tensile speed is 50mm / min, and the temperature is 25°C;

[0094] Low-temperature impact strength: Place the sample in a liquid nitrogen environment at -40°C for 20 minutes for Charpy impact;

[0095] TMA test: the temperature scanning range is 110-200°C, and the temperature rise rate is 10°C / min;

[0096] Embrittlement temperature test: MZ-40...

Embodiment 9

[0116] Polyvinyl chloride (brand SG4, purchased from Tianjin Organic Chemical No. U.S. PolyOne Corporation) mix uniformly in the ratio of 100 / 25 / 4 / 5, then add 1.5 parts of calcium stearate, 1.5 parts of zinc stearate, 5 parts of solid phosphite and β-diketone 3 parts of the compound and 30 parts of tris(2-ethylhexyl) phosphate (TOP) were mixed uniformly to obtain a mixture. Then, the mixture was kneaded uniformly at a temperature of 165° C. by a twin-roller kneader, and then released into sheets and cooled. Then put the obtained cold sheet into a flat vulcanizer with a molding temperature of 185°C and a press gauge pressure of 10MPa. After pressing for 5 minutes, take it off and keep the pressure in the cold press for cooling. The gauge pressure of the press is 8MPa, and it is cooled to After 50°C, samples were taken. The sample was cut with a cutting knife of standard size by the prototype machine, and the performance test was carried out on the sample. The experimental tes...

Embodiment 10

[0118] Polyvinyl chloride (brand SG5, purchased from Tianjin Organic Chemical Plant No. 2), Elvalo y (brand HP4051, DuPont Company), styrene-like (brand C-10, Henan Qinyang Hope Synthetic Material Factory) and MC100 (brand: JC-710, American PolyOne Corporation) in 100 / 16 / 6 / 10 portions The number ratio is mixed evenly, and 1.5 parts of calcium stearate, 1.5 parts of zinc stearate, 5 parts of solid phosphite, 3 parts of β-diketone compound and tris (2-ethylhexyl) phosphate (TOP ) 30 parts, mixed uniformly to obtain a mixture. Then, the mixture was kneaded uniformly at a temperature of 165° C. by a twin-roller kneader, and then released into sheets and cooled. Then put the obtained cold sheet into a flat vulcanizer with a molding temperature of 185°C and a press gauge pressure of 10MPa. After pressing for 5 minutes, take it off and keep the pressure in the cold press for cooling. The gauge pressure of the press is 8MPa, and it is cooled to After 50°C, samples were taken. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com