Preparation method of copolymer grafted carbon nano-tube super-hydrophobic material

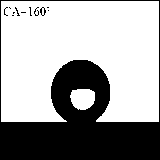

A carbon nanotube and multi-wall carbon nanotube technology, applied in the field of surface chemistry, can solve the problems of complex preparation method, poor superhydrophobic stability and high preparation cost, and achieve the effects of easy availability of raw materials, stable superhydrophobicity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

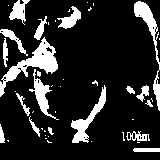

Image

Examples

Embodiment 1

[0023] 1. Synthesis of α-Methylstyrene and Butyl Methacrylate Copolymer

[0024] 1 g AMS, 9 g BMA, and 30 g THF were successively added to a three-necked flask, 0.3 g AIBN was added at 70° C., nitrogen gas was introduced, and after 21 h of magnetic stirring, the reaction solution was mixed with methanol at a mass ratio of 3:1. Precipitate with distilled water, centrifuge; dissolve the precipitate with acetone, reprecipitate with methanol and distilled water, centrifuge, repeat 3 times, then vacuum dry and grind to obtain the copolymer of α-methylstyrene and butyl methacrylate;

[0025] 2. Grafting α-Methylstyrene and Butyl Methacrylate Copolymer on the Surface of Multi-walled Carbon Nanotubes

[0026] Disperse 1 g of the copolymer of α-methylstyrene and butyl methacrylate and 0.05 g of multi-walled carbon nanotubes into a mixed solution of 30 ml of tetrahydrofuran and 10 ml of N, N-dimethylformamide, and ultrasonically vibrate After 30 minutes, nitrogen gas was passed throu...

Embodiment 2

[0032] 1. Synthesis of α-Methylstyrene and Butyl Methacrylate Copolymer

[0033] Add 0.5 g AMS, 10 g BMA, and 35 g THF to a three-necked flask successively, add 0.1 g AIBN at 65 ° C, feed nitrogen, and magnetically stir for 21 h. Precipitate with distilled water, centrifuge; dissolve the precipitate with acetone, reprecipitate with methanol and distilled water, centrifuge, repeat 3 times, then vacuum dry and grind to obtain the copolymer of α-methylstyrene and butyl methacrylate;

[0034] 2. Grafting α-Methylstyrene and Butyl Methacrylate Copolymer on the Surface of Multi-walled Carbon Nanotubes

[0035] Disperse 1 g of the copolymer of α-methylstyrene and butyl methacrylate and 0.02 g of multi-walled carbon nanotubes into a mixed solution of 30 ml of tetrahydrofuran and 10 ml of N, N-dimethylformamide, and ultrasonically vibrate After 30 minutes, nitrogen gas was passed through at 90°C to stir the reaction for 24 hours, vacuum filtered with a polyvinylidene fluoride microp...

Embodiment 3

[0039] 1. Synthesis of α-Methylstyrene and Butyl Methacrylate Copolymer

[0040] 5 g AMS, 10 g BMA, and 50 g THF were successively added into a three-necked flask, 0.5 g AIBN was added at 70° C., nitrogen gas was introduced, and after 21 h of magnetic stirring, the reaction solution was mixed with methanol with a mass ratio of 3:1. Precipitate with distilled water, centrifuge; dissolve the precipitate with acetone, reprecipitate with methanol and distilled water, centrifuge, repeat 3 times, then vacuum dry and grind to obtain the copolymer of α-methylstyrene and butyl methacrylate;

[0041] 2. Grafting α-Methylstyrene and Butyl Methacrylate Copolymer on the Surface of Multi-walled Carbon Nanotubes

[0042]Disperse 1 g of the copolymer of α-methylstyrene and butyl methacrylate and 0.1 g of multi-walled carbon nanotubes into 45 ml of tetrahydrofuran, ultrasonically oscillate for 30 minutes, and then pass nitrogen gas at 90°C to stir the reaction for 24 Hours, vacuum filtratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com