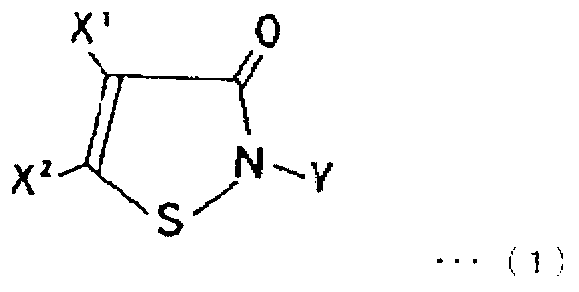

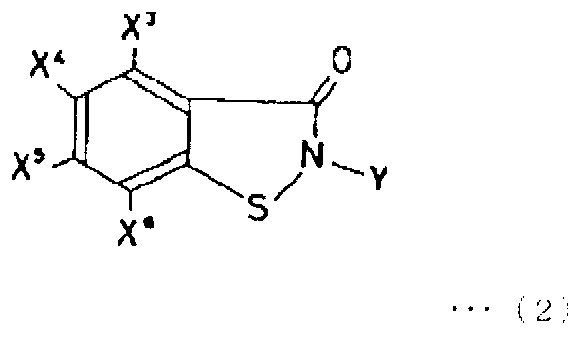

Binder composition for secondary battery negative electrode, slurry composition for secondary battery negative electrode, secondary battery negative electrode, secondary battery, and method for producing binder composition for secondary battery negat

A secondary battery and adhesive technology, applied in the direction of secondary batteries, battery electrodes, non-aqueous electrolyte battery electrodes, etc., can solve the problems of electrode film hindering electrical conductivity and insufficient bonding strength, and achieve the goal of inhibiting viscosity increase, inhibiting Reaction and swelling reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

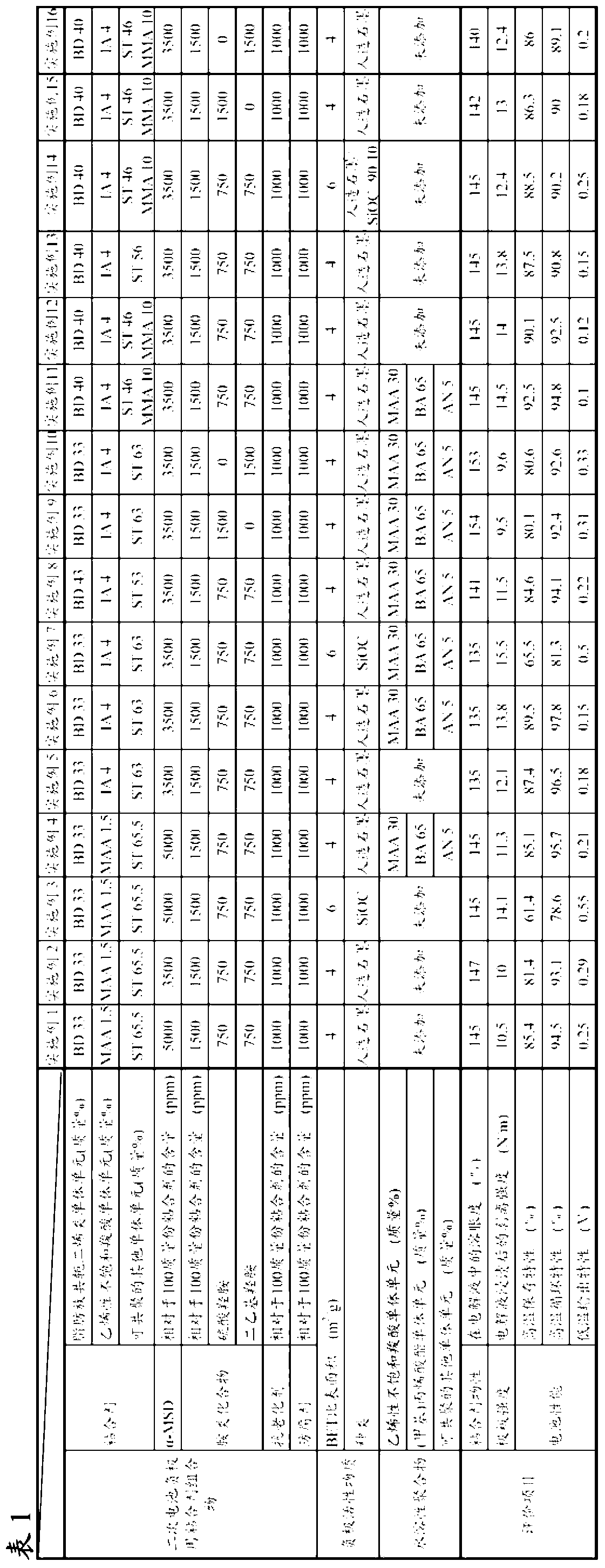

Embodiment 1

[0235] (manufacture of adhesive composition)

[0236] Put 33 parts of 1,3-butadiene, 1.5 parts of methacrylic acid, 65.5 parts of styrene, 0.4 parts of tertiary dodecyl mercaptan as a molecular weight regulator, and 4 parts of sodium dodecylbenzenesulfonate, 150 parts of ion-exchanged water, and 0.5 parts of potassium persulfate as a polymerization initiator were stirred thoroughly, then heated to 50°C to initiate polymerization. When the polymerization conversion rate reached 96%, cooling was performed to stop the reaction, and an aqueous dispersion liquid containing a binder was obtained.

[0237] Add 5% aqueous sodium hydroxide solution to the aqueous dispersion containing the above binder to adjust the pH to 8, then separate and remove unreacted monomers by heating and vacuum distillation, and then cool to below 30°C. Immediately thereafter, 5000ppm of α-methylstyrene dimer, 750ppm each of hydroxylamine sulfate and diethylhydroxylamine as an amine compound (1500ppm in tot...

Embodiment 2

[0249] Except that the addition amount of the α-methylstyrene dimer was 3500 ppm, the same operation as in Example 1 was performed to prepare a binder composition, a slurry composition, a negative electrode, and a battery, and evaluate them. The results are shown in Table 1.

Embodiment 3

[0251] As the negative electrode active material, use a BET specific surface area of 6m 2 / g of SiOC (volume average particle diameter: 18 μm), the same operation as in Example 1 was performed to prepare and evaluate a binder composition, a slurry composition, a negative electrode, and a battery. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Volume average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com