Graphite particle for nonaqueous secondary battery, method for producing same, negative electrode, and nonaqueous secondary battery

A secondary battery and graphite particle technology, applied in the direction of secondary batteries, battery electrodes, negative electrodes, etc., can solve the problems of reduced cycle characteristics, increased specific surface area, and reduced initial efficiency, and achieve high input and output characteristics, high cycle characteristics, the effect of high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

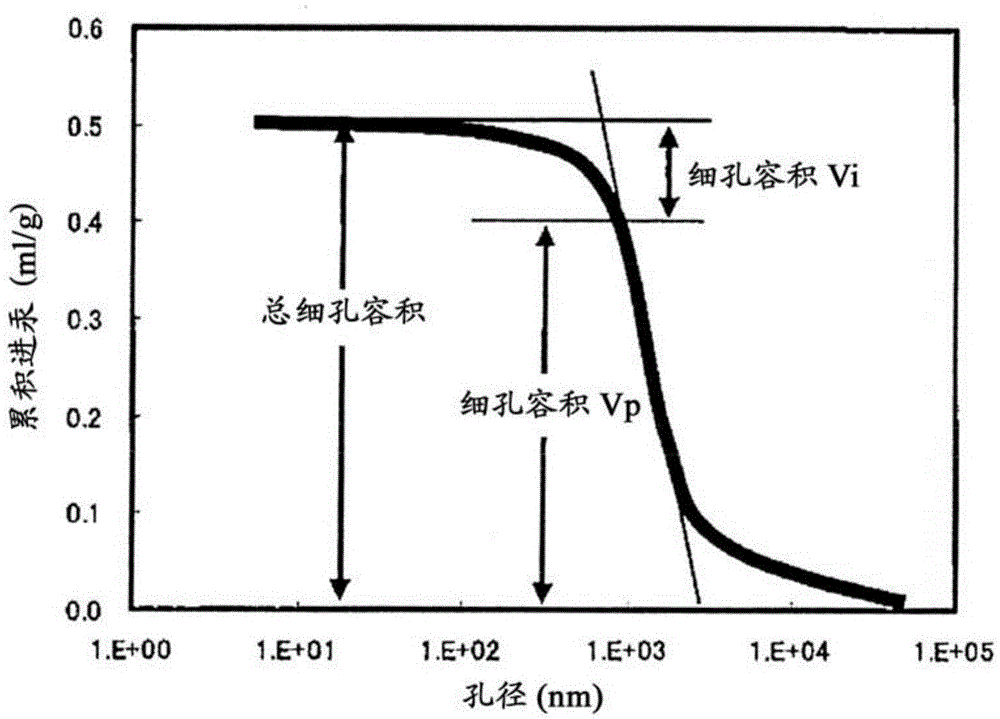

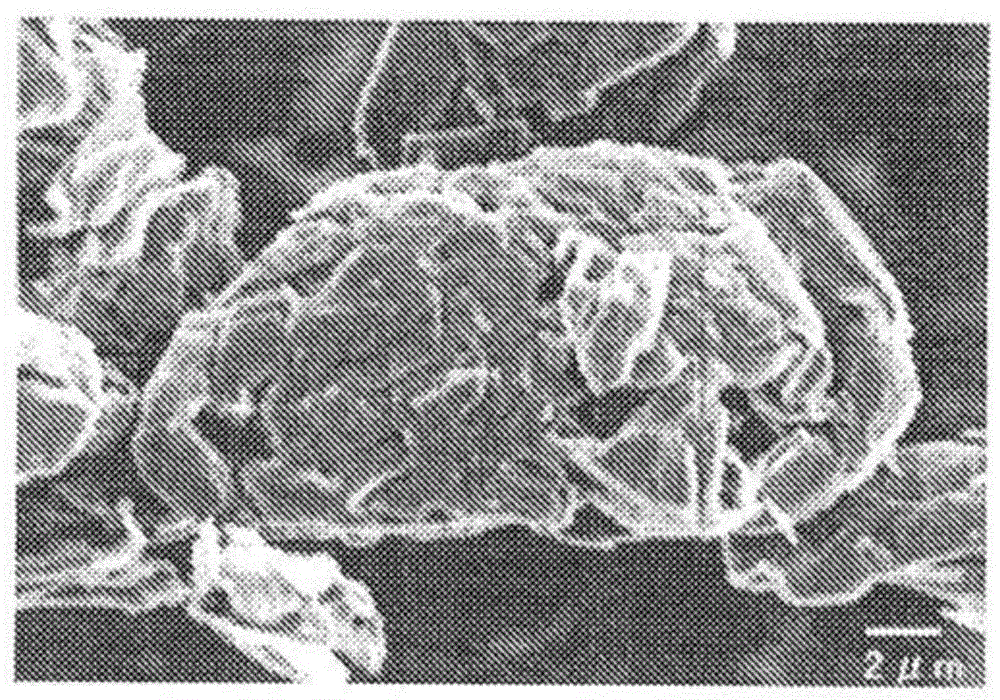

[0223] Spherical natural graphite with a volume-based average particle diameter of 17 μm was used as raw graphite, and as a surface roughening process, a pulverization device composed of a rotor and a stator was used to pulverize at a peripheral speed of the rotor of 145 m / s and an input speed of 200 kg / hour. Graphite having a concave-convex structure on the surface was obtained. With respect to 100 parts by mass of the obtained graphite, 30 parts by mass of pitch as a raw material organic substance was mixed using a kneader. After molding the obtained mixture, it fired and carbonized at 1000 degreeC in an inert atmosphere, and also graphitized at 3000 degreeC. The obtained graphite molded body was subjected to coarse pulverization and fine pulverization to obtain a powder sample composed of graphite particles. For this sample, DBP oil absorption, specific surface area, Raman R value, pore volume Vi, total pore volume, O / C, tap density, and average particle diameter were meas...

Embodiment 2

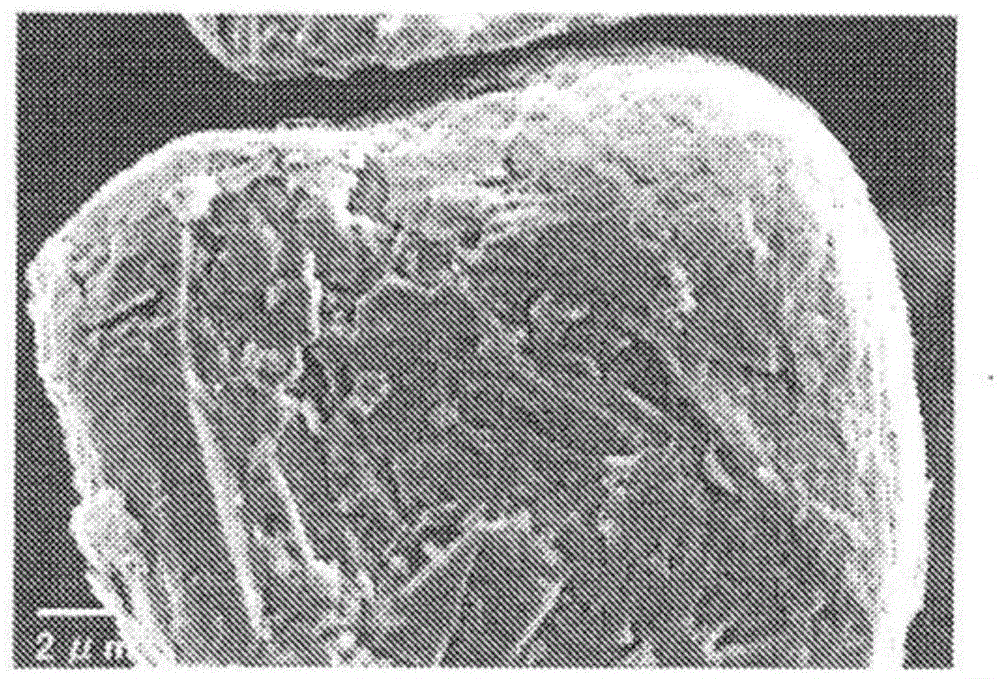

[0226] As a surface roughening process, except having set the peripheral speed of the rotor to 145 m / sec, it carried out similarly to Example 1, and obtained the powder sample which consists of graphite particles. For this sample, evaluation of physical properties and battery characteristics, and SEM observation were carried out in the same manner as in Example 1. The results are shown in Table 1.

Embodiment 3

[0228] As a surface roughening process, except having set the peripheral speed of the rotor to 130 m / sec, it carried out similarly to Example 1, and obtained the powder sample which consists of graphite particles. For this sample, evaluation of physical properties and battery characteristics, and SEM observation were carried out in the same manner as in Example 1. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil absorption | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com