Battery

A battery and non-aqueous electrolyte technology, applied in secondary batteries, lithium batteries, circuits, etc., can solve problems such as easy decomposition, insufficient capacity, unstable acid anhydride, etc., achieve decomposition inhibition, and improve high-temperature storage characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1 to 1-20 and comparative example 1-1 to 1-13

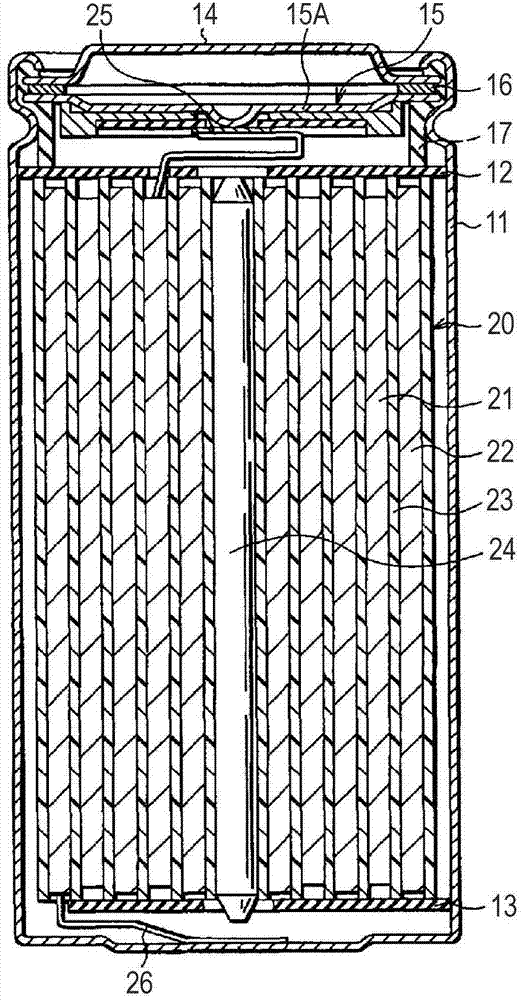

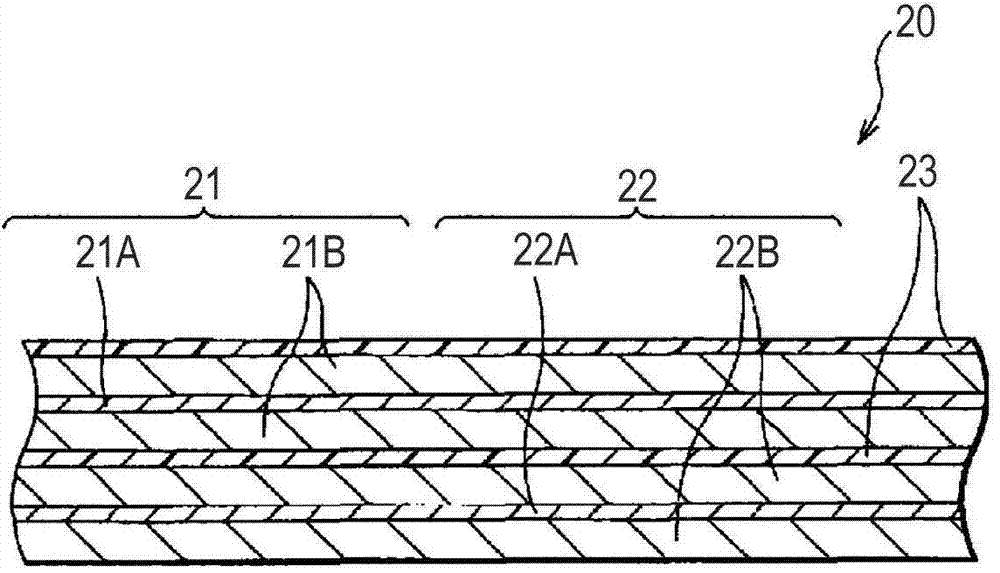

[0285] First, the positive electrode 21 is prepared. That is, lithium carbonate (Li 2 CO 3 ) and cobalt carbonate (CoCO 3 ) were mixed at a molar ratio of 0.5:1, followed by firing in air at 900°C for 5 hours to obtain a lithium-cobalt composite oxide (LiCoO 2 ). Next, 91 parts by mass of lithium cobalt composite oxide as a positive electrode active material, 6 parts by mass of graphite as a conductive agent, and 3 parts by mass of polyvinylidene fluoride as a positive electrode binder are mixed to form a positive electrode mixture, It was then dispersed in N-methyl-2-pyrrolidone to prepare a paste-like cathode mixture slurry. Finally, the positive electrode mixture slurry was coated on both sides of a positive electrode current collector 21A made of strip-shaped aluminum foil (thickness: 12 μm), dried, and then press-molded by a roll press to form a positive electrode active material layer. 21B. After that, a cathode lead 25 made of aluminum was mounted on one end of th...

reference example 1-1

[0289] Reference example 1-1 to 1-3

[0290] Batteries were prepared in the same manner as in Examples 1-6 to 1-8, but changing the content of water to 1,000 ppm, and then evaluated in the same manner.

[0291] The results are shown in Table 1.

[0292] Table 1

[0293]

[0294]

Embodiment 2-1 to 2-32

[0296] Each battery was prepared in the same manner, but using tPB as shown in Table 2 as the aromatic compound and changing the content of sulfonic anhydride and the content of water, and then evaluated in the same manner. The results are shown in Table 2. The above comparative example is also shown. Also, Examples 2-7 and Examples 2-23 are the same as Examples 1-7 and Examples 1-11, respectively.

[0297] Table 2

[0298]

[0299]

[0300] As shown in Table 2, the content of sulfonic anhydride and the content of water are preferably 0.1% by mass to 1% by mass and not more than 20 ppm, respectively.

[0301] Example 3-1 to 3-20, comparative example 3-1 to 3-12 and reference example 3-1 to 3-3

[0302] The secondary batteries of Examples 3-1 to 3-20, Comparative Examples 3-1 to 3-12, and Reference Examples 3-1 to 3-3 were prepared in the same manner as in Example 2-1 according to Table 3, but An anode prepared by using silicon as an anode active material in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com