Preparation method of water-soluble solid styrene-acrylic resin

A technology of acrylate and styrene-acrylic resin, which is applied in the field of polymer material preparation, can solve problems such as difficult heat dissipation and unpleasant odor, and achieve the effects of expanding application range, reducing system heat release, and simple polymerization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

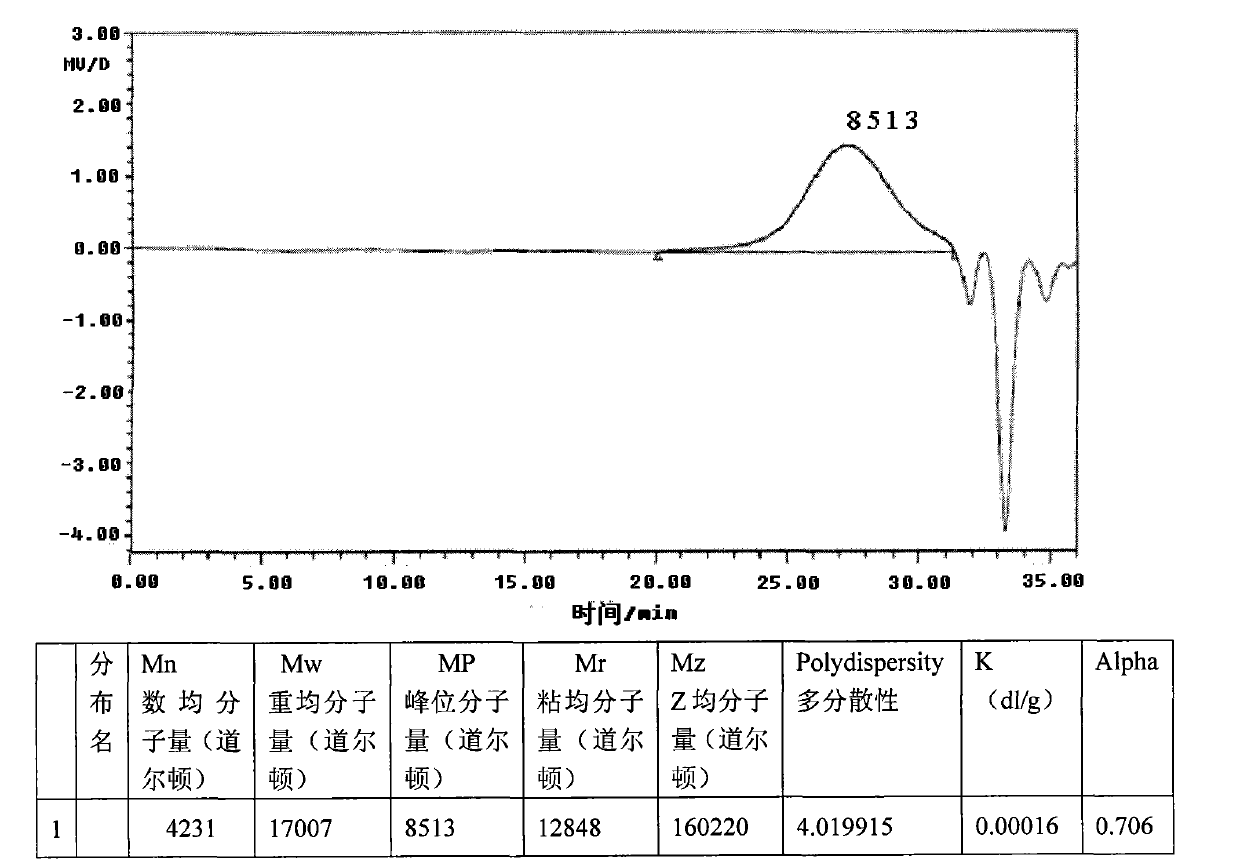

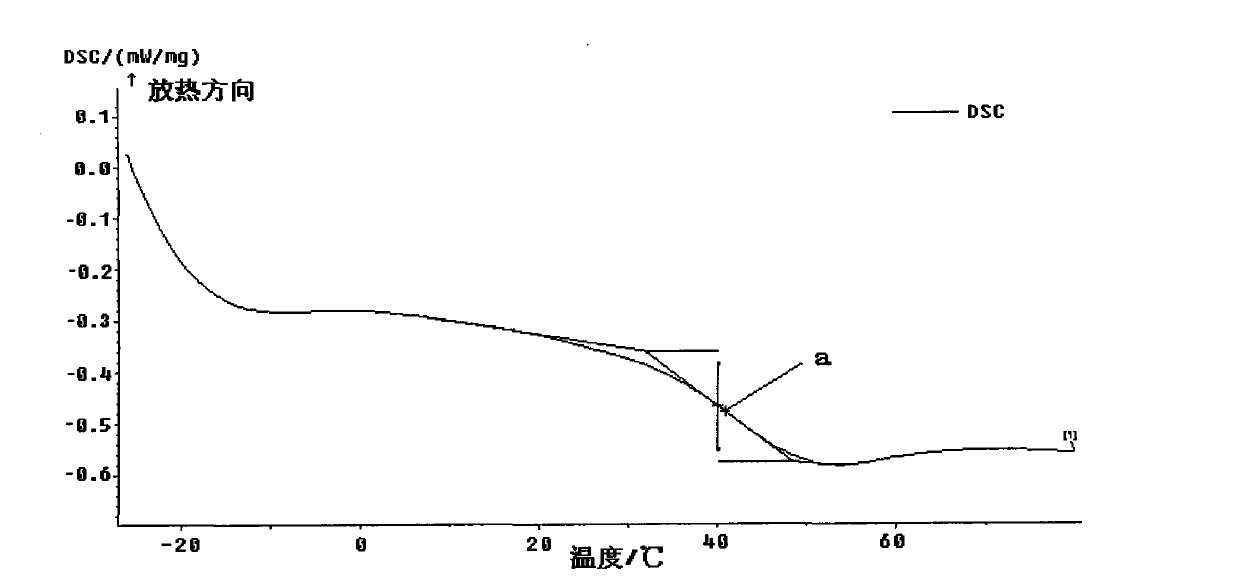

Embodiment 1

[0033] Step a: Weigh 8.40g of α-methylstyrene, 3.15g of methyl methacrylate, 4.20g of butyl acrylate and 5.25g of acrylic acid and dissolve them in 58.50g of ethylene glycol butyl ether solvent, and take another 1.05g of benzene peroxide Dissolve formyl in the above mixed solution and set it as component 1; weigh 33.60g α-methylstyrene, 12.60g methyl methacrylate, 16.80g butyl acrylate and 21.00g acrylic acid and dissolve them in 117.00g ethylene glycol In the alcohol butyl ether solvent, another 3.94g benzoyl peroxide is dissolved in the above mixed solution, which is set as component 2; 0.27g benzoyl peroxide is taken and dissolved in 19.50g ethylene glycol butyl ether solvent, and the For component 3.

[0034] Step b: Put component 1 in N 2 Put it in a 500mL four-neck flask under rapid stirring under protection, and rapidly raise the temperature to 120°C in 5-10 minutes through a methyl silicone oil bath, and react for 10-15 minutes after the temperature stabilizes, and us...

Embodiment 2

[0039] Step a: Weigh 4.80g of α-methylstyrene, 4.80g of styrene, 2.40g of methyl methacrylate, 4.80g of butyl acrylate, and 7.20g of acrylic acid, dissolve them in 54.00g of ethylene glycol butyl ether solvent, and take another Dissolve 1.80g of dicumyl peroxide in the above mixed solution and set it as component 1; weigh 19.20g of α-methylstyrene, 19.20g of styrene, 9.60g of methyl methacrylate, and 19.20g of butyl acrylate and 28.80g of acrylic acid were dissolved in 108.00g of ethylene glycol butyl ether solvent, and another 6.75g of dicumyl peroxide was dissolved in the above mixed solution, which was set as component 2; 0.45g of dicumyl peroxide was weighed to dissolve In 18.00 g of ethylene glycol butyl ether solvent, set it as component 3.

[0040] Other steps are as shown in Example 1.

[0041] The number average molecular weight of the product measured by GPC is 3265D, the weight average molecular weight is 6805D, and the molecular weight distribution is 2.1; the aci...

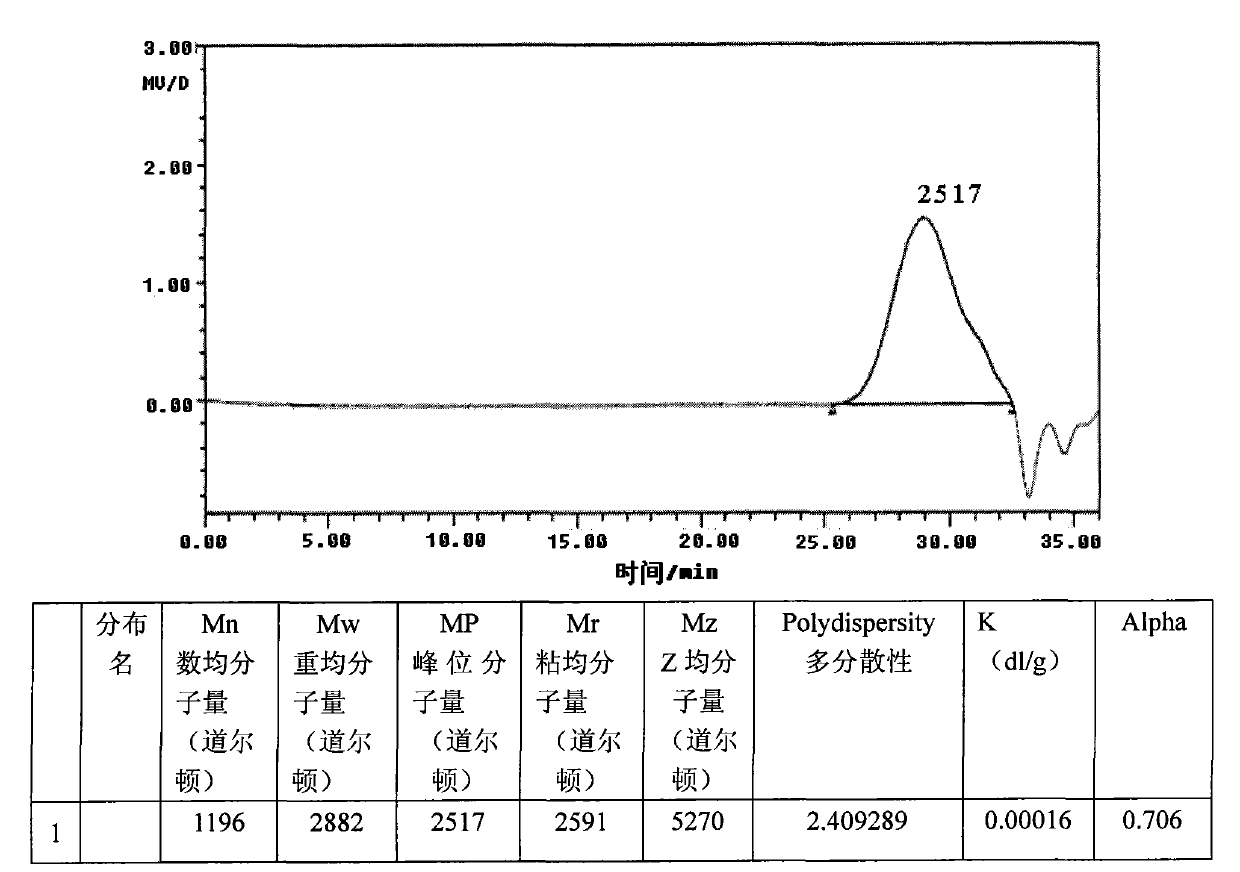

Embodiment 3

[0043] Step a: Weigh 9.60g styrene, 2.40g methyl methacrylate, 4.80g butyl acrylate, 7.20g acrylic acid and 0.48g 3-mercaptopropionic acid and dissolve them in 54.00g ethylene glycol butyl ether solvent, and take another 1.80g g of benzoyl peroxide was dissolved in the above mixed solution and set as component 1; 38.4g of α-methylstyrene, 9.60g of methyl methacrylate, 19.20g of butyl acrylate, 28.80g of acrylic acid and 1.92g of 3-Mercaptopropionic acid was dissolved in 108.00g of ethylene glycol butyl ether solvent, and another 6.75g of benzoyl peroxide was dissolved in the above mixed solution, which was set as component 2; 0.45g of benzoyl peroxide was weighed and dissolved in In 18.00g of ethylene glycol butyl ether solvent, set it as component 3.

[0044] Other steps are as shown in Example 1.

[0045] The number average molecular weight of the polymer measured by GPC is 3411D, the weight average molecular weight is 8538D, and the molecular weight distribution is 2.5; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com