Patents

Literature

35results about How to "Nucleation is easy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium metal composite negative electrode with lithium-philic and lithium-phobic gradient structure, and preparation method thereof

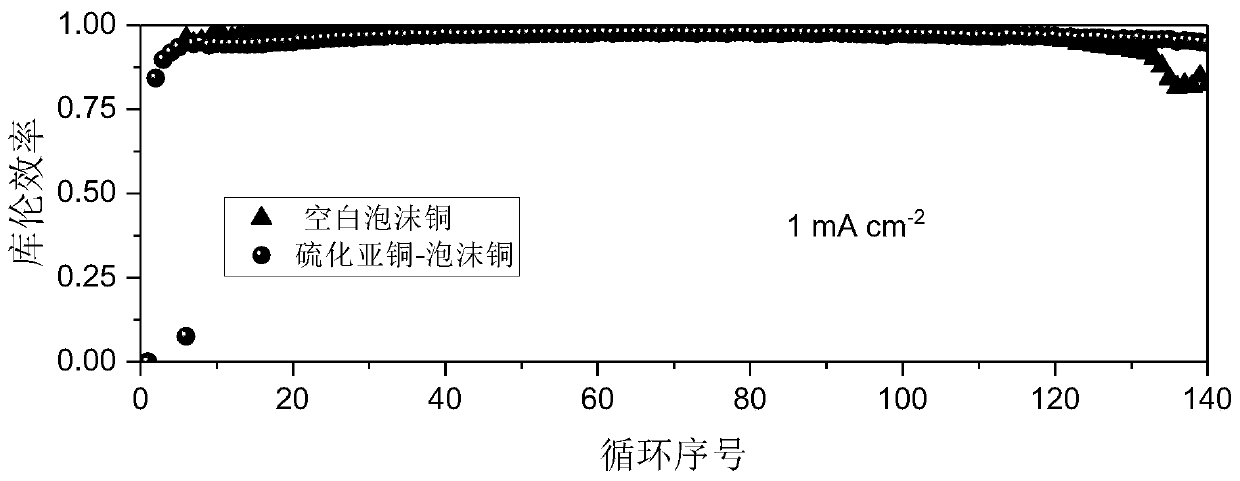

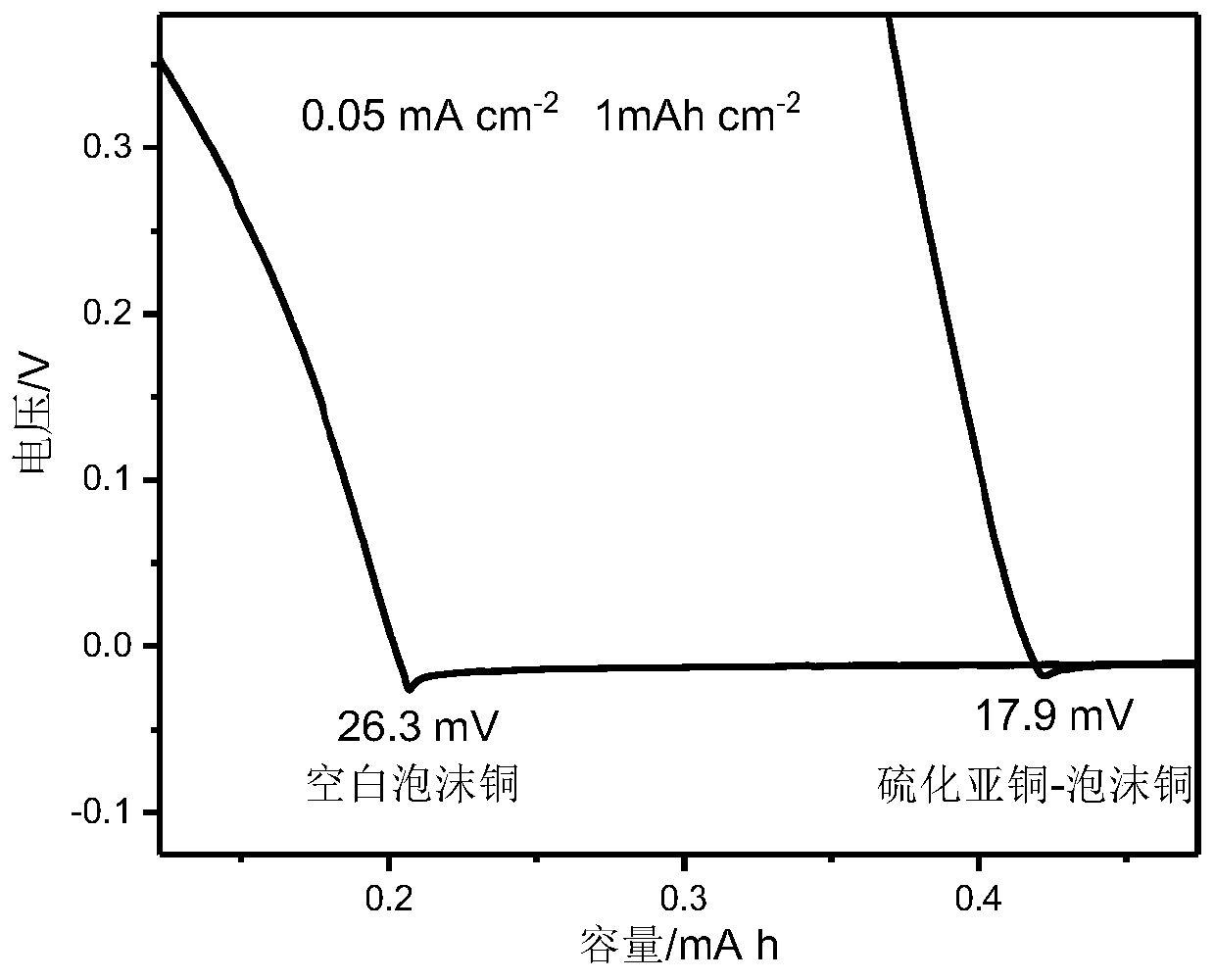

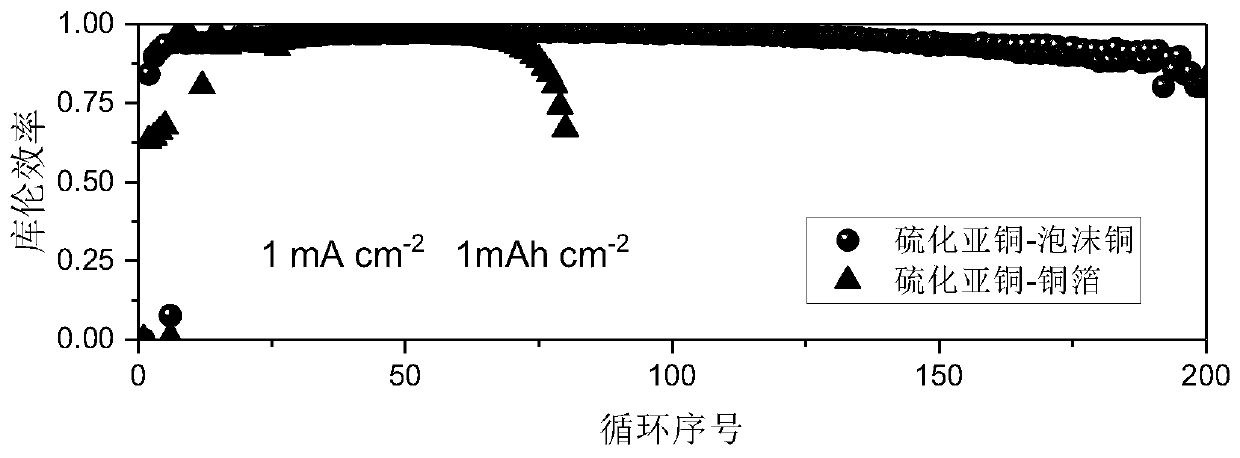

ActiveCN111599983AEasy to adjustEase chalkingNegative electrodesLi-accumulatorsLithium metalOverpotential

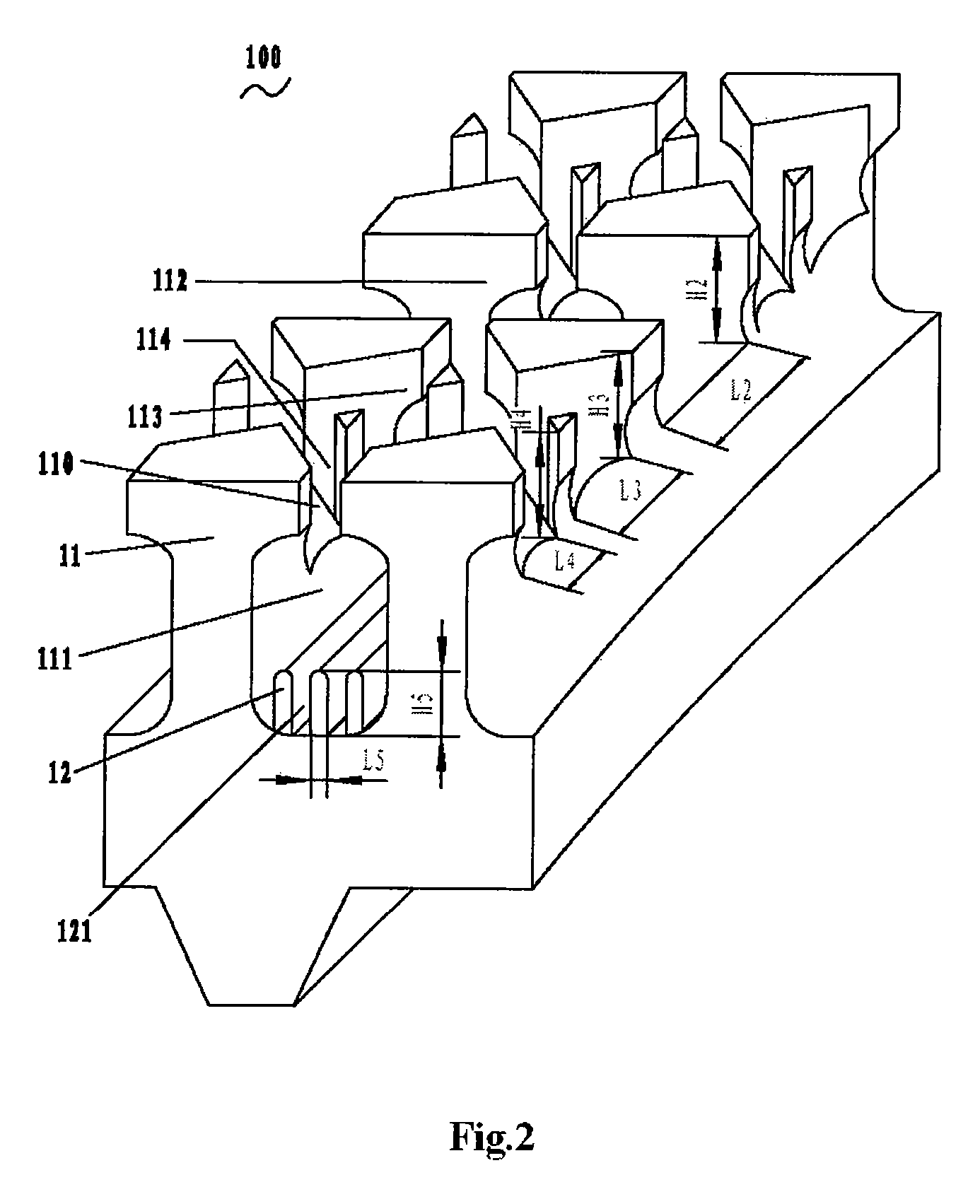

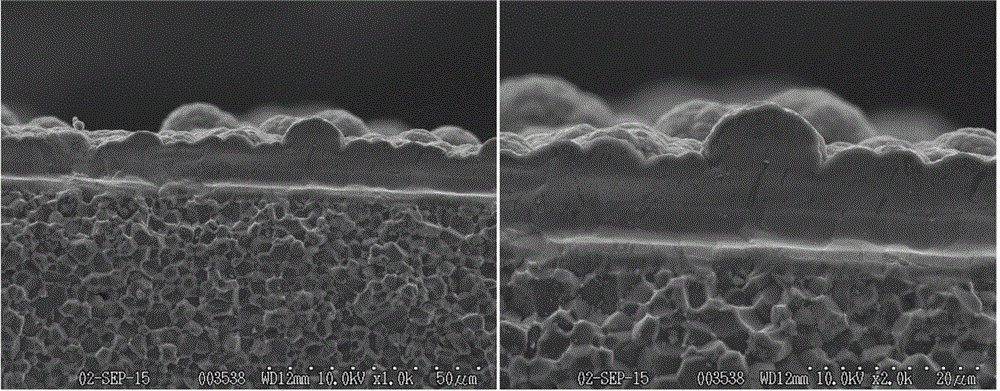

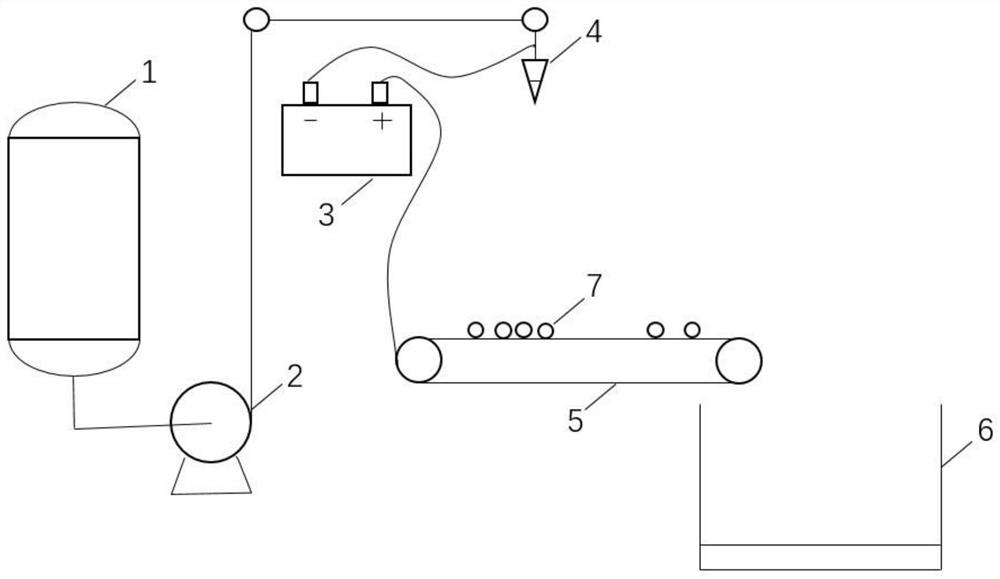

The invention discloses a lithium metal composite negative electrode with a lithium-philic and lithium-phobic gradient structure, and a preparation method thereof. The lithium metal composite negativeelectrode is of a three-layer structure, wherein the bottom layer is a 3D porous matrix framework, the middle layer is a lithium-philic layer compounded on the 3D porous matrix framework, and the toplayer is a lithium-phobic layer compounded on the surface of the lithium-philic layer. The preparation method comprises the following steps: (1) preparing a 3D porous matrix skeleton, and cleaning; (2) transferring the 3D porous matrix skeleton to a prepared precursor solution; (3) forming a lithium-philic layer on the 3D porous matrix skeleton in situ by adopting a solvothermal method; (4) modifying a lithium-phobic layer on the lithium-philic layer; and (5) finally filling with lithium by adopting an electro-deposition method. According to the invention, the overpotential in the lithium metal nucleation and deposition process can be reduced by utilizing the lithium-philic layer, and the uniform deposition and dissolution of the lithium metal in the continuous cycle process are realizedby utilizing the characteristic that the lithium ion diffusion is promoted by utilizing the lithium-phobic layer, so that the growth of dendritic crystals is effectively avoided, and the cycle life ofthe lithium metal battery is greatly prolonged.

Owner:SUN YAT SEN UNIV

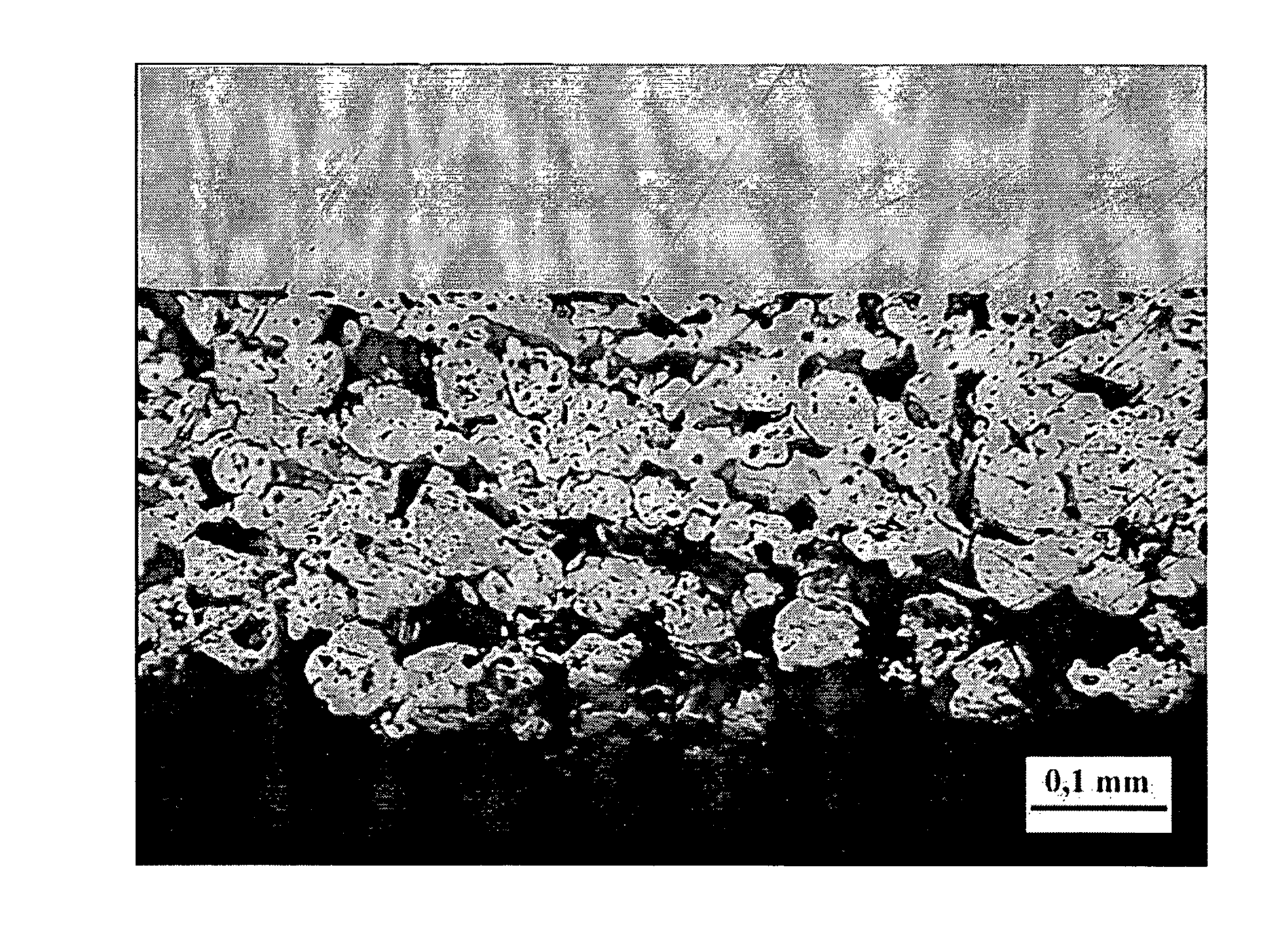

Method For Reducing Metal Oxide Powder And Attaching It To A Heat Transfer Surface And The Heat Transfer Surface

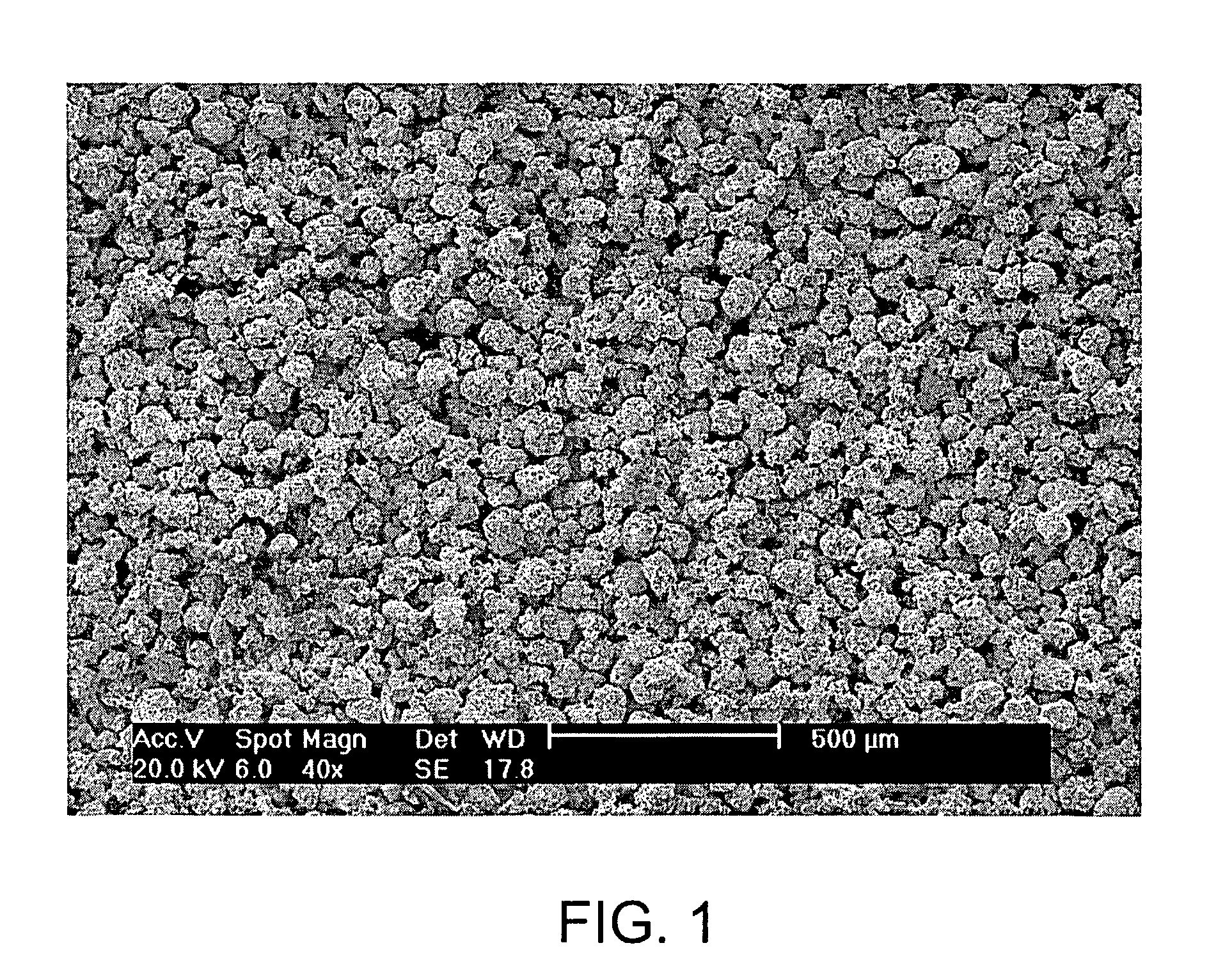

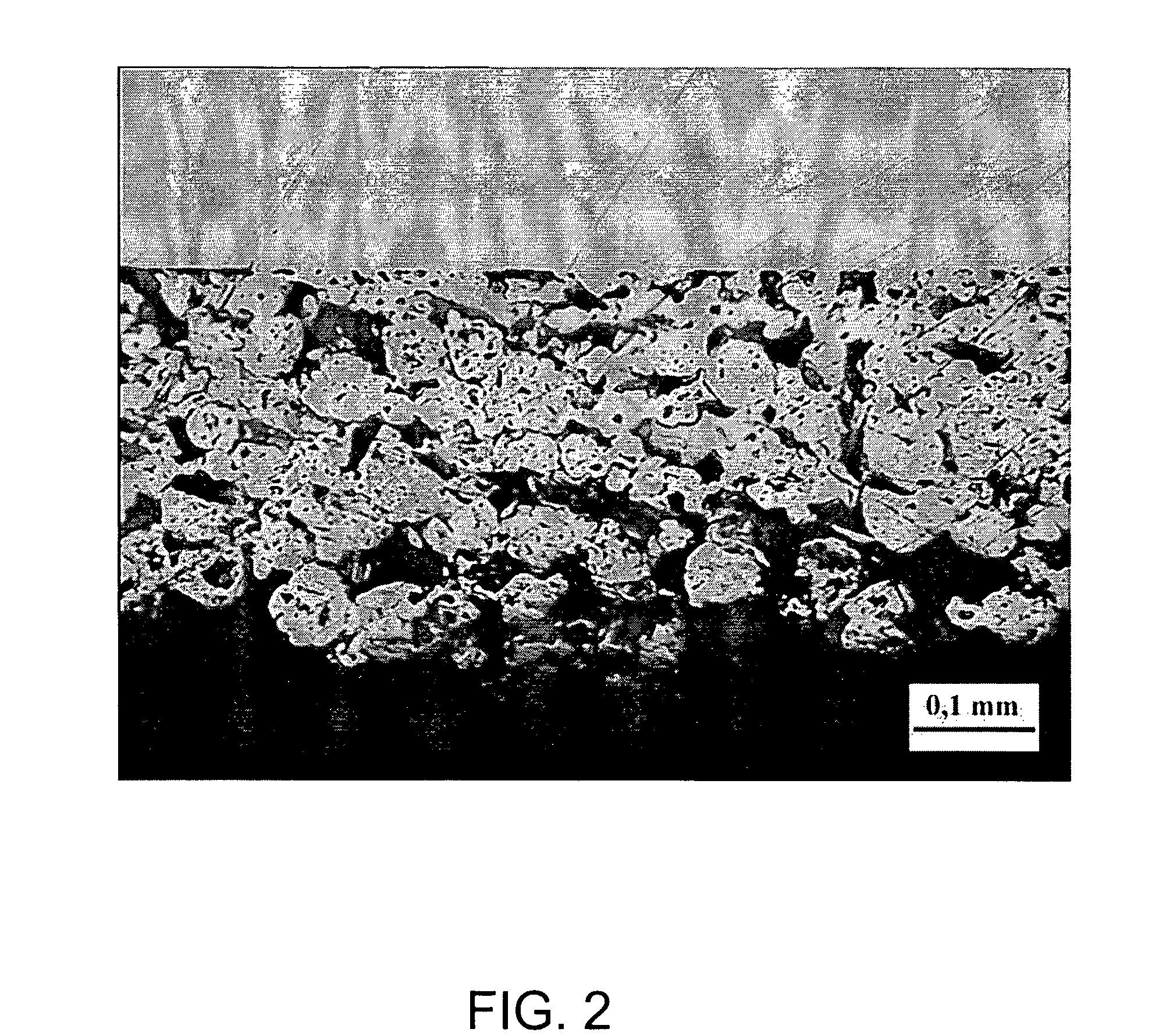

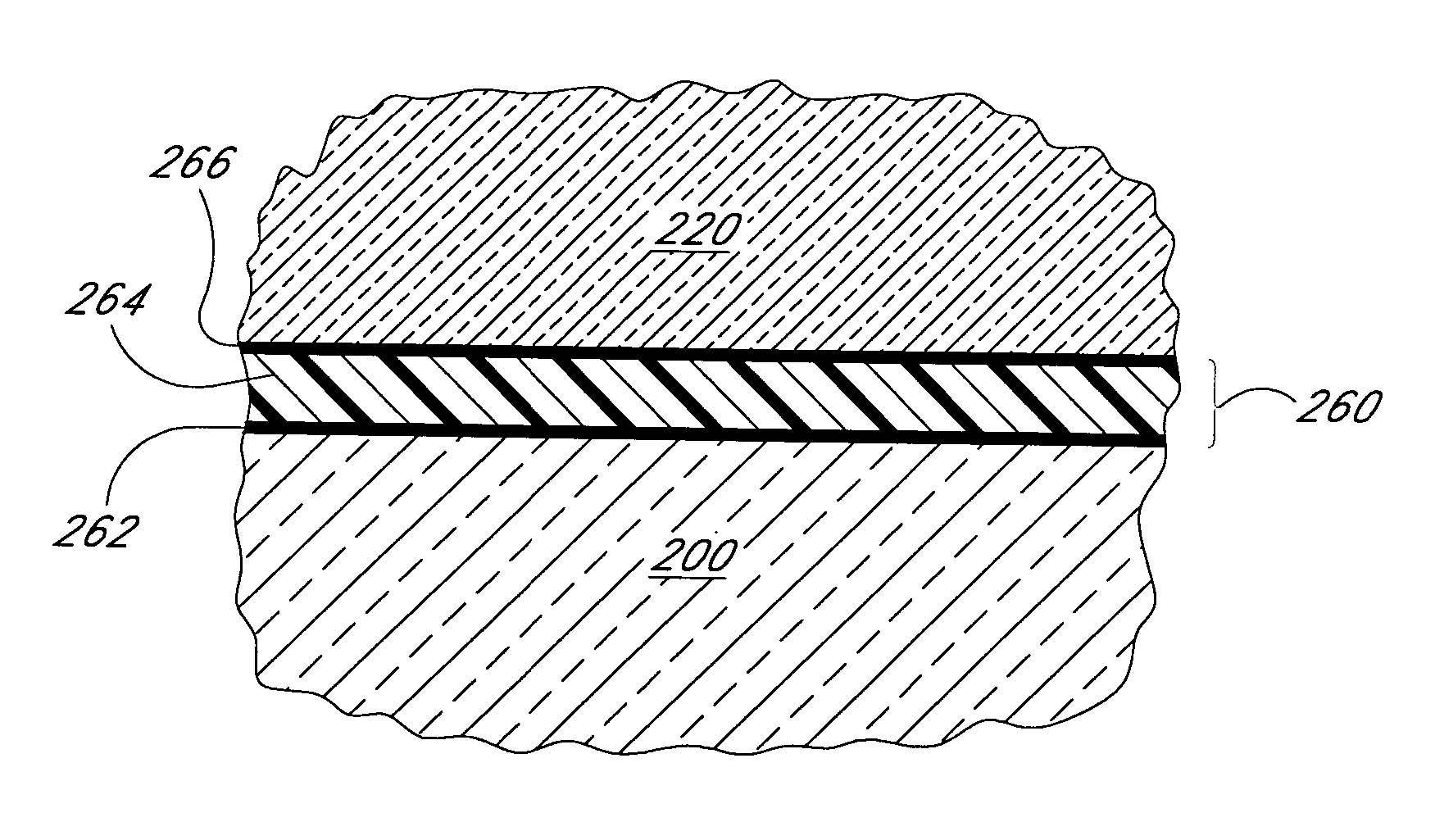

InactiveUS20070251410A1Clear energy savingLow investment costConductive materialPretreated surfacesSurface layerPorous layer

The purpose of the method developed is to form on top of a heat transfer surface a porous surface layer, which is to be fixed to the surface below it at a temperature and time applicable for industrial production. The heat transfer surface is copper or copper alloy. The powder forming a porous surface is fine-grained copper oxide powder, which is reduced to metallic copper on the heat transfer surface during heat treatment. The invention also relates to the heat transfer surface of copper or copper alloy, on which a porous layer has been formed from metallic copper, which is manufactured by reducing copper oxide powder and is attached using brazing solder.

Owner:RISSANEN PETRI +1

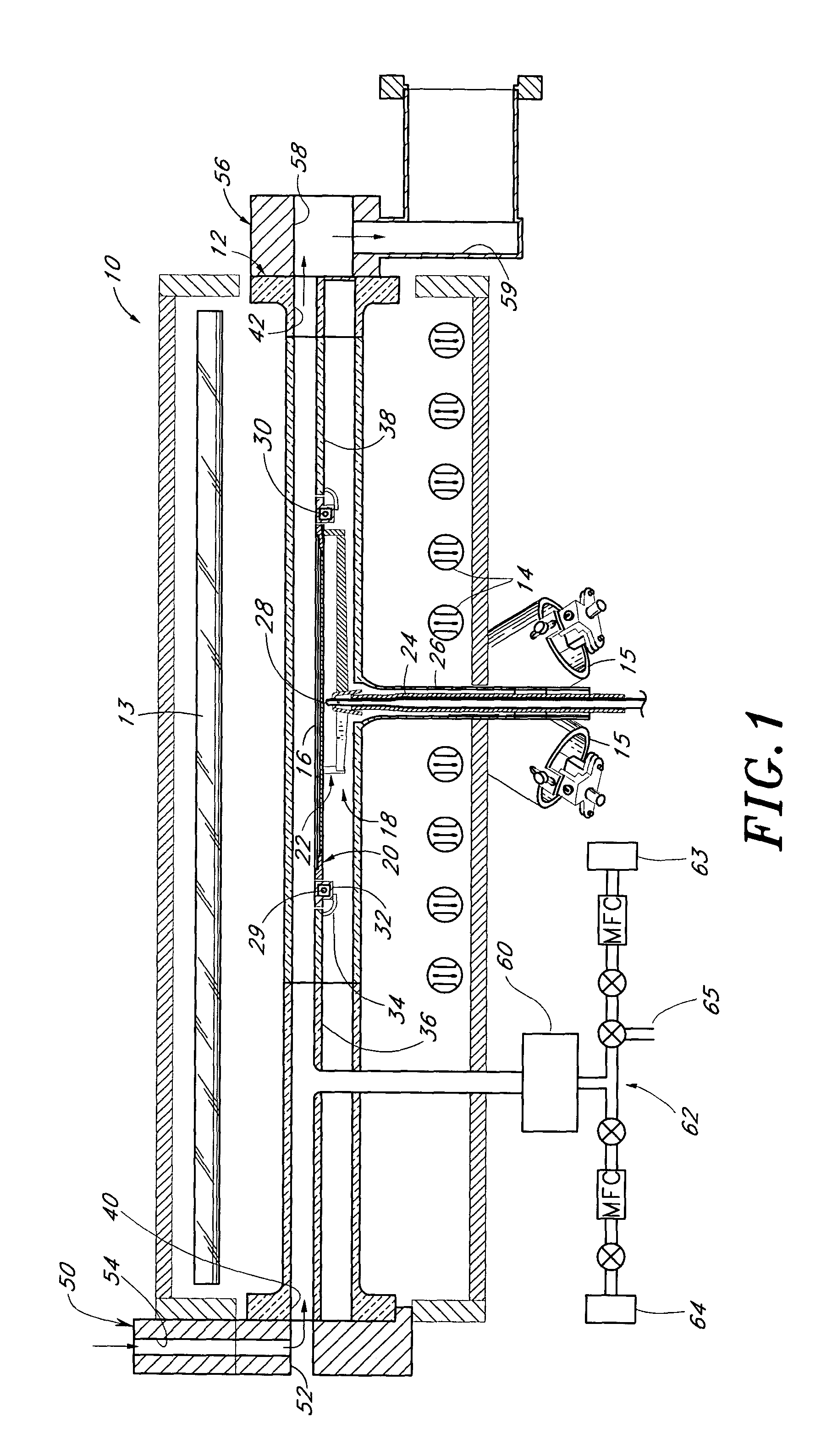

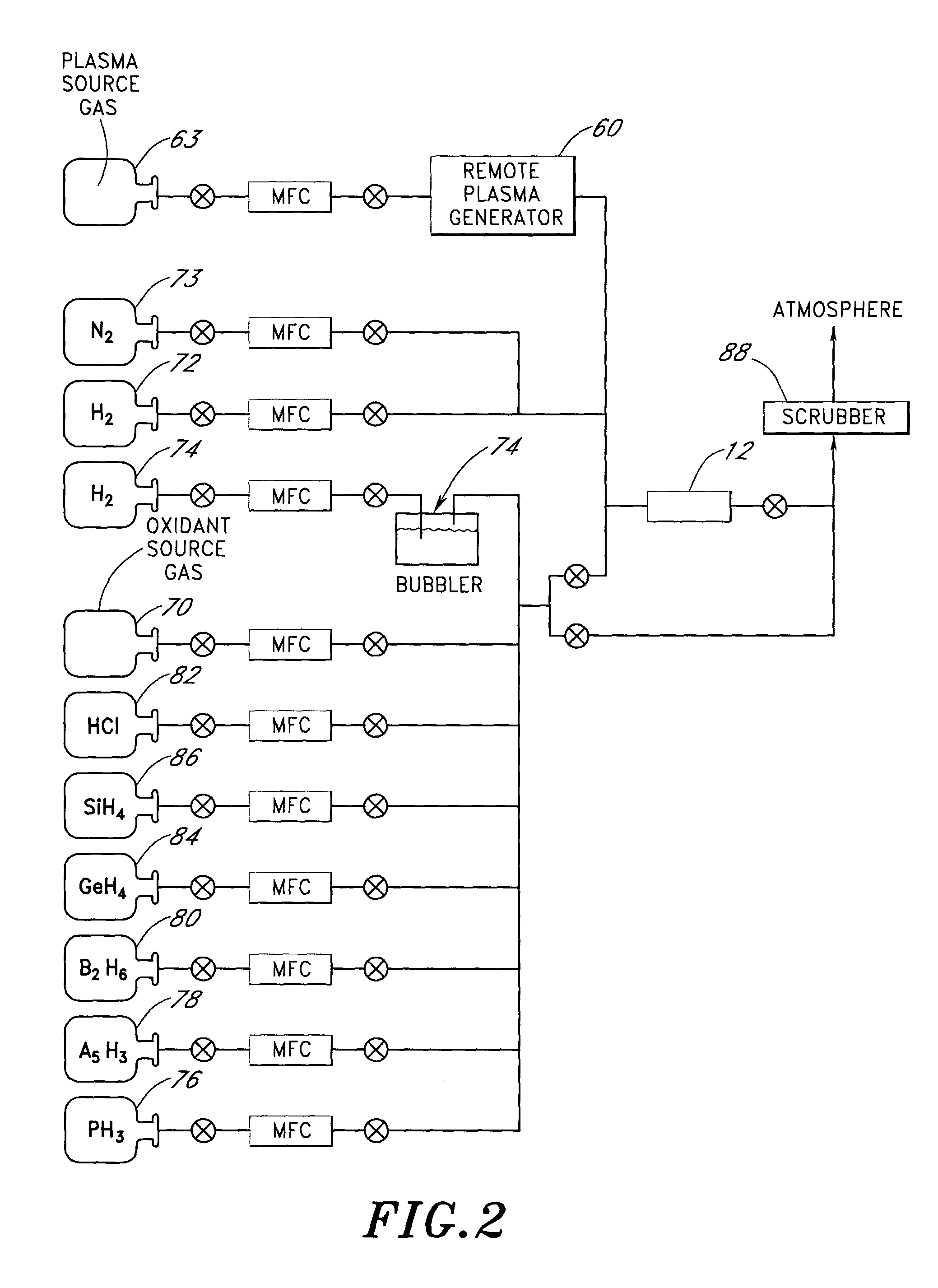

Surface preparation prior to deposition

InactiveUS7056835B2Without significantly affectingNucleation is easySemiconductor/solid-state device manufacturingChemical vapor deposition coatingGate dielectricAtomic layer deposition

Methods are provided herein for treating substrate surfaces in preparation for subsequent nucleation-sensitive depositions (e.g., polysilicon or poly-SiGe) and adsorption-driven deposition (e.g. atomic layer deposition or ALD). Prior to depositing, the surface is treated with non-depositing plasma products. The treated surface more readily nucleates polysilicon and poly-SiGe (such as for a gate electrode), or more readily adsorbs ALD reactants (such as for a gate dielectric). The surface treatment provides surface moieties more readily susceptible to a subsequent deposition reaction, or more readily susceptible to further surface treatment prior to deposition. By changing the surface termination of the substrate with a low temperature radical treatment, subsequent deposition is advantageously facilitated without depositing a layer of any appreciable thickness and without significantly affecting the bulk properties of the underlying material. Preferably less than 10 Å of the bulk material incorporates the excited species, which can include fluorine, chlorine and particularly nitrogen excited species.

Owner:ASM IP HLDG BV

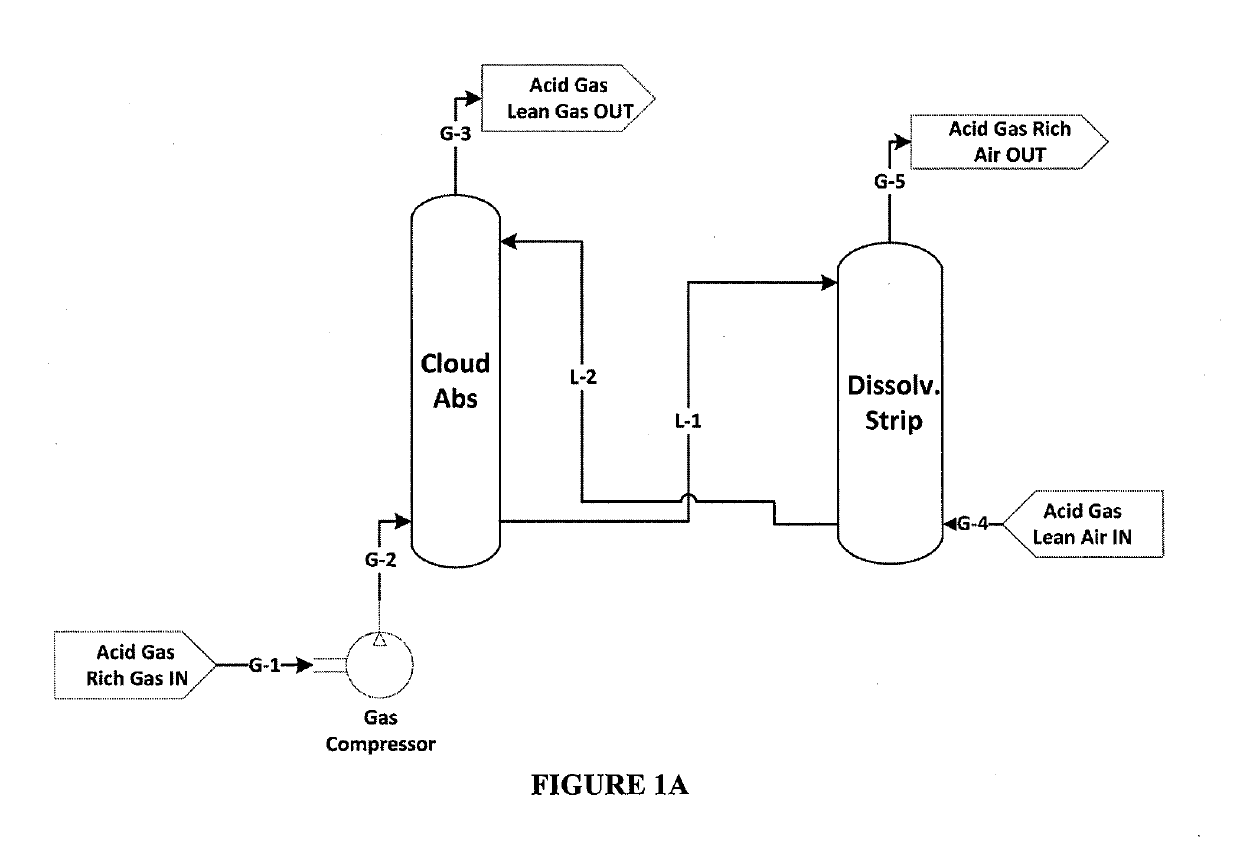

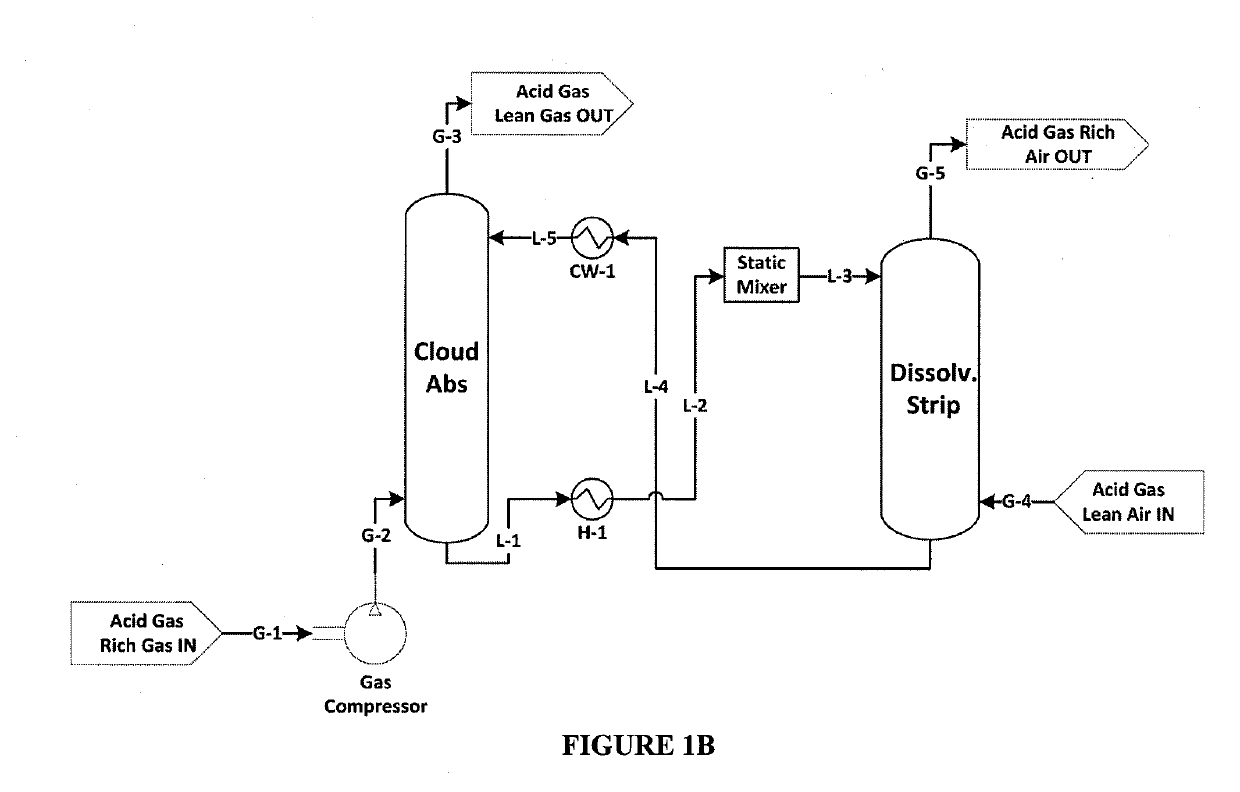

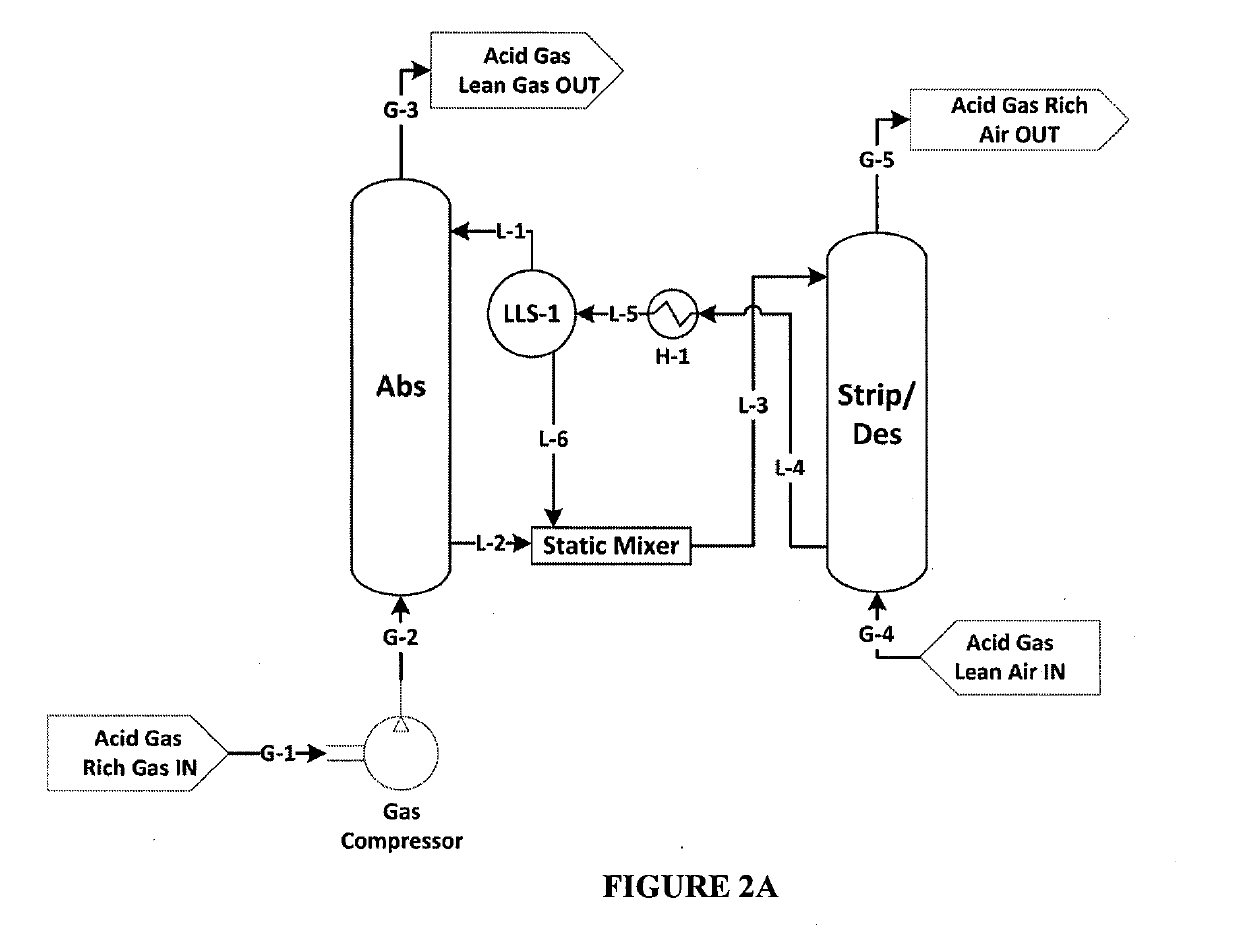

Systems and methods for separating gases

ActiveUS20190143260A1Improve absorption efficiencyLess coolingProductsGas treatmentDesorptionReverse osmosis

The invention pertains to processes for separating gases, acid gas, hydrocarbons, air gases, or combinations thereof. The processes may employ using a liquid phase cloud point with or without subsequent liquid-liquid separation. In some embodiments membranes can be employed with reverse osmosis to regenerate a solvent and / or an antisolvent. In some embodiments thermal switching phase changes may be employed during absorption or desorption to facilitate separation.

Owner:SOLVCOR TECH LLC

Systems and methods for acid-treating glass articles

ActiveUS9505651B2Promote crystallizationNucleation is easyLiquid surface applicatorsSemiconductor/solid-state device manufacturingSludgeEngineering

Described herein are various systems and methods for using acidic media to enhance the surface characteristics of glass articles while reducing the adverse effects of precipitate / sludge formation. The systems and methods generally implement a precipitation-capturing device that is configured to 1) permit formation of sludge thereon and 2) reduce formation of the sludge on other solid surfaces involved in the systems and methods.

Owner:CORNING INC

Method for increasing forming speed of anaerobic ammonia oxidation granule sludge

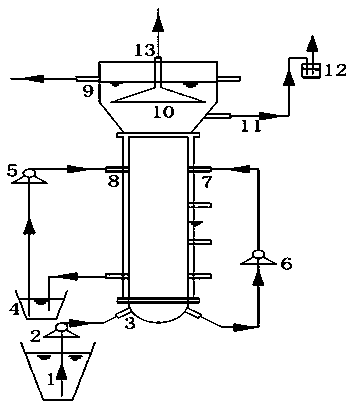

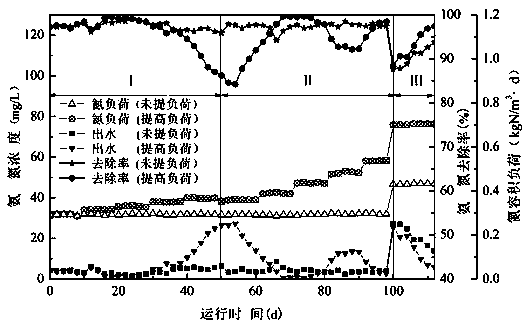

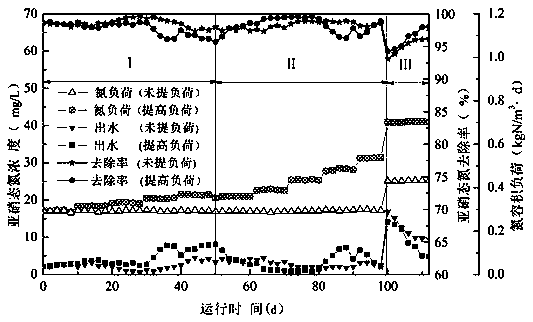

ActiveCN105502652AIncreased nitrogen loadingRapid enrichmentWater contaminantsTreatment with anaerobic digestion processesFecesSubstrate concentration

The invention relates to a method for increasing the forming speed of anaerobic ammonia oxidation granule sludge. The method comprises the steps that practical industrial wastewater with low C / N is taken as a culturing nutrient source of the anaerobic ammonia oxidation granule sludge, and the mass concentration ratio of NH4<+>-N to NO2<->-N of inflow water is controlled to be (1.05-1.42) to 1; a mixture of anaerobic sludge and livestock breeding faeces is taken as inoculated sludge, by means of the modes of changing the substrate concentration of the inflow water, shortening the hydraulic retention time, controlling the granule size, the granule sludge settling speed and MLVSS / MLSS of the anaerobic ammonia oxidation granule sludge and the like, a nitrogen load of anaerobic ammonia oxidation inflow water is changed, the retention and amplification problems of anaerobic ammonia oxidation bacteria can be effectively solved, and by means of granulation of anaerobic ammonia oxidation sludge, the influence of nitrogen removal efficiency dropping caused by environmental changes can be weakened to some extent.

Owner:上海生迈缘生物科技有限公司

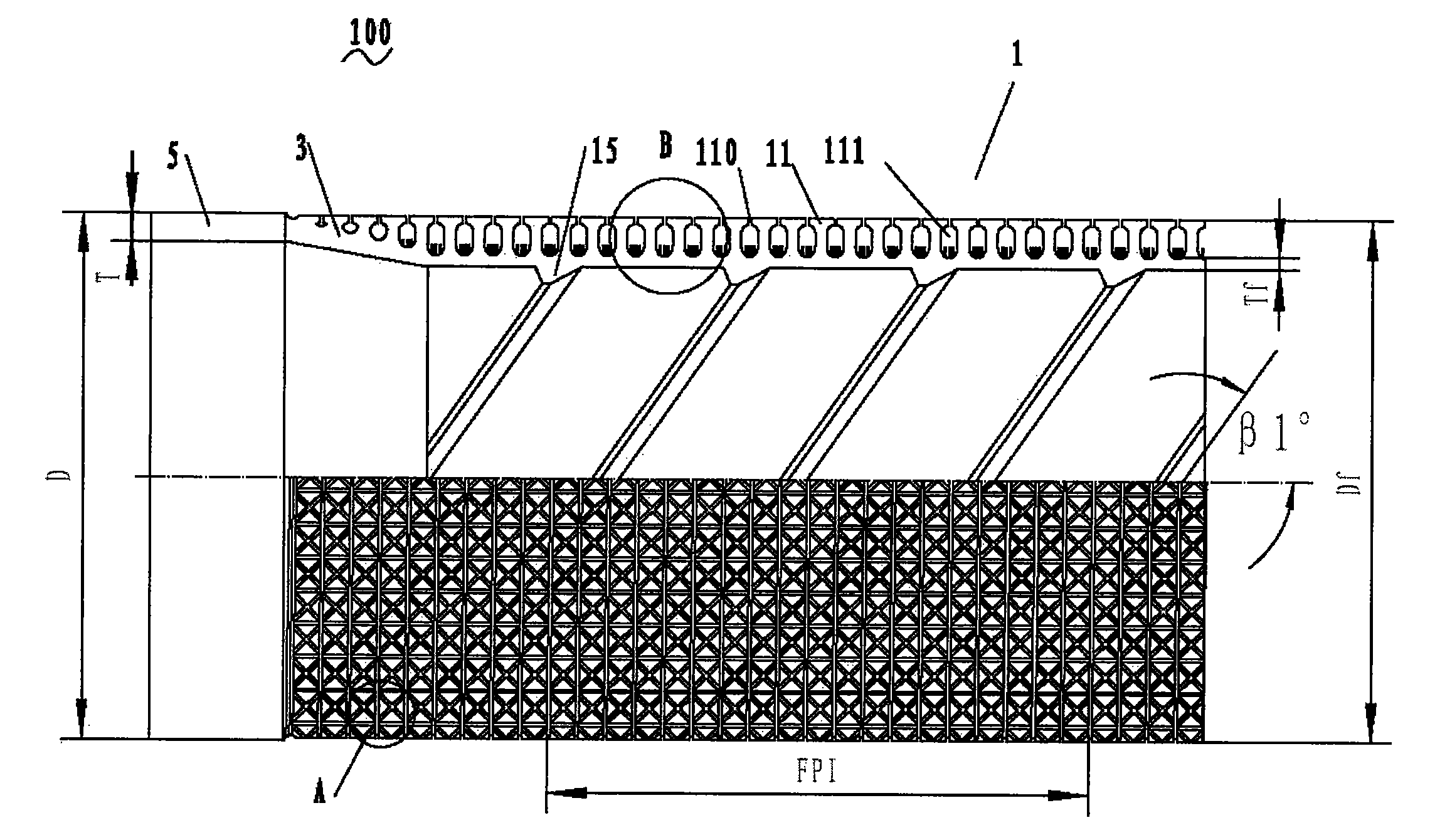

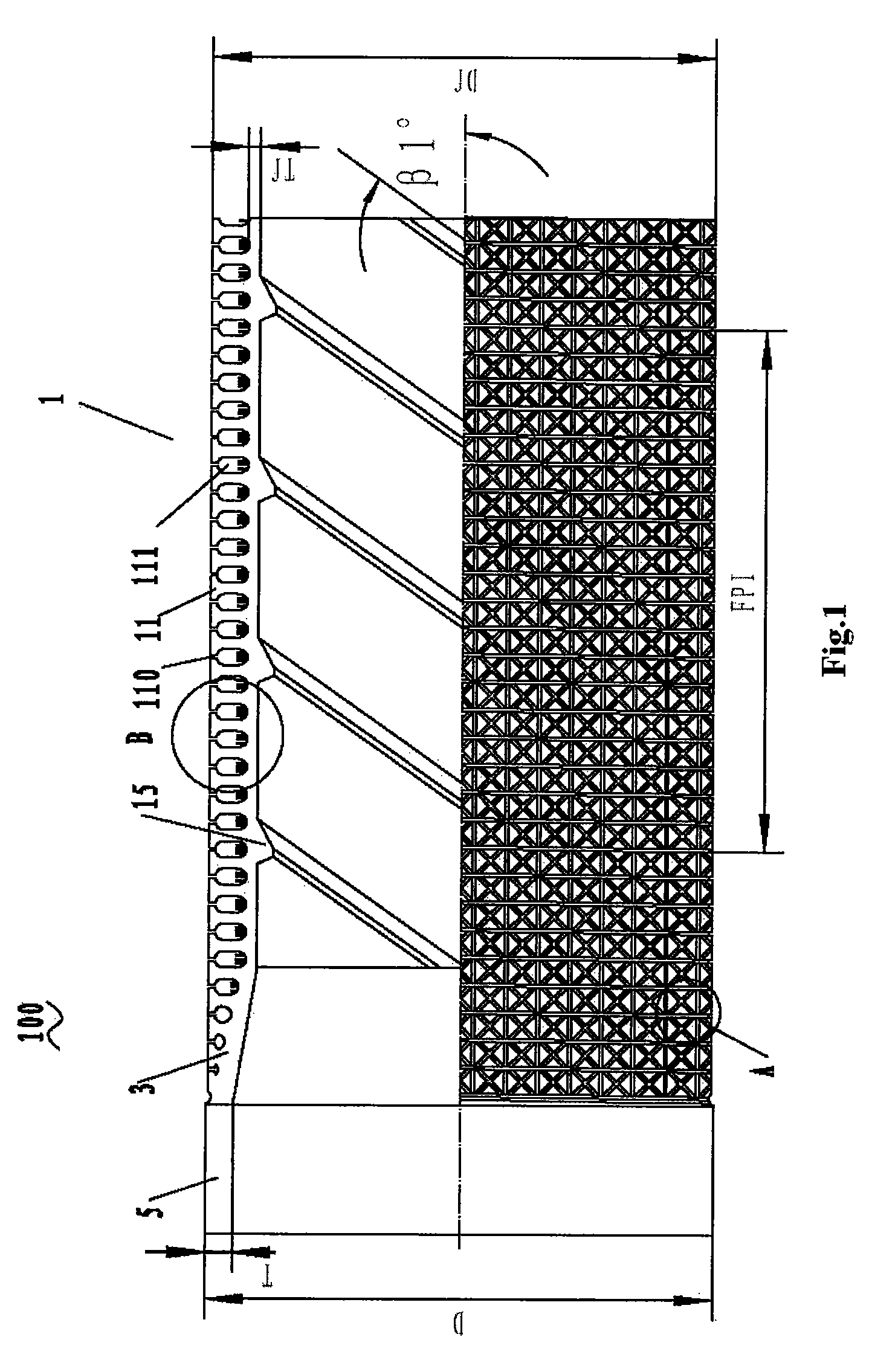

Flooded type evaporating heat-exchange copper tube for an electrical refrigeration unit

ActiveUS7841391B2Improve efficiencyNucleation is easyCorrosion preventionCoatingsElectricityEvaporation

The present invention discloses a flooded type evaporating heat-exchange copper tube for an electrical refrigeration unit. The evaporating heat-exchange tube comprises a smooth surface portion, a finned portion provided with plurality of fins and a transitional portion connecting the smooth surface portion to the finned portion, with primary evaporating chambers defined between the fins. Fifth fins extending upwardly are provided on a bottom wall of the primary evaporating chamber, which divide the primary evaporating chamber into at least two minor cavities, and an evaporating opening is defined between adjacent fins of the primary evaporating chamber. Due to plurality of minor cavities arranged in the evaporating heat-exchange tube, refrigerant film is easy to form on bottom walls of the minor cavities, and nucleus boiling is easily to be developed. Thereafter, the refrigerant gets boiled and evaporated to form bubbles to escape via evaporating openings. Surrounding refrigerant refills the empty minor cavities via the evaporating opening. This process of boiling, evaporation and refilling continues to go on. Thus, the number of vaporization nucleus is dramatically increased, and the refrigerant is much easier to form nucleus and get vaporized, thus improving the heat transfer property of the evaporating heat-exchange tube.

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP

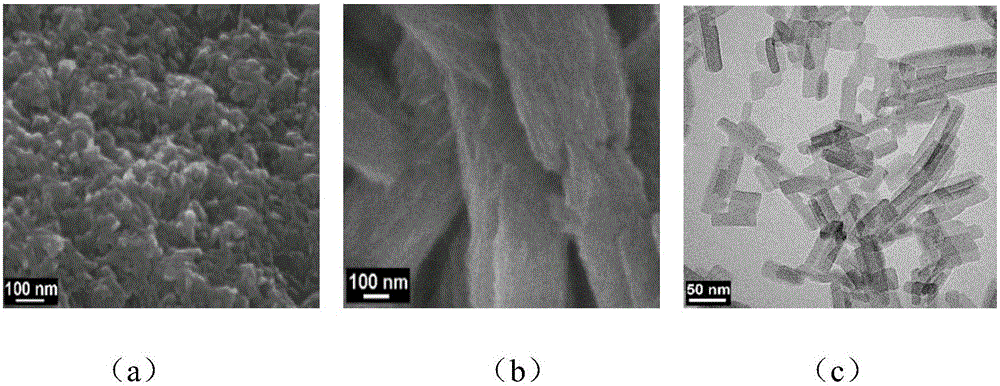

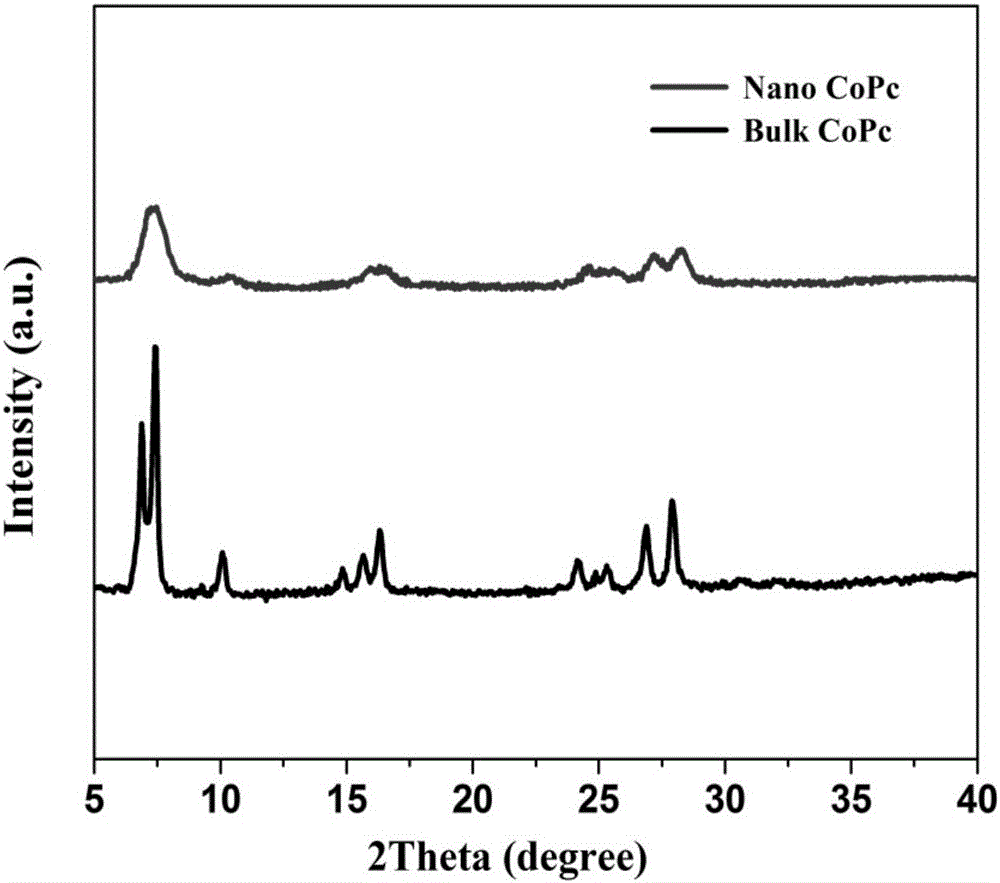

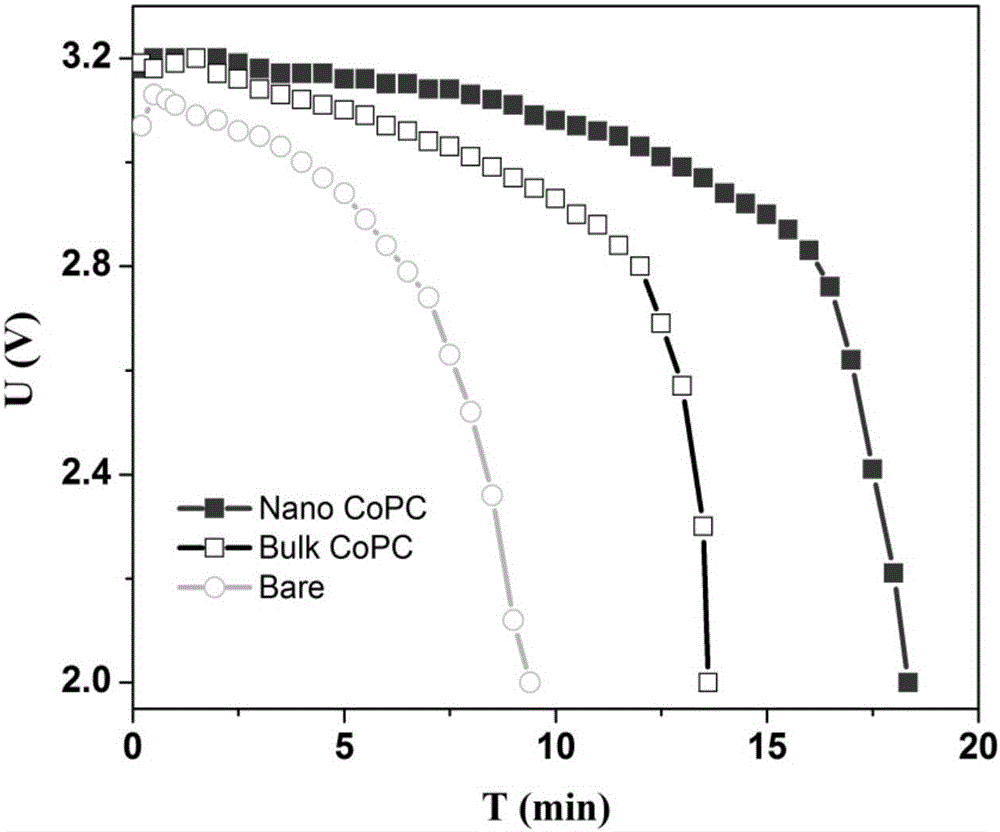

Li/SOCl2 nano cobalt phthalocyanine catalyst material for battery and preparation method of Li/SOCl2 nano copper phthalocyanine catalyst material

The invention discloses an Li / SOCl2 nano cobalt phthalocyanine catalyst material for a battery and a preparation method of the Li / SOCl2 nano cobalt phthalocyanine catalyst material, and belongs to the technical field of preparation of Li / SOCl2 catalytic materials for battery electrodes. The bulk solid cobalt phthalocyanine is firstly synthesized through microwave reaction; and then nano cobalt phthalocyanine is prepared by a recrystallization method. The method comprises the steps as follows: the bulk solid cobalt phthalocyanine is firstly dissolved into a concentrated sulfuric acid; a very dilute potassium hydroxide solution is added and quickly stirred for severe neutralization reaction; accelerated nucleation of the cobalt phthalocyanine is relatively easy; and the nano cobalt phthalocyanine is generated. The prepared nano cobalt phthalocyanine has the advantages of being high in purity, short in cycle, low in energy consumption and economical; large-scale production is facilitated; and the nano cobalt phthalocyanine catalyst material prepared by the method has relatively long discharge time and relatively high discharge energy, and can be widely used as an Li / SOCl2 battery catalyst.

Owner:SHAANXI UNIV OF SCI & TECH

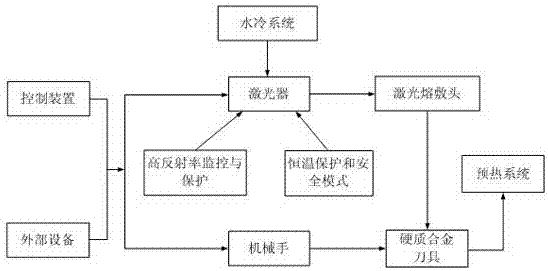

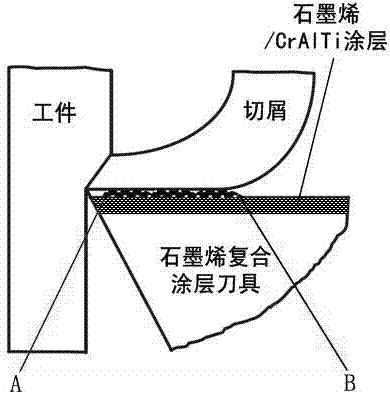

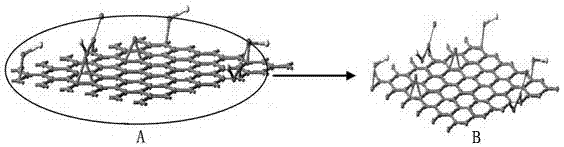

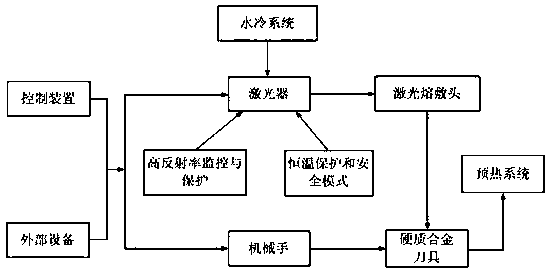

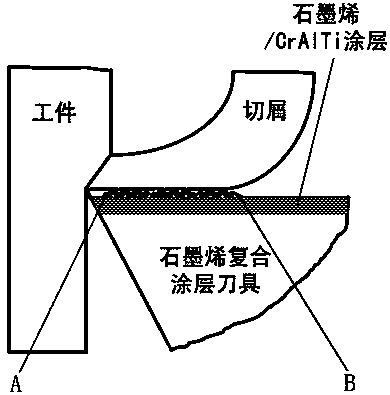

Preparation method of graphene-chromium titanium aluminum composite material and application thereof to cutter

ActiveCN106914612AImprove bindingHeating fastMetallic material coating processesAl powderLaser beams

The invention discloses a preparation method of a graphene-chromium titanium aluminum composite material and application thereof to a cutter. Through radiation of a laser beam, the graphene-chromium titanium aluminum composite material and a cutter surface layer material are molten for quick solidification to obtain a surface coating layer with low dilution rate and better compatibility with the cutter material; and the surface coating layer is actually a high-compact-combination graphene composite clad layer, so that the cutter matrix material and the coating layer material are organically combined. Such comprehensive performances as wear resistance, corrosion resistance and oxidation resistance of the cutter are obviously improved; and such purposes as cutter surface repair or improvement are realized. The preparation method comprises the following main preparation conditions: graphene nanopowder is 5-15 weight% of the composite material; Ti powder is 20-25 weight% of the composite material; Al powder is 20-25 weight% of the composite material; and Cr powder is 35-55 weight% of the composite material.

Owner:LUOYANG INST OF SCI & TECH

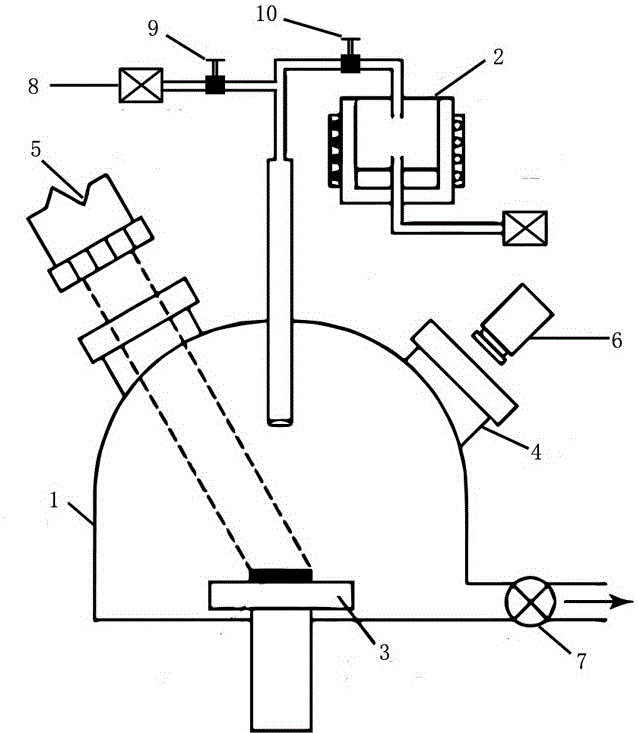

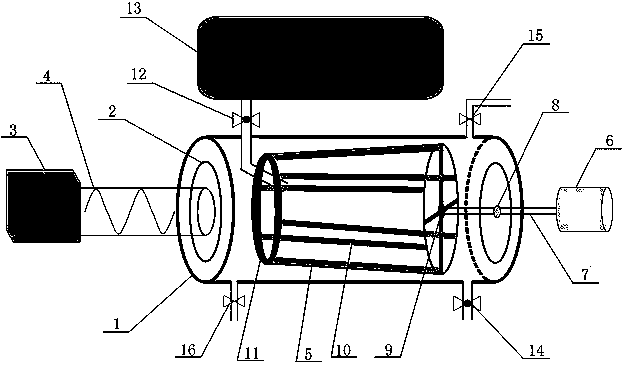

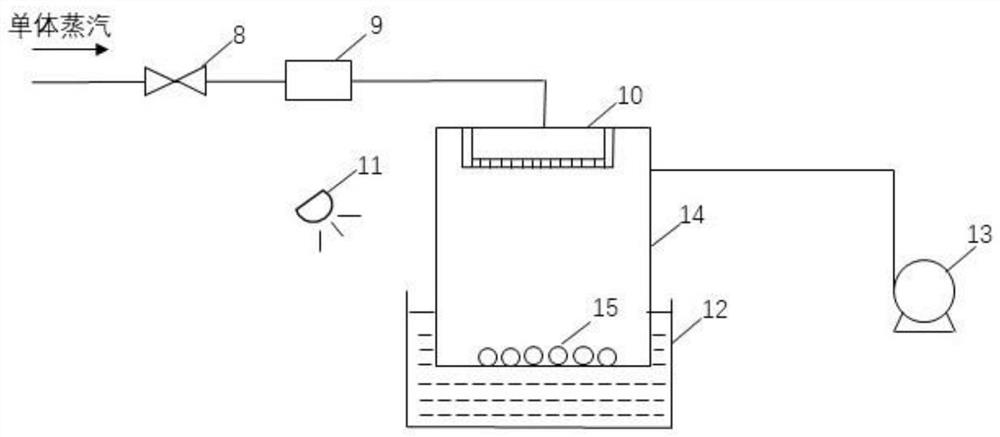

SiC film preparation device and method for preparing SiC film at low vacuum degree

ActiveCN105803422AIncrease profitIncrease reaction rateChemical vapor deposition coatingLaser transmitterDeposition temperature

The invention relates to a SiC film preparation device and a method for preparing a SiC film. The preparation device comprises a CVD reaction furnace and a precursor furnace. A heating table is arranged in the CVD reaction furnace, two quartz windows are formed on the side wall, and a laser transmitter and a pyrometer are arranged at the positions, corresponding to the two quartz windows, of the outer portion correspondingly. An air inlet in the top of the CVD reaction furnace is connected to an argon source and the precursor furnace through a nozzle and pipelines, the pipeline connected with the argon source is provided with a control valve I, and the pipeline connected with the precursor furnace is provided with a control valve II. The method for preparing the SiC film comprises the steps of 1, cleaning and preparing work before SiC film preparation, 2, adjusting work before SiC film preparation and 3, SiC film preparation and adjusting after preparation. According to the method for preparing the SiC film, the growth rate of the film is high, the requirement for the required vacuum degree is low, meanwhile, the deposition temperature is lower than that in conventional means, the manufacturing cost is low, and utilization and popularization are facilitated.

Owner:LUOYANG INST OF SCI & TECH

Fused quartz article having controlled devitrification

InactiveUS6875515B2Improve creep resistanceNucleation is easyAfter-treatment apparatusGlass/slag layered productsColloidal silicaSlurry

A fused quartz article, such as a muffle tube or crucible, with enhanced creep resistance. The enhanced creep resistance is the result of controlled devitrification of the fused quartz article. Controlled devitrification is achieved by coating the article with a colloidal silica slurry doped with metal cations, such as barium, strontium, and calcium. The metal cations in the slurry promote nucleation and growth of cristobalite crystals into the fused quartz at temperatures in the range from about 1000° C. to about 1600° C. The cristobalite has significantly higher viscosity, and therefore greater creep resistance at elevated temperatures, than fused quartz. Methods for applying a doped coating to a fused quartz article and improving the creep resistance of a fused quartz article are also disclosed.

Owner:GENERAL ELECTRIC CO

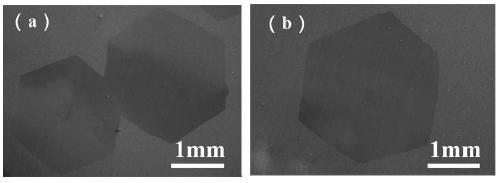

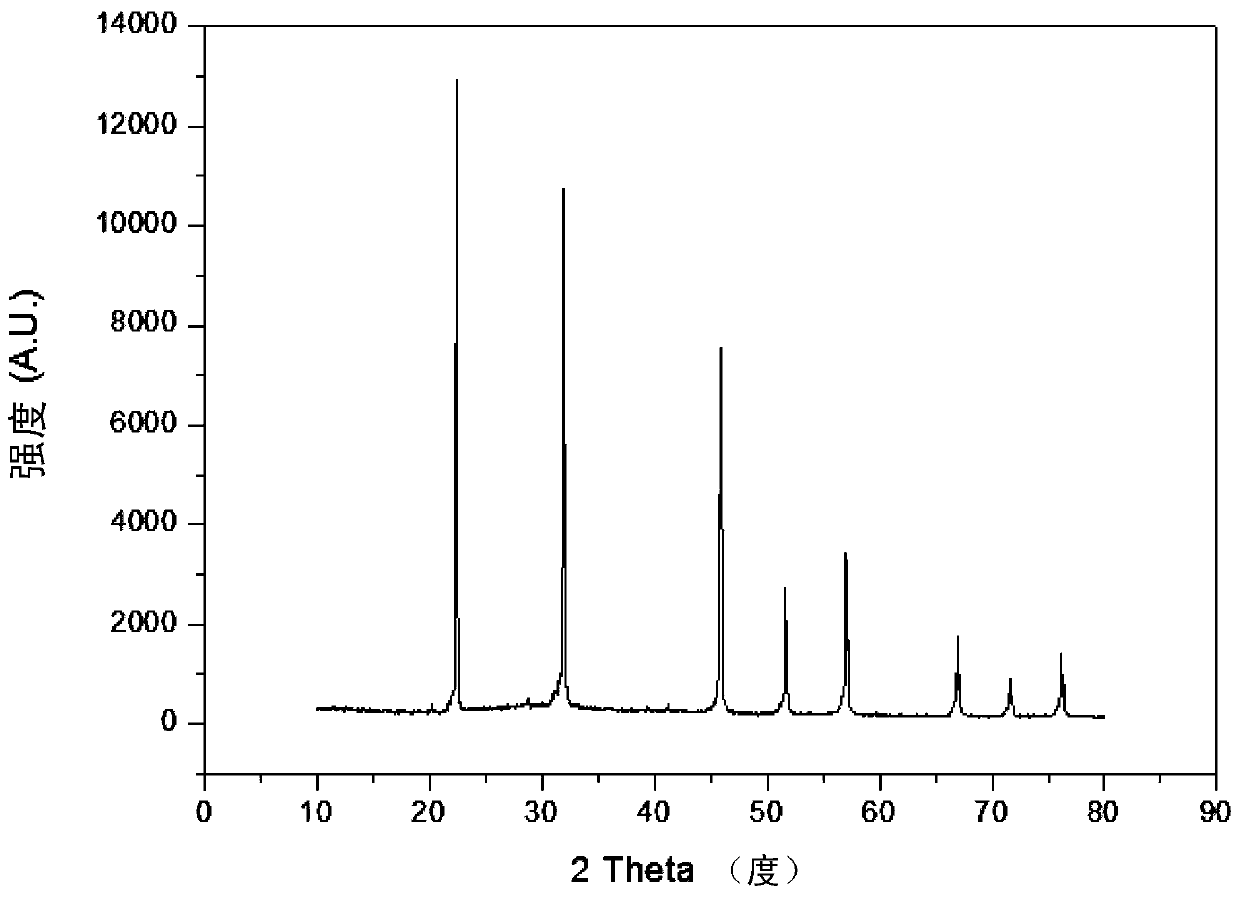

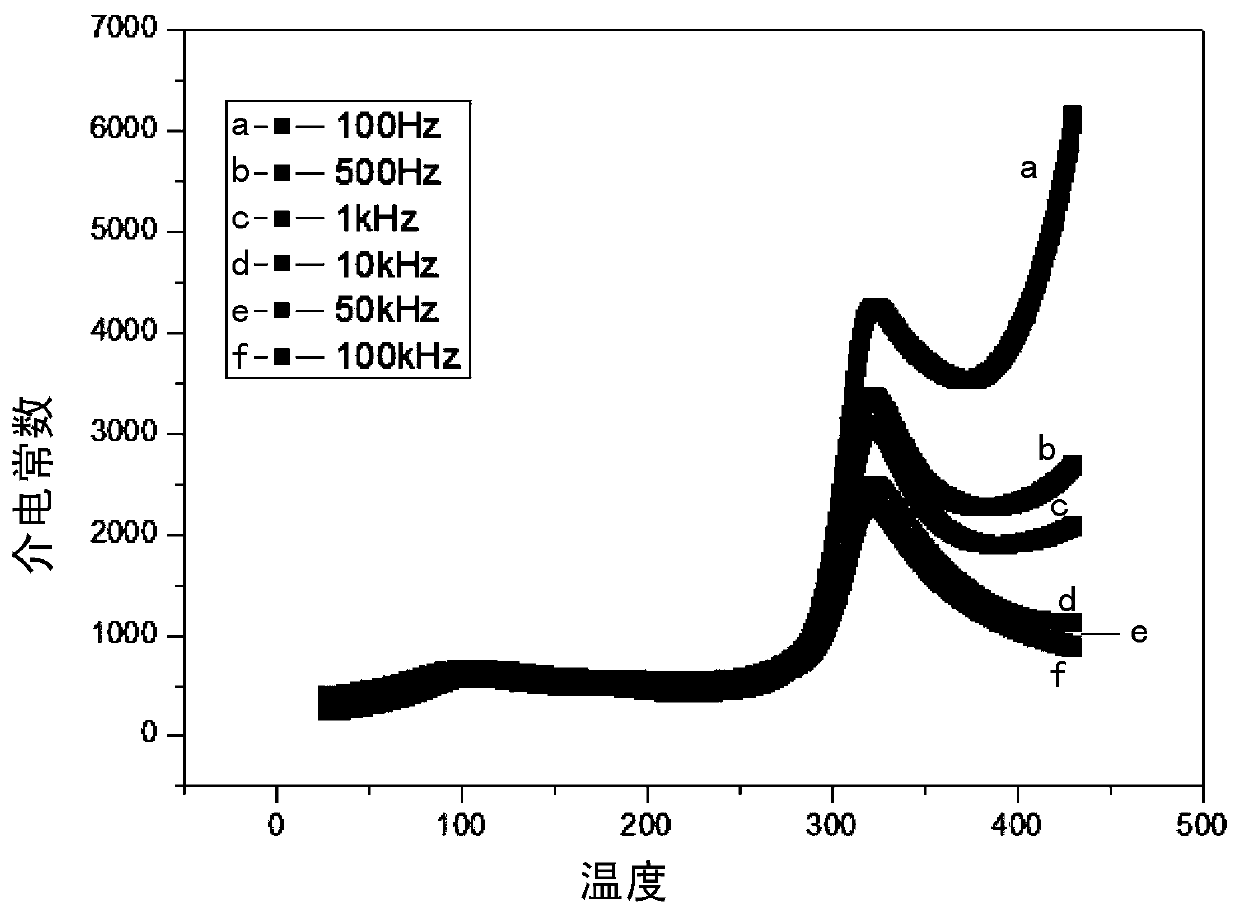

Potassium sodium niobate-bismuth sodium zirconate lead-free piezoelectric single crystal and growing method thereof

ActiveCN107268084ASolve sizeSolve the problem of many cracksPolycrystalline material growthFrom frozen solutionsCrucibleSingle crystal

The invention relates to a potassium sodium niobate-bismuth sodium zirconate lead-free piezoelectric single crystal and a growing method thereof. The chemical formula of the potassium sodium niobate-bismuth sodium zirconate lead-free piezoelectric single crystal is (1-y)(KxNa(1-x))NbO(3-y)(Bi0.5Na0.5)ZrO3, wherein x is larger than or equal to 0.4 and smaller than or equal to 0.6, and y is larger than or equal to 0 and smaller than or equal to 0.1. According to the method, raw materials and a growth auxiliary are mixed and presintered, and the potassium sodium niobate-bismuth sodium zirconate lead-free piezoelectric single crystal is obtained by growing with a Bridgman-Stockbarger method; the potassium sodium niobate-bismuth sodium zirconate lead-free piezoelectric single crystal growing with the Bridgman-Stockbarger method after addition of the growth auxiliary has the advantages that a nucleus is formed easily, the crystal size is larger (2-20 mm), fewer cracks are formed and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

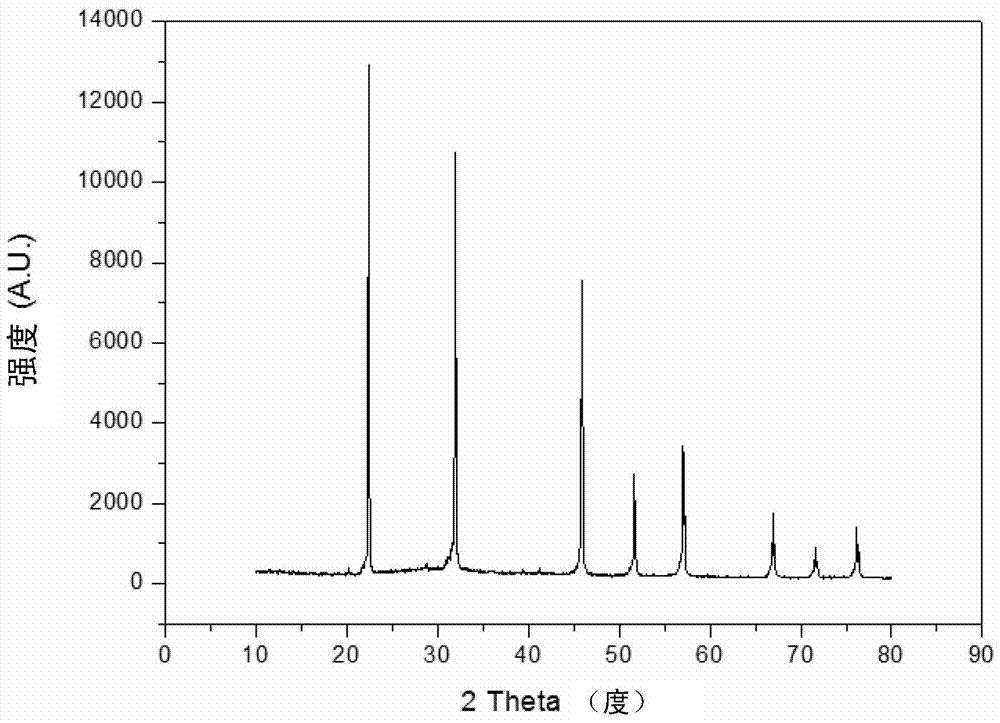

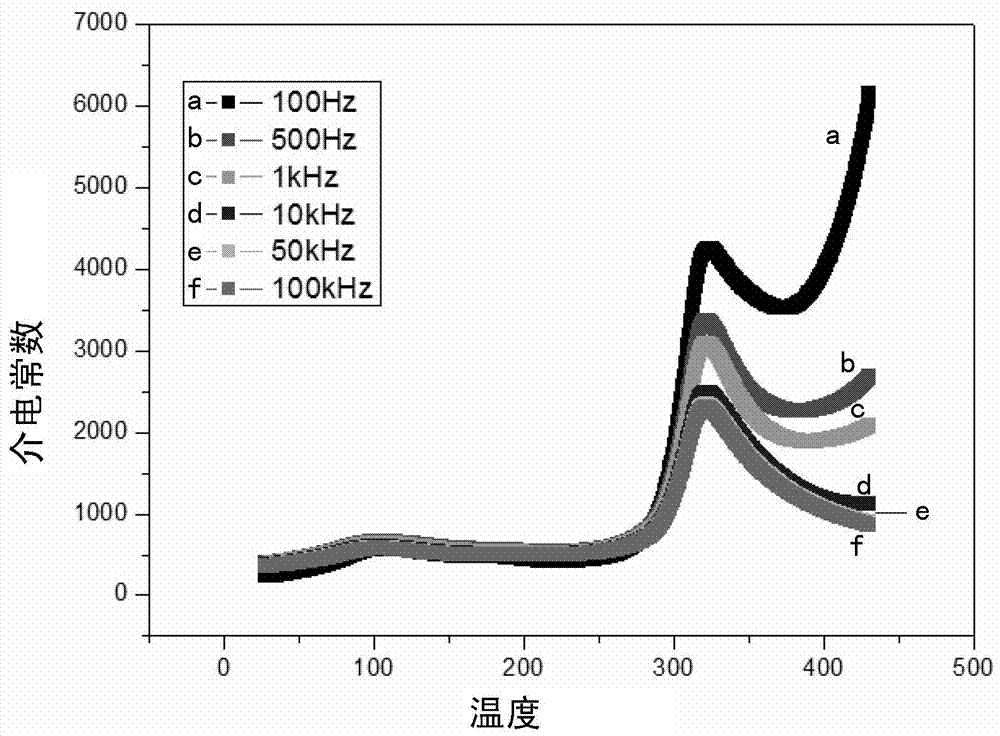

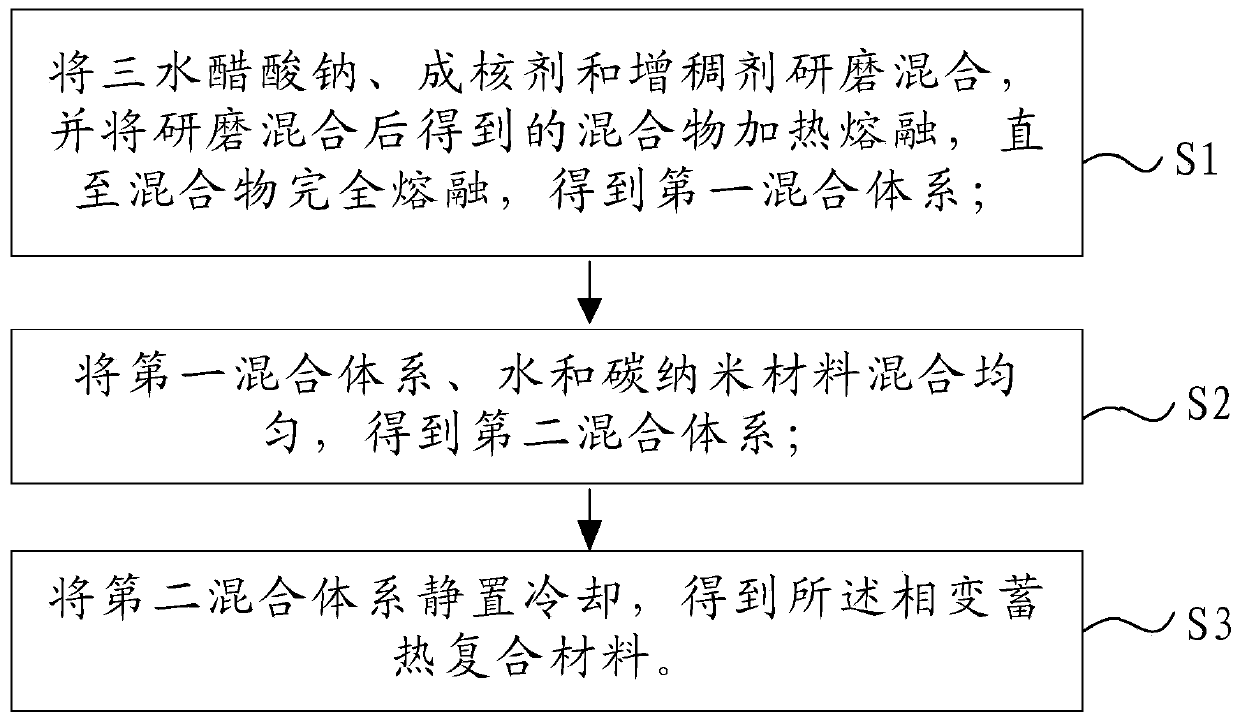

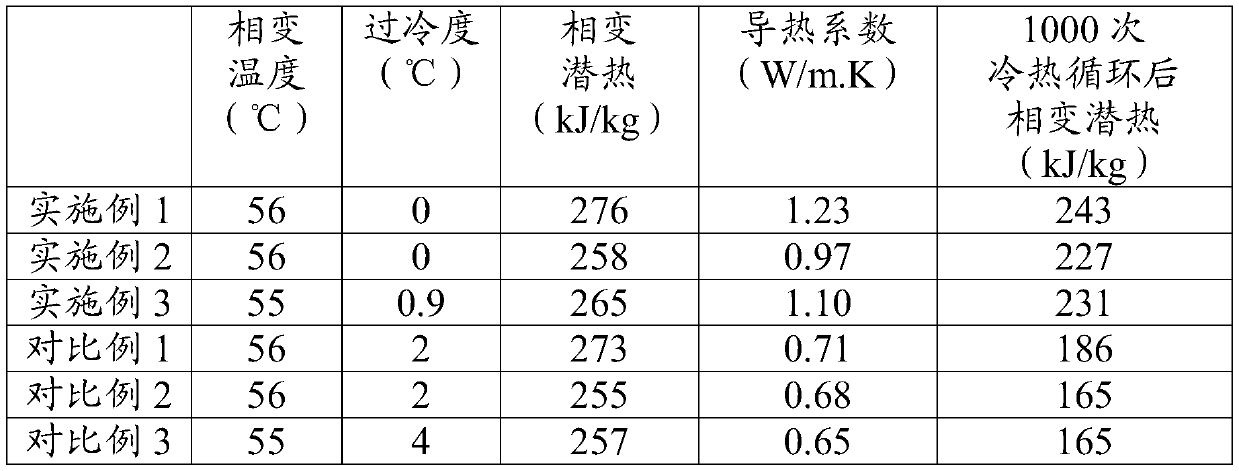

Phase change heat storage composite material and preparation method thereof

InactiveCN110591654AImprove thermal conductivityImprove stabilityHeat-exchange elementsHeat storage materialSodium Acetate Trihydrate

Relating to the field of renewable energy phase change heat storage materials, the invention provides a phase change heat storage composite material and a preparation method thereof. Relative to existing phase change heat storage composite materials, the phase change heat storage composite material provided by the invention reduces and even eliminates undercooling, solves the phase separation problem, improves the heat conductivity, and has high heat stability and cycling stability. The phase change heat storage composite material comprises the following components: sodium acetate trihydrate,a nucleating agent, a thickening agent, water and a carbon nano-material. The preparation method is used for preparation of the phase change heat storage composite material.

Owner:ENN GRAPHENE TECH CO LTD

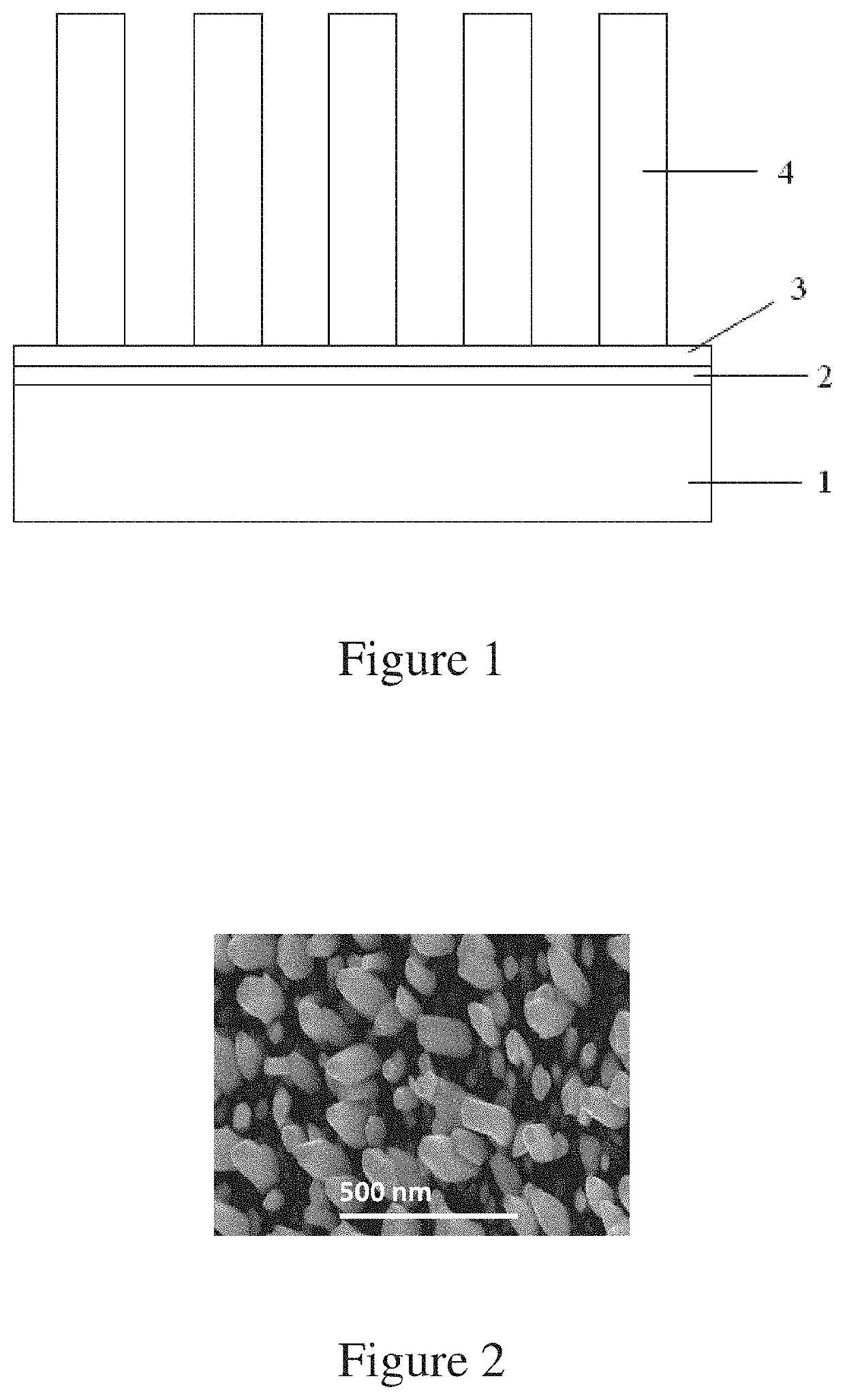

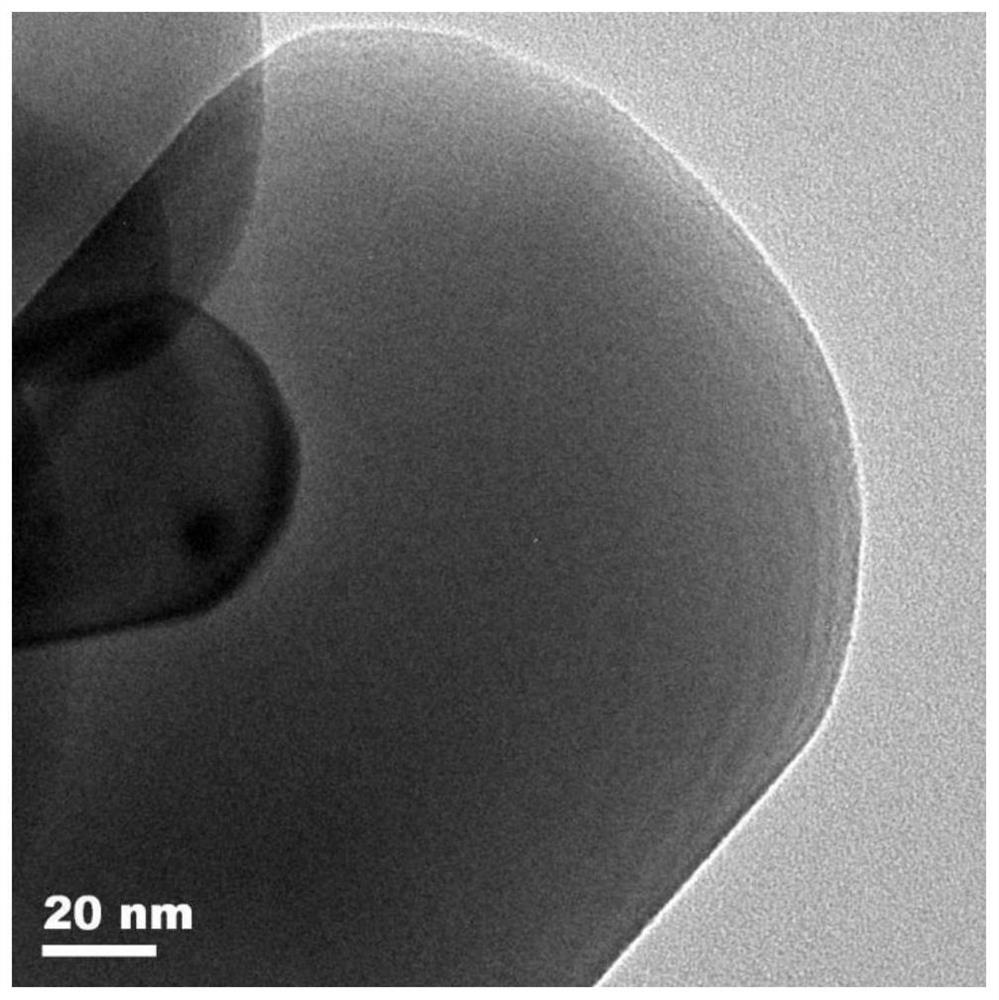

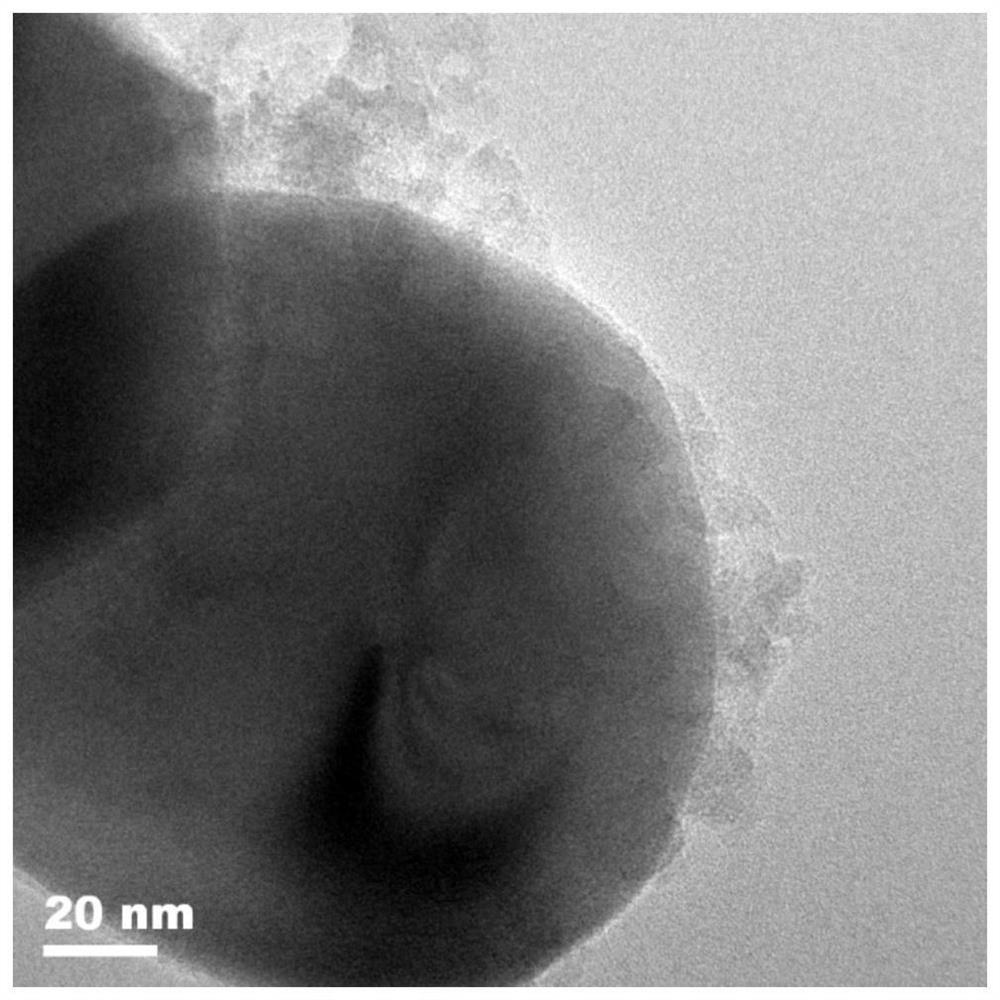

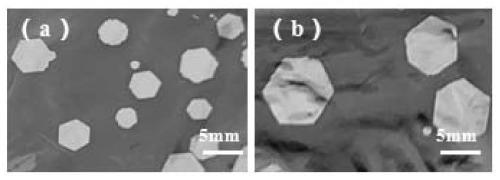

Indium nitride nanopillar epitaxial wafer grown on aluminum foil substrate and preparation method of indium nitride nanopillar epitaxial wafer

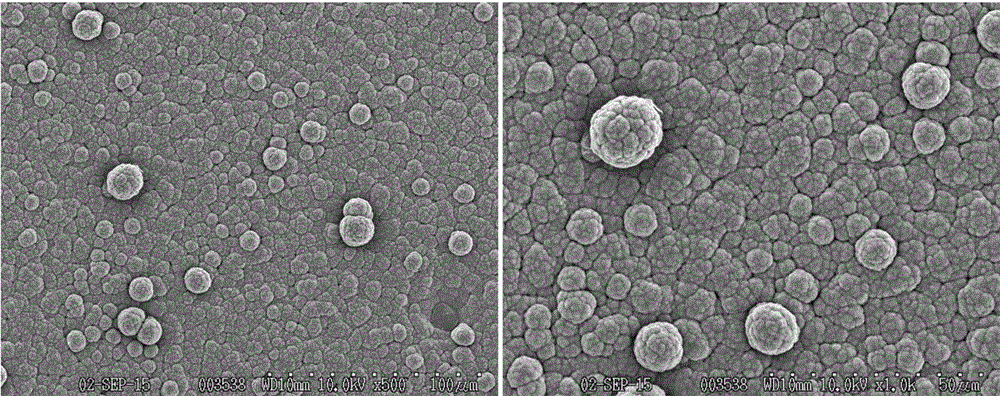

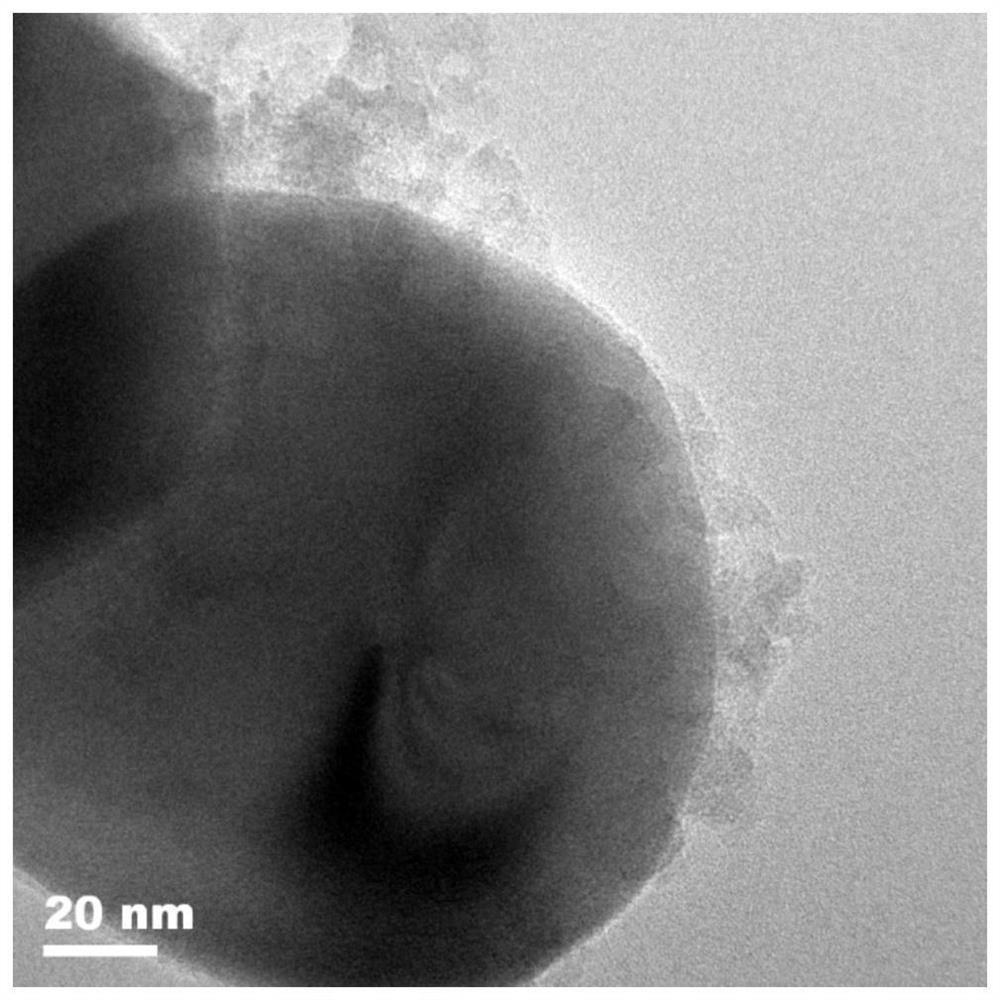

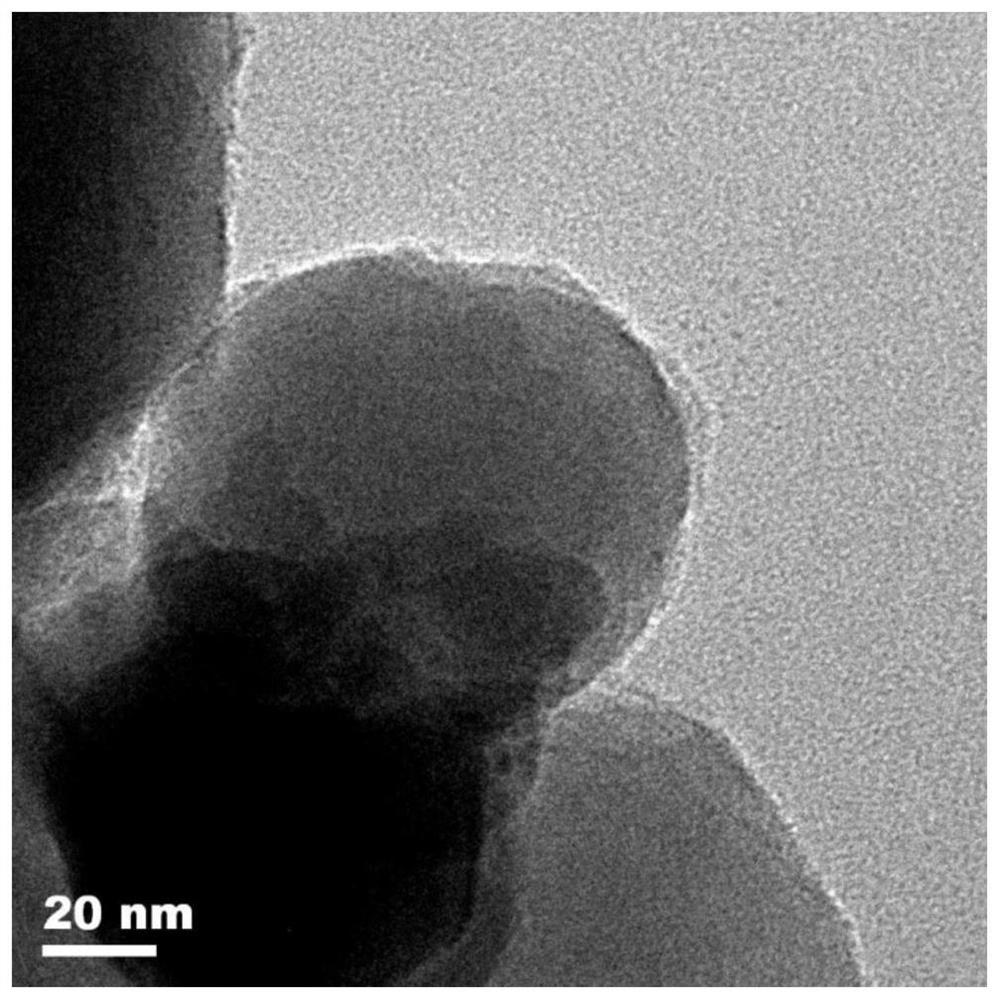

ActiveUS20200343346A1Facilitates nucleation and further growthReduce defect densityMaterial nanotechnologySemiconductor/solid-state device manufacturingPhysicsChemistry

An InN nanorod epitaxial wafer grown on an aluminum foil substrate (1) sequentially comprises the aluminum foil substrate (1), an amorphous aluminum oxide layer (2), an AlN layer (3) and an InN nanorod layer, (4) from bottom to top. The wafer can be prepared by pretreating the aluminum foil substrate with an oxidized surface and carrying out an in-situ annealing treatment; then, in a molecular beam epitaxial growth process, forming AlN nucleation sites on the annealed aluminum foil substrate, nucleating on the AlN and growing InN nanorods on the AlN. where the substrate temperature is 400-700° C., the pressure of a reaction chamber is 4.0-10.0×10−5 Torr and the beam ratio of V / III is 20-40.

Owner:SOUTH CHINA UNIV OF TECH

Aluminum precursor coated titanium dioxide, preparation method thereof and method for preparing aluminum coated titanium dioxide

ActiveCN113652102AGood weather resistanceIncrease repulsionInorganic pigment treatmentHydrated aluminaWeather resistance

The invention discloses aluminum precursor coated titanium dioxide. The surface of titanium dioxide is coated with an aluminum oxide precursor. The invention also discloses a preparation method of the aluminum precursor coated titanium dioxide and a method for preparing the aluminum coated titanium dioxide. The coating process is different from a common aluminum coating method in which hydrated alumina is directly formed and coated on titanium dioxide. According to the preparation method, the aluminum precursor is firstly generated and coats the surface of the titanium dioxide, and the aluminum precursor is of a molecular chain structure, so that the precursor is more easily coated on the surface of the titanium dioxide; the surface of the aluminum oxide precursor in the solution has a large number of hydroxyl groups, so that the repulsive interaction among particles is relatively large, the self-phase nucleation difficulty is high, and heterogeneous nucleation is facilitated, so that titanium dioxide is perfectly coated, then water is removed through drying, and non-bridging hydroxyl groups of adjacent colloidal particles are spontaneously converted into bridging hydroxyl groups; meanwhile, coordination water of a gel part structure is removed, and bridging hydroxyl groups are also formed among coating particles, so that a coating layer on the surface of the titanium dioxide is uniform and compact, and the weather resistance of the titanium dioxide is superior to that of the titanium dioxide prepared by a traditional aluminum coating method.

Owner:EAST CHINA UNIV OF TECH

CF/PEEK composite material with full-transverse crystal structure and preparation method of CF/PEEK composite material

The invention relates to a CF / PEEK composite material with a full transverse crystal structure and a preparation method thereof. The method comprises the following steps: (1) carrying out high-temperature decomposition on an original sizing agent on the surface of CF; (2) simultaneously carrying out microwave radiation and ultraviolet irradiation on the CF in a saturated water vapor environment, and marking a product as ACF; (3) immersing the ACF into the polyetherimide / dichloromethane / carbon nanotube suspension, taking out, and drying to obtain sized modified carbon fiber MCF; (4) laminatingand hot-pressing the MCF and a PEEK material; (5) performing instantaneous pressure application and unloading in the cooling process to enable the resin to obtain perturbation shear flow, and inducingnucleation and growth of the full-transverse crystal structure to obtain the CF / PEEK composite material with the full transverse crystal structure. The bending strength of the finally prepared composite material is 750-900 MPa, the bending modulus of the finally prepared composite material is 63-75 GPa, and the interlayer shear strength of the finally prepared composite material is 90-100 MPa. The method disclosed by the invention has the characteristics of high efficiency, environmental friendliness and capability of realizing large-scale production, and the prepared composite material can replace metal to be applied to the fields of aerospace, machinery, automobiles, rail transit and the like.

Owner:上海东华复材科技有限公司

Fused quartz article having controlled devitrification

InactiveUS20050081564A1Improve creep resistanceNucleation is easyAfter-treatment apparatusCoatingsColloidal silicaSlurry

Owner:MCNULTY THOMAS FRANCIS +4

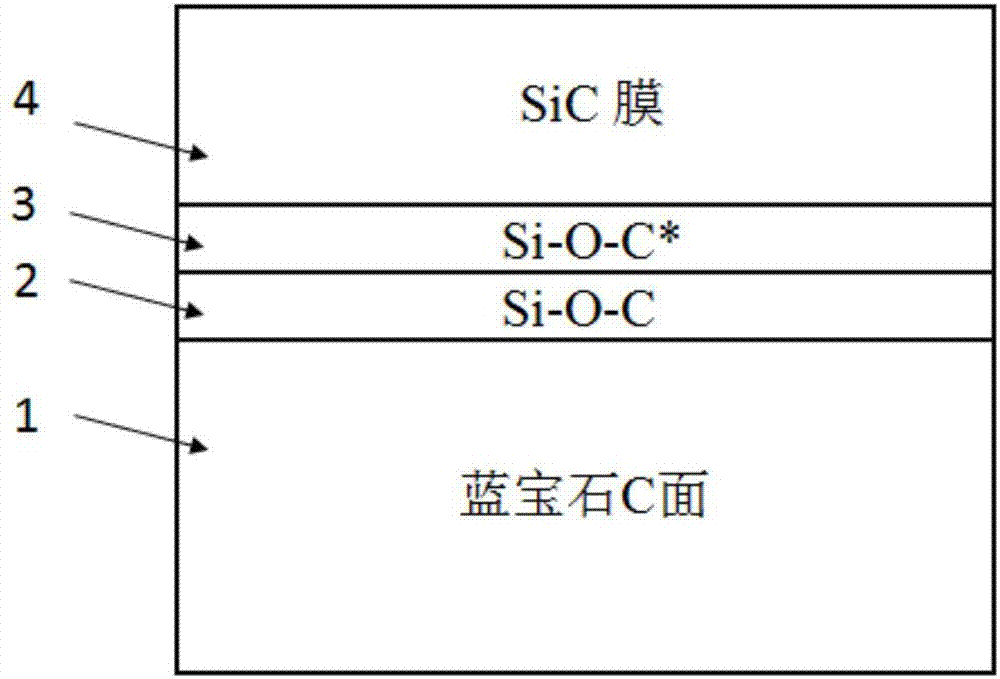

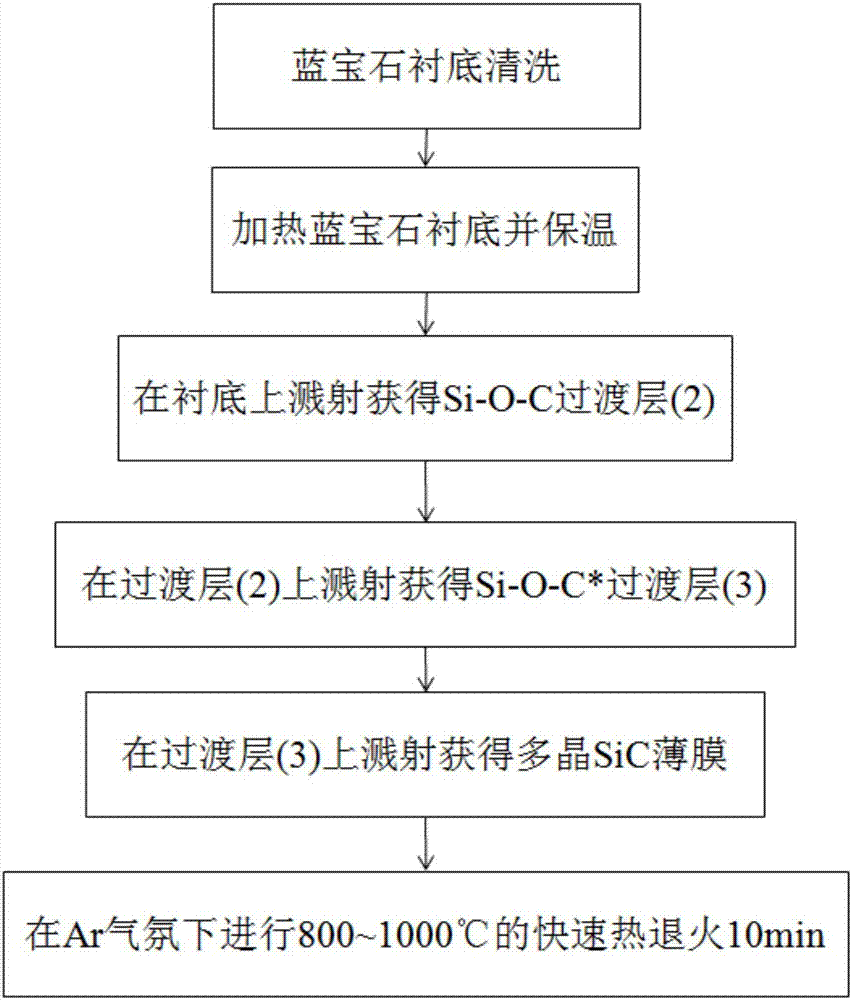

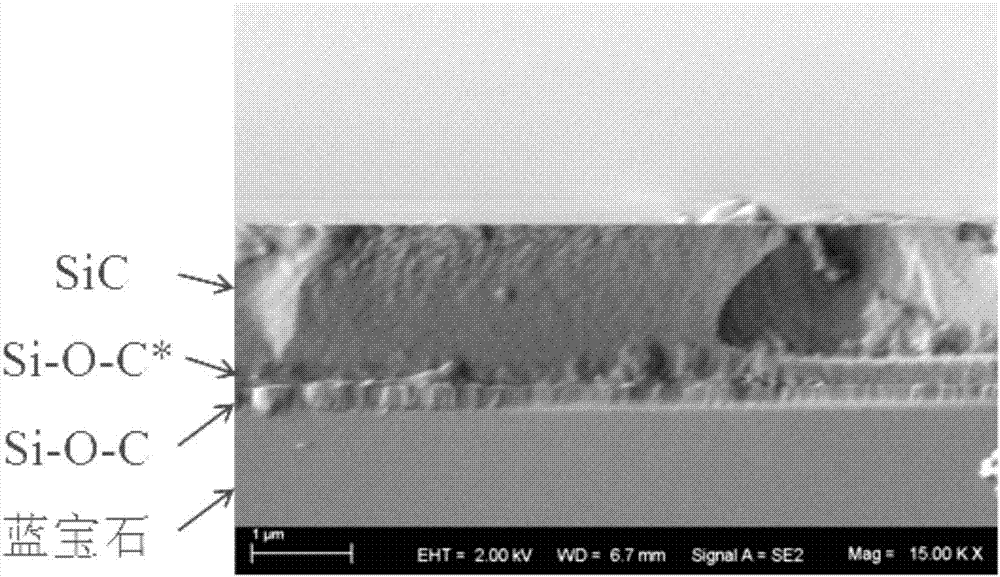

Method for preparing polycrystalline SiC film through sapphire substrate

ActiveCN107059119ANucleation is easyIncrease deposition ratePolycrystalline material growthAfter-treatment detailsSemiconductorVacuum state

The embodiment of the invention discloses a method for preparing a polycrystalline SiC film through a sapphire substrate and relates to the technical field of semiconductor film materials. The method comprises the steps of putting the cleaned sapphire substrate (1) and an SiC target material into a vacuum reaction cavity, pumping the vacuum reaction cavity into a high vacuum state, and heating the sapphire substrate (1); introducing argon and oxygen into the vacuum reaction cavity and maintaining air pressure; executing a magnetron sputtering process to obtain a transition layer (1) and a transition layer (3), wherein the sputtering process comprises pre-sputtering and formal sputtering; closing an oxygen channel, only introducing argon and maintaining the air pressure; executing the magnetron sputtering process again to obtain an SiC film (4); cooling the vacuum reaction cavity to a room temperature and then taking out a sample; and putting the taken sample into a quick annealing oven for thermal annealing. The method is suitable for preparation of the polycrystalline SiC film on the sapphire substrate.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

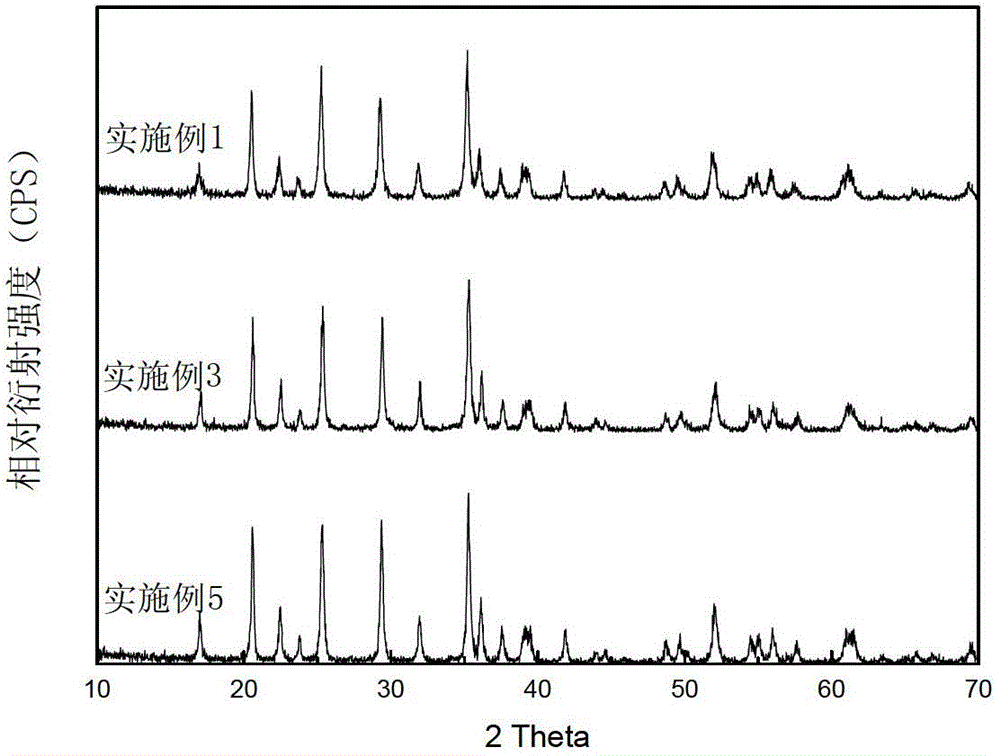

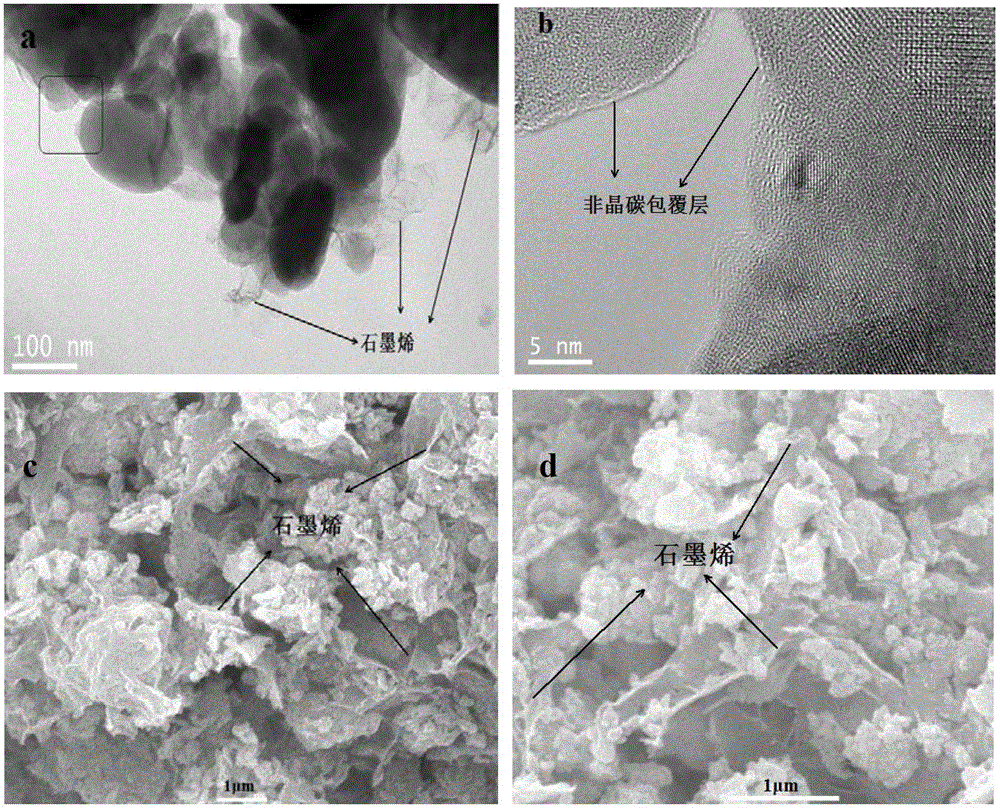

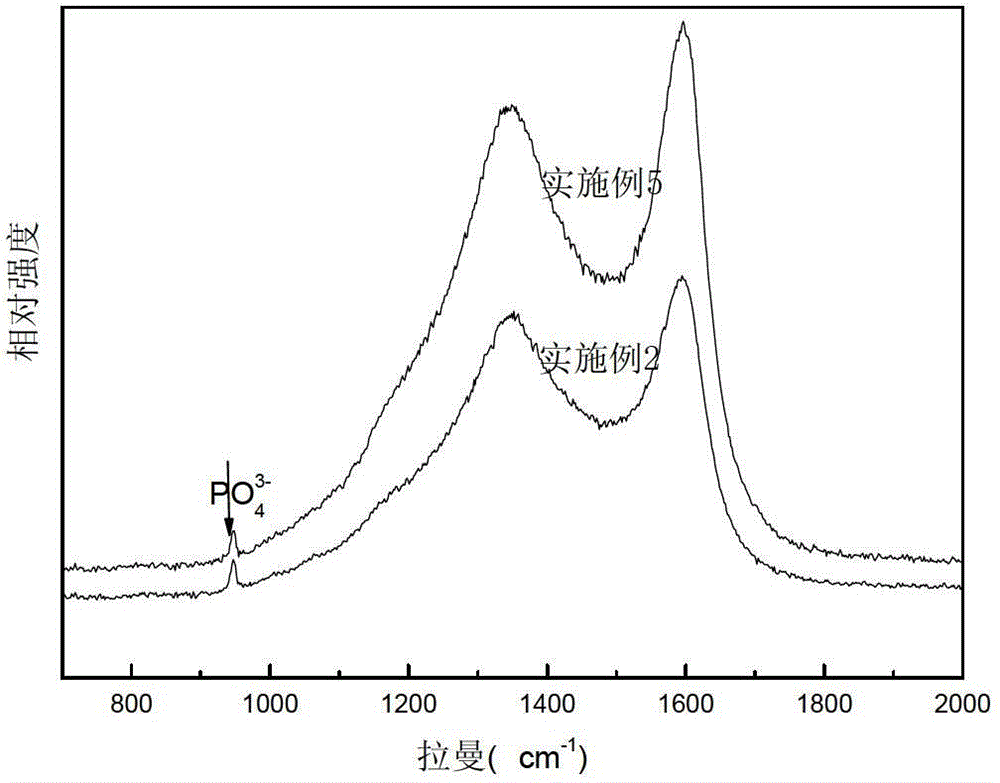

Preparation method of composite positive material with multi-level conductive network of lithium ion battery

The invention relates to a preparation method of a composite positive material (LiMnPO4 / graphene / carbon) with a multi-level conductive network of a lithium ion battery. The method comprises the following steps of: performing liquid-phase precipitation on at least one component material of LiMnPO4 and graphite oxide to form a composite precursor; mechanically activating the composite precursor and other components in a solvent medium; performing hydrothermal reaction on the activated product for 4 to 20 hours to obtain an in-situ composite lithium manganese phosphate / graphene material; mixing the nano-scale lithium manganese phosphate / graphene material and an organic carbon source; and performing heat treatment on the mixture under the protection of inert atmosphere at 500 to 700 DEG C for 1 to 4 hours to obtain the composite positive material. Primary particles of the material prepared by the method are nanoparticles and distributed uniformly; and the multi-level conductive network is formed among phosphate particles in situ. By the method, the size and the appearance of the positive material can be effectively controlled, and the prepared material has high purity, is crystallized intactly, and has excellent physical performance and high multiplying power cycling performance.

Owner:深圳市费特森新能源有限责任公司

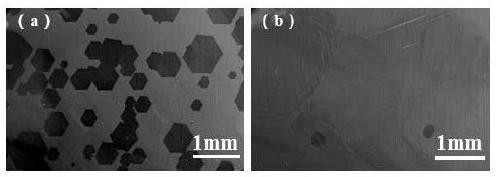

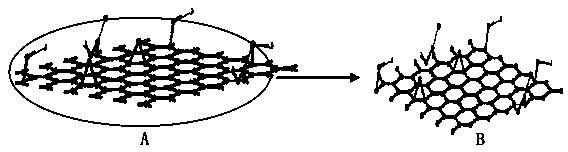

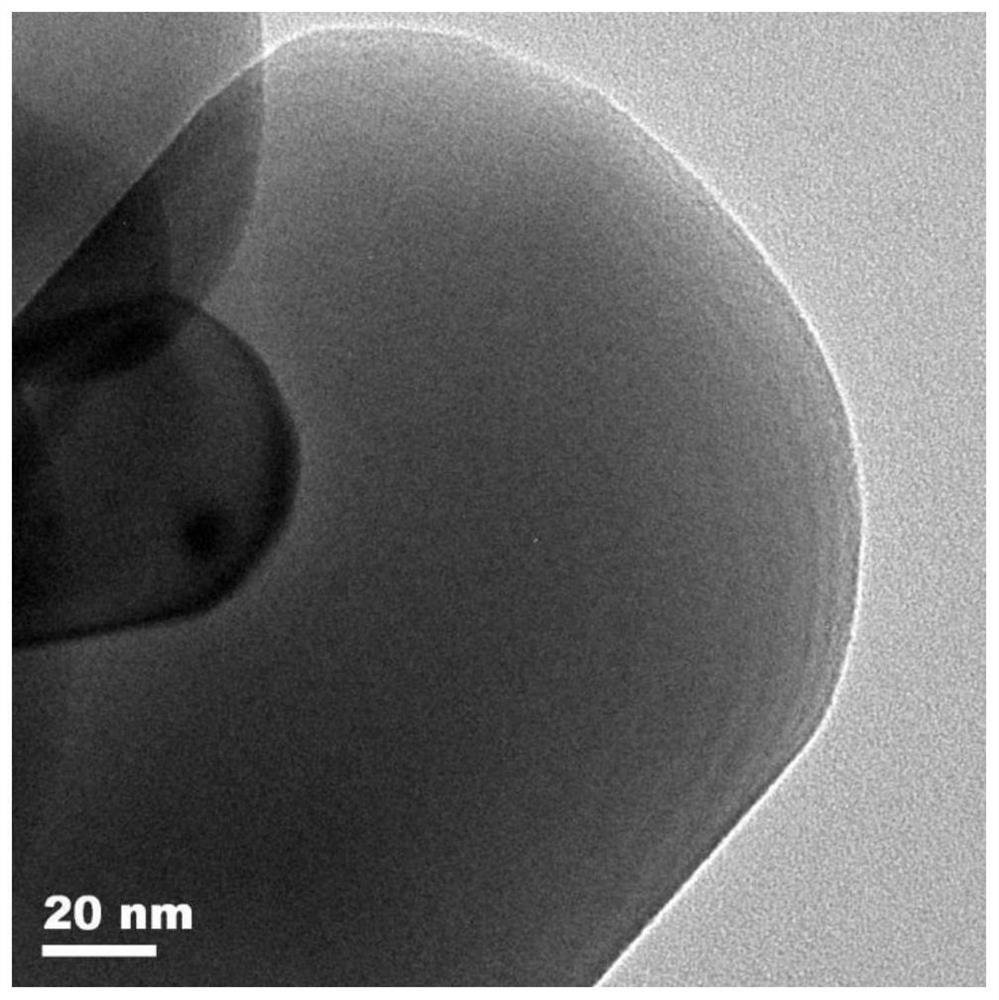

Preparation method of high-quality wafer-level graphene single crystal

ActiveCN110453280AImprove flatnessInhibition of oxidation and passivationPolycrystalline material growthFrom chemically reactive gasesMetal foilSingle crystal

The invention provides a preparation method of a high-quality wafer-level graphene single crystal. The method comprises the following steps: placing plasma-treated metal foil into a reaction furnace,introducing an inert atmosphere, performing heating to an annealing temperature, introducing hydrogen gas, and performing annealing treatment, wherein the metal foil is one selected from the group consisting of copper foil, nickel foil, molybdenum foil and cobalt foil, the plasma treatment atmosphere is at least one selected from the group consisting of air, hydrogen gas, argon gas, oxygen gas, and nitrogen gas, the power is 100-150 W, the pressure is 400-500 Pa, and the time is 1-30 min; and introducing a carbon source into the reaction furnace, adjusting the annealing temperature to a growthtemperature of the graphene single crystal, starting growth of the graphene single crystal, and after growth is completed, performing cooling to a room temperature.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

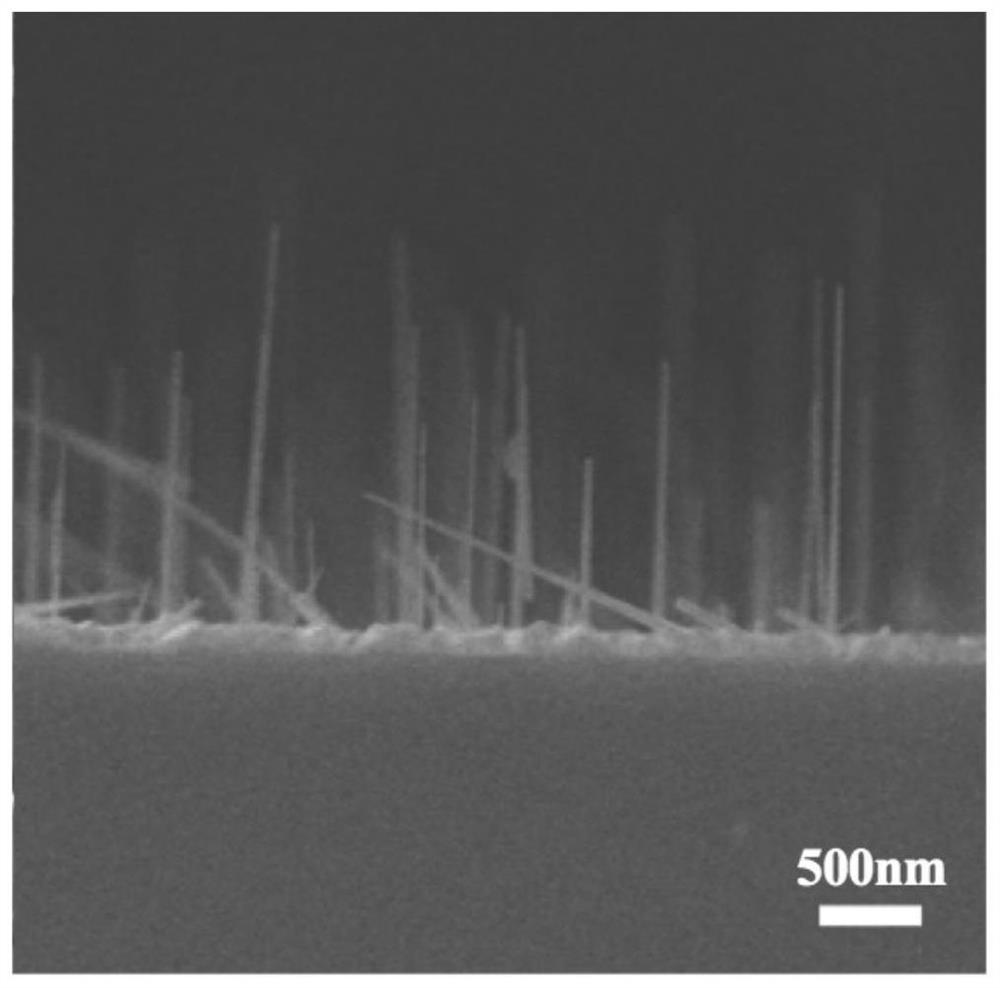

Method for growing gaas nanowires on si substrate

ActiveCN109767972BHigh densityEasy to shapeMaterial nanotechnologyNanoinformaticsPhysicsLight absorbance

The invention discloses a method for growing GaAs nanowires on a Si substrate, comprising the following steps: (1) selecting a substrate and crystal orientation: selecting Si (111) as the substrate; (2) cleaning and re-oxidizing the surface of the substrate; (3) Substrate annealing treatment: put the substrate into the reaction chamber, and anneal the treated Si substrate at 690-720°C for 10-15 minutes; (4) Preparation of GaAs nanowires: use molecular beam The epitaxial growth process uses a two-step temperature method to grow GaAs nanowires on the Si substrate after the above treatment. The invention has the advantages of simple growth process, low preparation cost, and can grow GaAs nanowires with high density and good shape. At the same time, the GaAs nano wire crystal prepared by the invention has good quality, large specific surface area, no heterogeneous element impurities, and high luminous efficiency and light absorption rate.

Owner:SOUTH CHINA UNIV OF TECH

Potassium sodium niobate-bismuth sodium zirconate lead-free piezoelectric single crystal and its growth method

ActiveCN107268084BSmall sizeReduce crackingPolycrystalline material growthFrom frozen solutionsCrucibleZirconate

The invention relates to a potassium sodium niobate-bismuth sodium zirconate lead-free piezoelectric single crystal and a growing method thereof. The chemical formula of the potassium sodium niobate-bismuth sodium zirconate lead-free piezoelectric single crystal is (1-y)(KxNa(1-x))NbO(3-y)(Bi0.5Na0.5)ZrO3, wherein x is larger than or equal to 0.4 and smaller than or equal to 0.6, and y is larger than or equal to 0 and smaller than or equal to 0.1. According to the method, raw materials and a growth auxiliary are mixed and presintered, and the potassium sodium niobate-bismuth sodium zirconate lead-free piezoelectric single crystal is obtained by growing with a Bridgman-Stockbarger method; the potassium sodium niobate-bismuth sodium zirconate lead-free piezoelectric single crystal growing with the Bridgman-Stockbarger method after addition of the growth auxiliary has the advantages that a nucleus is formed easily, the crystal size is larger (2-20 mm), fewer cracks are formed and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Composite fiber preparation method of microwave-assisted diamond-like carbon film covered glass fiber

InactiveCN102627413BHigh mechanical strengthChemically stableChemical vapor deposition coatingFiberDiamond-like carbon

The invention relates to a composite fiber preparation method of microwave-assisted diamond-like carbon film covered glass fibers. The method comprises the following steps of: 1) starting a microwave plastic chemical vapor deposition system and vacuumizing; 2) feeding natural gas into a cylindrical stainless steel vacuum chamber to enable the natural gas to be fully filled in the entire cylindrical stainless steel vacuum chamber; 3) starting a microwave source to enable the microwave source to generate microwaves to excite plasmas in a conical metal roller, so as to fully decompose the natural gas into hydrocarbon groups with activity; 4) adding raw material glass fibers into the conical metal roller; 5) starting a motor to enable the raw materials to be evenly dispersed and centrifugally move, wherein, at the moment, the hydrocarbon groups produced by the decomposed natural gas are deposited on the surfaces of the glass fibers and grow to a diamond-like carbon film, and composite fibers, i.e. the diamond-like carbon film covered glass fibers are formed and are regularly discharged; 6) repeating step 1 to step 5; and 7) after the production is finished, closing all valves and shutting down the microwave and the engine. The composite fiber preparation method of microwave-assisted diamond-like carbon film covered glass fibers provided by the invention has the advantages of low cost, simplicity in implementation and convenience in operation.

Owner:LANZHOU UNIVERSITY

Preparation method of graphene-chromium-titanium-aluminum composite material and its application in cutting tools

ActiveCN106914612BImprove bindingHeating fastMetallic material coating processesSurface layerTitanium

The preparation method of graphene-chromium-titanium-aluminum composite material and its application on cutting tools, through laser beam radiation, make it melt together with the surface material of the cutting tool and then solidify rapidly, so as to obtain a compound with a small dilution rate and good compatibility with the cutting tool material Surface coating, the surface coating is actually a highly dense bonded graphene composite cladding layer, which organically combines the tool base material and coating material. Thus, the comprehensive properties of the tool such as wear resistance, corrosion resistance, and oxidation resistance are significantly improved, and the purpose of tool surface repair or improvement is realized. The main preparation conditions are: the percentage of graphene nano powder in the total mass of the composite material is 5-15%, the percentage of Ti powder in the total mass of the composite material is 20-25%, and the percentage of Al powder in the total mass of the composite material is 20-25%. %, Cr powder accounts for 35-55% of the total mass of the composite material.

Owner:LUOYANG INST OF SCI & TECH

A kind of preparation method of aluminum precursor coated titanium dioxide

ActiveCN113652102BGood weather resistanceIncrease repulsionInorganic pigment treatmentHydrated aluminaWeather resistance

The invention discloses an aluminum precursor coated titanium dioxide, wherein the surface of the titanium dioxide is coated with an aluminum oxide precursor. The invention also discloses a preparation method of the aluminum precursor coated titanium dioxide and a method for preparing the aluminum coated titanium dioxide. The coating process of the present invention is different from the usual aluminum coating method which directly forms hydrated alumina to coat the titanium dioxide. In the present invention, the aluminum precursor is first formed and coated on the surface of titanium dioxide, and the molecular chain structure of the aluminum precursor makes it easier to coat the precursor on the surface of titanium dioxide; moreover, there are a large number of hydroxyl groups on the surface of the aluminum oxide precursor in the solution, making it The repulsion between particles is relatively large, and self-nucleation is difficult, which is conducive to heterogeneous nucleation, so that the titanium dioxide is perfectly coated, and then dried to remove moisture, and the non-bridging hydroxyl groups of adjacent colloidal particles are spontaneously transformed into bridging hydroxyl groups; at the same time , the gel part structure coordination water is excluded, and bridging hydroxyl groups are also formed between the coating particles, so that the coating layer on the surface of titanium dioxide is uniform and dense, and the weather resistance of titanium dioxide is better than that of traditional aluminum coating methods.

Owner:EAST CHINA UNIV OF TECH

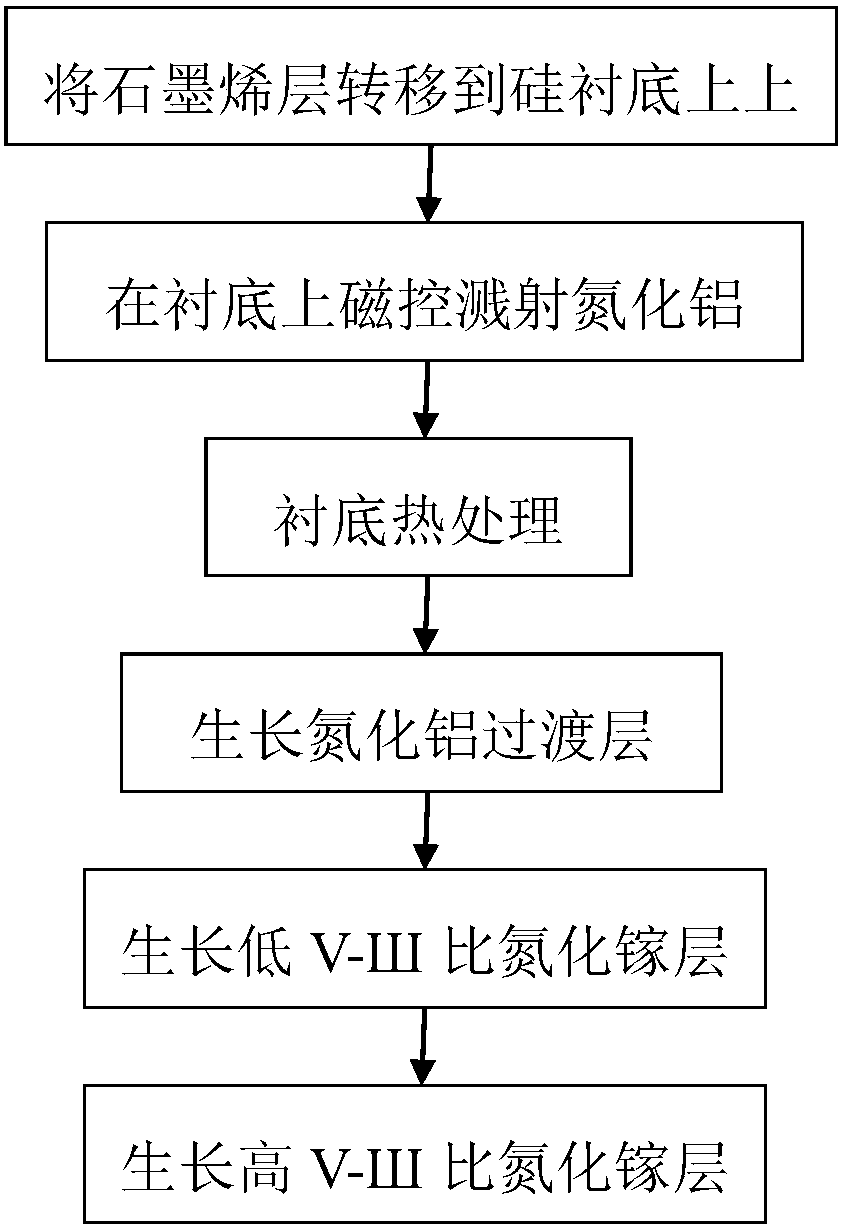

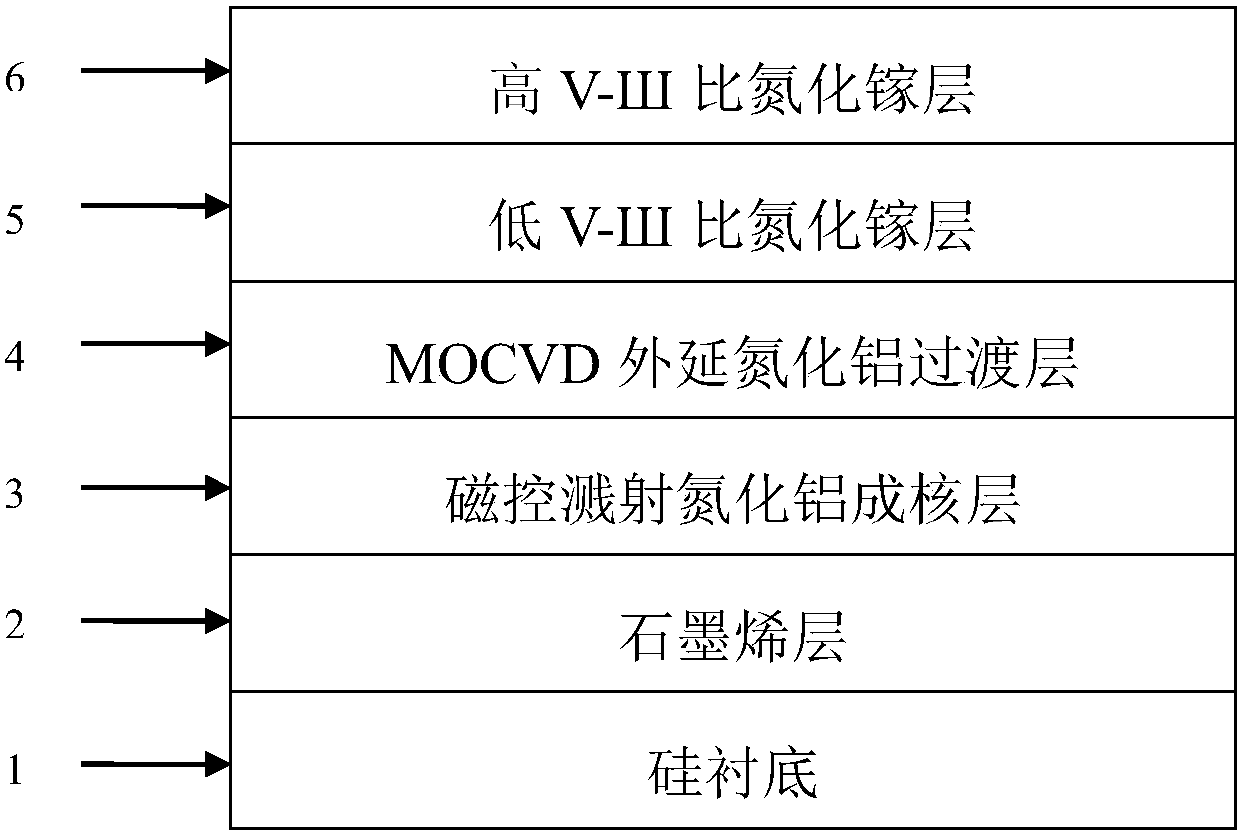

Growth method of gallium nitride on silicon based on graphene and magnetron sputtering aluminum nitride

ActiveCN105655238BNucleation is easyQuality improvementVacuum evaporation coatingSemiconductor/solid-state device manufacturingGas phaseSingle layer graphene

The invention relates to a silica-based gallium nitride growing method based on graphene and magnetron sputtering aluminum nitride. The method includes the following steps that 1, single-layer graphene is transferred to a silicon substrate through a transferring technology of graphene on a copper substrate; 2, an aluminum nitride film grows on the silicon substrate covered by the graphene layer through magnetron sputtering; 3, heat treatment is conducted; 4, an aluminum nitride film is formed in an epitaxy mode through a metal organic chemical vapor deposition (MOCVD) method; 5, a sample is put into MOCVD, and a low-V / III-ratio GaN epitaxial layer and a high V / III ratio GaN epitaxial layer are sequentially formed in an epitaxy mode. The good-quality gallium nitride epitaxial layer covering the silicon substrate of the graphene layer is obtained easily through the method.

Owner:XIDIAN UNIV

Photothermographic material

InactiveUS7122300B2Increase graininessGood effectPhotothermographic systemsSilver halide emulsionsEngineeringSilver halide

A photothermographic material comprising a support, and an image-forming layer and a non-photosensitive layer provided on a surface of the support, wherein the image-forming layer and the non-photosensitive layer are adjacent to each other; the image-forming layer includes a photosensitive silver halide, a first non-photosensitive organic silver salt, a first reducing agent, a polyhalogen compound and a binder; and the non-photosensitive layer includes a second non-photosensitive organic silver salt.

Owner:FUJIFILM HLDG CORP +1

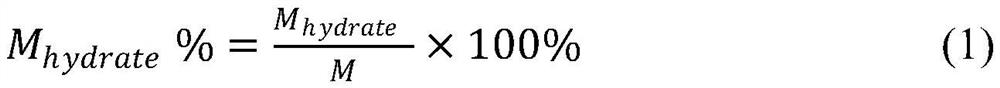

Hydrate energy storage temperature control material and preparation method thereof

ActiveCN112625655BImprove thermal conductivityNucleation is easyLiquid spraying plantsLiquid surface applicatorsTemperature controlPolystyrene

The invention discloses a hydrate energy storage temperature control material and a preparation method thereof. The material contains coolant hydrate and a cross-linked polymer. The preparation process first prepares coolant hydrate in an autoclave, and then crushes and sieves the hydrate particles; then uses an electrostatic spraying device to evenly coat the polystyrene suspended ultrafine powder on the surface of the hydrate particles, and then puts it into the plasma In the body instrument, polystyrene is modified to form free radicals on the surface of polystyrene powder. Finally, under the irradiation of the high-pressure mercury lamp of the UV lighting system, the monomer is grafted and polymerized with the free radical on the surface of polystyrene to stabilize the structure of the material and make the final product. The invention prepares hydrate energy storage and temperature control materials with good stability, and provides a method for preparing various types of coolant hydrate materials. The product can fully utilize the advantages of hydrate energy storage and temperature control, and can periodically It can be used in various fields such as construction and refrigeration.

Owner:DALIAN UNIV OF TECH

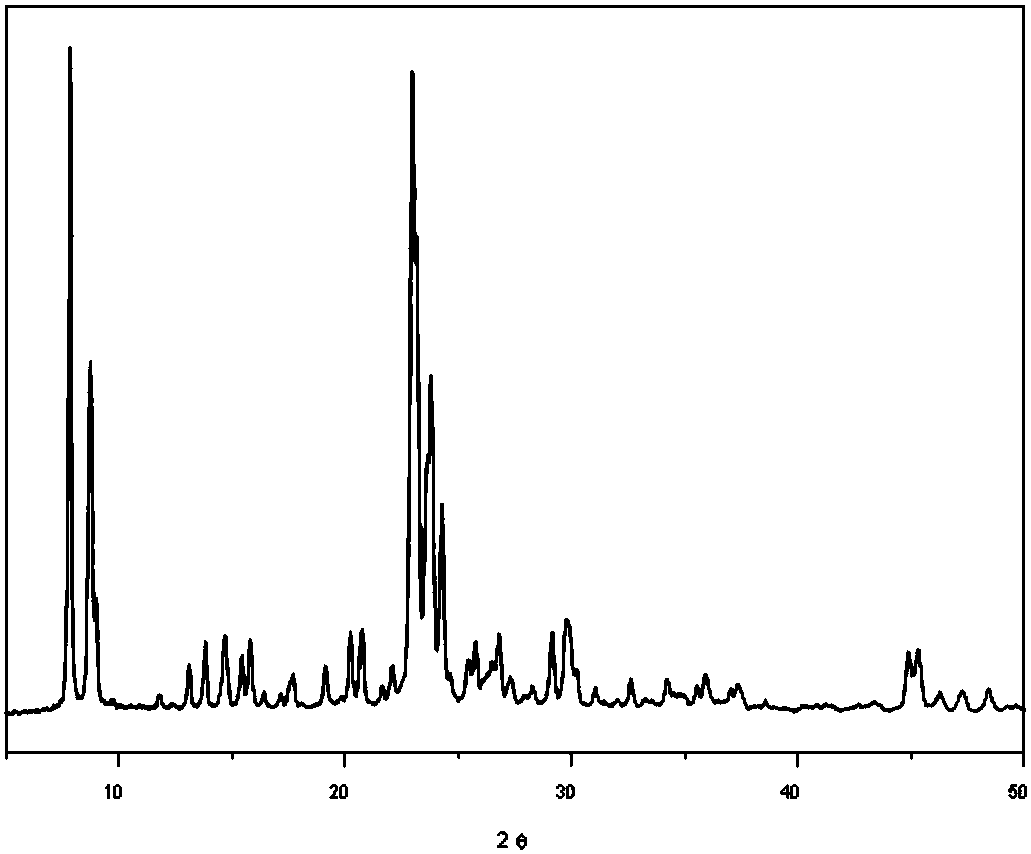

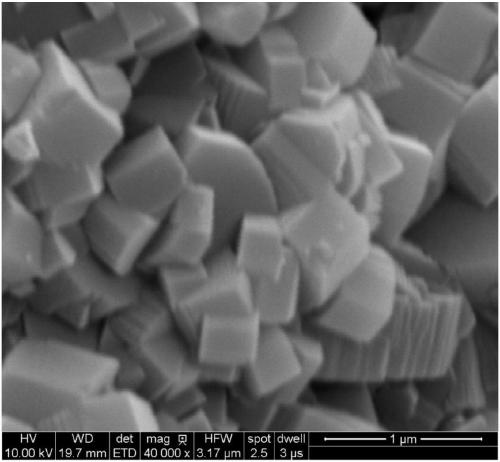

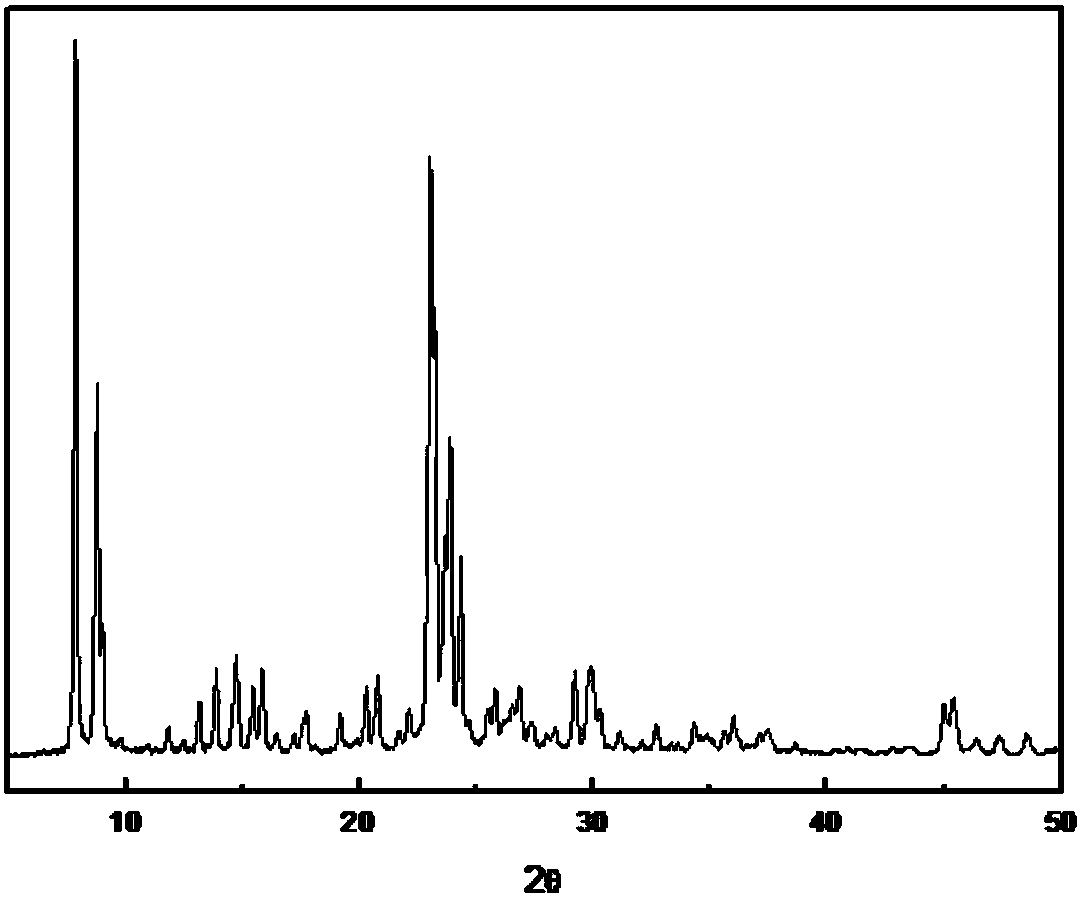

ZSM-5 molecular sieve and preparation method thereof

ActiveCN110467197AGood crystal formHigh crystallinityMaterial nanotechnologyPentasil aluminosilicate zeoliteContinuous crystallizationCrystallinity

The invention provides a ZSM-5 molecular sieve and a preparation method thereof. The preparation method includes the following steps: a) mixing an aluminum source, an alkali source and part of total water consumption, and then adding a template for mixing; b) adding a silicon source, and stirring the materials at 100 DEG C-120 DEG C for crystallization; and c) adding the remaining water for continuous crystallization at 150 DEG C-180 DEG C to obtain the ZSM-5 molecular sieve. The ZSM-5 molecular sieve with good crystal form, high crystallinity and high yield is prepared by using granular silica gel, the cheap template and a small amount of water and adjusting the template concentration in the crystallization process and changing the crystallization temperature by adding water in stages. The method has the advantages of low cost, short synthesis cycle, simple process and easy industrialization.

Owner:WISON ENG

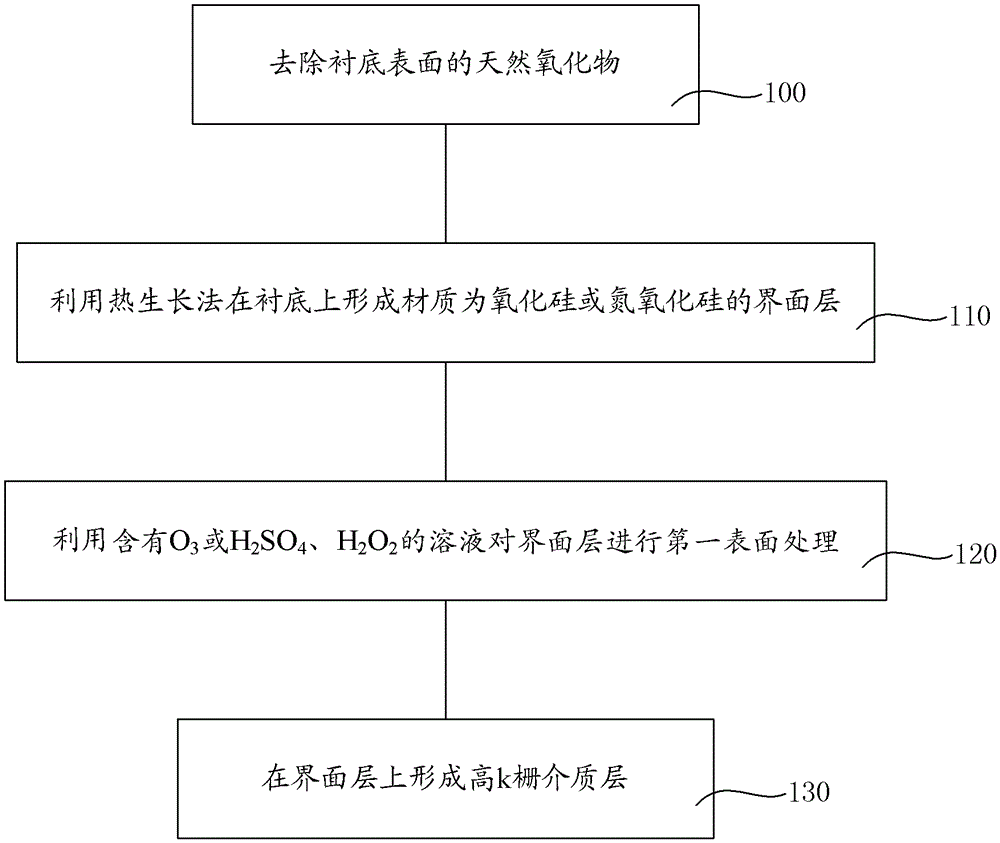

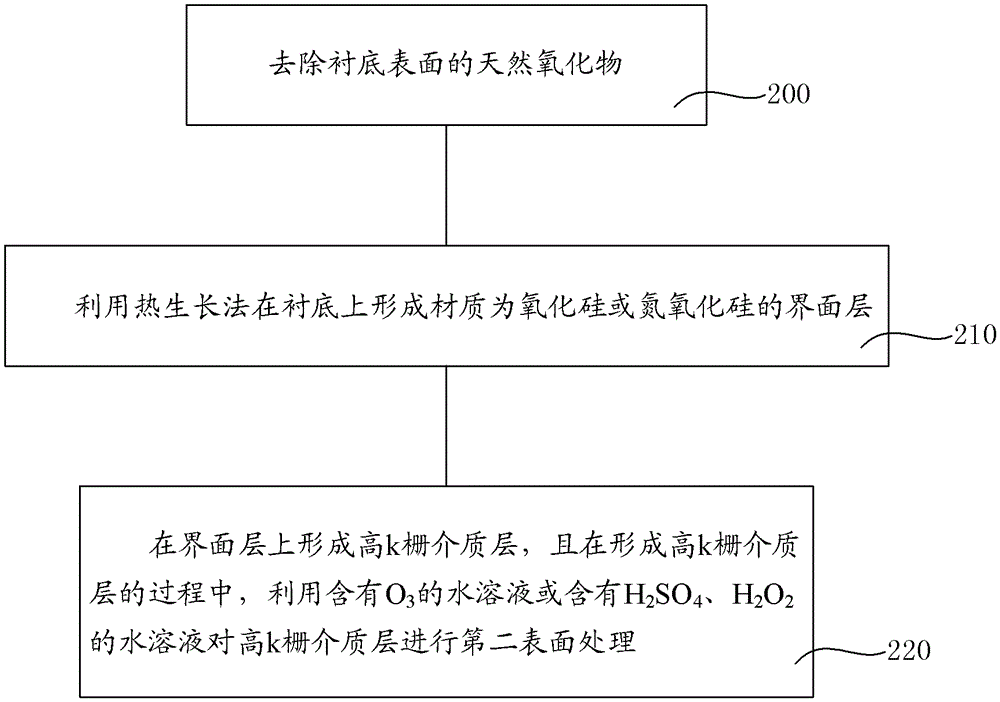

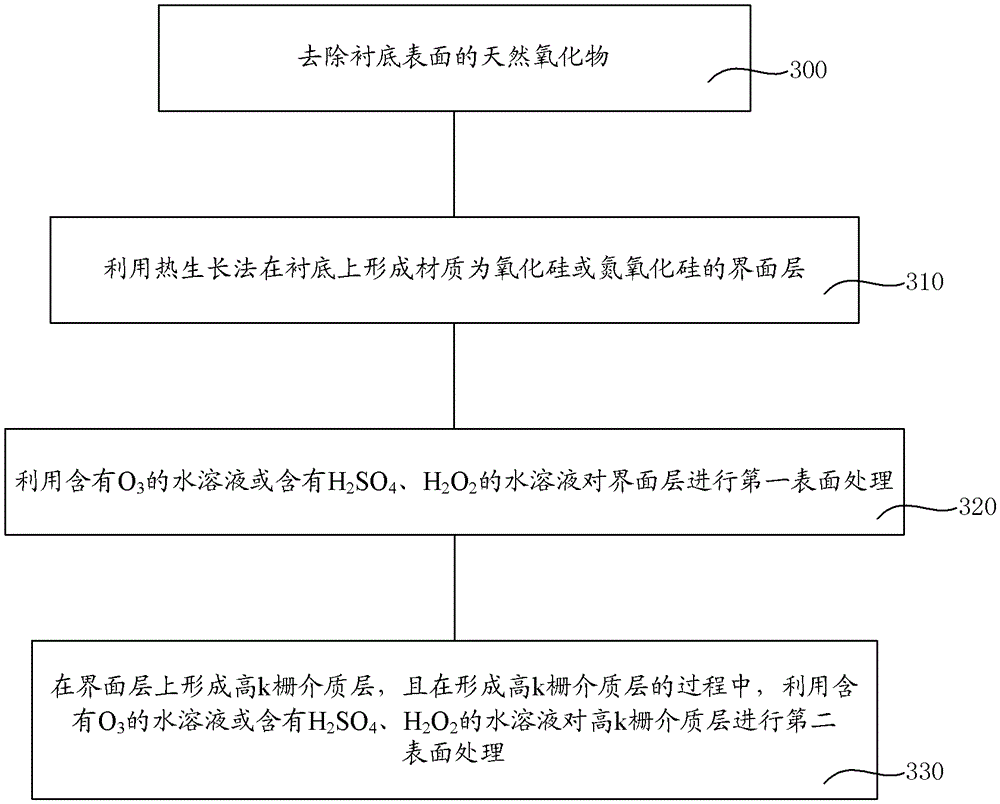

Fabrication method of gate dielectric layer, fabrication method of transistor

ActiveCN103295891BIncrease OH bondNucleation is easySemiconductor/solid-state device manufacturingGate dielectricInterface layer

The invention provides a manufacturing method for a gate dielectric layer and a manufacturing method for a transistor. The manufacturing method for the gate dielectric layer comprises the steps that an interface layer is formed on a substrate by the adoption of a thermal growth method; a high-k gate dielectric layer is formed on the interface layer; surface processing is conducted on the interface layer or the high-k gate dielectric layer by the adoption of aqueous solution containing O3 or H2SO4 and H2O2. According to the manufacturing method for the gate dielectric layer and the manufacturing method for the transistor, due to the facts that the best interface layer is formed by the adoption of the thermal growth method, and the surface processing is conducted on the interface layer or the high-k gate dielectric layer by the adoption of the aqueous solution containing O3 or H2SO4 and H2O2, a large number of OH keys which are suitable for improving the coverage rate of the high-k gate dielectric layer are formed on the surface of the interface layer or the high-k gate dielectric layer, the high-k gate dielectric layer can nucleate more easily on the interface layer, and interfacial characterization between the interface layer and the high-k gate dielectric layer is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com