Phase change heat storage composite material and preparation method thereof

A technology of composite materials and phase change heat storage, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of reducing the cycle life of materials, restricting practical applications, and easy precipitation of materials, so as to reduce the time of heat storage and release , Solve the problem of phase separation and enhance the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

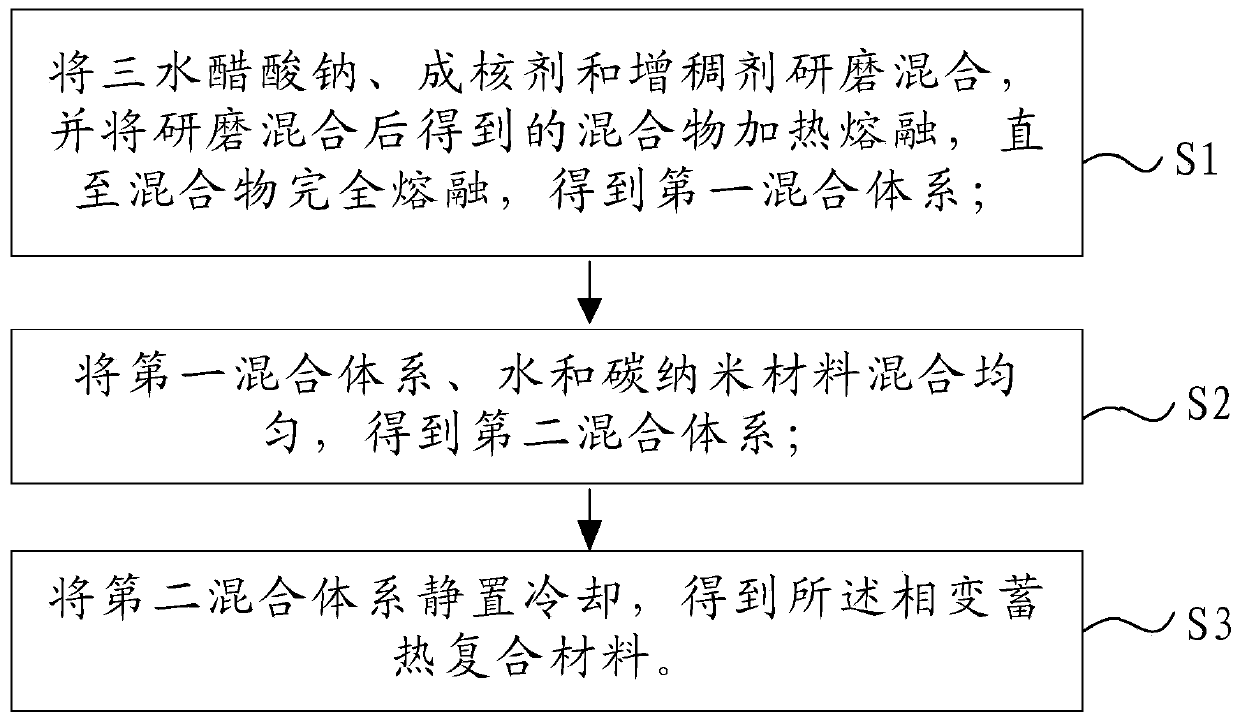

Method used

Image

Examples

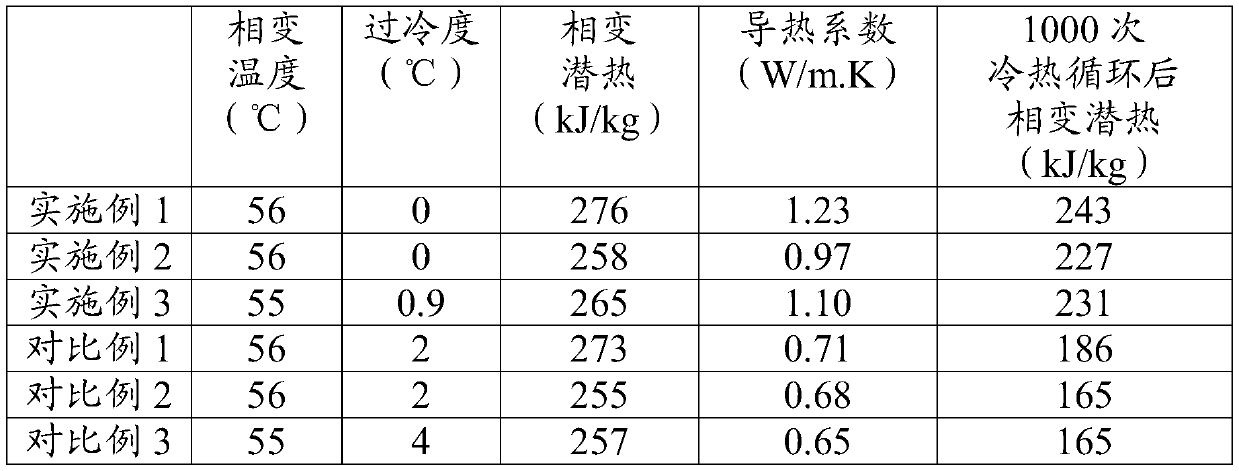

Embodiment 1

[0049] Weigh 91g of sodium acetate trihydrate, 2g of disodium hydrogen phosphate, and 2g of sodium carboxymethylcellulose. After mixing evenly, place the mixture in a ball mill for grinding until the particle size of the mixture reaches 20 μm-300 μm, then grind and mix The final mixture was added to the reactor, and the temperature of the reactor was set at 65°C. After the mixed material is completely melted, add 5g of deionized water, and then add 2g of graphene powder (sheet thickness 1-10 layers, sheet diameter 3-10μm) into the reaction kettle while stirring at a rotation rate of 1000rpm, and add it for about 20min. After finishing, continue to stir for 30 minutes, let it stand for cooling, and obtain the phase change thermal storage composite material.

Embodiment 2

[0051] Weigh 88.5g of sodium acetate trihydrate, 2.5g of anhydrous sodium acetate, and 2g of sodium polyacrylate. After mixing evenly, place the mixture in a ball mill for grinding until the particle size of the mixture reaches 20 μm-300 μm, and then grind and mix The mixture was added to the reactor, and the temperature of the reactor was set to 70°C. After the mixed material is completely melted, add 4g of deionized water, and then add 3g of wound carbon nanotube powder (diameter 15-20nm, length 5-15μm) into the reactor at a rate of 1500rpm while stirring for about 20min. Stir for 30 minutes, let it stand for cooling, and obtain a phase change thermal storage composite material.

Embodiment 3

[0053] Weigh 93g of sodium acetate trihydrate, 3g of sodium bromide, and 2g of xanthan gum. After mixing evenly, place the mixture in a ball mill for grinding until the particle size of the mixture reaches 20 μm-300 μm, and then add the ground and mixed mixture to Into the reactor, set the temperature of the reactor to 65°C. After the mixed material is completely melted, add 4g of deionized water, then add 1g of nitrogen-doped multilayer graphene powder (sheet thickness 1-10 layers, sheet diameter 3-10 μm, Nitrogen content 5%), add in about 20 minutes, continue to stir for 30 minutes, let it stand for cooling, and obtain a phase change thermal storage composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com