A kind of preparation method of aluminum precursor coated titanium dioxide

A technology of titanium dioxide and precursors, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve the problem of uneven coating layer, different thickness of coating layer, and insignificant increase in weather resistance of coated titanium dioxide And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

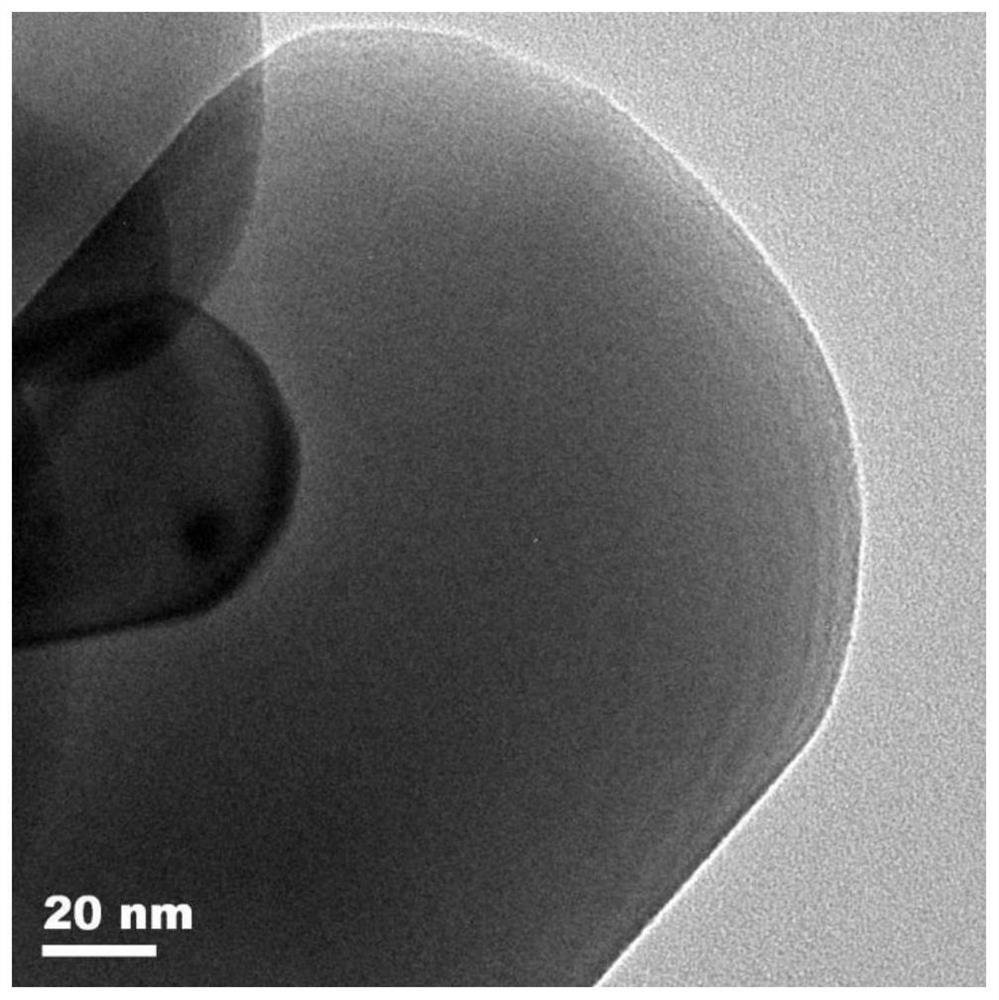

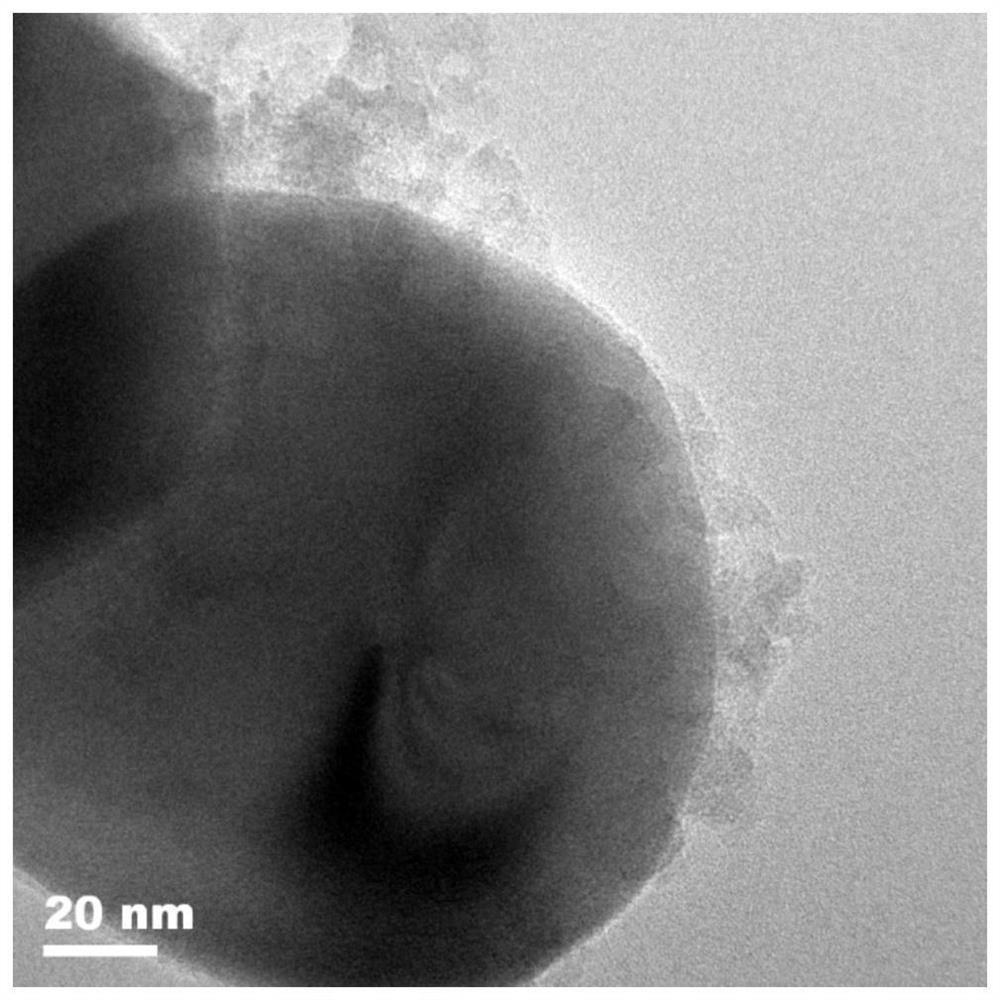

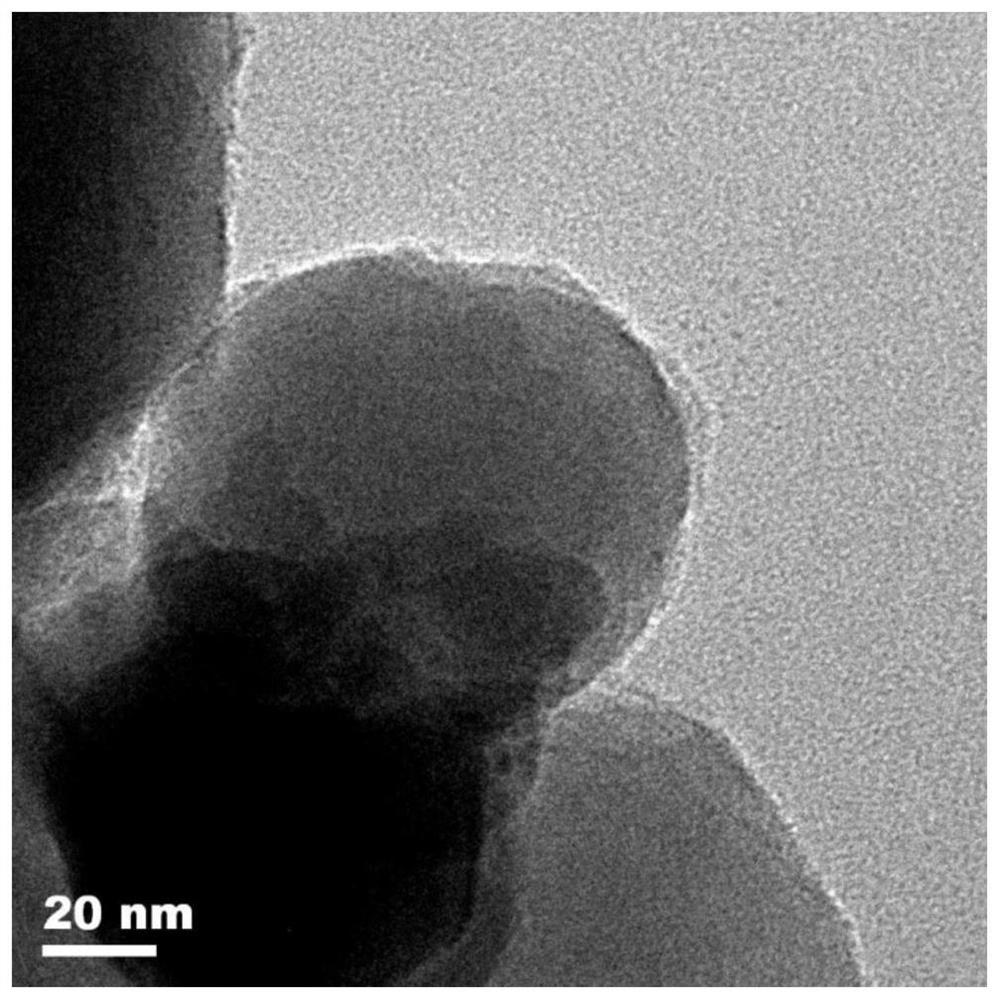

Image

Examples

Embodiment 1

[0032] An aluminum precursor is coated with titanium dioxide, and the surface of titanium dioxide is coated with alumina precursor.

[0033] In the present embodiment, the alumina precursor is basic aluminum aluminum carbonate.

Embodiment 2

[0035] A new type of aluminum coated titanium dioxide, the aluminum precursor coated with titanium dioxide is dried into a hydrated alumina film, the hydrated alumina film is coated on the surface of titanium dioxide.

Embodiment 3

[0037] Preparation method of aluminum precursor coated titanium dioxide, the steps thereof comprising,

[0038] (1) Take the titanium dioxide or titanium dioxide pulp prepared in the laboratory, or the commercially available titanium dioxide or titanium dioxide pulp mixed with water, prepare a titanium dioxide slurry with a concentration of 40-200g / L, and add sodium hexametaphosphate, which accounts for 1-5% of the mass fraction of titanium dioxide, as a dispersant, and ultrasonic dispersion;

[0039] (2) Add soluble aluminum salts accounting for 0.5-10% of the mass fraction of titanium dioxide, the concentration of soluble aluminum salt solution is 0.1-3mol / L, stirring 0.5h-3h; soluble aluminum salts contain aluminum sulfate, aluminum nitrate, aluminum chloride;

[0040] (3) Add a soluble ammonium salt that accounts for step (2) using the mass fraction of the soluble aluminum salt 50-200%, the concentration of the soluble ammonium salt solution is 0.1-3mol / L, stirred evenly; Sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com