Patents

Literature

65results about How to "Promote heterogeneous nucleation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting tungsten from scheelite

ActiveCN102021328AReduce lossesLow costProcess efficiency improvementWater dischargeReaction temperature

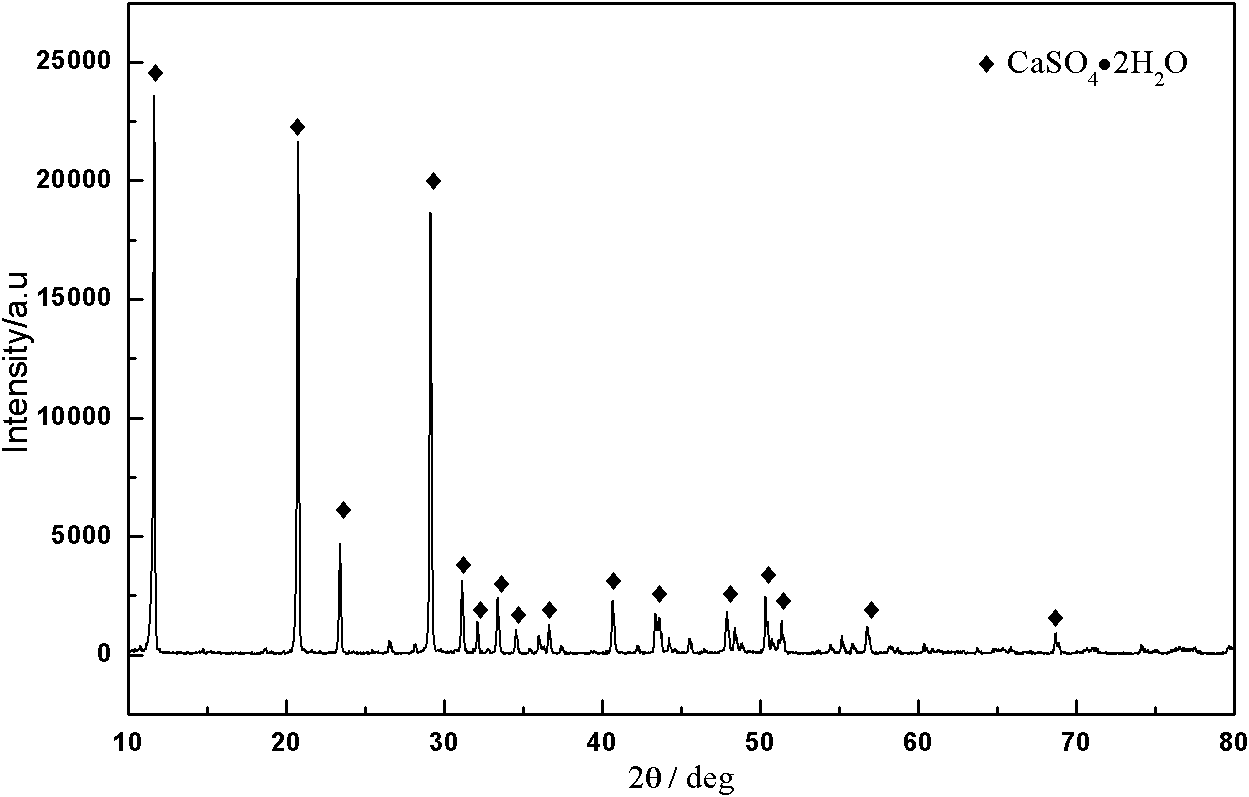

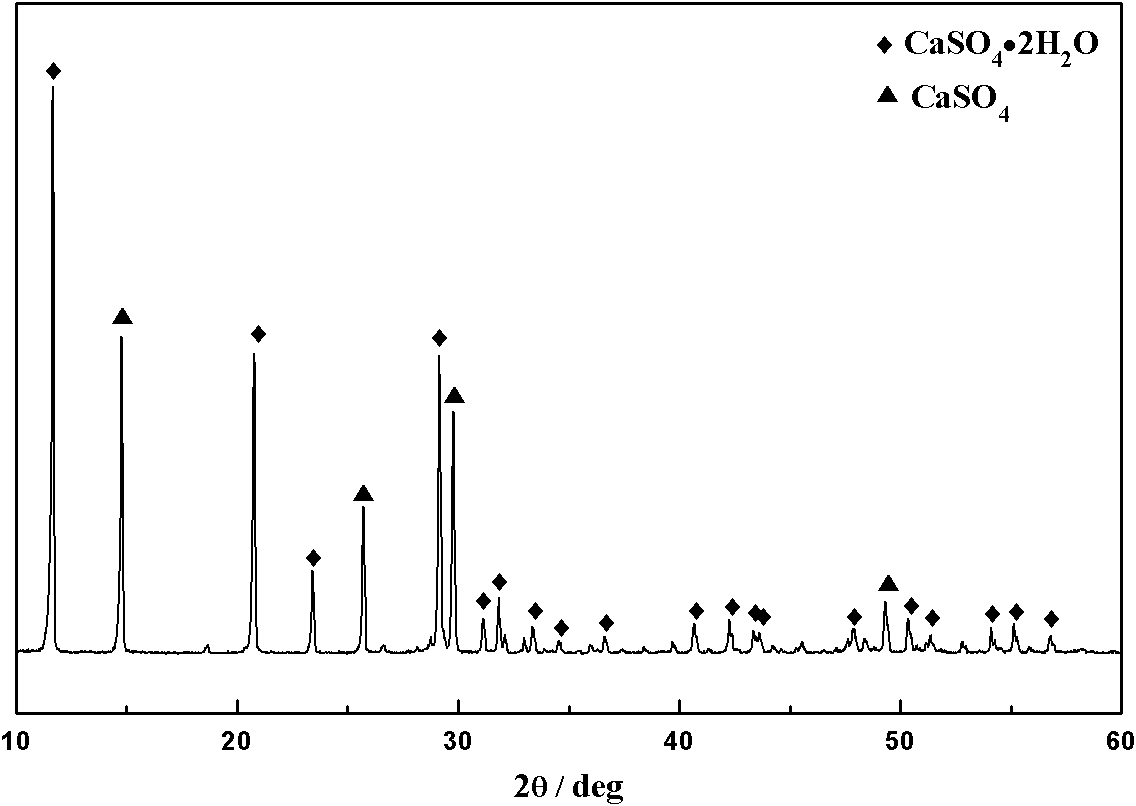

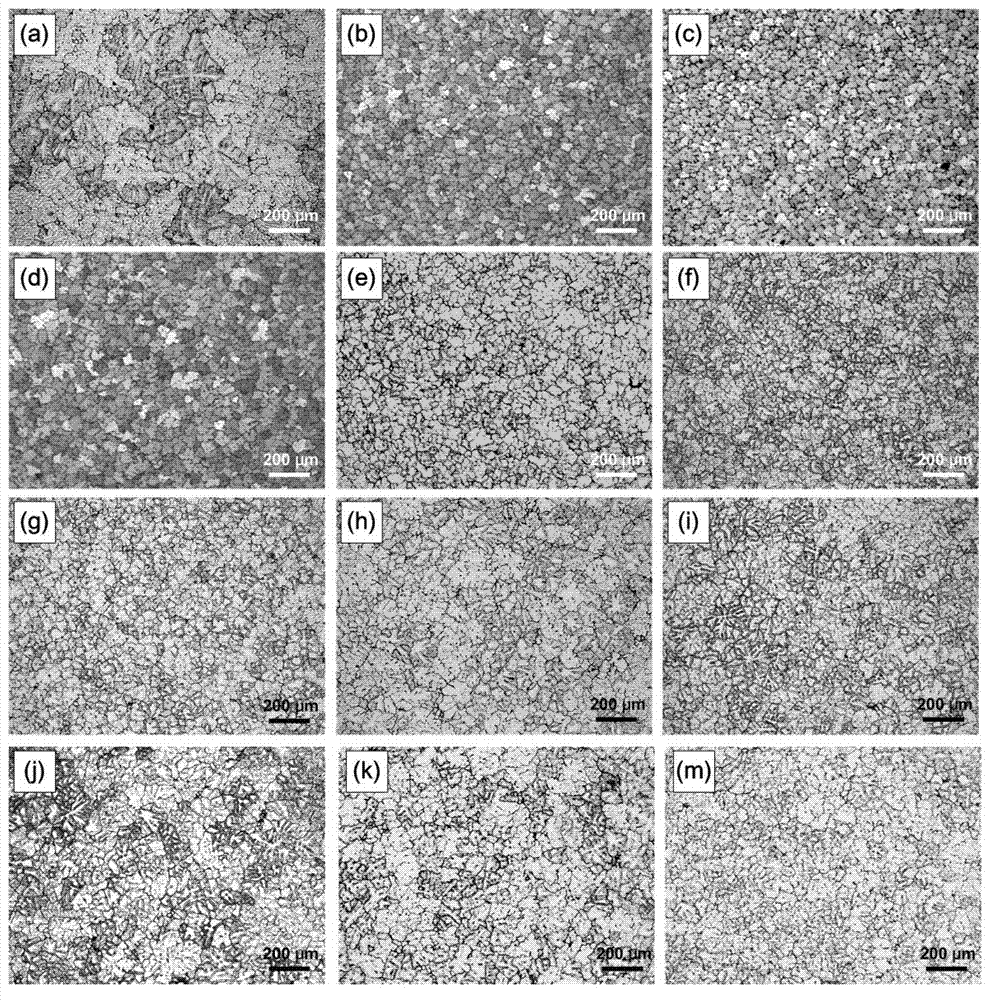

The invention discloses a method for extracting tungsten from scheelite, comprising the following steps of: mixing the scheelite with a mixed solution of phosphoric acid and sulfuric acid for reaction, adding dihydrate gypsum as seed crystals, and controlling the concentration of SO4<2->, the content of P2O5 and the reaction temperature to obtain the dihydrate gypsum with good filtering and washing properties. The invention has the advantages that one-step efficient normal pressure leaching of the scheelite is achieved, thus resources and energy consumption are saved, and the resolution ratio of the scheelite is up to above 98%; the problems of Cl<-> corrosion and serious HCl volatilization are overcome; the cyclic utilization of phosphoric acid is basically achieved, and the leaching cost and waste water discharge are greatly reduced; leaching equipment is simple, is convenient for operation and is easy to realize industrialization; the single and stable dihydrate gypsum is obtained, the filter efficiency of the dihydrate gypsum is high, the washing property of the dihydrate gypsum is good, and the P2O5 content in the washed dihydrate gypsum is reduced to be below 2%, thereby reducing the loss of phosphoric acid; and the passivation phenomenon of calcium sulfate solid film when the tungsten ore is leached is avoided.

Owner:CENT SOUTH UNIV

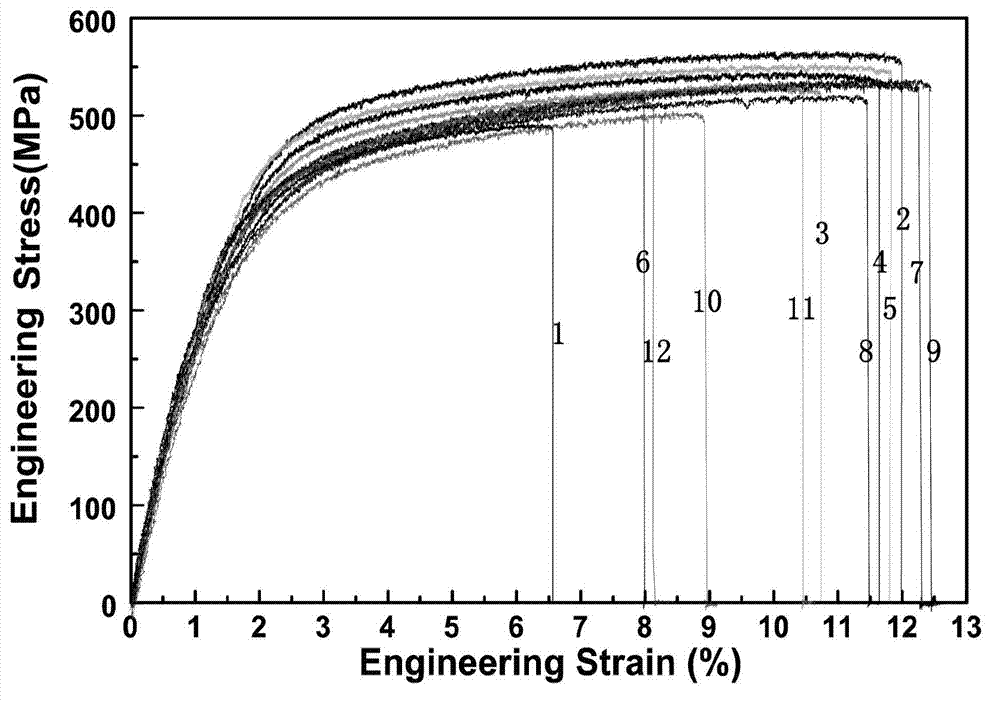

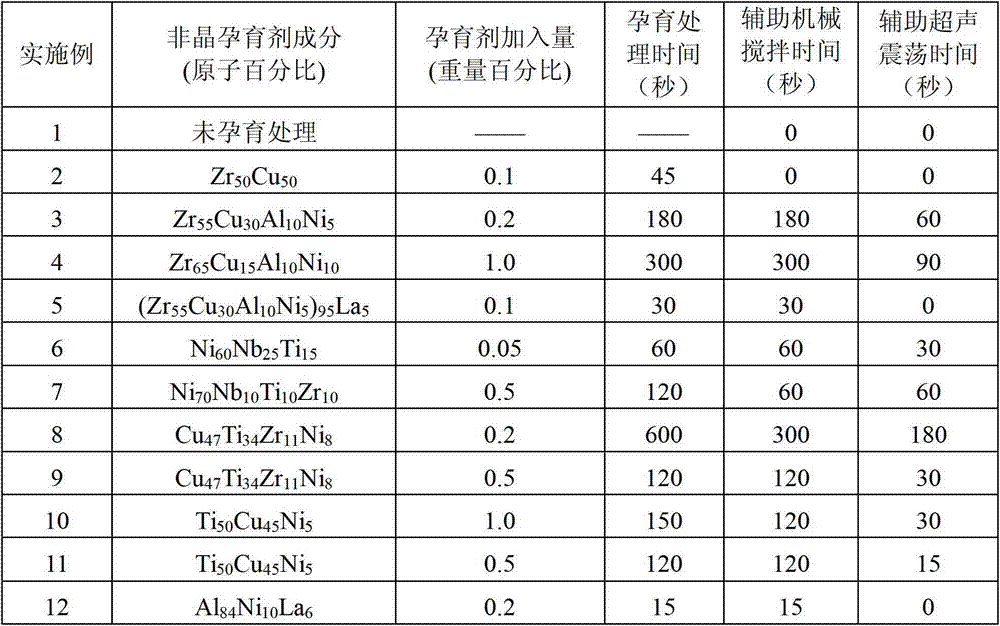

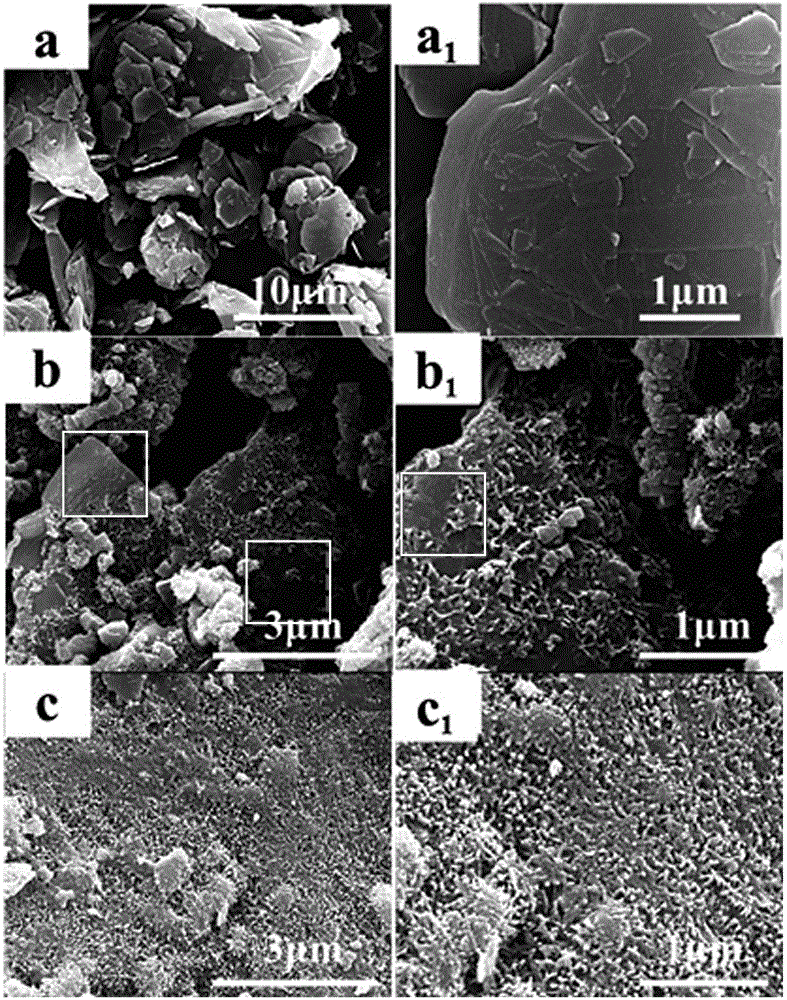

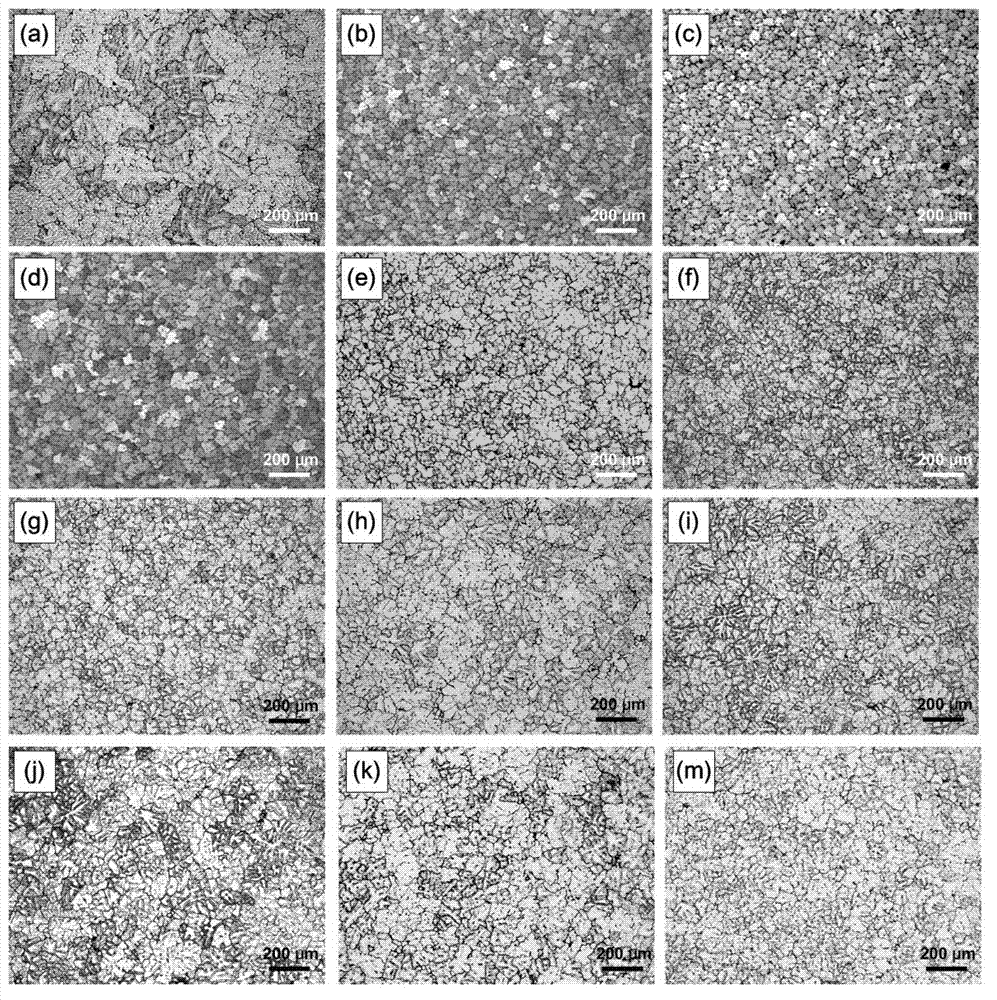

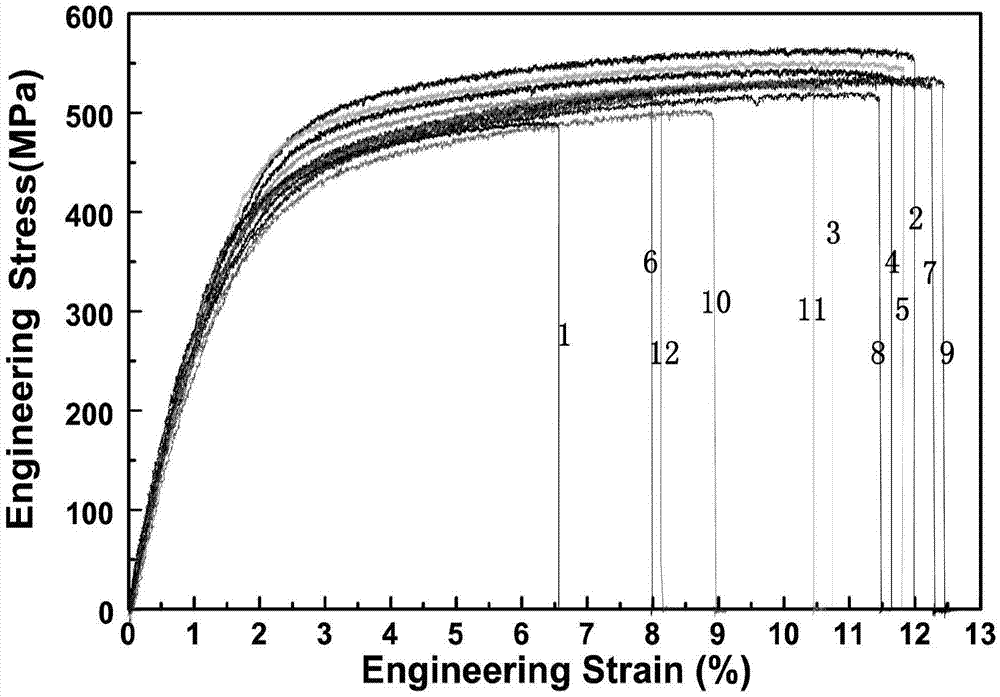

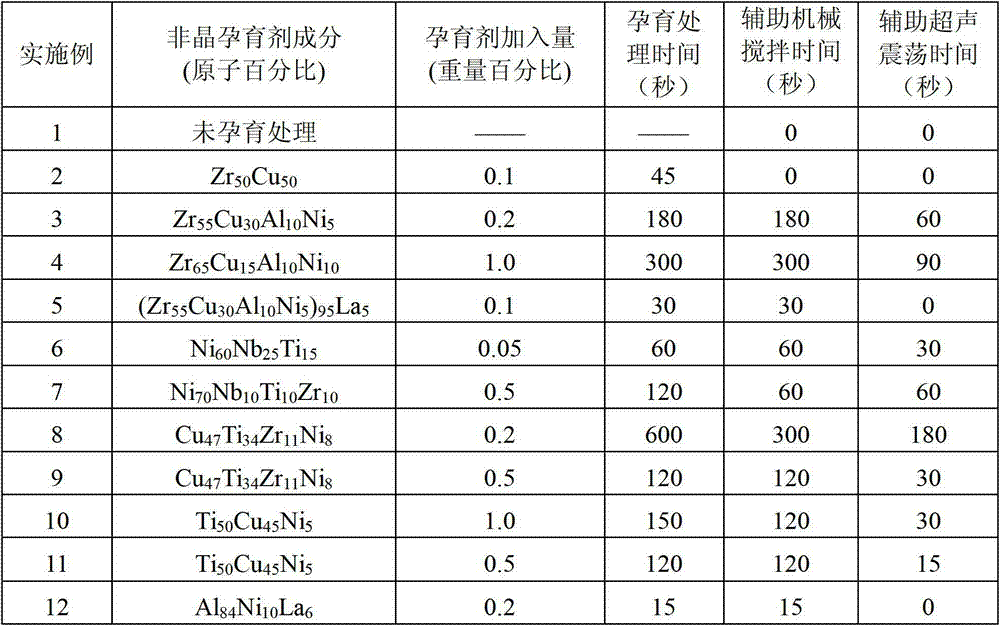

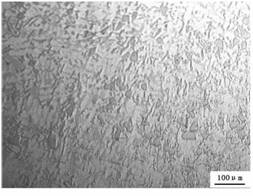

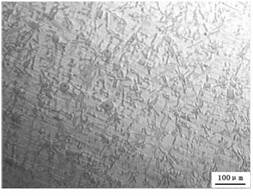

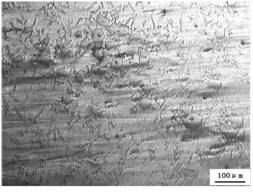

Amorphous alloy inoculation method for treating cast aluminum alloy

The invention relates to an amorphous alloy inoculation method for treating cast aluminum alloy. The amorphous alloy inoculation method for treating the cast aluminum alloy comprises preparation of inoculant and amorphous inoculation treatment. The technological parameter of the inoculation treatment is as follows: adding a prepared amorphous thin strip into aluminum melt before the aluminum is cast, the temperature of the aluminum melt is from 750 DEG C to 770 DEG C; the added amount of the amorphous inoculant is 0.05-1.0 wt.% of the weight of the aluminum; the treating time of inoculation is 15-600 seconds; an auxiliary machinery stirs for 0-300 seconds; and auxiliary ultrasound shocks for 0-180 seconds. The inoculant utilized by the amorphous alloy inoculation method is multivariate amorphous alloy including Zr series, Ni series, Cu series, Al series, Ti series and the like, precious metal is not contained, and cost is lower. The inoculant is in a thin-strip shape, can be dispersed in the melt uniformly and conveniently, the actual receiving ratio of modificator is high, tissue after refining is uniform, the time of modification treatment and alloy solidification are greatly shortened, and production efficiency is high. Moreover, the amorphous alloy inoculation method for treating cast aluminum alloy is applicable to large-batch continuous production of the amorphous alloy for a long time.

Owner:JILIN UNIV

Thermally conductive and insulating composite material and preparation method thereof

The invention discloses a thermally conductive and insulating composite material and a preparation method thereof. The composite material comprises the following components in parts by weight: 100 parts of a polymer matrix and 5-33 parts of a modified carbon-based filler, wherein the modified carbon-based filler is formed by conducting secondary coating modification on a carbon-based filler through an insulting metallic oxide. Through the secondary coating of the carbon-based filler, the coating rate of the carbon-based filler is improved, and thus a coating raw material can be utilized to the greatest extent; the composite material can keep high insulativity when the relatively high thermal conductivity of the composite material is ensured, so that the application range of the composite material is enlarged.

Owner:SICHUAN UNIV

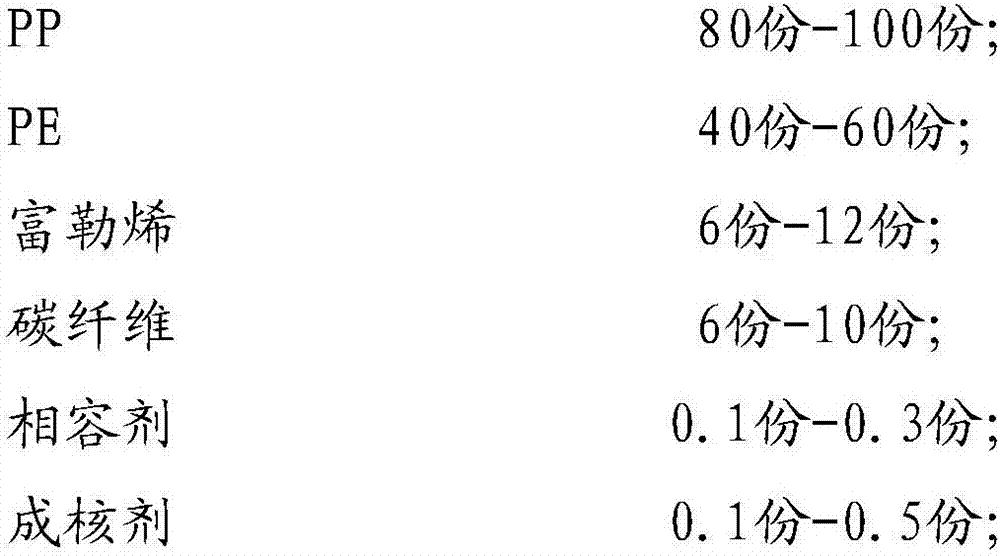

High-performance anti-static PP (polypropylene)-PE (polyethylene) composite material and preparation method thereof

InactiveCN107141597AImprove antistatic performancePromote heterogeneous nucleationFiberCarbon fibers

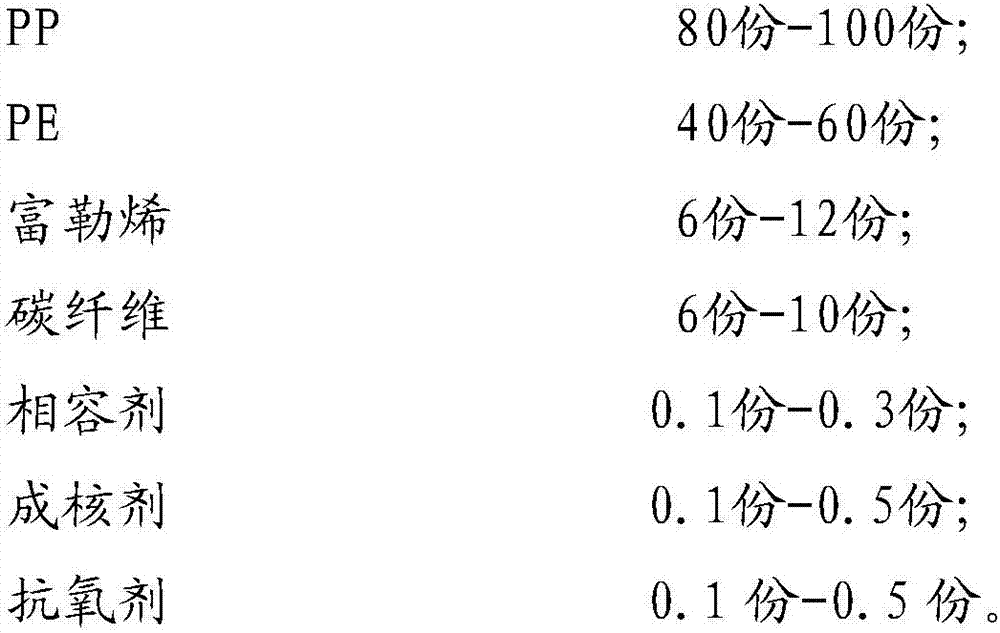

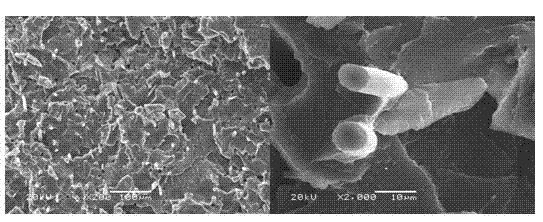

The invention relates to a high-performance anti-static PP (polypropylene)-PE (polyethylene) composite material and a preparation method thereof. The high-performance anti-static PP-PE composite material consists of the following components in parts by weight: 80 to 100 parts of PP, 40 to 60 parts of PE, 6 to 12 parts of fullerene, 6 to 10 parts of carbon fibers, 0.1 to 0.3 part of a compatilizer, 0.1 to 0.5 part of a nucleating agent and 0.1 to 0.5 part of an antioxidant. The fullerene is added, so the anti-static performance of the PP-PE composite material is improved, and the high-performance anti-static PP-PE composite material has more excellent anti-static property compared with other anti-static fillers; the nucleating agent NA-11 is added, so that heterogeneous nucleation of the PP composite material is promoted and the physical performance of the material is improved; and the carbon fibers have the characteristics of high strength and high modulus, and the PP-PE composite material is filled with the carbon fibers, so that the strength and the modulus of the PP-PE composite material are improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Preparation method of foamed polypropylene beads

The invention discloses a preparation method of foamed polypropylene beads. The method comprises the following steps that 1, polypropylene resin, an active filler and auxiliaries are added into a high-speed mixing machine and mixed to be uniform at the temperature of 10-20 DEG C, and a polypropylene foaming material is obtained; 2, the polypropylene foaming material is added into a triple-screw extruder, plastification and mixing are conducted, a supercritical fluid is injected, the mouth mold pressure is controlled to be 5-25 MPa, the mouth mold temperature is 110-160 DEG C, instant pressure release is conducted through a mouth mold, foaming is conducted, and super-fine hole foamed polypropylene is obtained; 3, super-fine hole foamed polypropylene is subjected to mold surface water-ring hot-cutting granulation, drying and sieving, and the foamed polypropylene beads are obtained. The method is low in production cost, high in capacity, safe and environmentally friendly, no foaming agent decomposed residue exists in the prepared foamed polypropylene beads, secondary foaming can be conducted, the foaming ratio can be adjusted, the rebound resilience of a finished product is high, decomposing and recycling are easy, and the foamed polypropylene beads can be widely used in the fields of plastic packaging, transportation industry, military aerospace, office supplies and the like.

Owner:湖北聚石新材料科技有限公司

Polyethylene terephthalate composite material and preparation method thereof

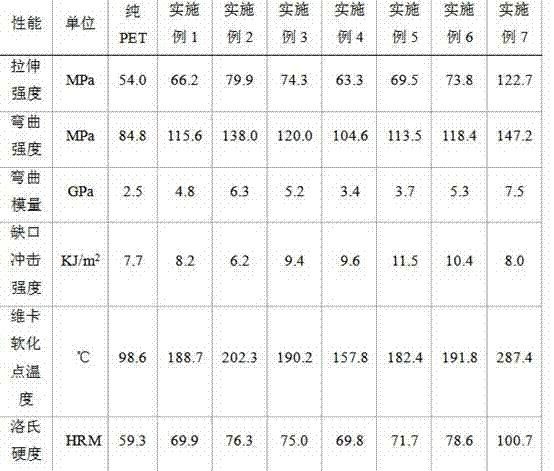

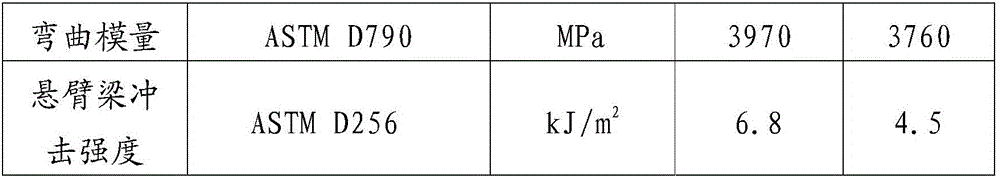

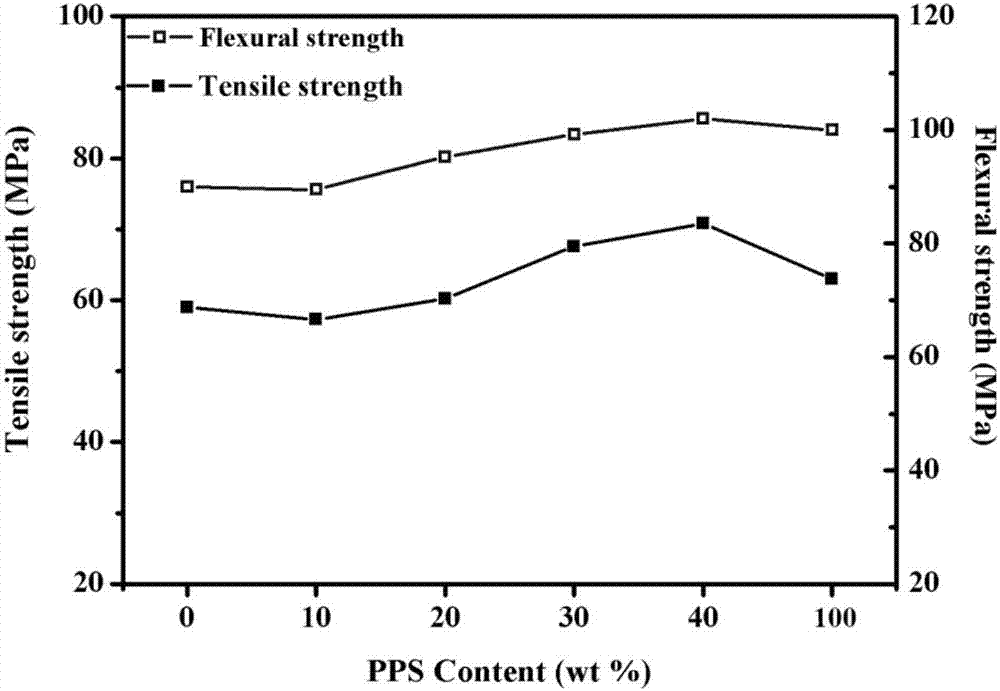

The invention discloses a polyethylene terephthalate composite material comprising the following components in percentage by weight: 69-97% of polyethylene terephthalate, 2-30% of carbon fiber, 0.5-5% of nucleating agent, 0.1-1% of coupling agent, 0.01-0.1% of antioxidant and the balance of surface treatment agent of carbon fiber. The polyethylene terephthalate composite material provided by the invention has the advantages of high tensile strength, high flexural strength and good heat resistance and serves as engineering plastics with excellent mechanical property and heat property.

Owner:EAST CHINA UNIV OF SCI & TECH

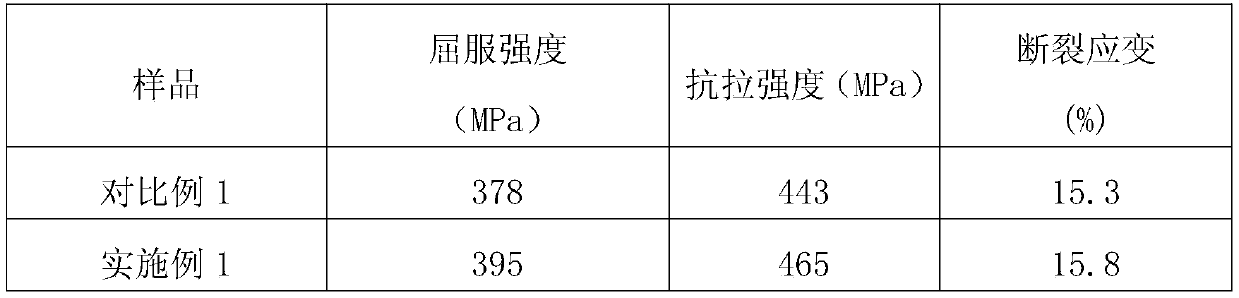

High-strength Mg-Ca-Mn-Al-Zn series wrought magnesium alloy containing gadolinium and yttrium rare earth elements and preparation method thereof

The invention discloses a high-strength Mg-Ca-Mn-Al-Zn series wrought magnesium alloy containing gadolinium and yttrium rare earth elements and a preparation method thereof, and belongs to the field of wrought magnesium alloy materials. The high-strength Mg-Ca-Mn-Al-Zn series wrought magnesium alloy comprises the following components in percentage by mass: 0.50-2.00% of calcium, 0.10-2.00% of aluminum, 0.10-2.00% of zinc, 0.10-3.00% of manganese, 0.10-3.00% of rare earth (gadolinium or yttrium), and the balance magnesium and inevitable impurities (Si, Ni, Cu and the like). The preparation method of the magnesium alloy comprises the following steps of: firstly, melting a pure magnesium ingot; after fully melting, adding metal calcium, manganese, aluminum, zinc, rare earth (gadolinium or yttrium) and the like; after fully stirring, casting into an ingot; then, homogenizing the ingot; extruding through a reverse extrusion process to obtain a corresponding extruded profile; and preparing the novel wrought magnesium alloy with high strength and high plasticity through smelting, homogenizing and subsequent extrusion (reverse extrusion) processes. The strength and the toughness of the wrought magnesium alloy are enhanced, and the wrought magnesium alloy has better mechanical properties.

Owner:NORTHEASTERN UNIV

Method for in-situ reducing residual stress of titanium-based composite material prepared through selective laser melting

InactiveCN110405209AReduce residual stressImprove performanceAdditive manufacturing apparatusIncreasing energy efficiencyTitanium matrix compositesRare-earth element

The invention discloses a method for in-situ reducing the residual stress of a titanium-based composite material prepared through selective laser melting. The method includes the steps that titanium-based composite material powder is prepared, wherein the titanium-based composite material powder comprises a combination of titanium or a titanium alloy and chemical substances generating reinforcingbodies, and the chemical substances comprise one or more of a B (boron) element, a C (carbon) element and rare earth elements; one or more layers of the titanium-based composite material powder is laid on a base plate of a selective laser melting device, and selective laser melting is performed; and one or more times of laser remelting is performed on the surface solidified after the selective laser melting; and operation is repeated till a titanium-based composite material component is prepared. According to the method, after laser remelting is performed on the surface solidified after selective laser melting, the local heat effect caused by scanning a powder layer by using high-energy laser beams as a heat source is lowered, the reaction of the reinforcing bodies can be more thorough, precipitation of the reinforcing bodies is thinner and smaller, the residual stress in the component preparing process is lowered, and the performance of the material is changed.

Owner:SHANGHAI UNIV OF ENG SCI

A method for inoculating cast aluminum alloys with amorphous alloys

The invention relates to an amorphous alloy inoculation method for treating cast aluminum alloy. The amorphous alloy inoculation method for treating the cast aluminum alloy comprises preparation of inoculant and amorphous inoculation treatment. The technological parameter of the inoculation treatment is as follows: adding a prepared amorphous thin strip into aluminum melt before the aluminum is cast, the temperature of the aluminum melt is from 750 DEG C to 770 DEG C; the added amount of the amorphous inoculant is 0.05-1.0 wt.% of the weight of the aluminum; the treating time of inoculation is 15-600 seconds; an auxiliary machinery stirs for 0-300 seconds; and auxiliary ultrasound shocks for 0-180 seconds. The inoculant utilized by the amorphous alloy inoculation method is multivariate amorphous alloy including Zr series, Ni series, Cu series, Al series, Ti series and the like, precious metal is not contained, and cost is lower. The inoculant is in a thin-strip shape, can be dispersed in the melt uniformly and conveniently, the actual receiving ratio of modificator is high, tissue after refining is uniform, the time of modification treatment and alloy solidification are greatly shortened, and production efficiency is high. Moreover, the amorphous alloy inoculation method for treating cast aluminum alloy is applicable to large-batch continuous production of the amorphous alloy for a long time.

Owner:JILIN UNIV

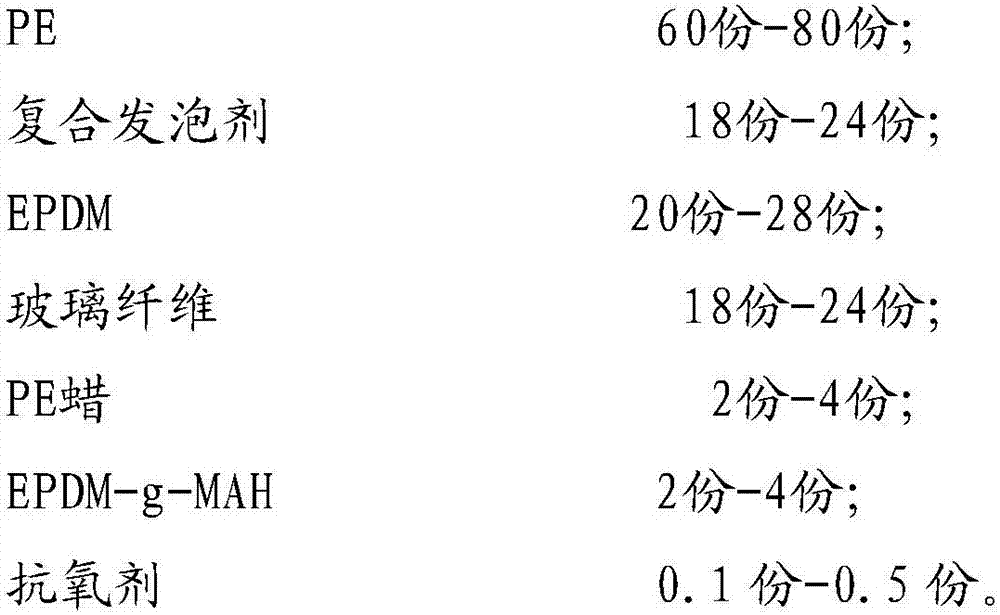

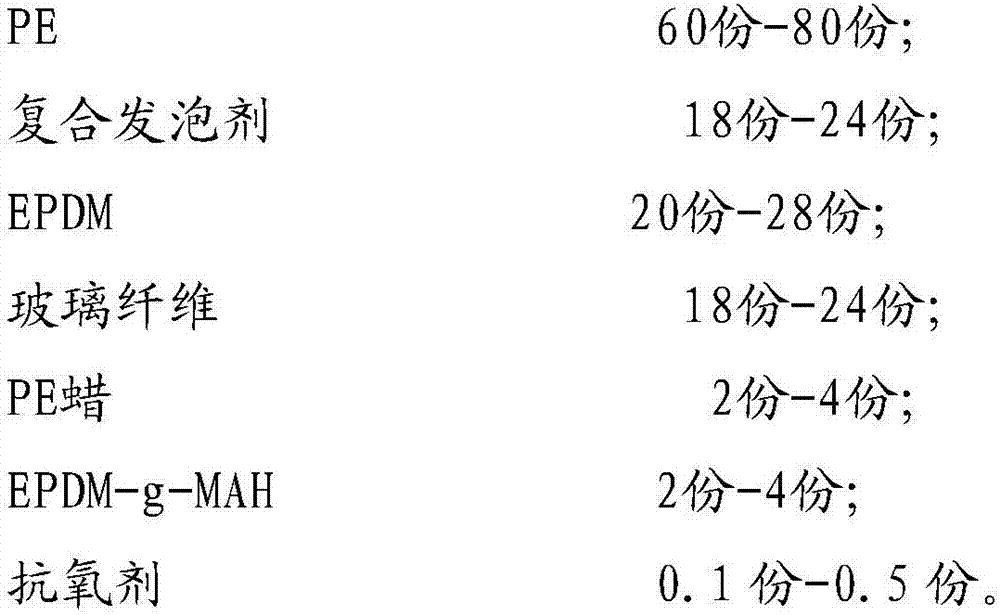

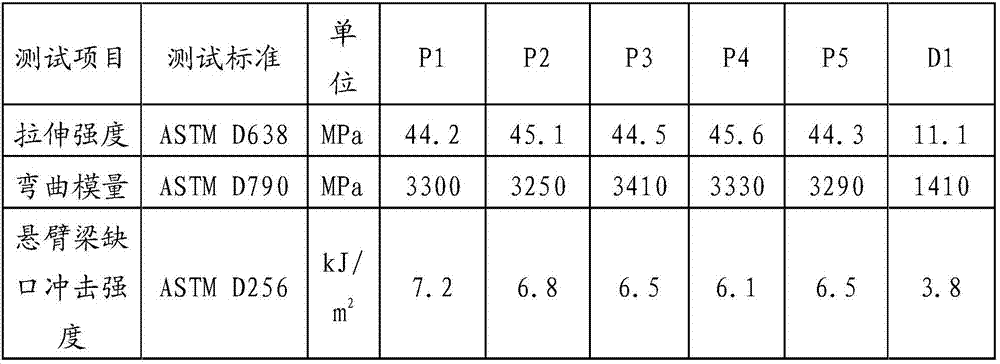

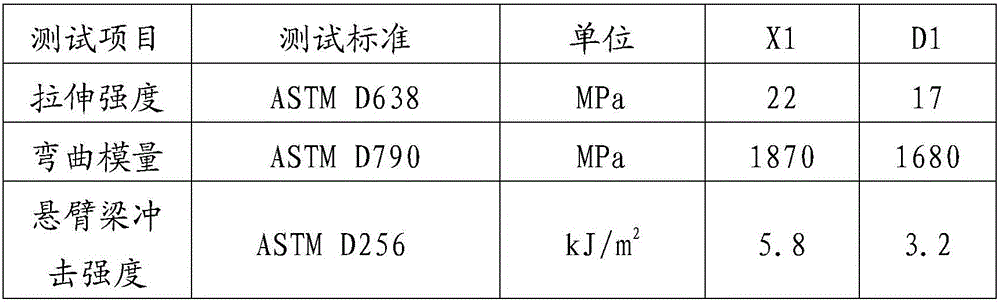

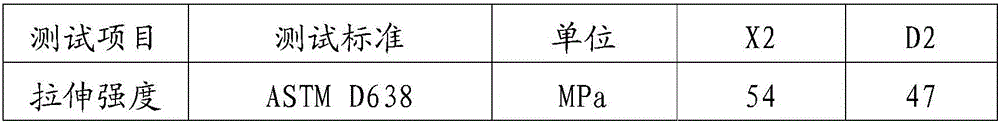

PE (Poly Ethylene) foaming material and preparation method thereof

The invention relates to a PE (Poly Ethylene) foaming material and a preparation method of the PE foaming material. The PE foaming material comprises the following components in parts by weight: 60-80 parts of PE, 18-24 parts of composite foaming agent, 20-28 parts of EPDM (Ethylene-Propylene-Diene Monomer), 18-24 parts of glass fiber, 2-4 parts of PE wax, 2-4 parts of EPDM-g-MAH (Ethylene-Propylene-Diene Monomer grafted Maleic Anhydride) and 0.1-0.5 parts of antioxidant. In the PE foaming material, addition of ZnO can effectively facilitate decomposition of a foaming agent AC (Azodicarbonamide); an N atom of an AC azo group is provided with a lone pair electron and belongs to a lewis base substance, but Zn<2+> of ZnO can receive the lone pair electron and belongs to a lewis acid substance, so that combination of the N atom and Zn<2+> can easily facilitate decomposition of the foaming agent AC; nano CeO2 mainly exerts an effect of a nucleating agent, forms a liquid-solid interface between a melt and gas, and facilitates heterogeneous nucleation of bubbles, so that the activation energy of bubble nucleation and the nucleation number are reduced; and a fine and dense bubble structure with high closed porosity is finally formed.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Preparation method and application of modified mica powder

ActiveCN106243512AHigh reactivityPromote heterogeneous nucleationPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsPolyolefinPolymer science

The invention relates to a preparation method of modified mica powder. The preparation method includes the steps of: (1) weighing raw materials including mica powder, acetone, dibenzoyl peroxide and acrylic acid; 2) adding the mica powder to the acetone and adding the dibenzoyl peroxide and acrylic acid with stirring, performing a reaction for 2-4 h at 60-80 DEG C, filtering a reaction product, and drying the reaction product in a drying box at 80-100 DEG C for 6-8 h to obtain mica powder surface-modified by the acrylic acid (A); and 3) performing extrusive granulation to the product (A) with polyethylene wax according to certain mass ratio in an extruder to prepare the modified mica powder. The modified mica powder is a core-shell filler with the mica powder as the core while the polyethylene wax as a shell. The polyethylene wax has good compatibility with polyolefin, so that a problem of compatibility between the mica powder and the polyolefin is solved well.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Modified poly (phthalazinone ether sulfone ketone) resin, microporous material and preparation methods thereof

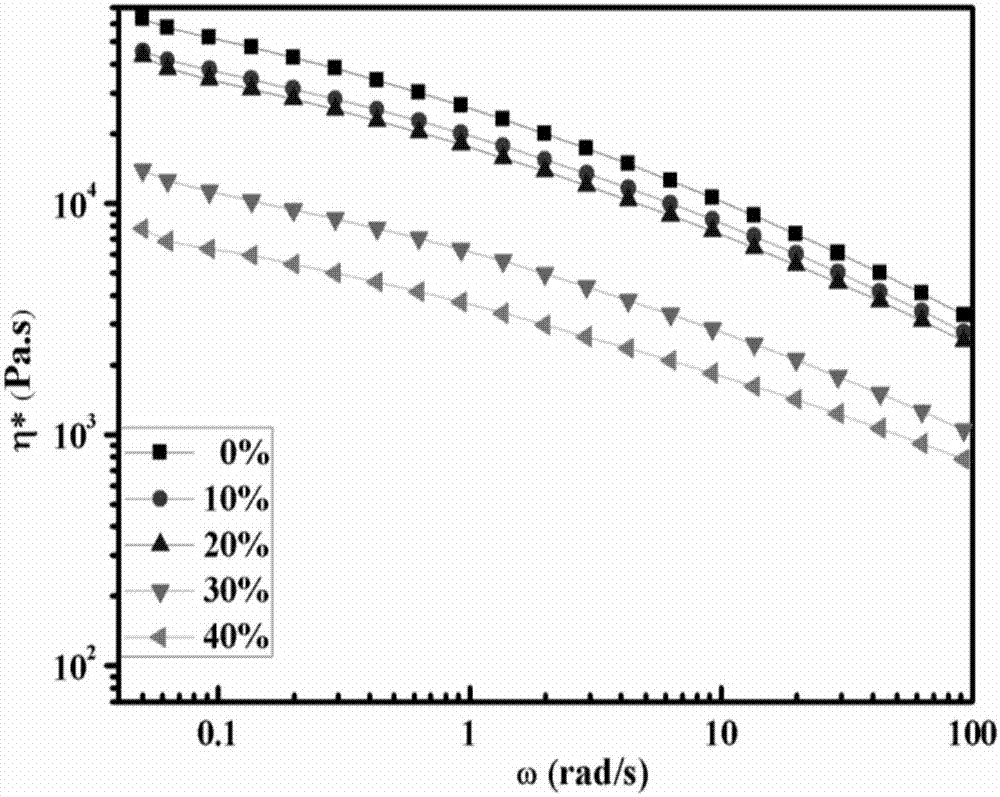

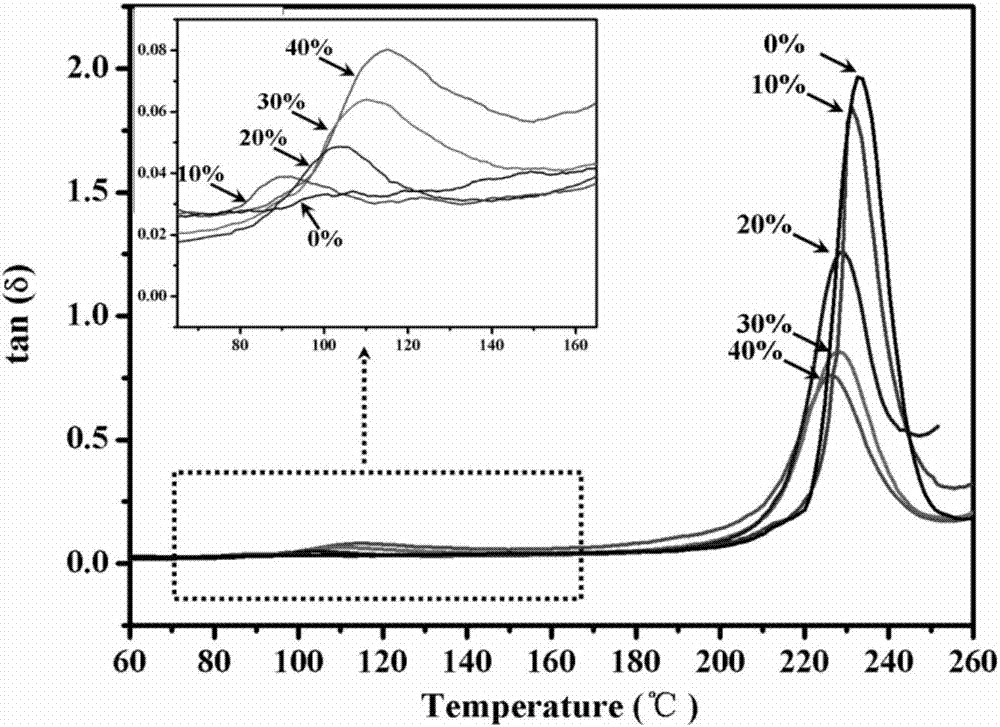

The invention provides modified poly (phthalazinone ether sulfone ketone) resin which is prepared from PPESK resin, PPS resin and ground glass fibers. The invention also provides a preparation method of the modified poly (phthalazinone ether sulfone ketone) resin. The preparation method comprises the following steps: step 1, mixing materials; and step 2, loading the premixed material obtained in the step 1 into a twin screw for granulation through melt extrusion, and conducting cooling and pelleting. The invention also provides a preparation method of a modified poly (phthalazinone ether sulfone ketone) microporous material, and further claims to protect the modified poly (phthalazinone ether sulfone ketone) microporous material. The modified poly (phthalazinone ether sulfone ketone) microporous material inherits the excellent properties of resin and simultaneously endows the material with a special porous structure, the apparent density is reduced by nearly 30% compared with a solid material with the same components, and the preparation method is an effective method for realizing light weight of material and greatly enlarges the range of application of the PPESK resin.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

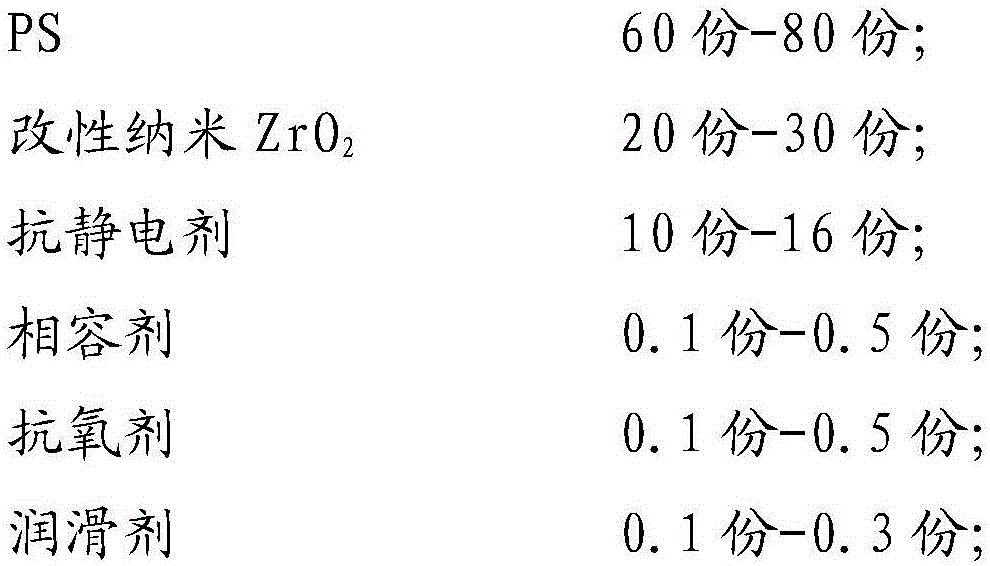

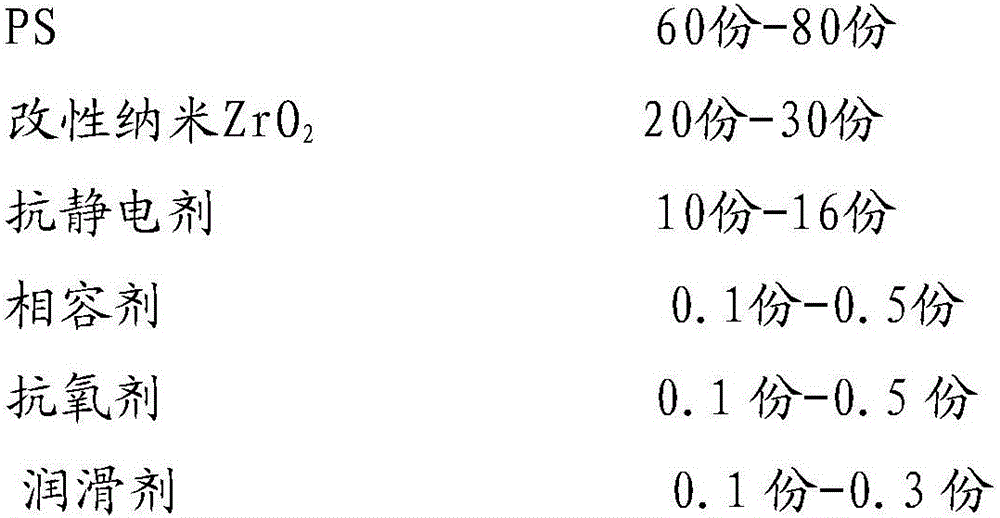

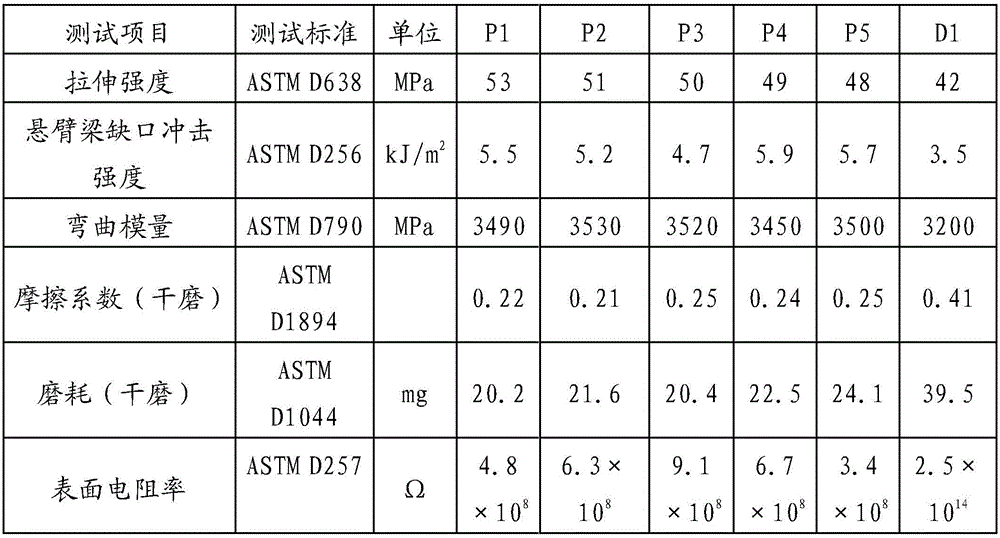

Antistatic, wear-resistant and high-performance PS composite material and preparation method thereof

The invention relates to an antistatic, wear-resistant and high-performance PS composite material and a preparation method thereof. The antistatic, wear-resistant and high-performance PS composite material is prepared by, by weight, 60-80 parts of PS, 20-30 parts of modified nano ZrO2, 10-16 parts of antistatic agent, 0.1-0.5 part of compatibilizer, 0.1-0.5 part of antioxidant and 0.1-0.3 part of lubricating agent. The antistatic, wear-resistant and high-performance PS composite material has the advantages that due to the fact that the nano ZrO2 is grafted by poly-butyl acrylate (PBA), a PBA organic coating layer can be formed on the surface of the nano ZrO2, a strong three-dimensional protection effect is generated, ZrO2 agglomeration is prevented, the ZrO2 can be evenly dispersed in a PS matrix, and the mechanical performance of the PS composite material is increased.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Preparation method of in-situ micro-nano particle-reinforced Al-Cu-Mg-Si alloy sheet in melt

The invention provides a preparation method of an in-situ micro-nano particle-reinforced Al-Cu-Mg-Si alloy sheet in a melt, which utilizes an in-situ self-propagation reaction in an Al-Ti-B4C system in an alloy melt to form micro-nano TiC-TiB2 ceramic particles, and TiC-TiB2 ceramic particles are directly formed in situ in the melt directly. Compared with the added particles, the dispersion effectof TiC-TiB2 ceramic particles is better, and the interface between the particles and a substrate is clean and pollution-free without harmful interface reaction, thus avoiding the disadvantages of uneven particle dispersion and harmful interface pollution. When the Al-Cu-Mg-Si alloy is reinforced, the micro-nano TiC-TiB2 ceramic particles can serve as the heterogeneous nucleation core of alpha-Al,promote the heterogeneous nucleation of alpha-Al, improve the nucleation rate, and thus increases the strength of the alloy pass through the crystal grain refinement and does not reduce plasticity while increasing strength.

Owner:JILIN UNIV

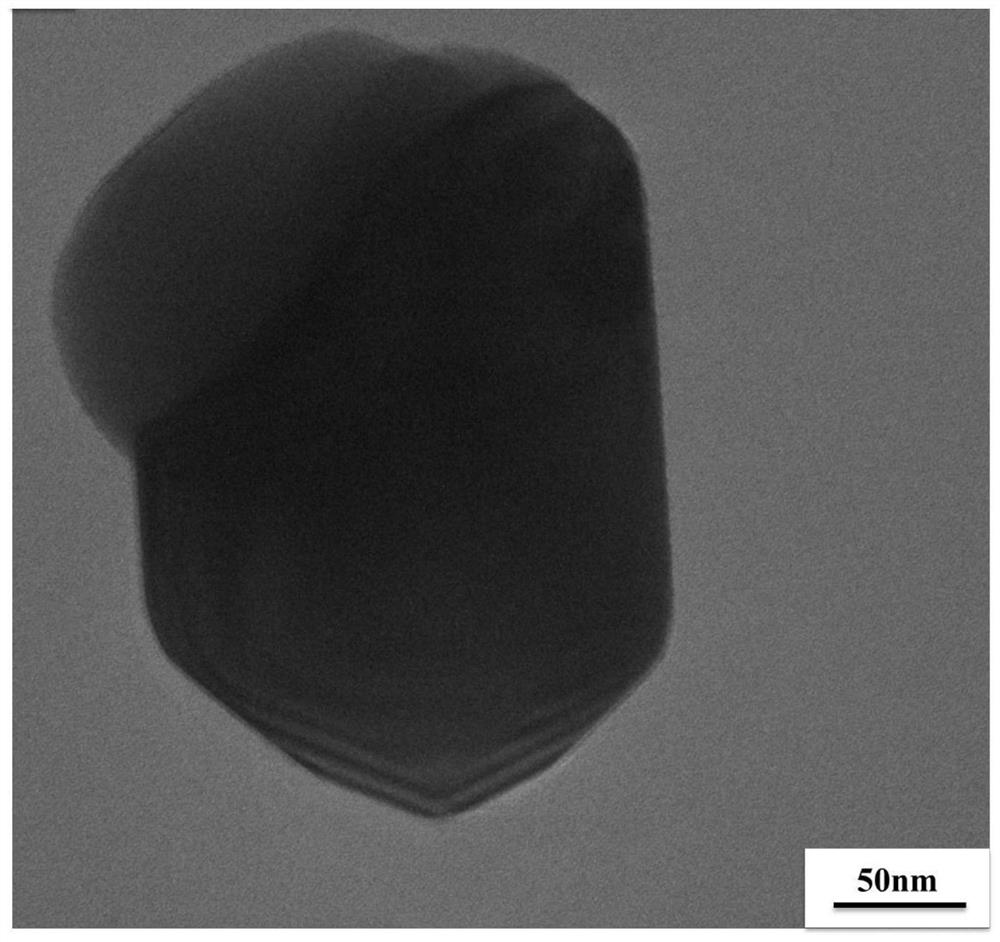

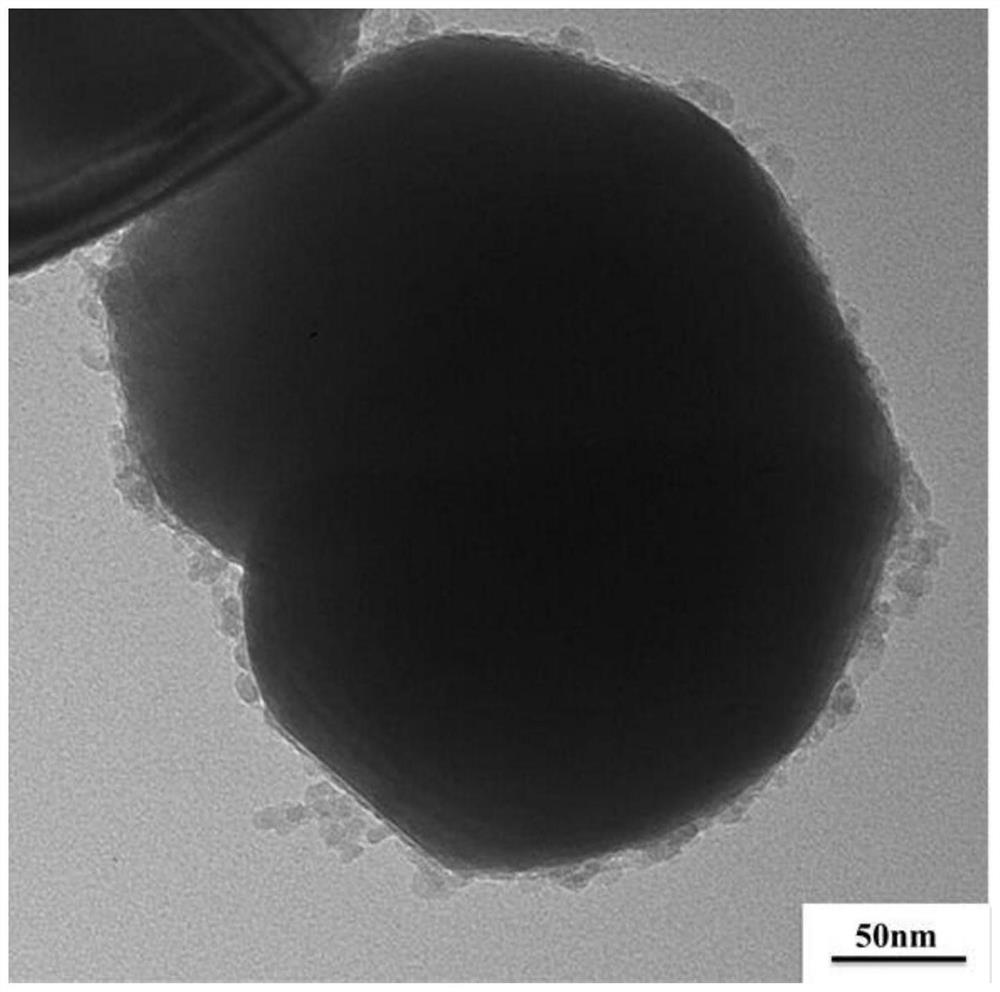

Gamma-alumina nanofiber and preparation method thereof

ActiveCN111646492AThorough responseIncrease satietyMaterial nanotechnologyChemical/physical/physico-chemical microreactorsMicroreactorAluminium hydroxide

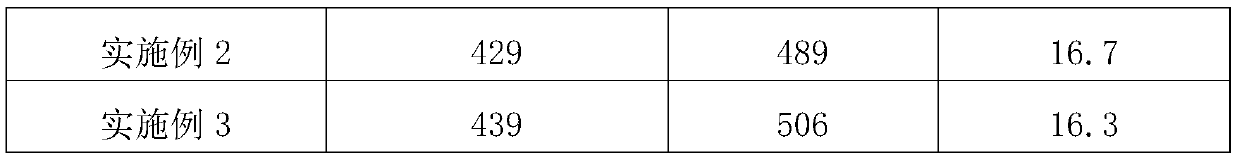

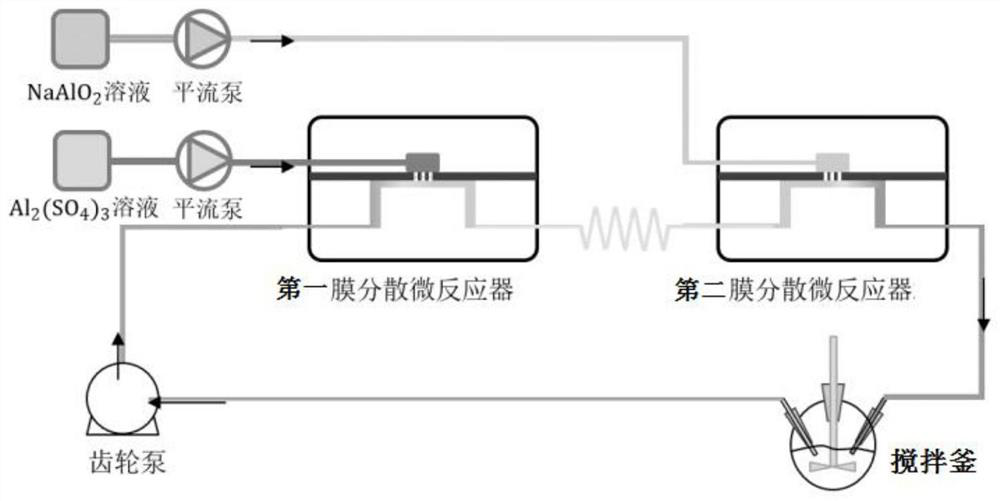

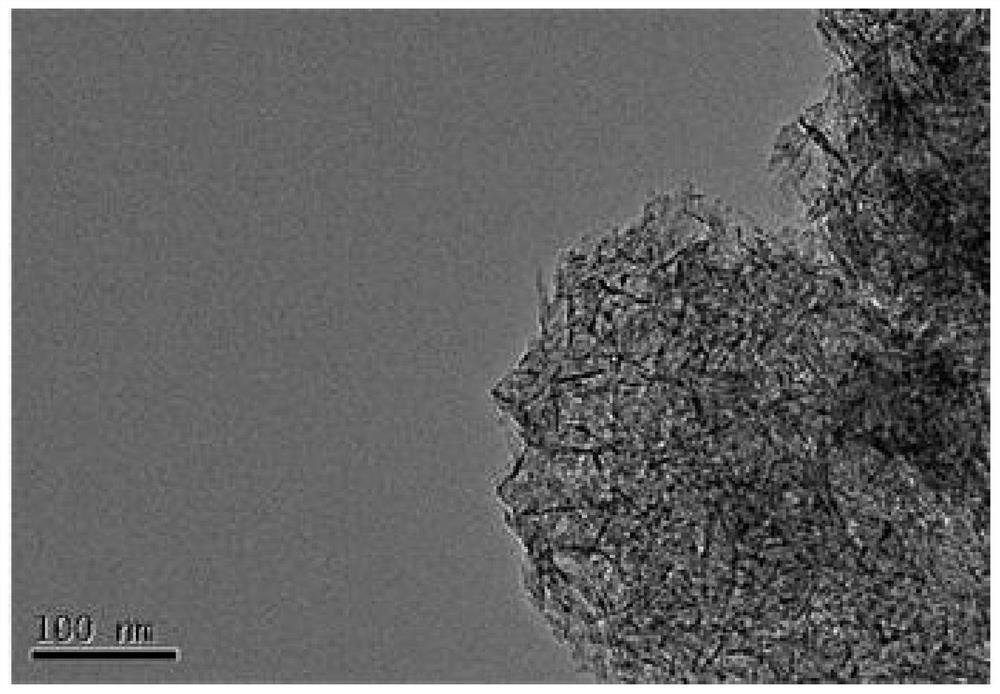

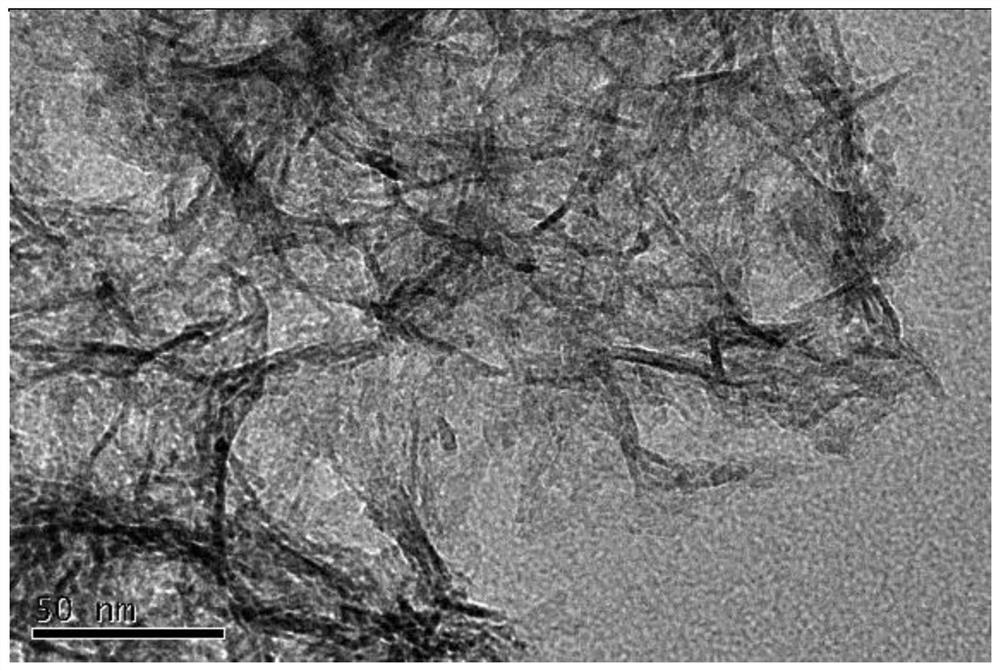

The invention provides a gamma-aluminum oxide nanofiber and a preparation method thereof, and belongs to the technical field of chemical material preparation. A dispersion phase in a dispersion phasesolution is dispersed into countless tiny and uniform liquid drops under the action of a microporous membrane through the first membrane dispersion micro-reactor and the second membrane dispersion micro-reactor which are connected in series, and the liquid drops enter a mobile phase channel; the method has great mass transfer efficiency and is complete in reaction of the mobile phase and the dispersion phase; according to the method, the supersaturation degree uniformity in a reaction system can be effectively improved, in the circulation process with aluminum hydroxide turbid liquid as a mobile phase, a solid phase in the mobile phase can promote heterogeneous nucleation, a new phase is attached to the surfaces of existing particles, anisotropic fibrous gamma-aluminum oxide is generated,and then the macropore proportion of the fibrous gamma-aluminum oxide is increased. The result of the embodiment shows that the stacking density of the prepared gamma-aluminum oxide nanofiber is 0.16-0.23 g / cm3, the specific surface area is 285-570 m2 / g, and the pore volume is 1.2-1.92 cm3 / g.

Owner:TSINGHUA UNIV

Preparation method of plastic slipping agent

The invention discloses a preparation method of a plastic slipping agent, which belongs to the technical field of fine chemical industry. Unsaturated components of oleamide such as linoleic acid amideand linolenic acid amide are removed by adopting a skeleton nickel selective hydrogenation method, so that a substance with higher purity which can reduce the viscosity of plastic resin melt and improve the mobility can be obtained, then the obtained oleamide substance is used for modifying 3-gamma-chloropropyl trimethoxysilane, and when the oleamide substance is added in the preparation processof a plastic product, the surface tension of a plastic film is reduced, the wetting angle is reduced, and the wetting effect of the plastics can be improved. As the content of polyether chains is increased, the surface water absorption performance of the plastics is improved, the surface resistivity is reduced, and the antistatic capability is improved. The problems that the existing plastic slipping agent is single in product performance, the plastic film and the plastic product cannot resist the static electricity for a long time and the haze and transparency of the film are severely influenced can be solved.

Owner:袁杰

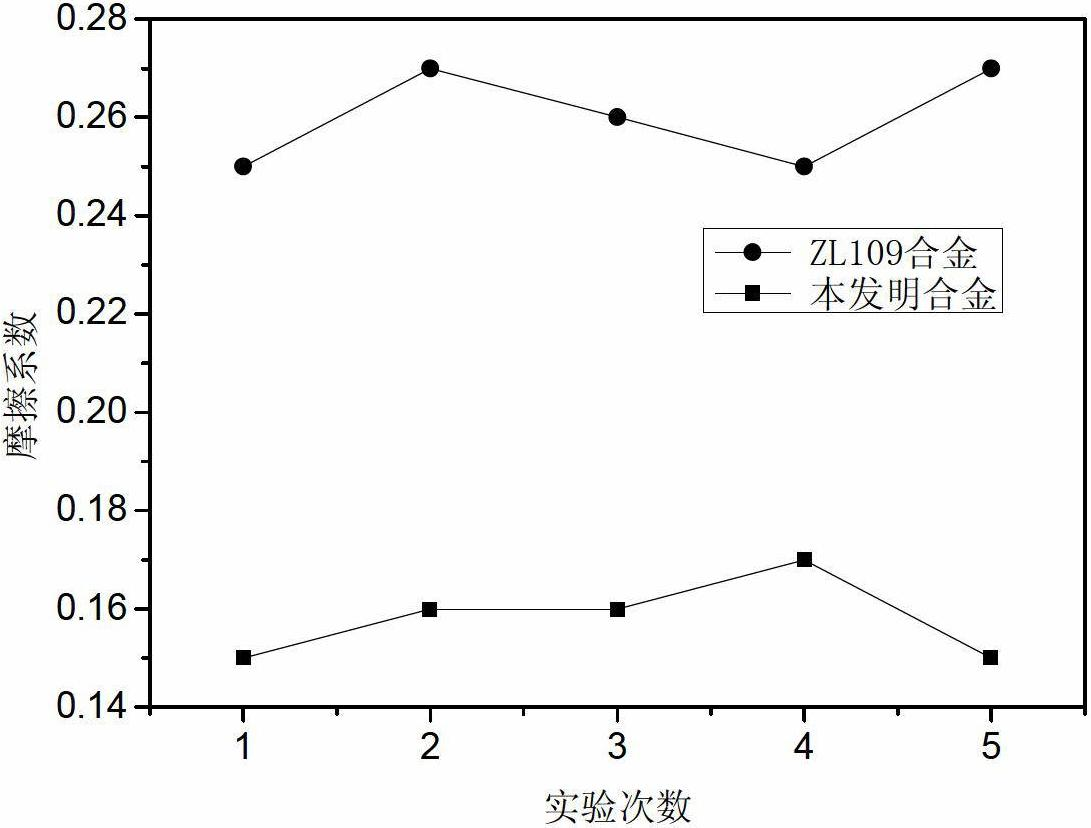

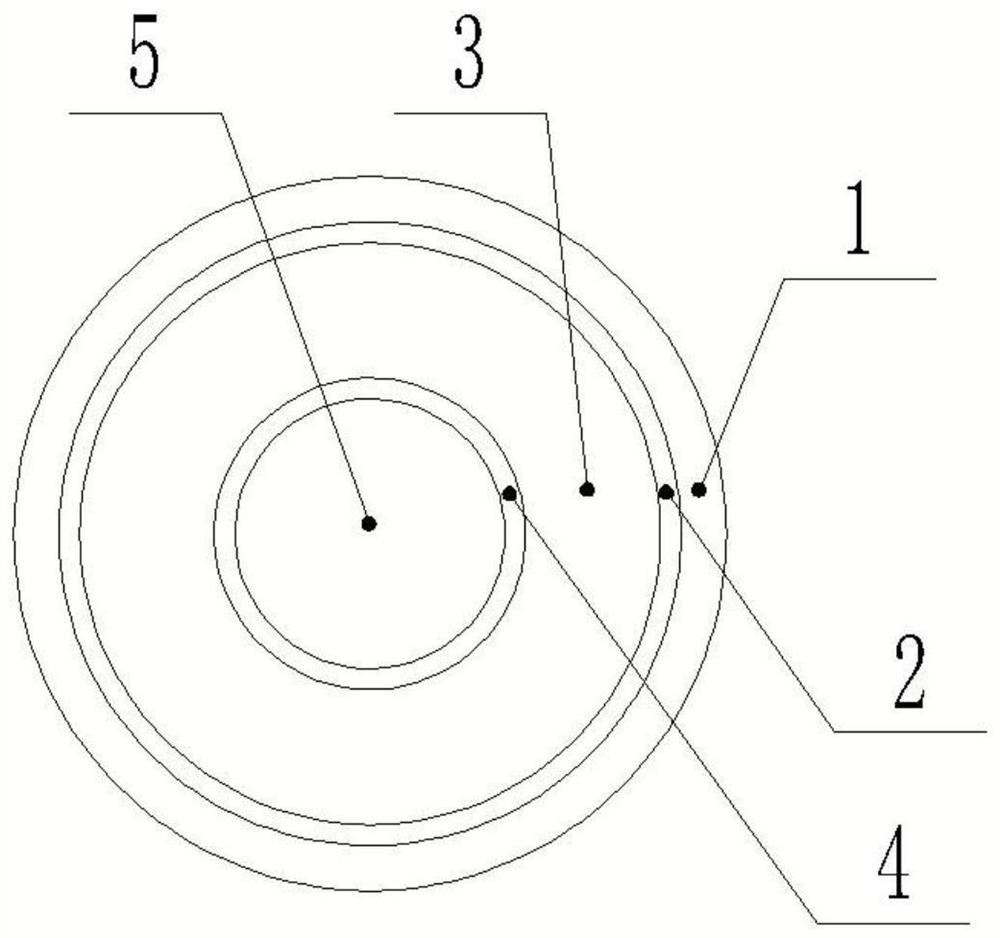

Eutectic aluminum silicon alloy piston material of vehicle engine

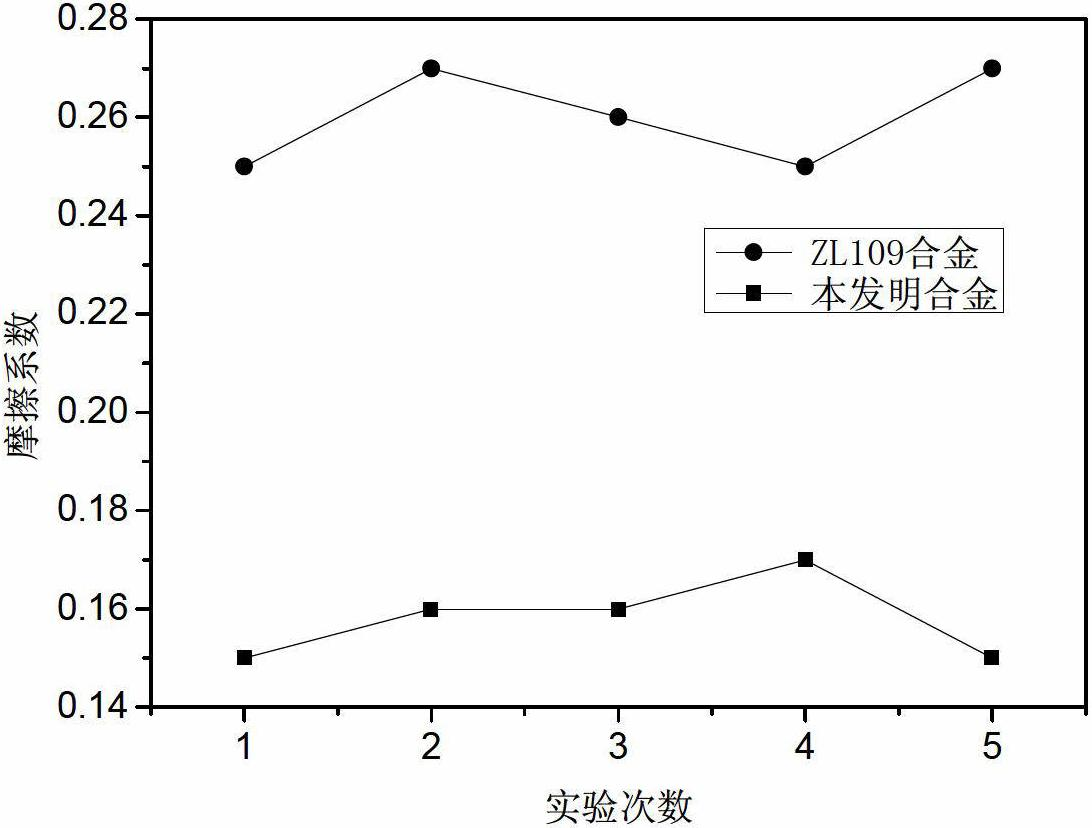

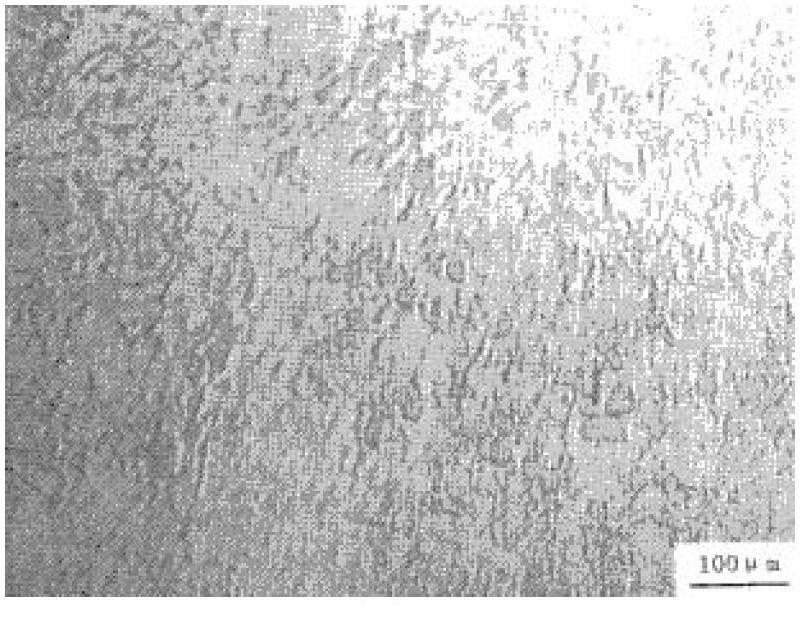

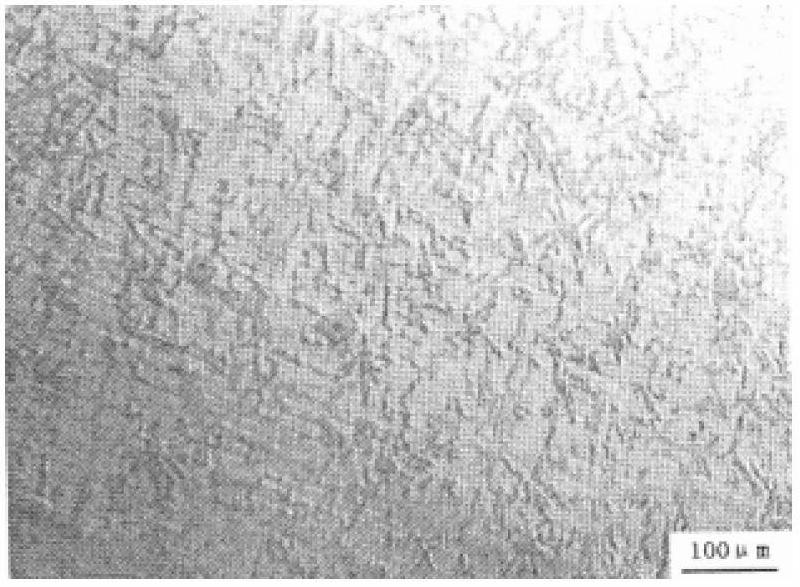

InactiveCN102676888AGood high temperature performanceSmall coefficient of thermal expansionPlungersMachines/enginesTrace elementSilicon alloy

The invention provides a eutectic aluminum silicon alloy piston material of a vehicle engine. On the basis of ZL109 alloy, the novel eutectic alloy material with high strength and low thermal expansion coefficient can be prepared by adjusting the alloy composition and adding trace elements such as V, Zr and P. The eutectic aluminum silicon alloy has the characteristics of being excellent in high-temperature property, high in hardness, low in thermal expansion coefficient, good in wear resistance and the like, thus being better in accordance with the requirements of the high-performance vehicle engine.

Owner:TIANJIN LIZHONG ALLOY GROUP

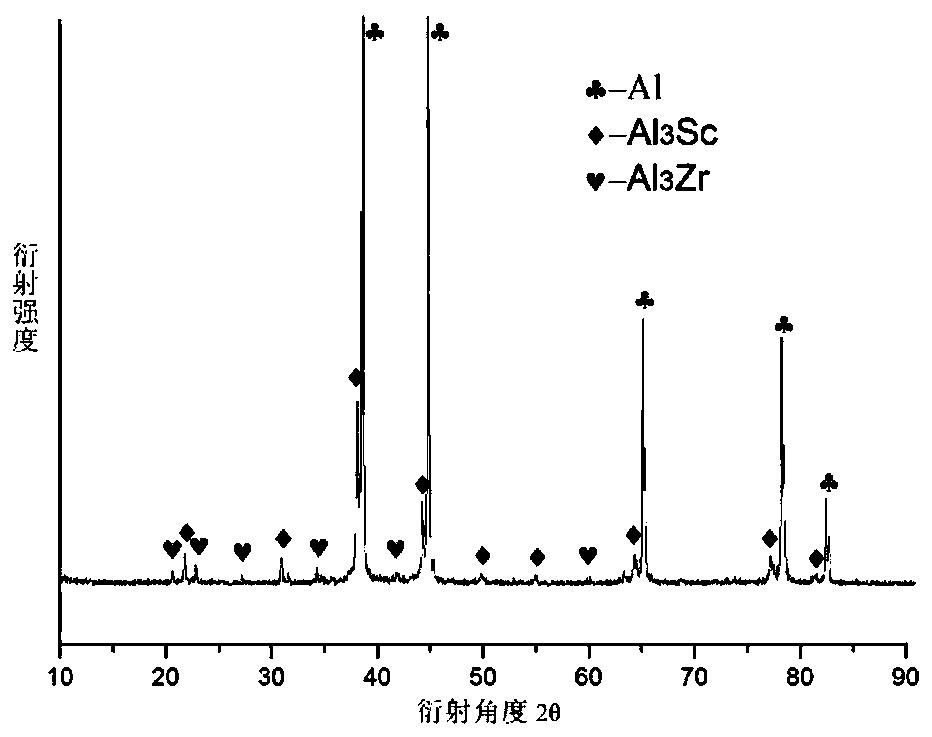

Preparation method of thin strip-type nano Al3(Sc, Zr)/Al compound inoculant

The invention relates to a preparation method of a thin strip-type nano Al3(Sc, Zr) / Al compound inoculant and relates to an aluminum-based alloy. The preparation method comprises the following steps:preparing an Al-4Sc-4Zr intermediate alloy by means of an in-situ synthesis method by taking a material, including 4% of Sc, 4% of Zr and the balance Al, as a raw material; forging the intermediate alloy to prepare a melt rapid quenching prefabricated member; and rapidly quenching the melt to prepare the thin strip-type nano Al3(Sc, Zr) / Al compound inoculant. The method prepares Sc and Zr into thenano compound inoculant which is used for refining an aluminum alloy for the first time, so that defects that processes in the prior art are relatively many in flow, complex to operate and high in cost, Al3Sc particles in the alloy are gathered and settled in the melt, Al3Sc particles are oversized, nuclear particles cannot be dispersed and distributed in a matrix, nuclear types are single and nuclear quantity is relatively small are overcome.

Owner:HEBEI UNIV OF TECH

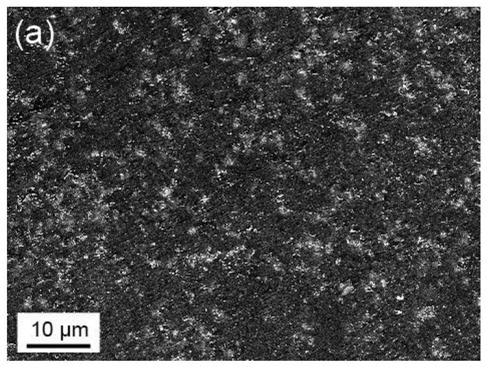

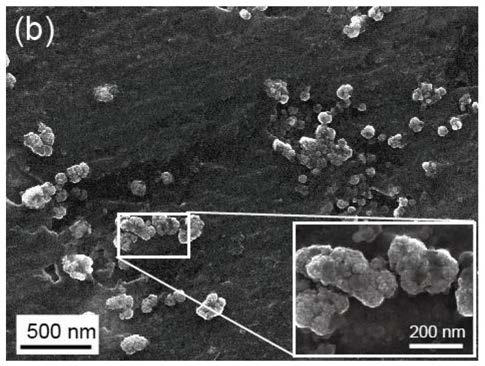

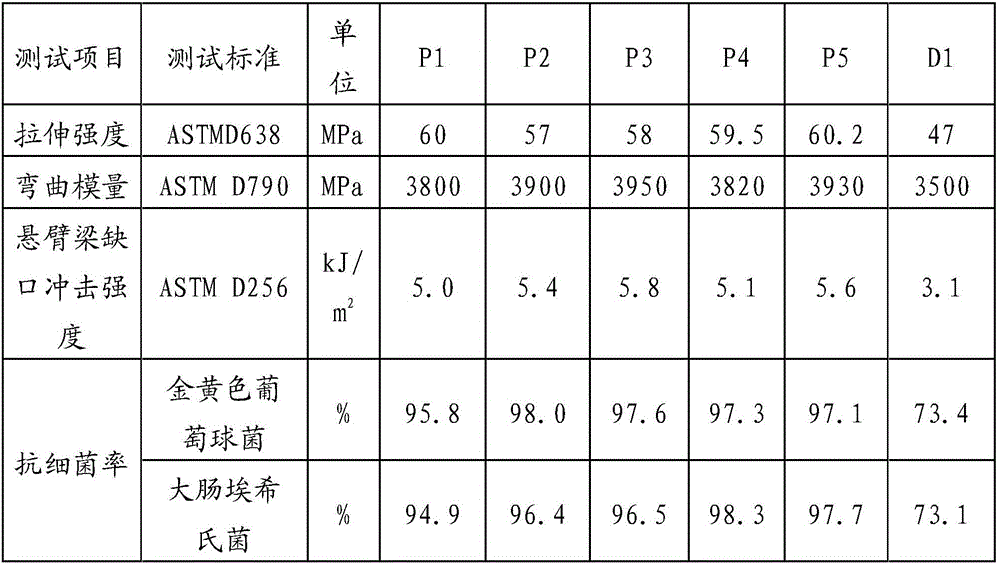

Antibacterial and high-performance PS composite material and preparation method thereof

The invention relates to an antibacterial and high-performance PS composite material and a preparation method thereof. The antibacterial and high-performance PS composite material is prepared by, by weight, 60-80 parts of PS, 20-40 parts of modified mica powder, 8-12 parts of antibacterial agent, 0.1-0.5 part of antioxidant and 0.1-0.3 part of lubricating agent. The reaction activity of acrylic acid is quite high, one end of the acrylic acid is highly-acidic carboxyl and can have chemical bonding with the surface of the mica powder to generate acrylate combined to the surface of the mica powder, the other end of the acrylic acid has double bonds and can have copolymerization or grafting reaction with unsaturated monomer or polymer, and accordingly the mica powder and polyethylene wax can be connected by the 'bridge' effect of the acrylic acid, and the polyethylene wax can firmly wrap the surface of the mica powder to form core-shell filler which uses the mica powder as the core and the polyethylene wax as the shell.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Eutectic aluminum-silicon alloy piston material

InactiveCN102660702AImprove high temperature performanceSmall coefficient of thermal expansionAdditive ingredientTrace element

The invention provides a eutectic aluminum-silicon alloy piston material. A novel eutectic alloy material which is high in strength and low in heat expansion coefficients is prepared by adjusting alloy ingredients and adding trace elements such as V, Zr, P on the basis of ZL109 alloy. According to the eutectic aluminum-silicon alloy piston material, the alloy has the characteristics of high high-temperature performance, high hardness, low heat expansion coefficients, high abrasive resistance and the like, and meets the requirement of high-performance vehicle engine pistons.

Owner:TIANJIN LIZHONG ALLOY GROUP

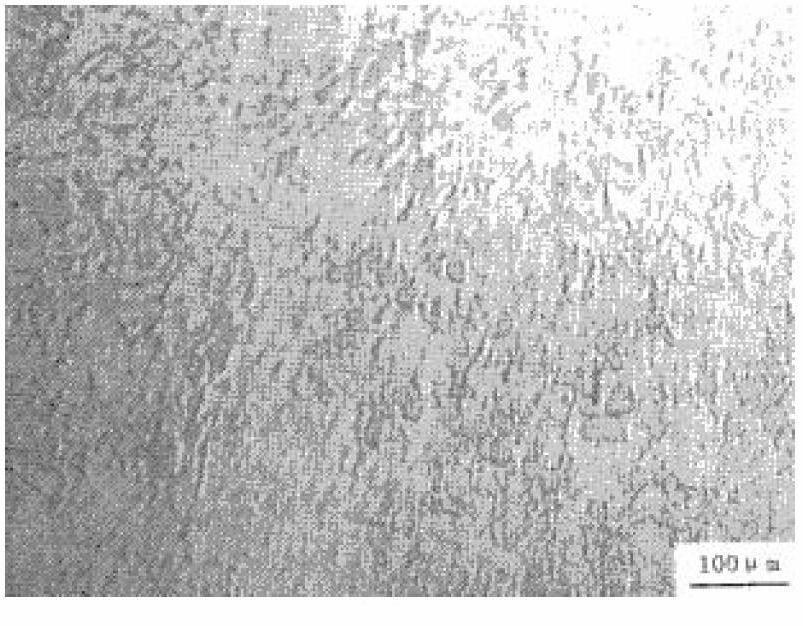

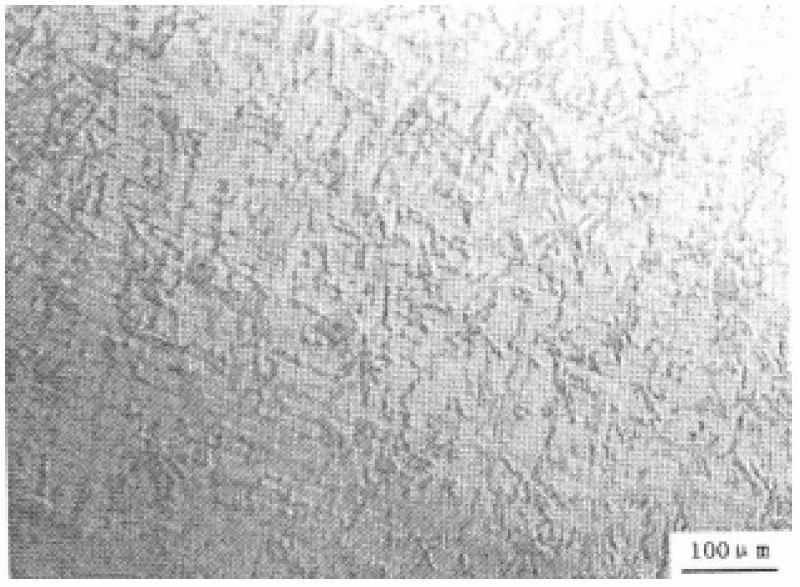

Preparation method of cocrystallized Al-Si alloy piston material

ActiveCN102644012AImprove high temperature performanceSmall coefficient of thermal expansionAlloyHardness

The invention provides a preparation method of a cocrystallized Al-Si alloy piston material. According to the preparation method, on the basis of ZL109 alloy, by adjusting the alloy constituents and the alloy micro constituents such as V, Zr, P and the like and strictly controlling the deterioration technology, a novel cocrystallized Al-Si alloy piston material which is high in intensity and low in thermal expansion coefficient can be prepared, a recrystallization texture can be thinned by Zr and V, the deterioration treatment can be carried out by adding P, and an Al-P black core can be formed, so that the heterogeneous nucleation of primary crystalline silicon can be promoted, and the primary crystalline silicon can be thinned, wherein the average grain size is about 12mu m. The alloy of the preparation method has the characteristics of being good in high-temperature performance, high in hardness, small in thermal expansion coefficient, good in abrasive resistance and the like, thereby being better accordant with the requirement of a high-performance engine piston for a vehicle.

Owner:天津新立中合金集团有限公司

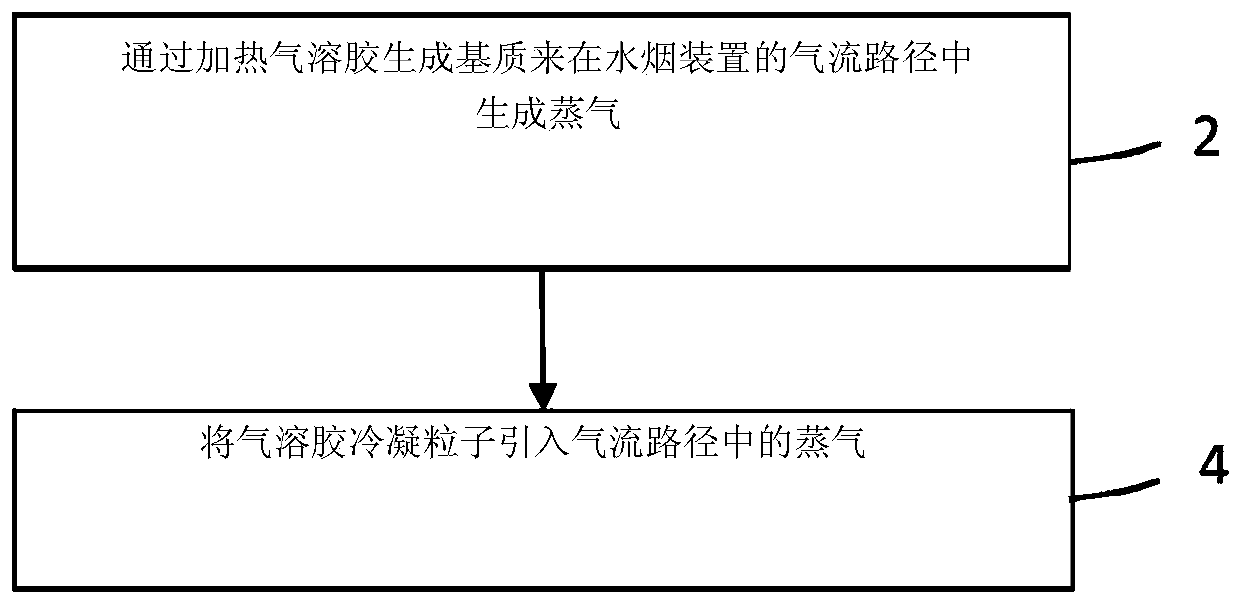

Shisha device with aerosol condensation

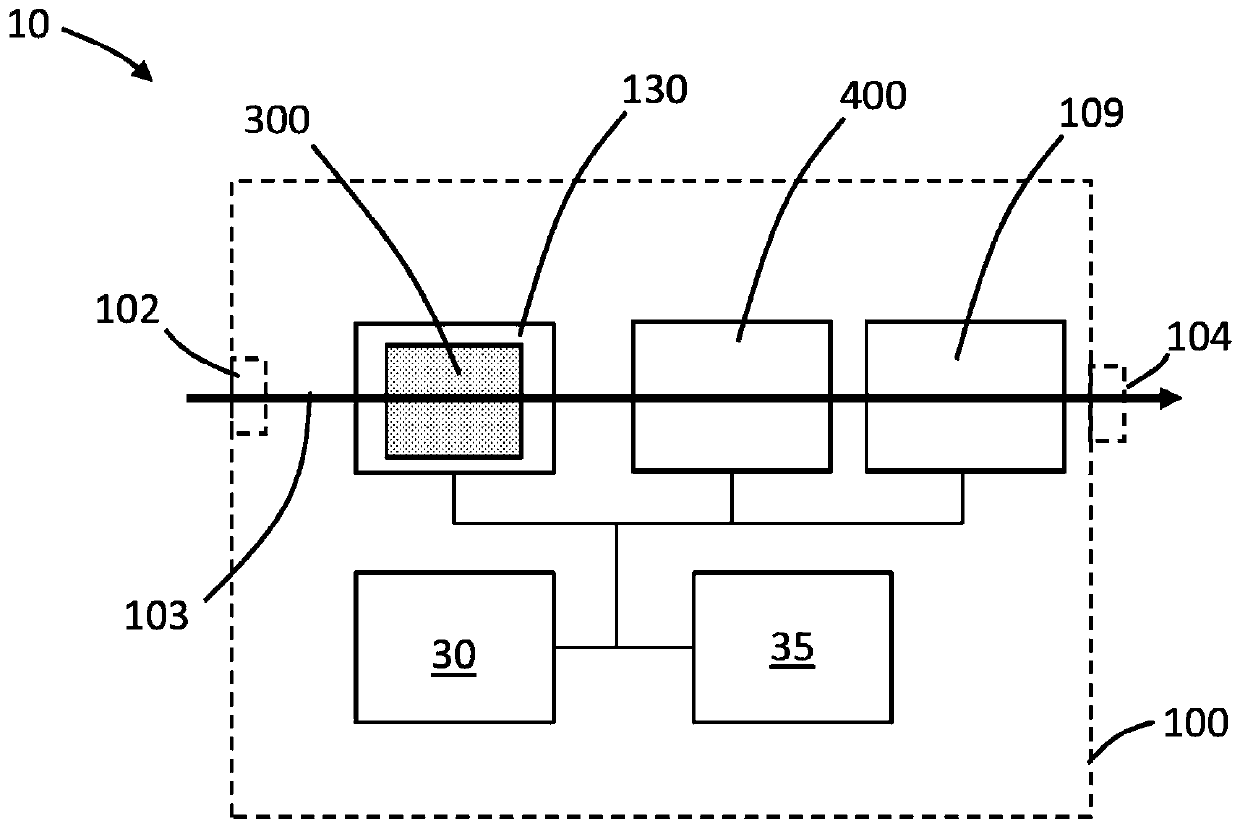

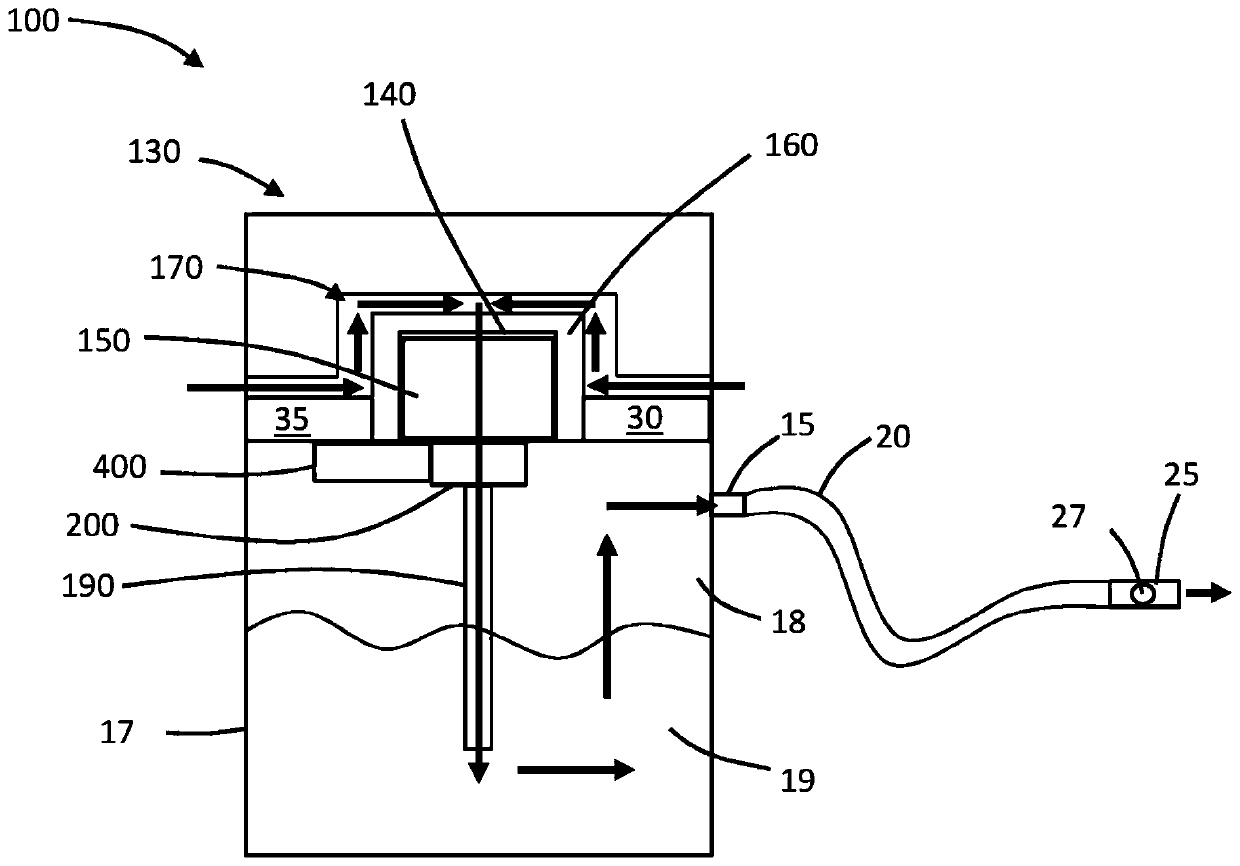

PendingCN111107757AQuality improvementPromote heterogeneous nucleationTobacco treatmentTobacco pipesEngineeringMechanical engineering

A method includes generating an aerosol by heating, without combusting, an aerosol generating substrate (300) in a shisha device (100). The method further includes introducing at least one aerosol condensation particle to an airflow path (103) of the shisha device. The airflow path (103) carries the aerosol generated by the aerosol generating substrate to an outlet (104) of the shisha device for delivery to a user.

Owner:PHILIP MORRIS PROD SA

Method for improving compactness of silicon dioxide coating layer on surface of titanium dioxide

ActiveCN111621171AReduce photocatalytic activityImprove compactnessInorganic pigment treatmentPeristaltic pumpPhysical chemistry

A method for improving compactness of a silicon dioxide coating layer on the surface of titanium dioxide comprises the following steps: (1) preparing titanium dioxide into titanium dioxide slurry; (2)adjusting the reaction temperature to ensure that the temperature is constant in the titanium dioxide coating process; (3) adding a pre-dispersing agent and NaCl solid into the titanium dioxide slurry under the action of stirring, the pre-dispersing agent being trisodium citrate; (4) adjusting the pH value of the titanium dioxide initial slurry; (5) applying a compact SiO2 coating layer with sodium silicate in a parallel flow manner by adopting a peristaltic pump, and curing to obtain coated product slurry; and (6) washing and drying the coating slurry product, and carrying out steam powder treatment to obtain compact SiO2 coated titanium dioxide. The process is simple and the raw material cost is low. The dispersity of the titanium dioxide slurry can be improved, and the formation of a silicon dioxide coating layer is favorably induced, so that a titanium dioxide coating product with a more uniform and compact coating layer is prepared.

Owner:中信钛业股份有限公司 +1

A kind of preparation method of expanded polypropylene beads

The invention discloses a preparation method of foamed polypropylene beads. The method comprises the following steps that 1, polypropylene resin, an active filler and auxiliaries are added into a high-speed mixing machine and mixed to be uniform at the temperature of 10-20 DEG C, and a polypropylene foaming material is obtained; 2, the polypropylene foaming material is added into a triple-screw extruder, plastification and mixing are conducted, a supercritical fluid is injected, the mouth mold pressure is controlled to be 5-25 MPa, the mouth mold temperature is 110-160 DEG C, instant pressure release is conducted through a mouth mold, foaming is conducted, and super-fine hole foamed polypropylene is obtained; 3, super-fine hole foamed polypropylene is subjected to mold surface water-ring hot-cutting granulation, drying and sieving, and the foamed polypropylene beads are obtained. The method is low in production cost, high in capacity, safe and environmentally friendly, no foaming agent decomposed residue exists in the prepared foamed polypropylene beads, secondary foaming can be conducted, the foaming ratio can be adjusted, the rebound resilience of a finished product is high, decomposing and recycling are easy, and the foamed polypropylene beads can be widely used in the fields of plastic packaging, transportation industry, military aerospace, office supplies and the like.

Owner:湖北聚石新材料科技有限公司

Aluminum precursor coated titanium dioxide, preparation method thereof and method for preparing aluminum coated titanium dioxide

ActiveCN113652102AGood weather resistanceIncrease repulsionInorganic pigment treatmentHydrated aluminaWeather resistance

The invention discloses aluminum precursor coated titanium dioxide. The surface of titanium dioxide is coated with an aluminum oxide precursor. The invention also discloses a preparation method of the aluminum precursor coated titanium dioxide and a method for preparing the aluminum coated titanium dioxide. The coating process is different from a common aluminum coating method in which hydrated alumina is directly formed and coated on titanium dioxide. According to the preparation method, the aluminum precursor is firstly generated and coats the surface of the titanium dioxide, and the aluminum precursor is of a molecular chain structure, so that the precursor is more easily coated on the surface of the titanium dioxide; the surface of the aluminum oxide precursor in the solution has a large number of hydroxyl groups, so that the repulsive interaction among particles is relatively large, the self-phase nucleation difficulty is high, and heterogeneous nucleation is facilitated, so that titanium dioxide is perfectly coated, then water is removed through drying, and non-bridging hydroxyl groups of adjacent colloidal particles are spontaneously converted into bridging hydroxyl groups; meanwhile, coordination water of a gel part structure is removed, and bridging hydroxyl groups are also formed among coating particles, so that a coating layer on the surface of the titanium dioxide is uniform and compact, and the weather resistance of the titanium dioxide is superior to that of the titanium dioxide prepared by a traditional aluminum coating method.

Owner:EAST CHINA UNIV OF TECH

Polylactic acid green nano-nucleating temperature resistance agent and preparation method of same

ActiveCN109401234AGood dimensional stabilityImprove temperature resistancePotato starchPyrophosphate

The invention discloses a polylactic acid green nano-nucleating temperature resistance agent and a preparation method of same. The temperature resistance agent includes mineral clay, a composite dispersant, alkali and composite starch, wherein the mineral clay is a mixture of attapulgite and bentonite, the composite dispersant is a mixture of sodium polyacrylate and sodium pyrophosphate, and the composite starch is a mixture of caltrop starch and potato starch. The preparation method includes: sun-drying the attapulgite and bentonite until water weight percentage is not more than 20%, mixing the attapulgite and bentonite, coarse-curing the mixture into mineral clay granules, spraying the composite dispersant solution, and compressing the mixture into a sheet-like mixture; mixing and stirring the sheet-like mixture with water to make slurry, sieving and emulsifying the slurry, and performing high speed shearing to obtain an emulsion; performing cyclone classification and dehydration, transferring the mixture into a drying-type crushing and surface modifying machine, and adding the composite starch for surface modification; crushing the modified material to obtain the polylactic acidgreen nano-nucleating temperature resistance agent, which is easy to disperse completely in polylactic acid and provides the polylactic acid with excellent heterogeneous nucleation, thereby improvingcrystalline degree of the polylactic acid and significantly improving the temperature resistance thereof.

Owner:江苏圣一纳米科技有限公司 +1

High-performance eutectic aluminum silicon alloy piston material of vehicle engine

ActiveCN102676889AGood high temperature performanceSmall coefficient of thermal expansionTrace elementSilicon alloy

The invention provides a high-performance eutectic aluminum silicon alloy piston material of a vehicle engine. On the basis of ZL109 alloy, the novel eutectic alloy material with high strength and low thermal expansion coefficient can be prepared by adjusting the alloy composition and adding trace elements such as V, Zr and P. The eutectic aluminum silicon alloy has the characteristics of being excellent in high-temperature property, high in hardness, low in thermal expansion coefficient, good in wear resistance and the like, thus being better in accordance with the requirements of the high-performance vehicle engine.

Owner:天津新立中合金集团有限公司

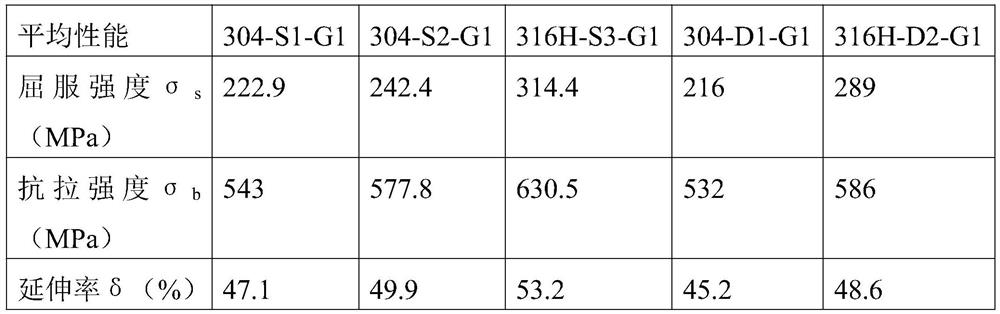

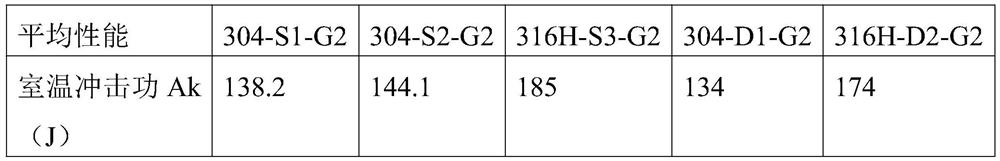

Modified austenitic stainless steel surfacing electrode and preparation method thereof

ActiveCN112440026APrevent evaporationHigh strengthWelding/cutting media/materialsSoldering mediaIron powderGraphite

The invention discloses a modified austenitic stainless steel surfacing electrode and a preparation method thereof. The modified austenitic stainless steel surfacing electrode comprises a coating anda core wire, and the core wire comprises a second interlayer, a core wire outer layer, a first interlayer and a core wire inner layer from outside to inside; the core wire inner layer comprises metalchromium powder and graphite; and the core wire outer layer comprises nickel powder, silicon powder, manganese powder and iron powder. According to the modified austenitic stainless steel surfacing electrode and the preparation method thereof, a traditional welding rod structure is creatively changed for the first time, the inner layer and the outer layer of the core wire are filled with the high-melting-boiling-point elements and the low-melting-boiling-point elements respectively, most of the low-melting-point elements and the low-boiling-point elements are prevented from entering a high-temperature area in the center of a molten pool to be evaporated, and the physical and chemical properties such as strength and corrosion resistance of a weld joint are effectively improved.

Owner:鄂尔多斯市特种设备检验所

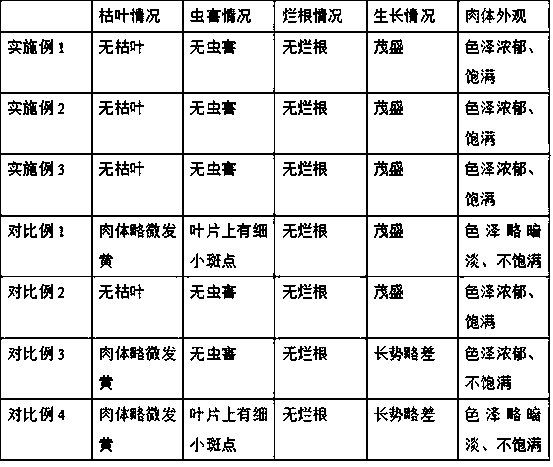

Succulent plant fertilizer and preparation method thereof

InactiveCN108440126APromote co-activated fermentationImprove disease resistanceAlkali orthophosphate fertiliserExcrement fertilisersMicrosphereDecomposition

The invention discloses a succulent plant fertilizer and a preparation method thereof, and belongs to the technical field of flowering plant fertilizers. Earthworms are used as an organic raw material, decomposition promoting bacteria are added to promote the co-activation fermentation of straws and mixed garbage in order to enhance the activity of beneficial enzymes in soil, promote the disease resistance of succulent plants and improve the fertility supply performance of the soil, bamboo sawdust used as a raw material reacts with acrylamide and acrylic acid to obtain a substance with a goodwater retention property, 3,5-dihydroxybenzoic acid is used as a raw material to obtain a substance for inhibiting the biosynthesis of gibberellin in the succulent plants, reducing the plant height, making the succulent stems thick and strong and improving the survival rate, and hollow microspheres formed by assembling nanorods are hydrothermally synthesized within a short time under the regulation of a lower concentration of polyallylammonium chloride in order to achieve sustained release of active ingredients. The problems of short fertilizer effect time, no meeting of the growth demands ofthe succulent plants, easy causing of water formation, rotten roots, pests and diseases, and influences on the ornamental value of the succulent plants of current succulent plant fertilizers are solved.

Owner:何治伟

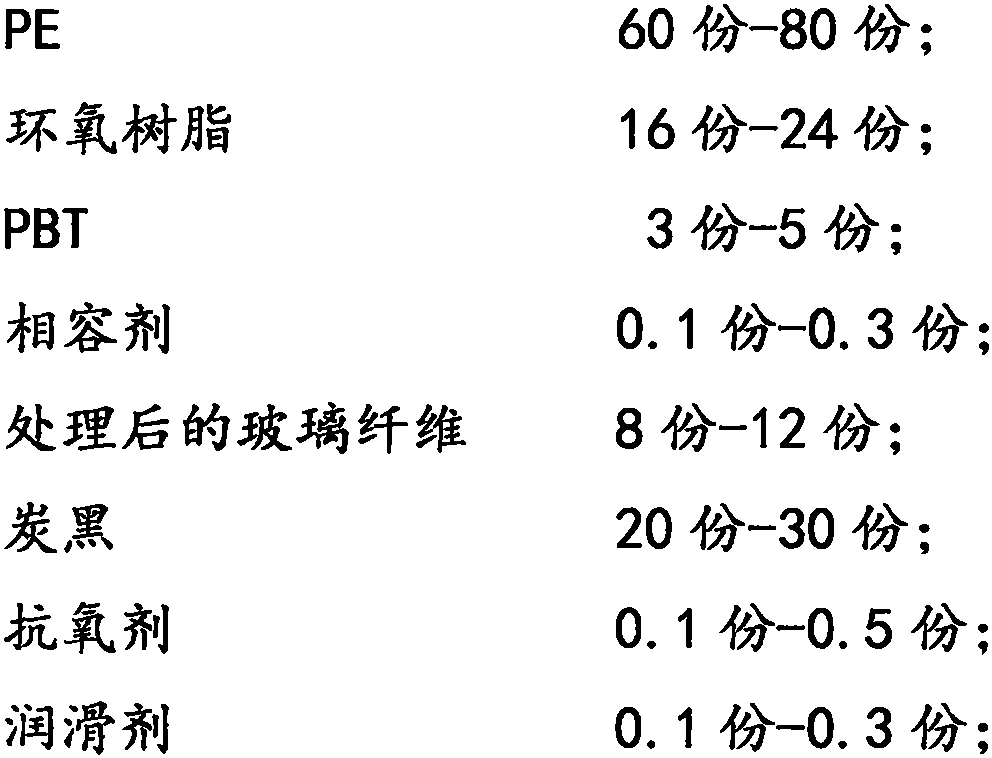

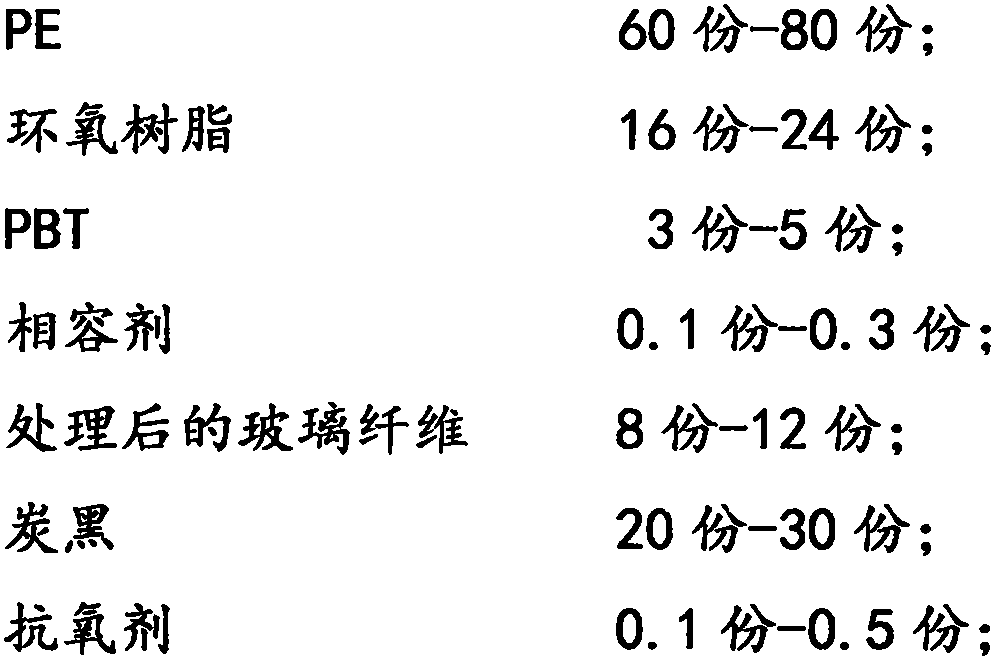

Anti-static PE composite material

The invention relates to an anti-static PE composite material. The anti-static PE composite material is prepared from the following components: in parts by weight, 60-80 parts of PE, 16-24 parts of epoxy resin, 3-5 parts of PBT, 0.1-0.3 part of a compatibilizer, 8-12 parts of treated glass fiber, 20-30 parts of carbon black, 0.1-0.5 part of an antioxidant and 0.1-0.3 part of a lubricant. Accordingto the technical scheme, surface treatment is performed on the adopted glass fiber with a silane coupling agent, and after the ethoxy groups of the coupling agent molecules are hydrolyzed, firm bonding is formed between the hydrolyzed ethoxy groups and hydroxyl groups on the surface of the glass fiber; and amino groups at the other end can be reacted with epoxy groups in epoxy resin so as to formchemical bonds, and high interfacial bonding is formed between the epoxy resin and the glass fiber; and sufficient overlapping can be formed between the glass fiber, and formation of a continuous conductive path is ensured, so that the resistivity of the composite system is reduced significantly.

Owner:任素飞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com