Patents

Literature

57results about How to "Small fluctuations in concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting tungsten from scheelite

ActiveCN102021328AReduce lossesLow costProcess efficiency improvementWater dischargeReaction temperature

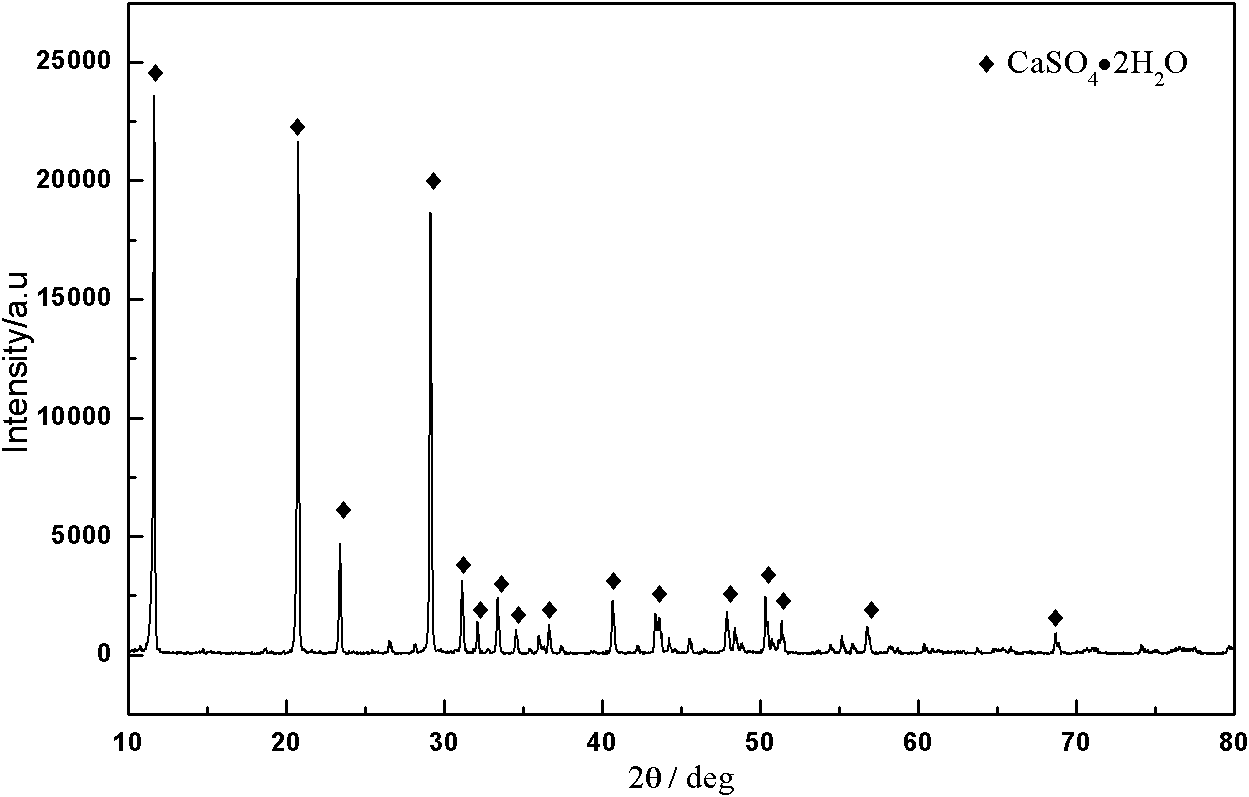

The invention discloses a method for extracting tungsten from scheelite, comprising the following steps of: mixing the scheelite with a mixed solution of phosphoric acid and sulfuric acid for reaction, adding dihydrate gypsum as seed crystals, and controlling the concentration of SO4<2->, the content of P2O5 and the reaction temperature to obtain the dihydrate gypsum with good filtering and washing properties. The invention has the advantages that one-step efficient normal pressure leaching of the scheelite is achieved, thus resources and energy consumption are saved, and the resolution ratio of the scheelite is up to above 98%; the problems of Cl<-> corrosion and serious HCl volatilization are overcome; the cyclic utilization of phosphoric acid is basically achieved, and the leaching cost and waste water discharge are greatly reduced; leaching equipment is simple, is convenient for operation and is easy to realize industrialization; the single and stable dihydrate gypsum is obtained, the filter efficiency of the dihydrate gypsum is high, the washing property of the dihydrate gypsum is good, and the P2O5 content in the washed dihydrate gypsum is reduced to be below 2%, thereby reducing the loss of phosphoric acid; and the passivation phenomenon of calcium sulfate solid film when the tungsten ore is leached is avoided.

Owner:CENT SOUTH UNIV

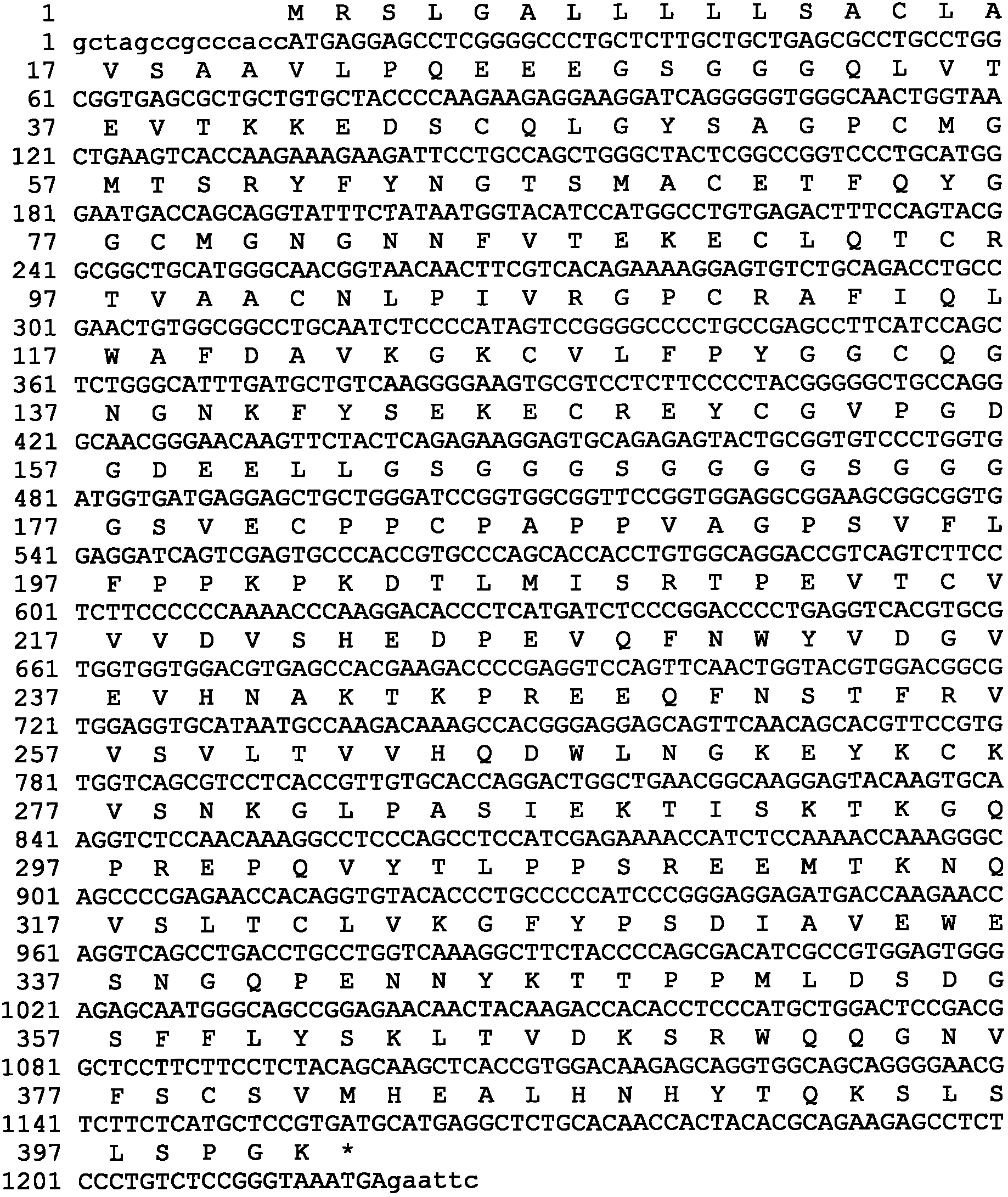

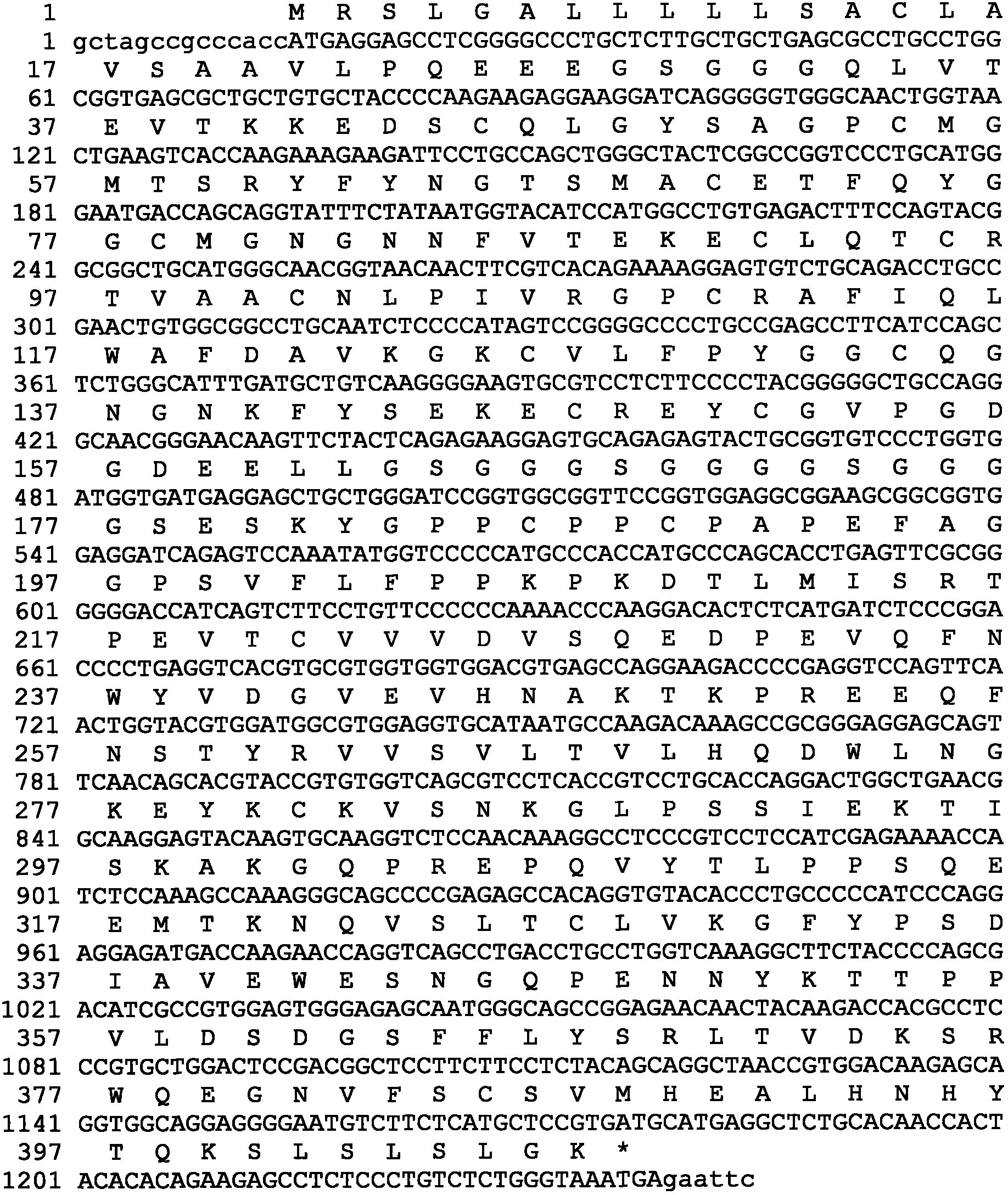

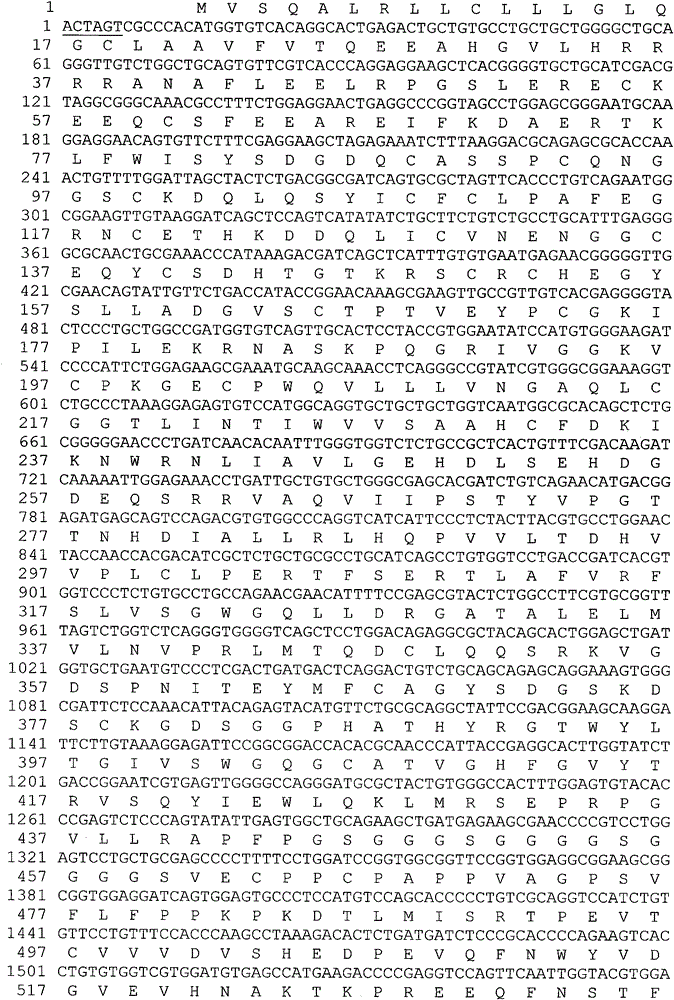

Human urinary trypsin inhibitor (hUTI) of reorganization-dimerization and preparation method and application thereof

ActiveCN103044554AIncrease productionEfficient and convenient purificationPeptide/protein ingredientsAntipyreticURINARY TRYPSIN INHIBITORHalf-life

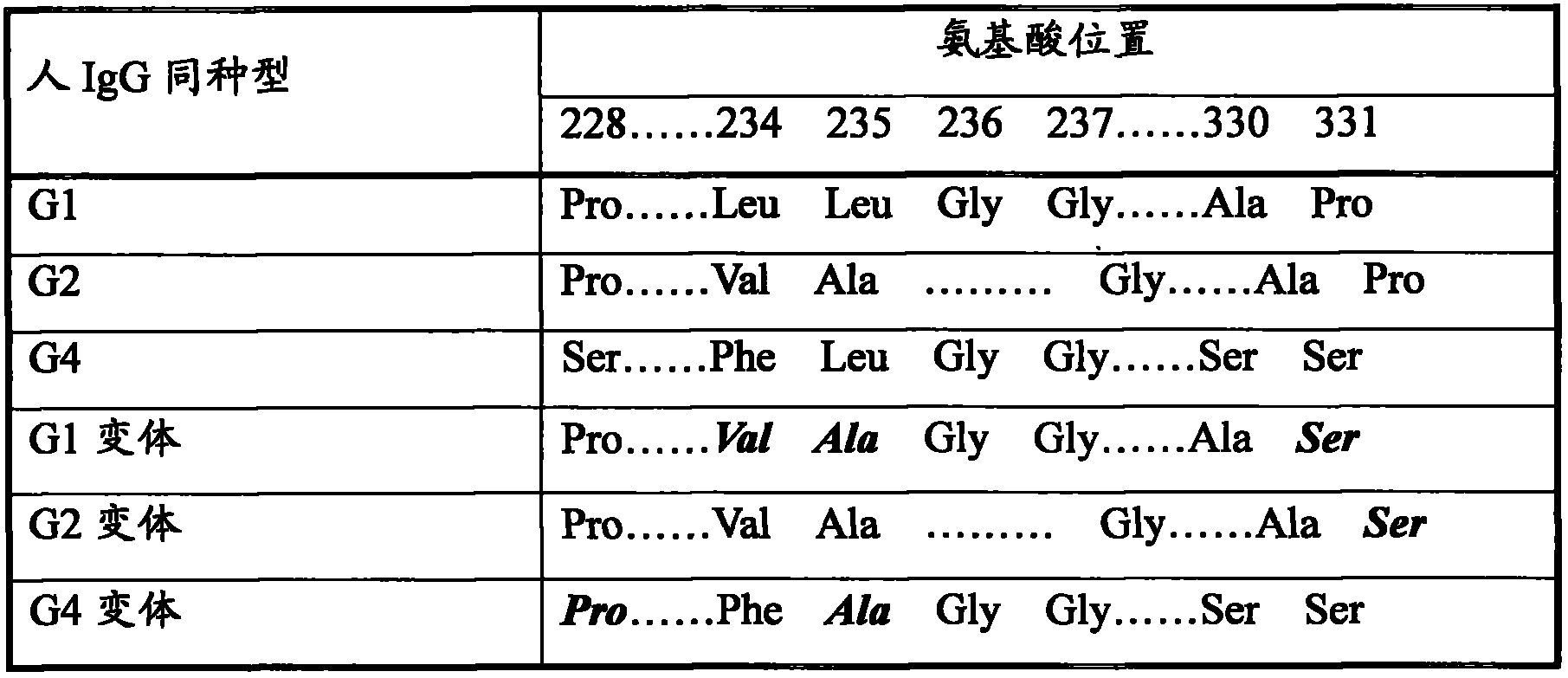

The invention discloses a human urinary trypsin inhibitor (hUTI) of reorganization-dimerization and preparation method and application thereof, wherein the hUTI protein of reorganization-dimerization successively comprises amino acid residue sequence of human UTI, a peptide linker and a human IgGFc variant from N-terminal to C-terminal. The hUTI protein of reorganization-dimerization has the in-vitro biological activity similar with that of the human urinary trypsin inhibitor, higher biological activity in vivo and an extended half-life period in vivo.

Owner:PHARMAB

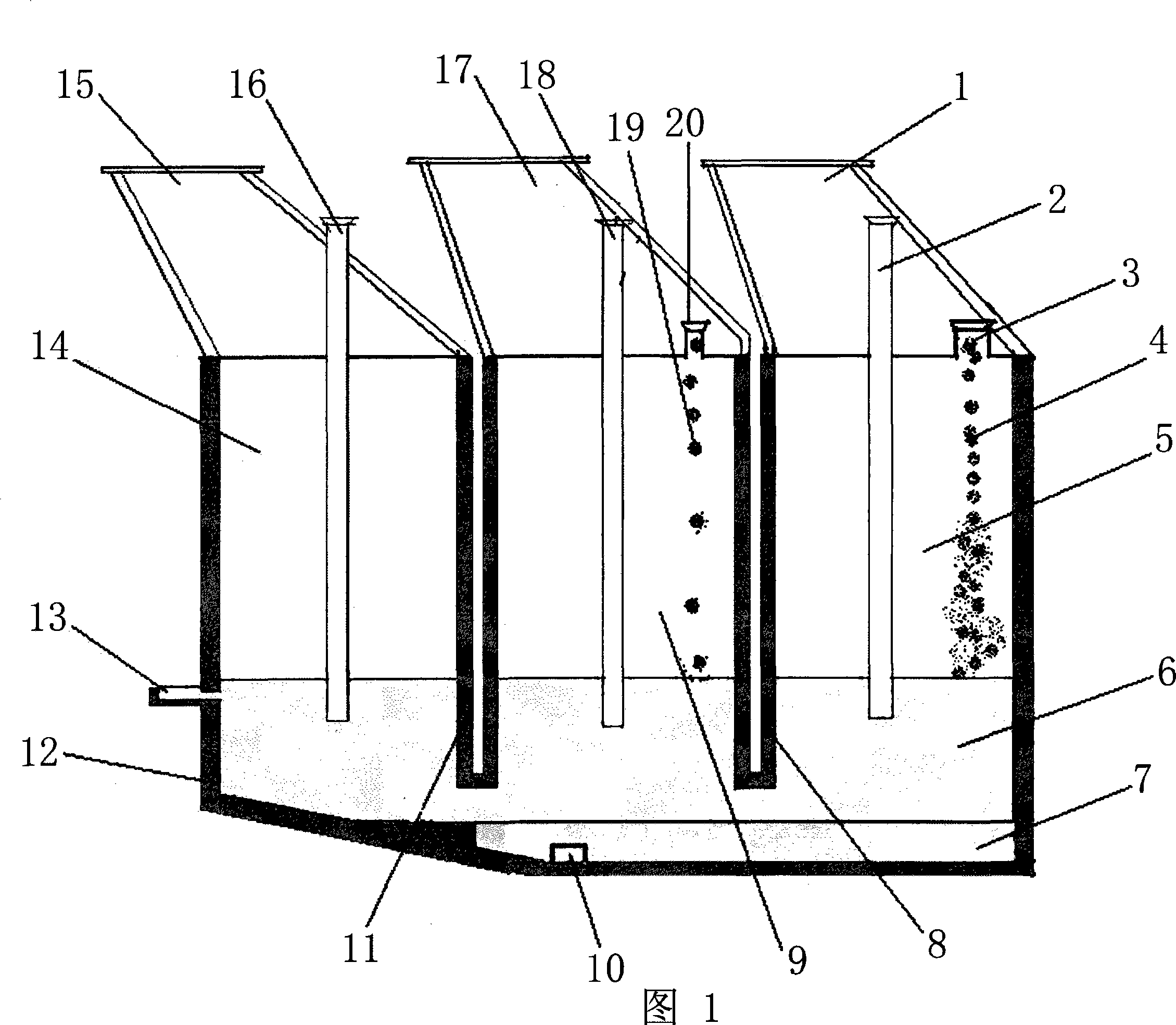

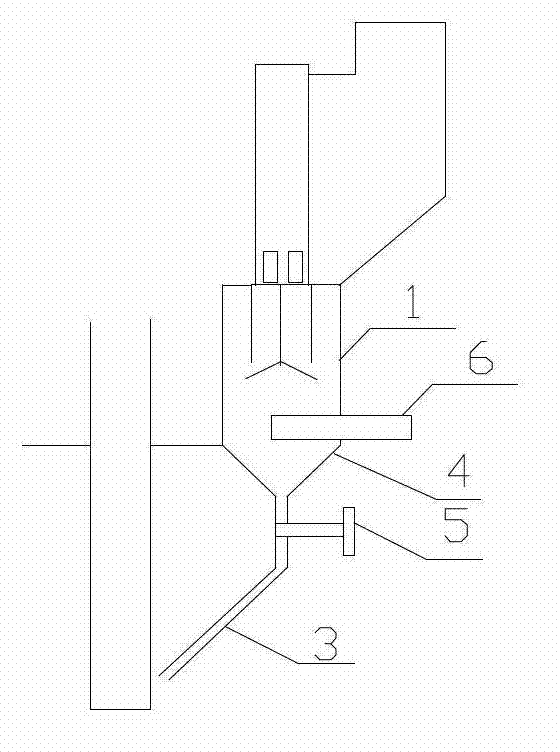

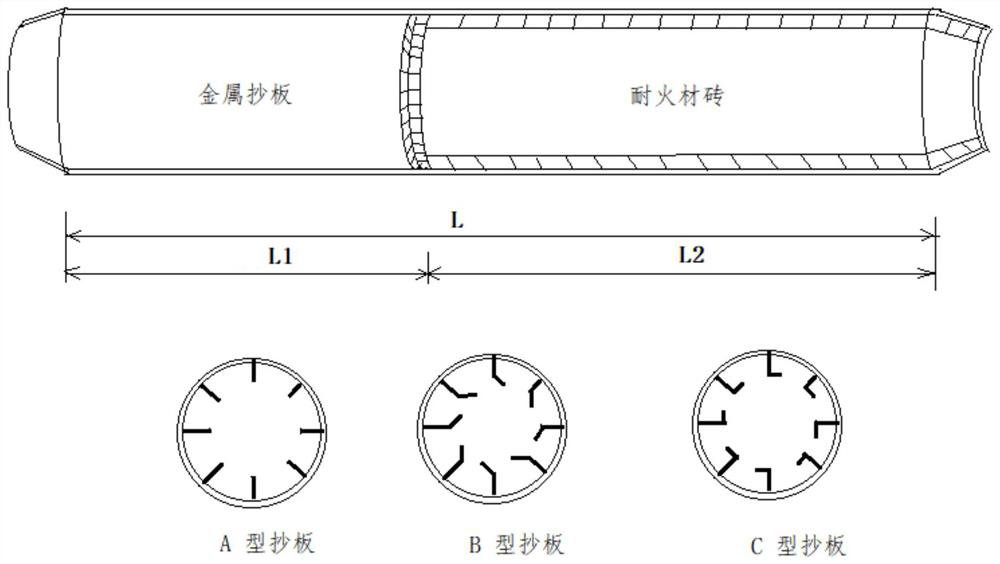

Method and equipment for continuous smelting of lead sulphide concentrate

ActiveCN101200777AQuality improvementTake advantage ofChemical industrySulfur-trioxide/sulfuric-acidMelting tankSiphon

A lead sulfide ore concentrate continuous smelting method and equipment thereof are provided. The invention relates to a pyrometallurgical process of lead sulfide ore concentrate and the equipment adopted for realizing the process. In the device, a partition wall is arranged in the space above the liquid slag layer of the molten pool of the furnace body, which separates the device into three regions of an oxidation region, a reduction region and a fuming region that are not communicated. The top of every region is equipped with a flue gas outlet and is respectively equipped with a spray gun. A material smelting inlet is arranged on the top part of the oxidation region. A siphon discharging outlet is arranged on a crude lead layer on the bottom of the furnace body. A slag discharging outlet is arranged on the liquid slag layer of the fuming region. The smelting materials are continuously fed in the furnace from the top of the oxidation region. The liquid metal lead is continuously discharged out of the furnace from the siphon discharging outlet. SO2 obtained in the oxidation area is used for preparing sulfate acid. Valuable metal smoke dust such as high zinc that is obtained in the fuming region is reused. The invention has the advantages of short process line, fully utilization of slag heat, obvious energy saving effect, less investment in the metallurgical furnace equipment, low activity-based cost, small concentration fluctuation of SO2, cheap reducing agent and wide resources.

Owner:YUNNAN TIN GROUP HLDG

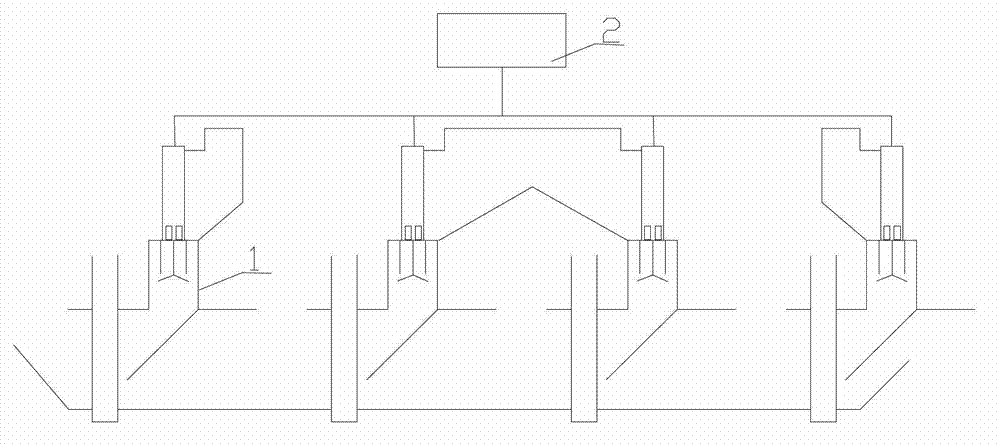

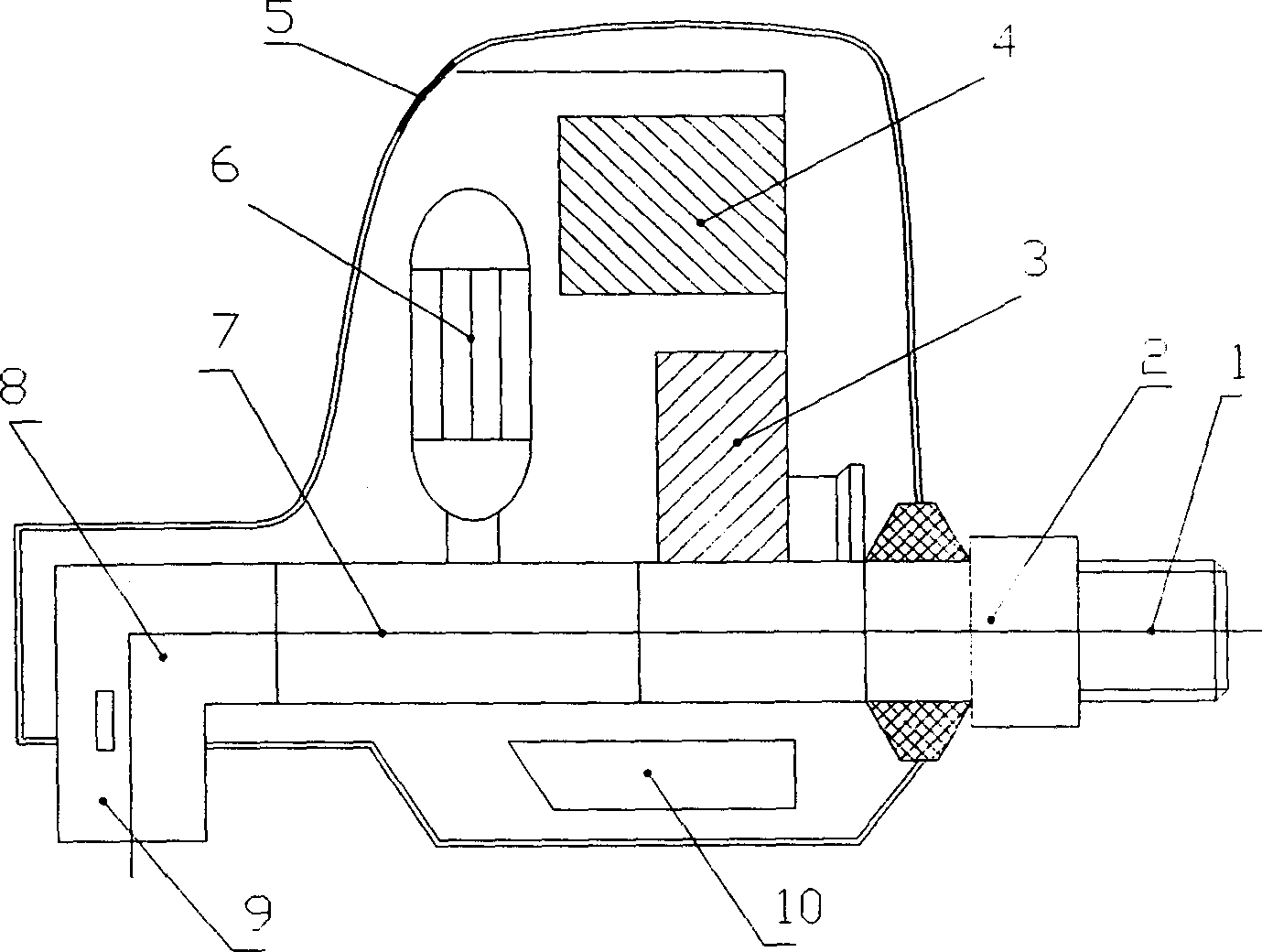

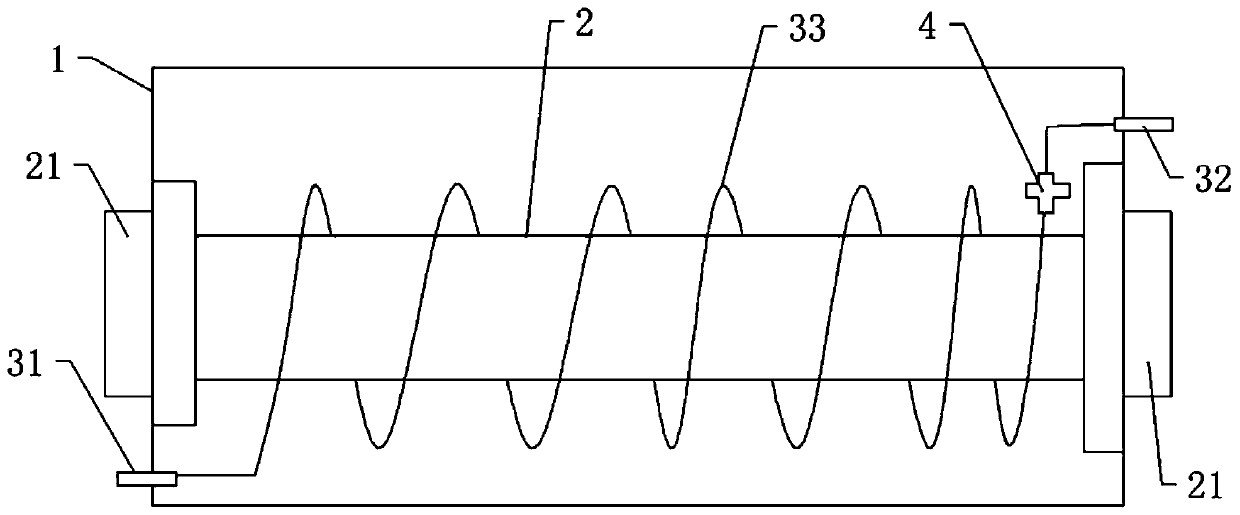

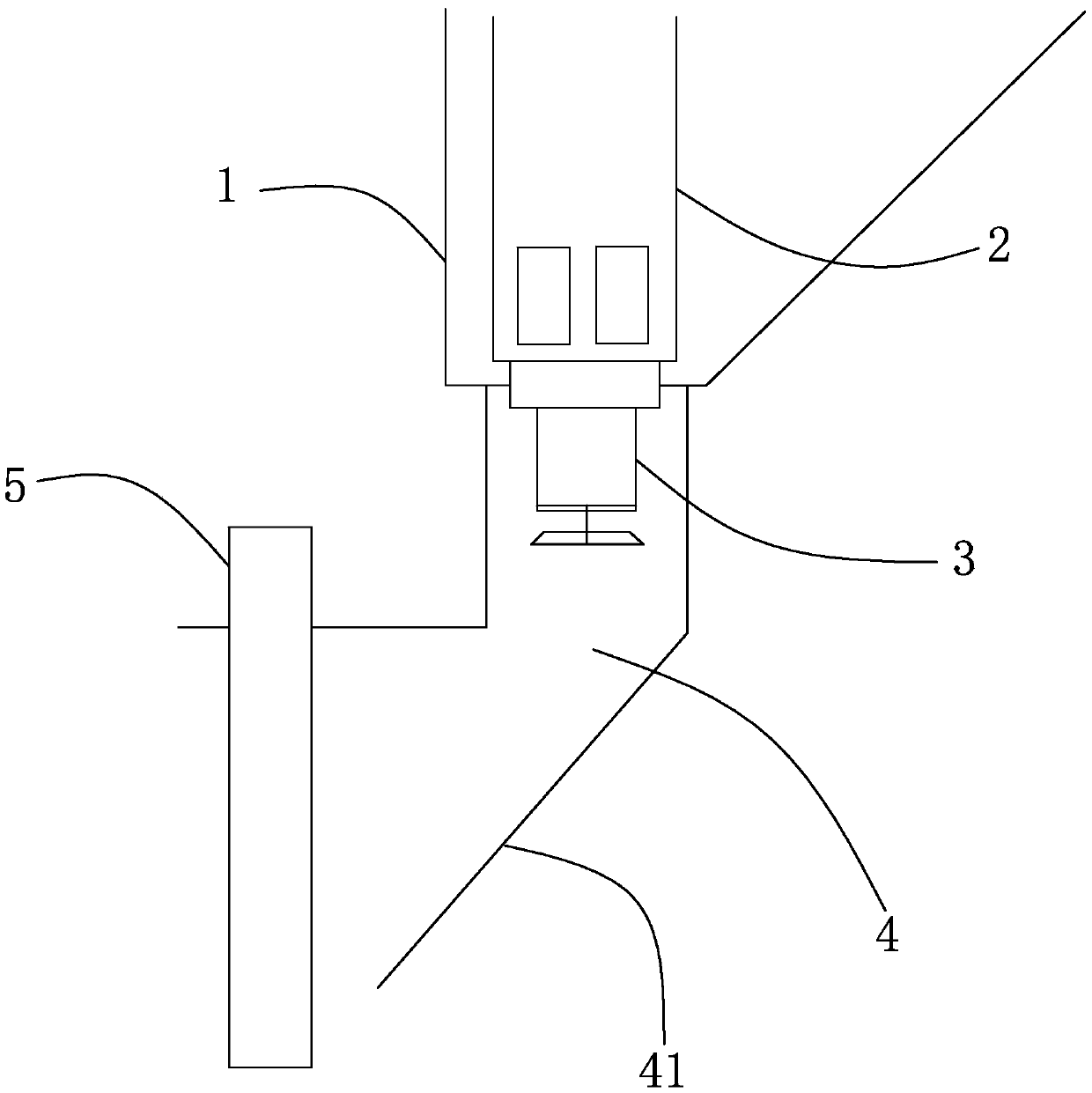

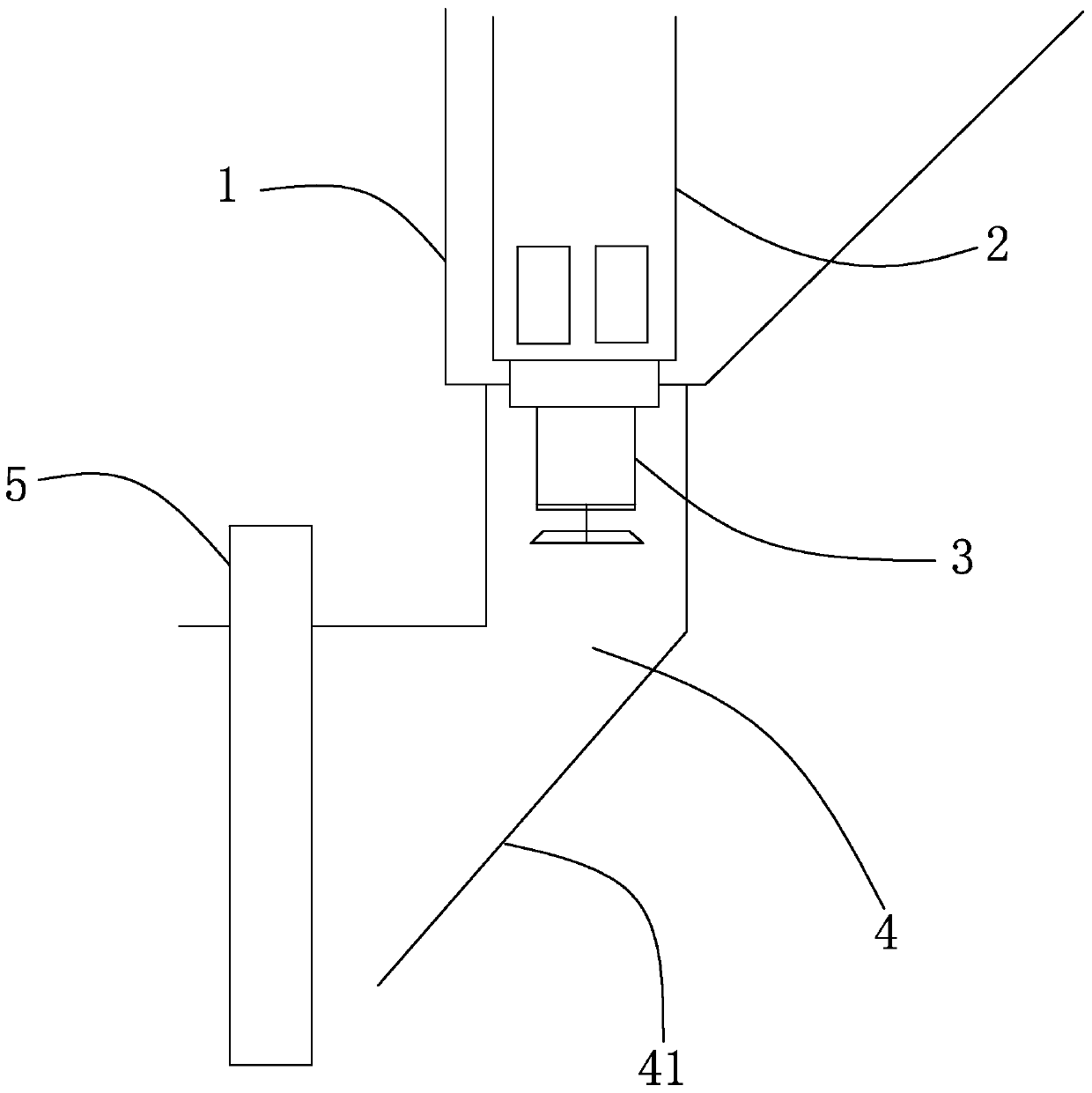

Continuous feeding device for aluminum electrolysis cell and electrolysis cell with same

The invention belongs to the technical field of aluminum electrolysis cells, and particularly relates to a continuous feeding device for an aluminum electrolysis cell and an electrolysis cell with the same. The continuous feeding device for the aluminum electrolysis cell is capable of improving the stability of the electrolysis cell, lowering energy consumption, reducing sediment and pressure drop at the furnace bottom and prolonging the service life of the cell. According to the technical scheme, the continuous feeding device for the aluminum electrolysis cell comprises a sleeve, a funnel and an upper delivery pipe, wherein the open end of the funnel is fixedly connected with the bottom of the sleeve; and the outlet end of the funnel is fixedly connected with one end of the upper delivery pipe. Since the funnel is arranged at the bottom of the sleeve, so that the flow velocity of fed materials can be reduced, continuous feeding is realized, and the problem caused when alumina powder which is not completely dissolved sinks into the aluminum liquid is avoided.

Owner:HUNAN CHUANGYUAN ALUMINUM IND

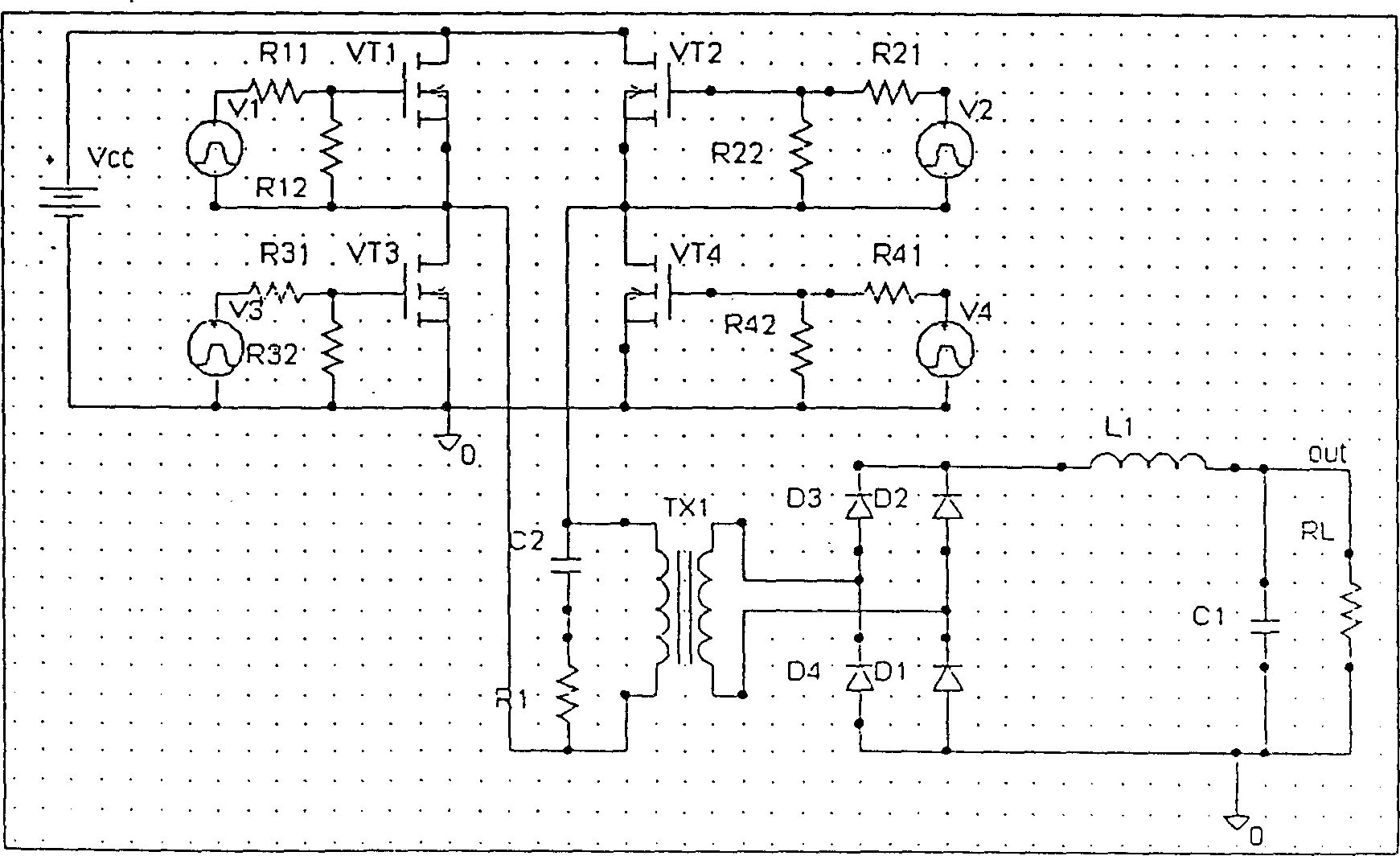

Ultrasmall size active oxygen water-purifier

InactiveCN1450002AWork reliablySmall fluctuations in concentrationOzone preparationWater/sewage treatment by oxidationWater qualityEngineering

The present invention relates to a water quality purifying equipment formed from high-frequency pulse power supply, active oxygen generator, vortex mixer and infrared controller. It adopts the low-temp. plasma technique to produce the free radicals of active oxygen, and utilizes the technique of activating water particles and vortex-mixing lots of free radicals, at the same time uses induction control switch, safe isolated transformer, antispattering water-saving device and perform filter so as to make the complete equipment work have the advantages of stable and reliable preformance, high sterilization efficiency, quick speed, simple structure, having no residue and having no secondary pollution, so that it has extensive application.

Owner:上海复洁环境科技工程有限公司

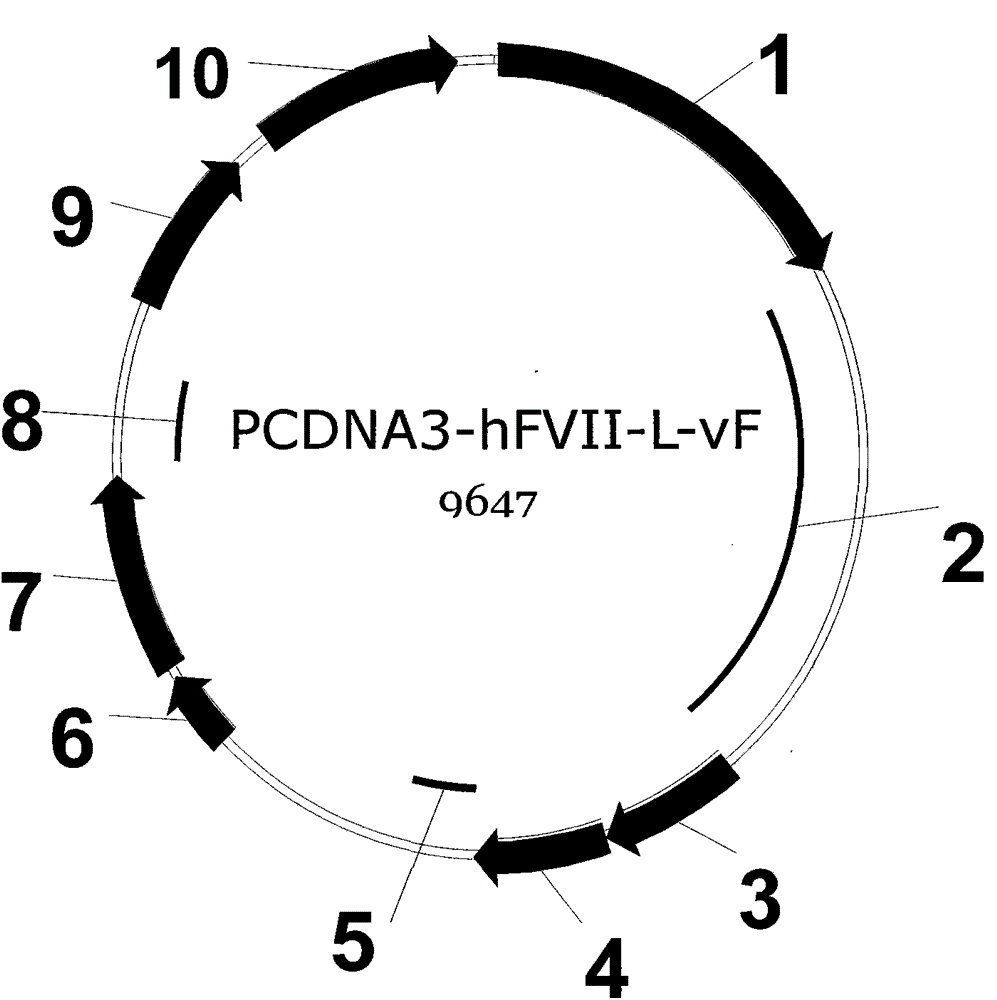

Hydrochloric tamsulosin sustained-release capsule and its preparation method

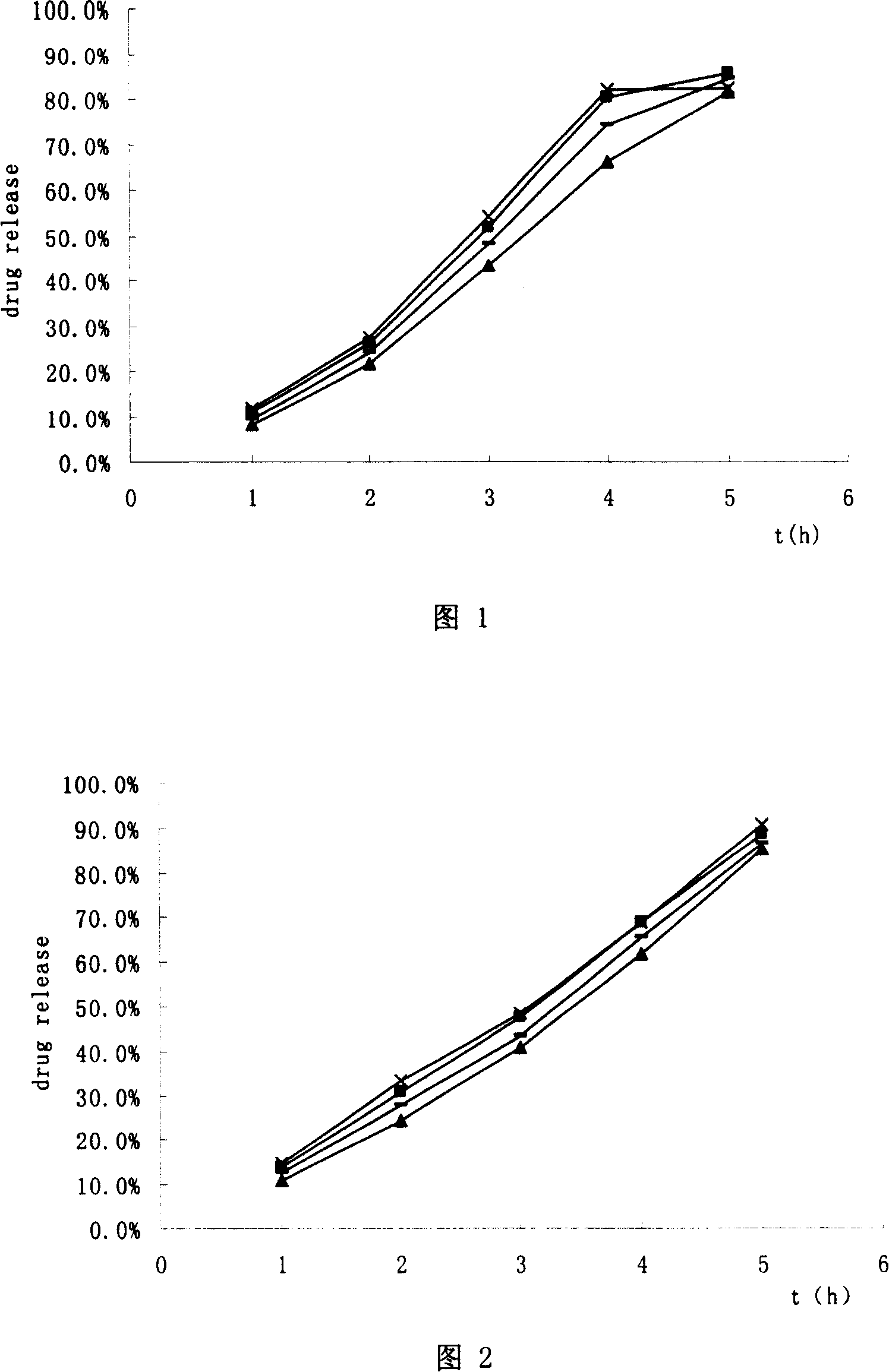

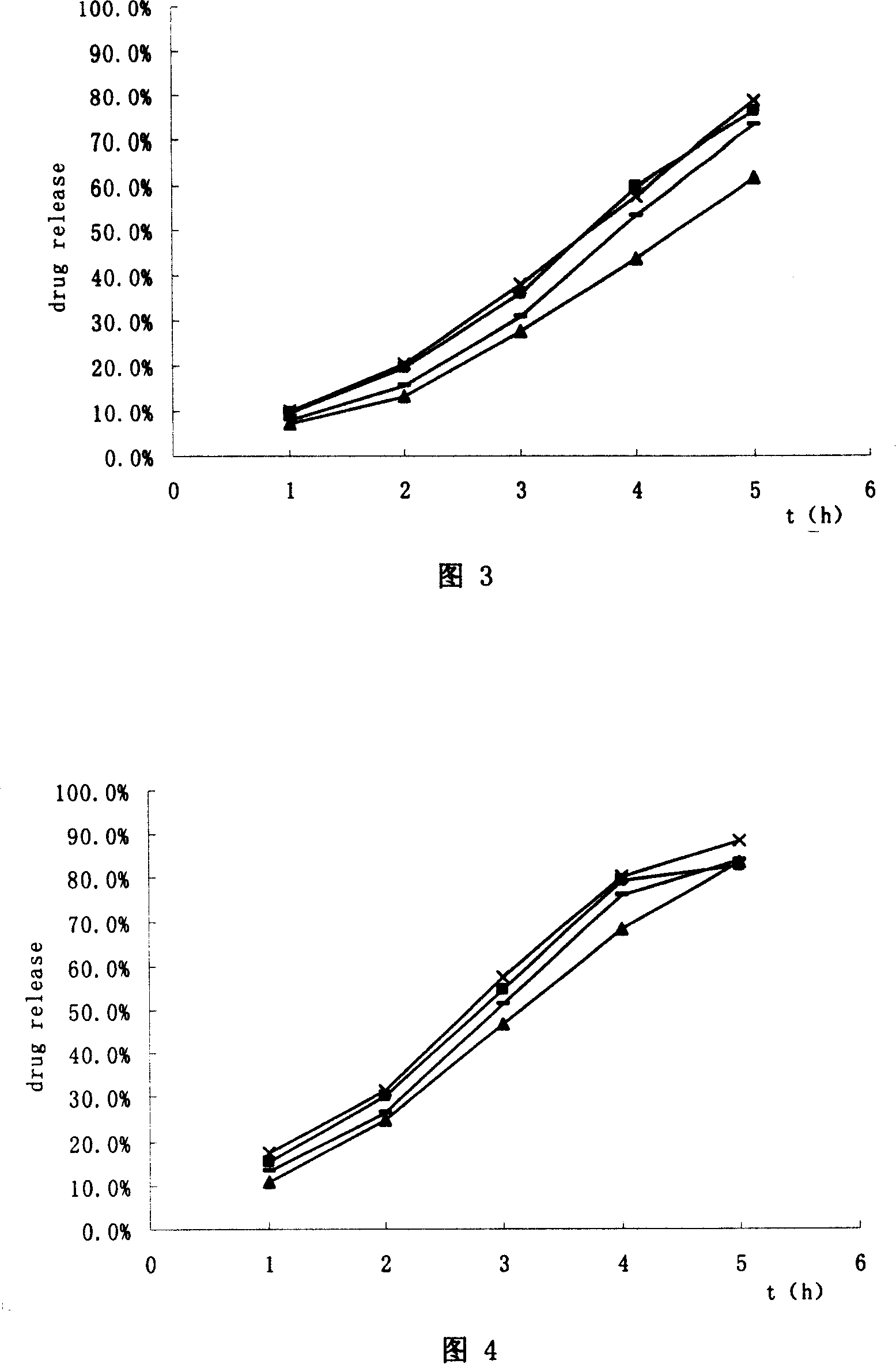

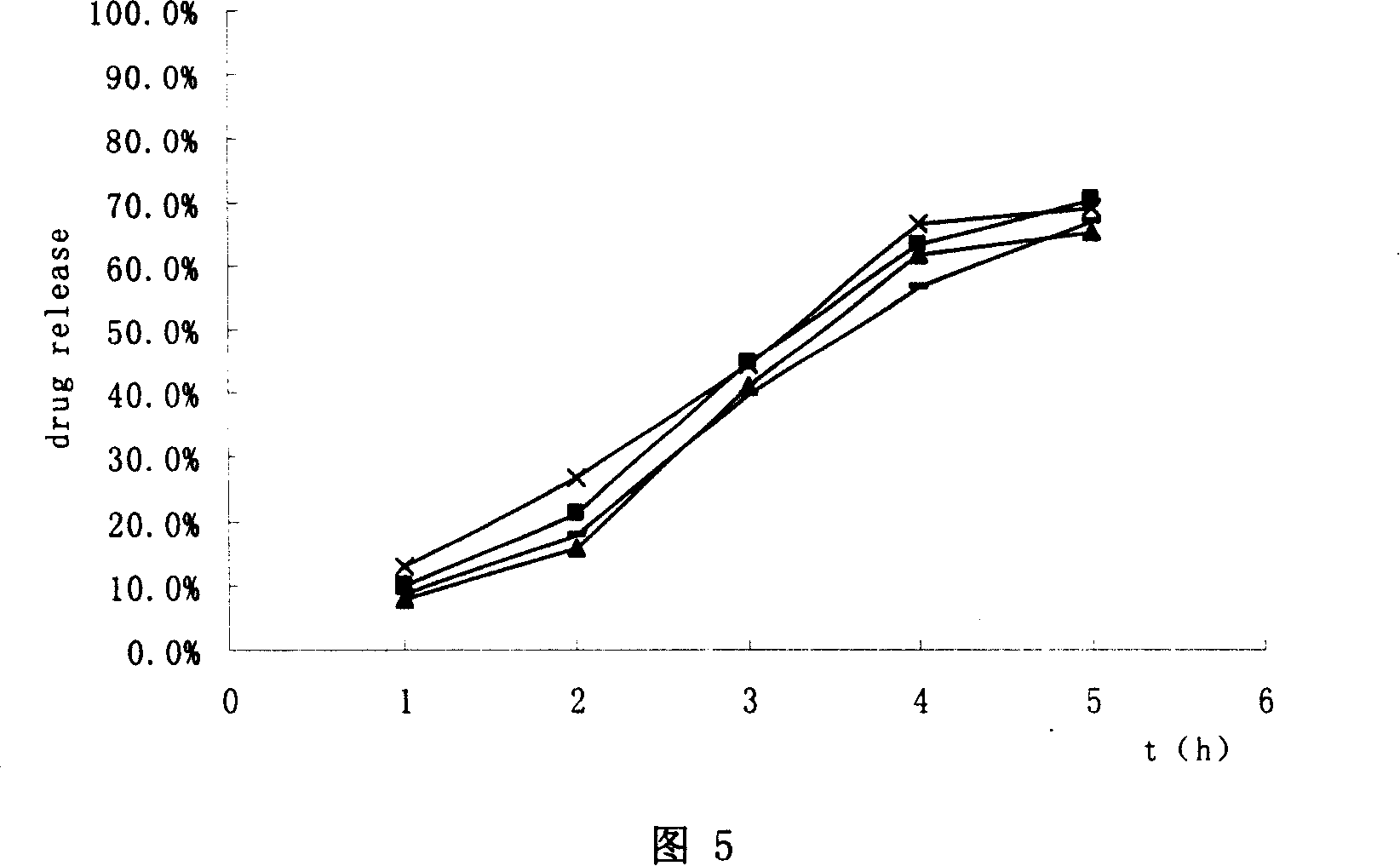

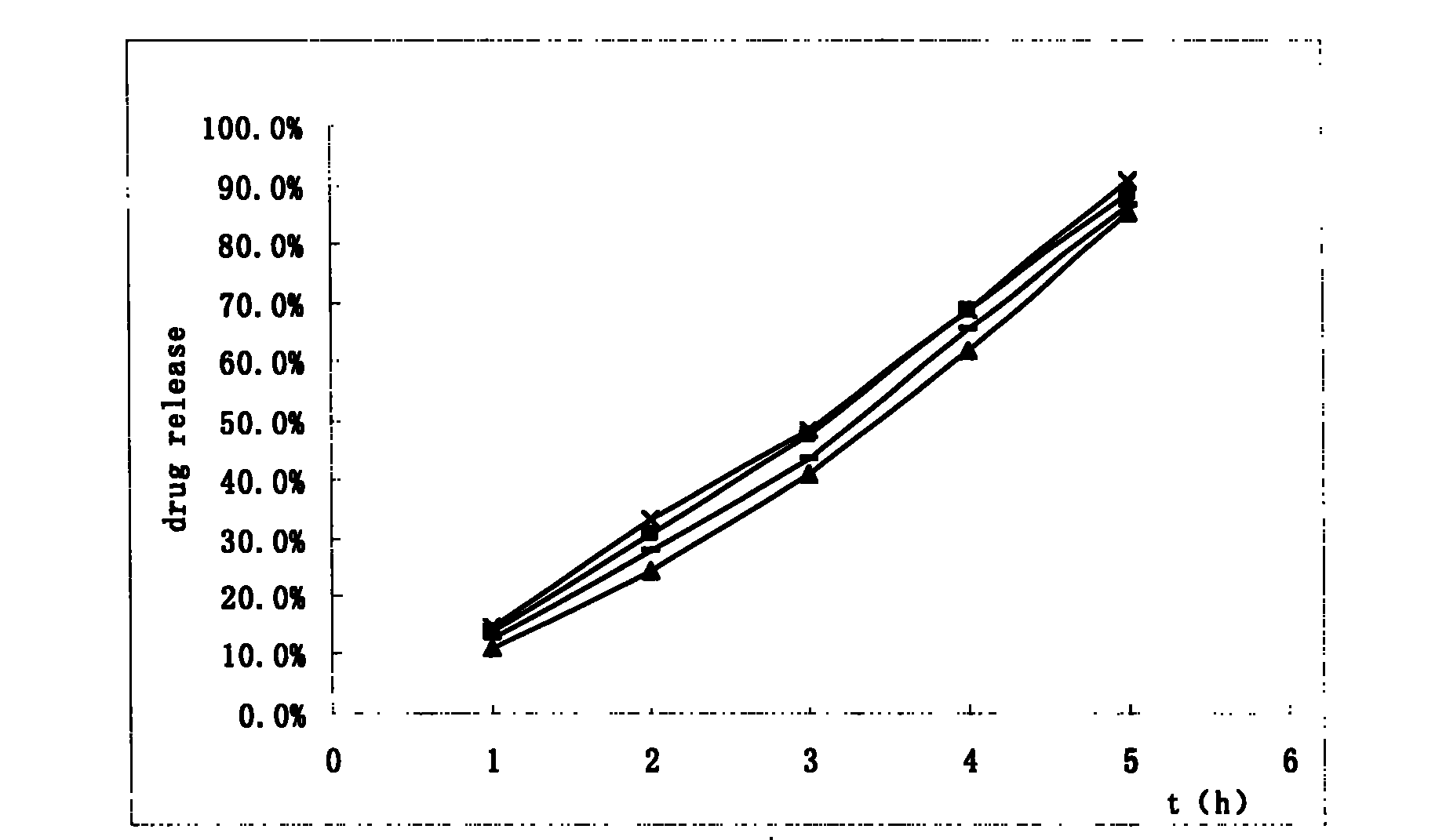

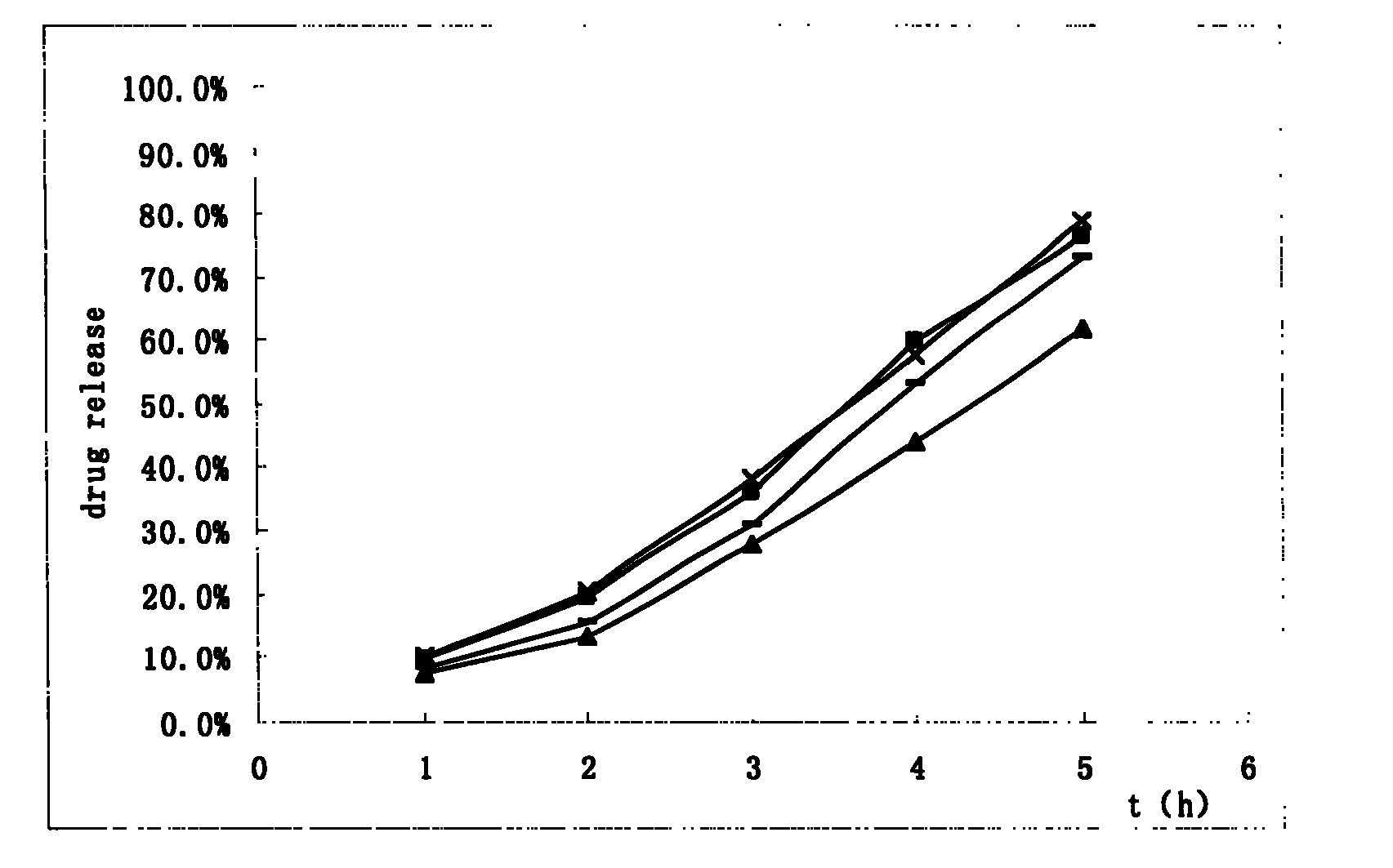

ActiveCN101125134APrecise Controlled ReleaseControl releaseOrganic active ingredientsPharmaceutical delivery mechanismSide effectOral medication

The present invention provides a tamsulosin hydrochloride sustained-release capsule. The tamsulosin hydrochloride sustained-release capsule of the present invention can avoid the sudden release of the drug tablets and the performance differences generated from the gastric emptying differences, display minor food effect or do not display food effect, and obtain the stable curve of the plasma drug concentration and longer action time simultaneously, so as to reduce the occurrence of cardiovascular side effects, greatly improve the safety, effectiveness and compliance of the medication for the patients. The tamsulosin hydrochloride sustained-release capsule of the present invention can ensure the sustained and regular release of the main ingredient tamsulosin hydrochloride after the oral administration, and the present invention is characterized by convenient administration, durable function, stable efficacy, fewer side effects and so on.

Owner:CHANGZHOU NO 4 PHARMA FACTORY

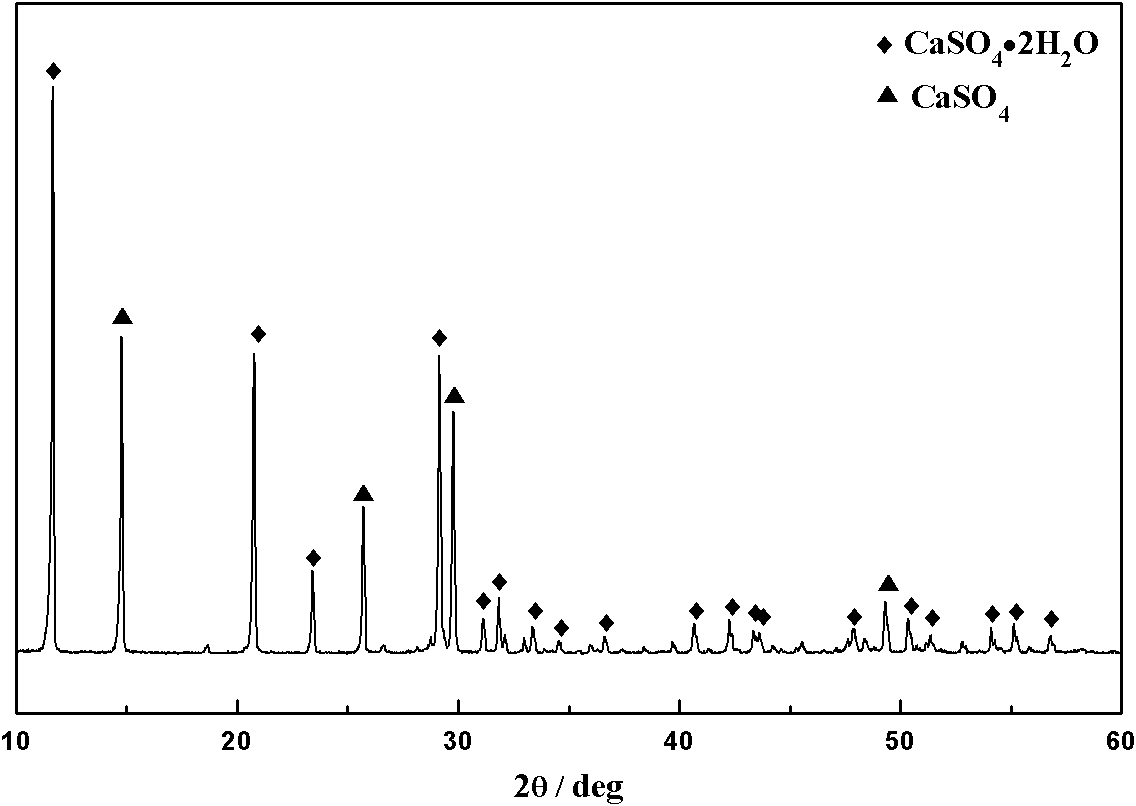

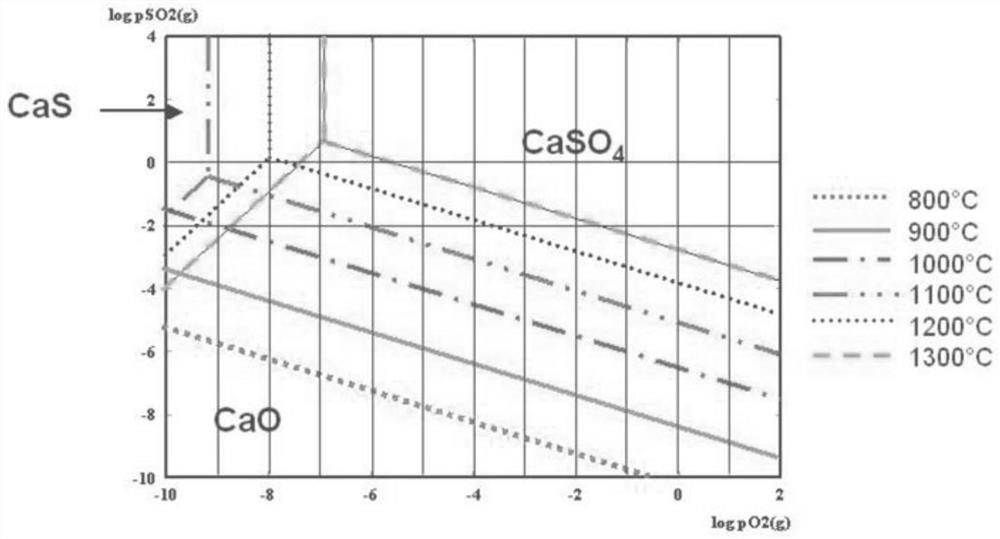

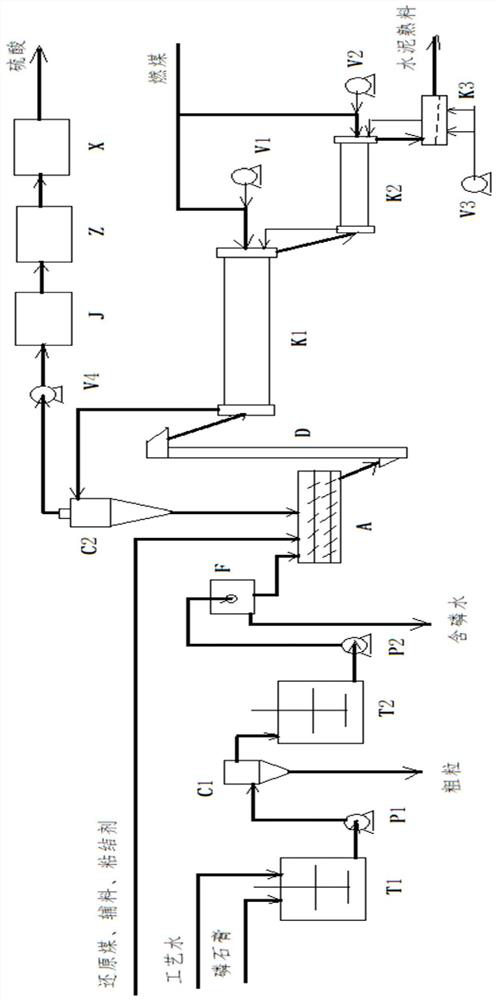

Production method for producing cement and sulfuric acid from phosphogypsum

InactiveCN112694067AImprove product qualityEliminate the environmental problems of stackingSulfur compoundsCeramic production plantsReductive decompositionDust control

The invention discloses a production method for producing cement and sulfuric acid by using phosphogypsum. The method comprises the following steps: carrying out pretreatment purification on phosphogypsum to reduce insoluble phosphorus, water-soluble phosphorus impurities and most free water in the phosphogypsum, kneading with a reducing agent, granulating, and directly feeding the material into a reductive decomposition integrated rotary kiln with fluidization preheating function; controlling a gas phase atmosphere to perform step-by-step heating, drying, dehydration and reductive decomposition under the combustion of the pulverized coal; sulfur dioxide gas generated after reductive decomposition is used for producing sulfuric acid after being subjected to dust removal and purification; and the reduced and decomposed material enters an oxidation calcining kiln for cement clinker sintering, and the gas-phase atmosphere is controlled under the combustion of pulverized coal for heating, mineralizing and sintering to obtain the cement clinker. Compared with the prior art, the production method for producing cement and co-producing sulfuric acid by using phosphogypsum has the advantages that the coal consumption for reduction and firing is reduced, the production efficiency and the product quality are improved, the device investment is saved, the economic benefit of producers is increased, and the environmental protection problem of phosphogypsum stacking treatment is eliminated.

Owner:CHENGDU QIANLIJIN TECHCAL INNOVATION CO LTD

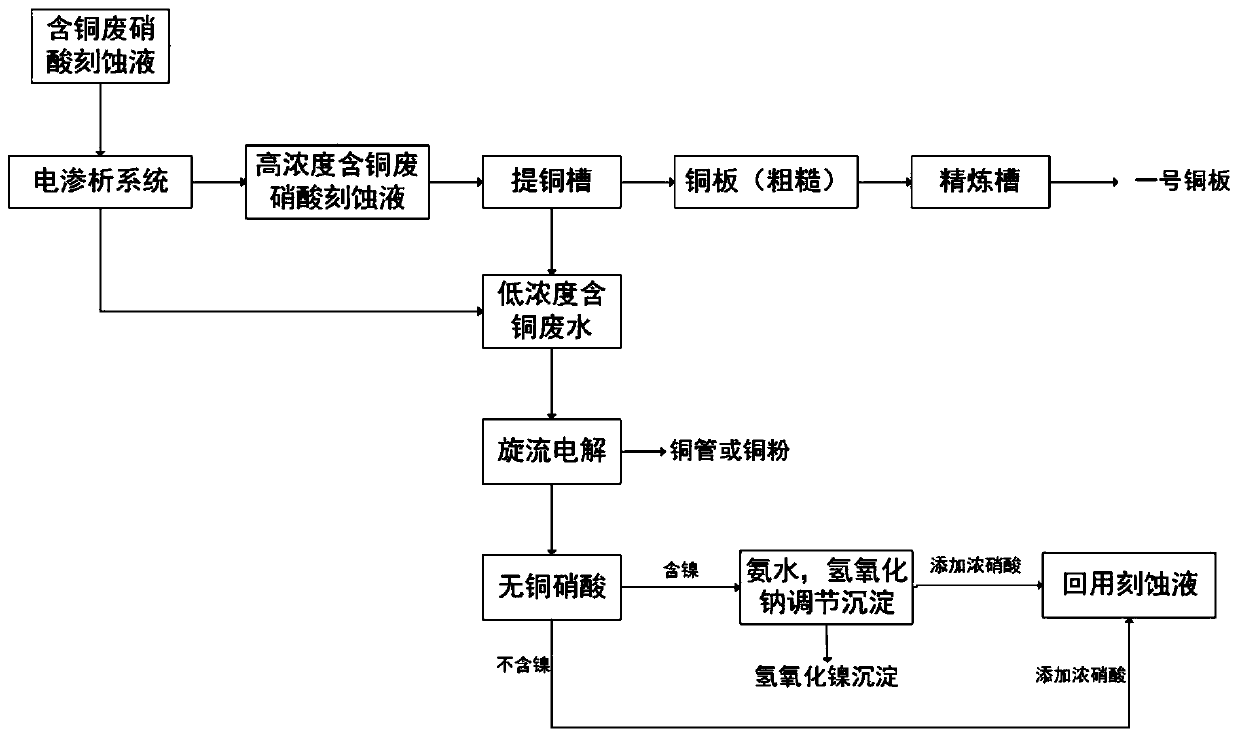

Method for recovery and reusing of etching liquid containing copper ions and nitrate

ActiveCN109868476AHigh economic valueImprove automationPhotography auxillary processesProcess efficiency improvementHigh concentrationElectrolysis

The invention discloses a method for recovery and reusing of etching liquid containing copper ions and nitrate, and belongs to the technical field of etching liquid recovery. The method comprises thefollowing steps that a high-concentration copper-containing solution and a low-concentration copper-containing solution are obtained from the etching liquid through an electrodialysis device, the high-concentration copper-containing solution enters a copper extraction tank to be subjected to circulating electrolysis, thus the copper ions are reduced to generate copper elementary substances, the copper elementary substances are deposited on a copper electrode serving as a cathode, the cathode serves as an anode in a refining tank, thus the anode in the refining tank is dissolved out on the cathode, and a copper plate is obtained; electrolyte, with the low copper ion concentration, obtained in the copper extraction tank and the low-concentration copper-containing solution generated in the electrodialysis device are subjected to swirling flow electrolysis, and thus a copper pipe and / or copper powder are / is obtained; and concentrated nitric acid is added into clear liquid, and thus the etching liquid is recycled. If the etching liquid contains nickel ions, after electrolysis is completed, lye is added to adjust pH, and thus the nickel ions are precipitated. Copper recycled through themethod is high in economic value, a chemical agent is not put, and secondary pollution is avoided; and the etching liquid is regenerated and recycled, and resources are maximally utilized.

Owner:湖北永绍科技股份有限公司 +1

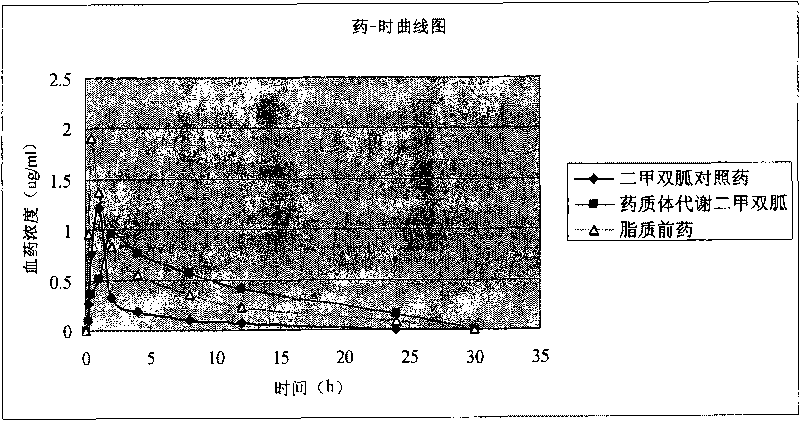

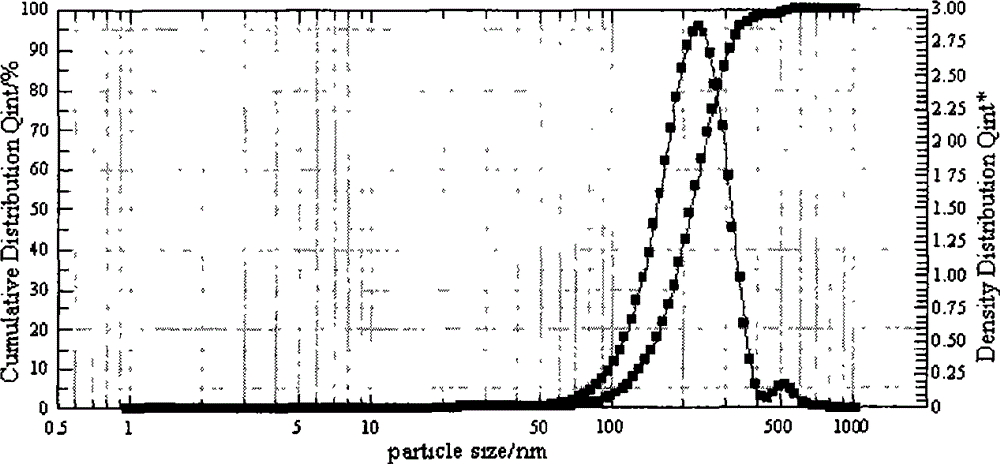

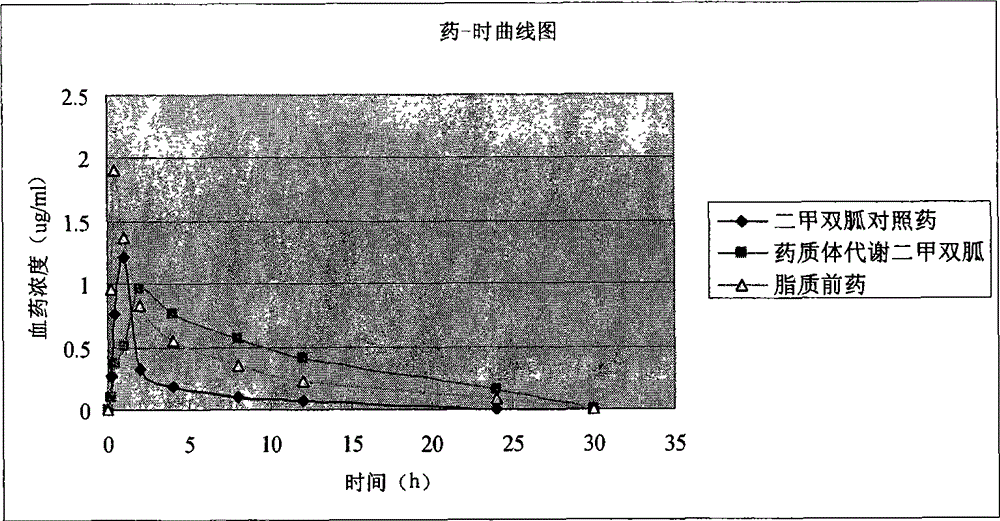

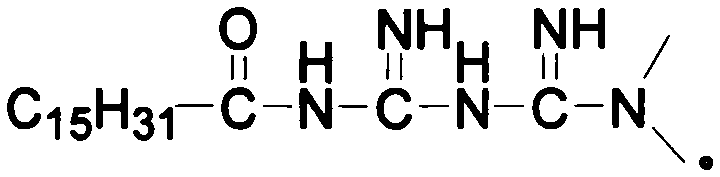

Lipid prodrug of drug containing guanidino and pharmacosome thereof

InactiveCN101723857ASolve the problem of low bioavailability due to difficulty in crossing biofilmsSolve the problem of low bioavailabilityOrganic active ingredientsOrganic chemistryLong chain fatty acidLipid formation

The invention relates to a lipid prodrug of a drug containing guanidino and pharmacosome thereof. The lipid prodrug is a medicinal compound which is in covalent union with long-chain fatty acid with a single chain or double chains and contains guanidino. The pharmacosome is formed in such a way that the lipid prodrug disperses freely in a proper medium, is orderly arranged into a single-layer or double-layer structure, and is automatically assembled finally. The pharmacosome has biological targeting property, can effectively enhance the bioavailability of the drug and opens up a novel concept for solving the problems of poor transmembrane capability, low bioavailability and the like of a water soluble drug.

Owner:INST OF PHARMACOLOGY & TOXICOLOGY ACAD OF MILITARY MEDICAL SCI P L A

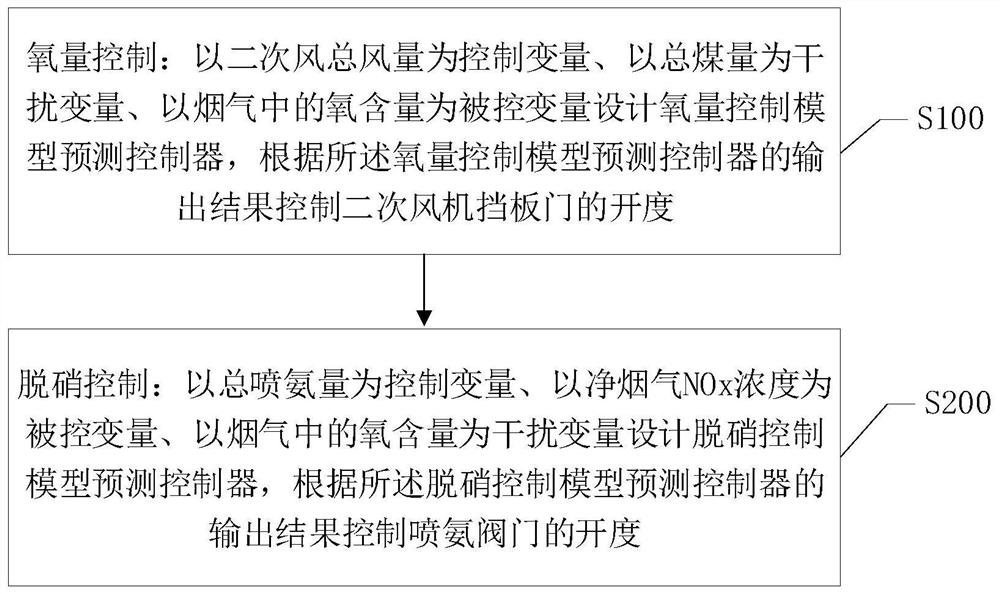

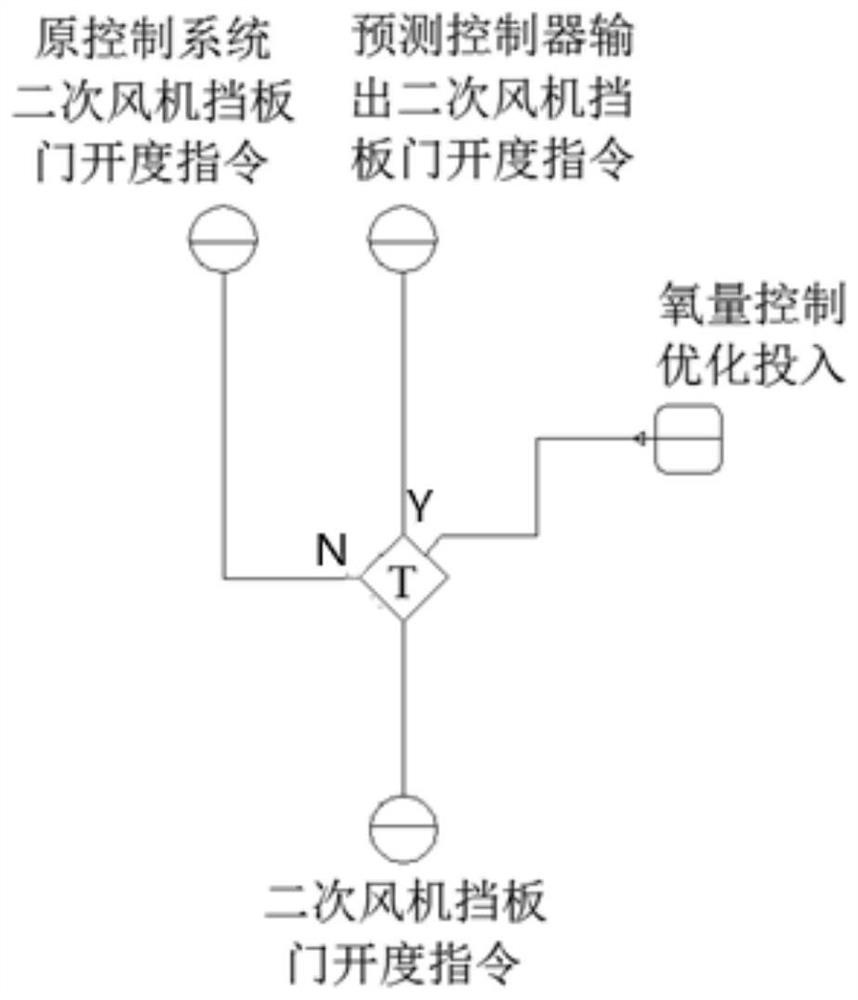

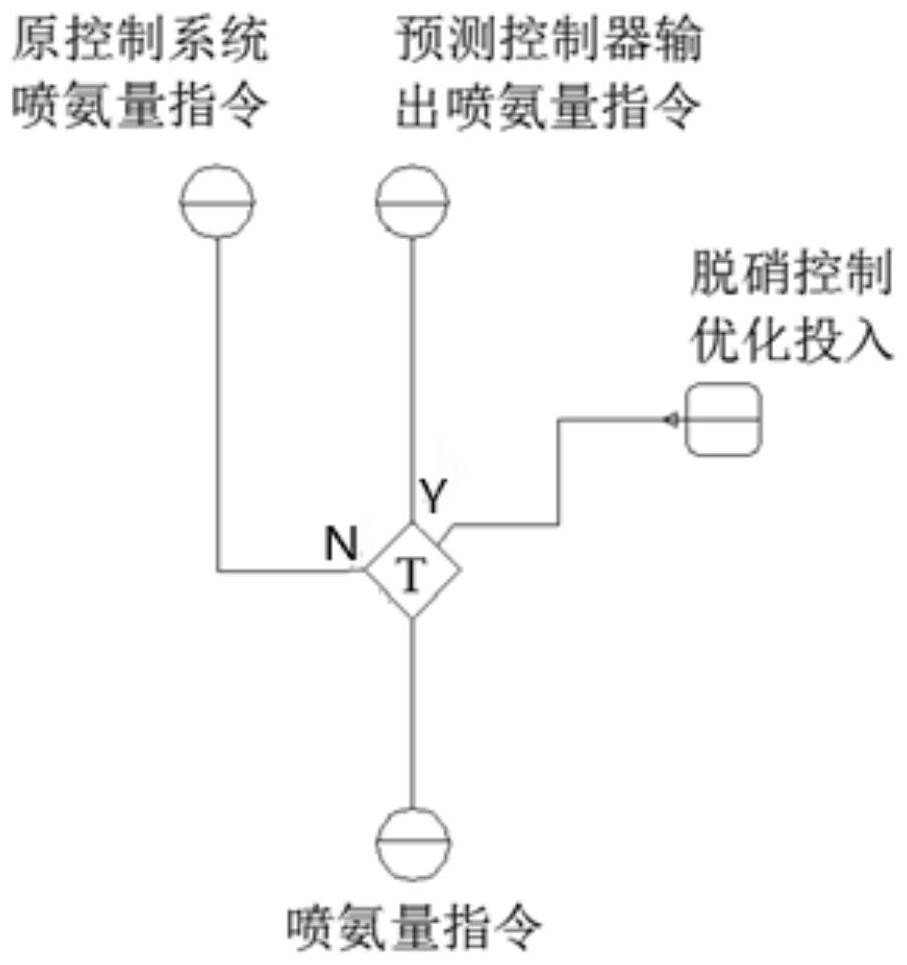

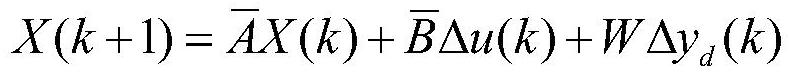

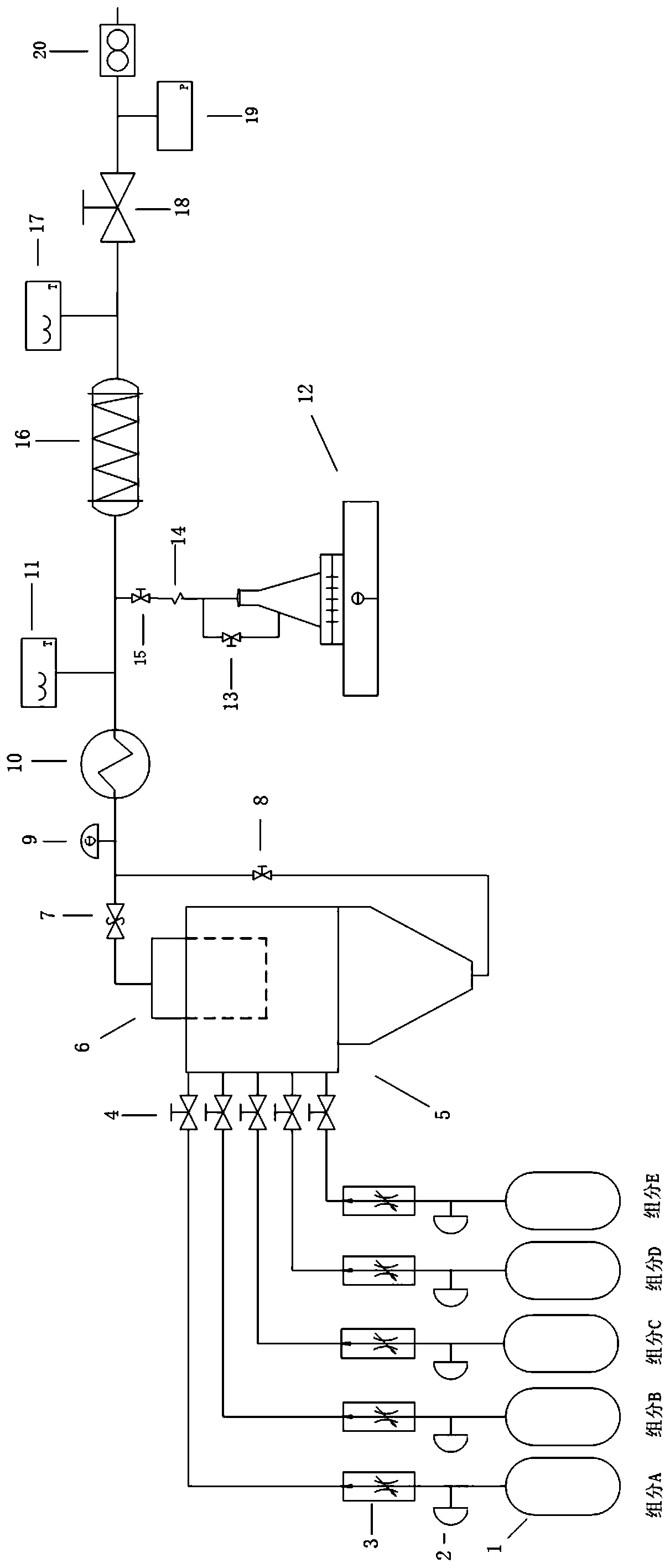

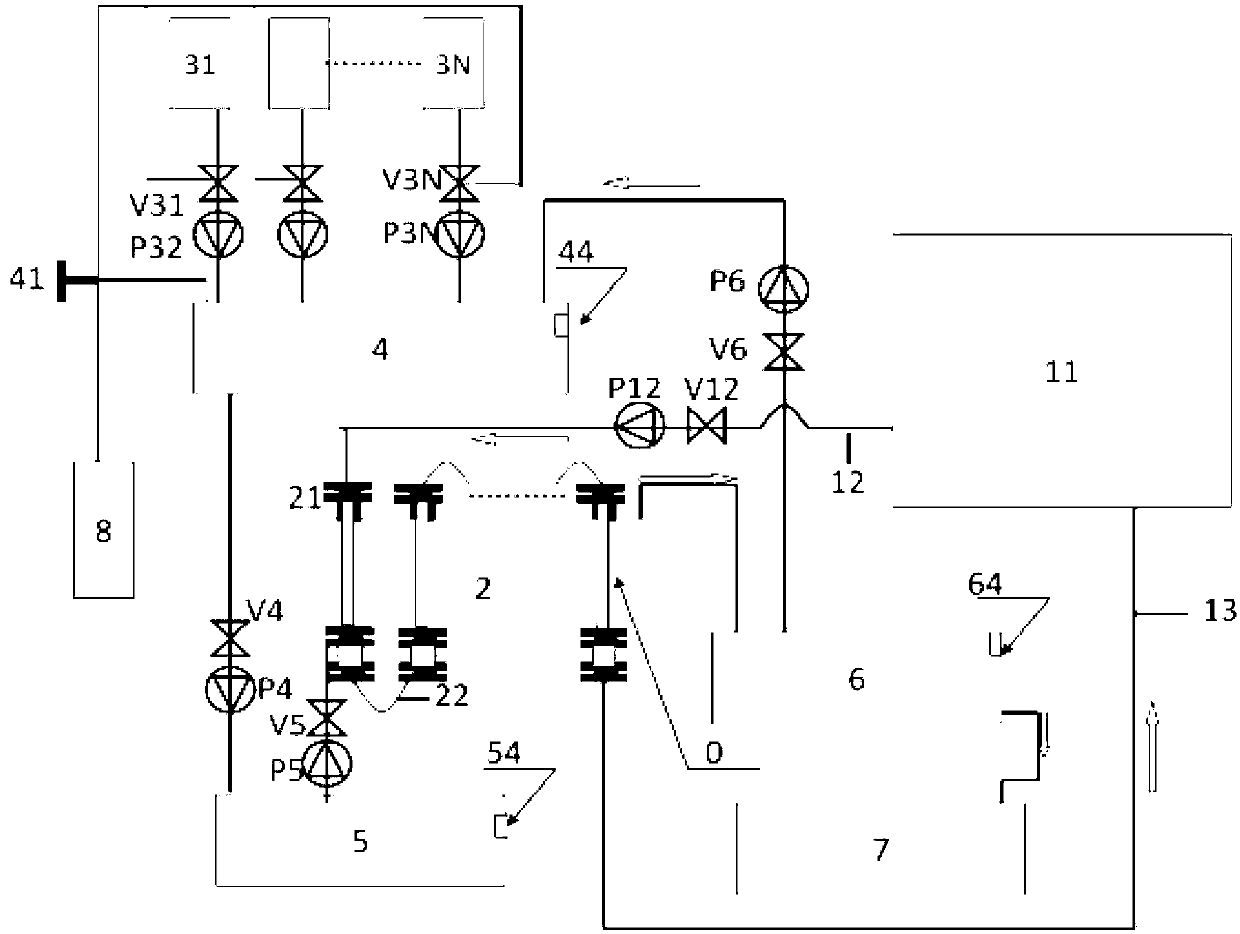

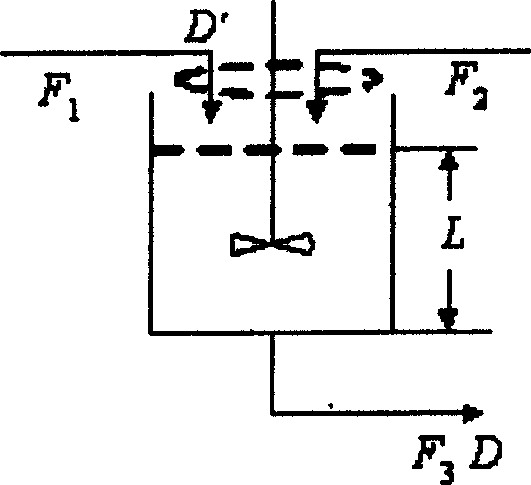

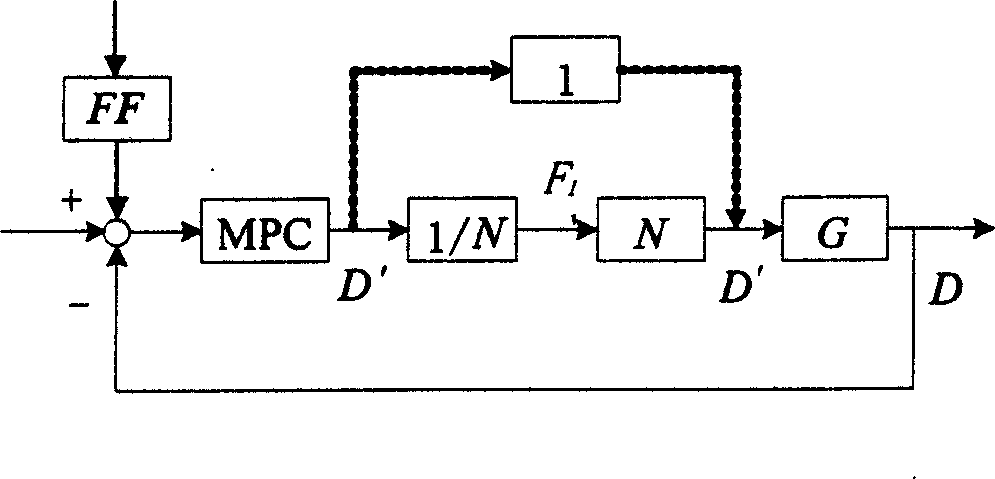

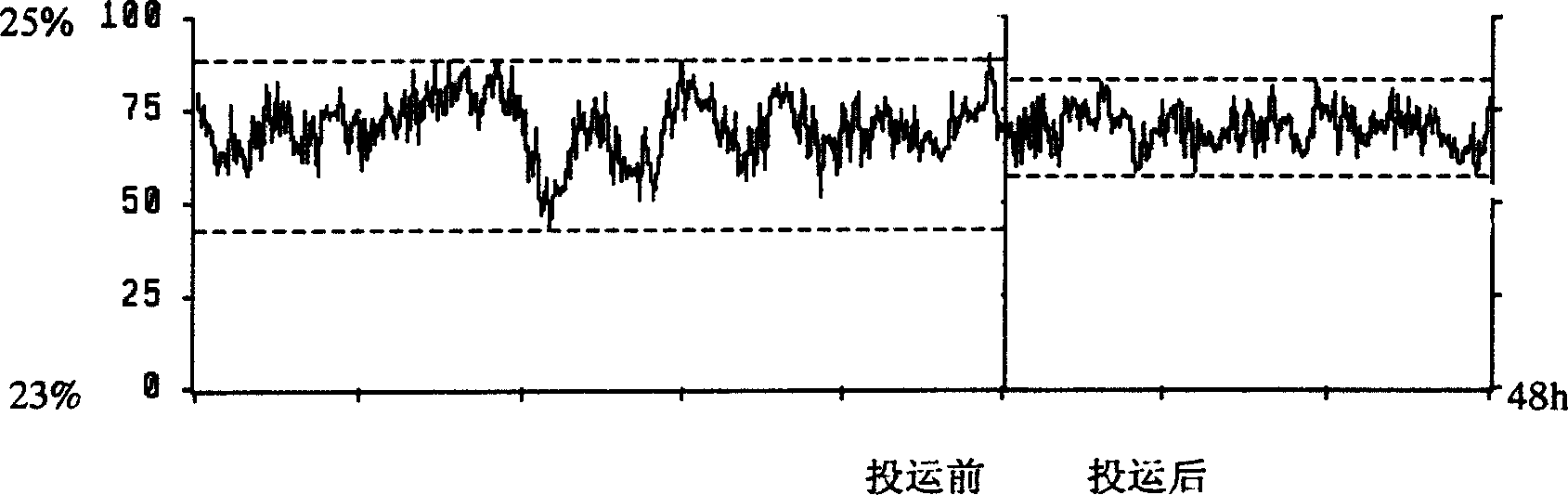

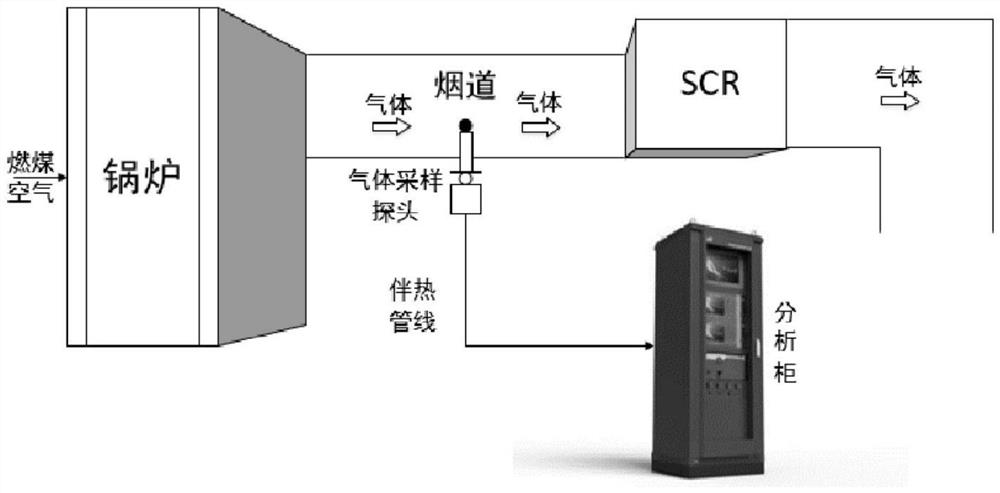

SNCR denitration control method and device for circulating fluidized bed unit and storage medium

ActiveCN111841276ASmall fluctuations in concentrationReduce volatilityDispersed particle separationAir volumeControl system

The invention discloses an SNCR denitration control method and device for a circulating fluidized bed unit and a storage medium. The method comprises the following steps: S1, oxygen amount control: designing an oxygen amount control model prediction controller by taking the total air amount of secondary air as a control variable, the total coal amount as an interference variable and the oxygen content in flue gas as a controlled variable, and controlling the opening degree of a baffle door of a secondary air fan according to an output result of the oxygen amount control model prediction controller; and S2, denitration control: designing a denitration control model prediction controller by taking the total ammonia spraying amount as a control variable, taking the NOx concentration of the clean flue gas as a controlled variable and taking the oxygen content in the flue gas as an interference variable, and controlling the opening degree of an ammonia spraying valve according to an outputresult of the denitration control model prediction controller. The fluctuation range of the NOx generation amount under the variable load working condition can be reduced through oxygen amount controloptimization, oxygen amount measuring points serve as feedforward control through denitration control optimization, the delay time of a control system can be shortened, and the ammonia spraying amount can be saved through combination of the oxygen amount control optimization and the denitration control optimization.

Owner:YANTAI LONGYUAN POWER TECH

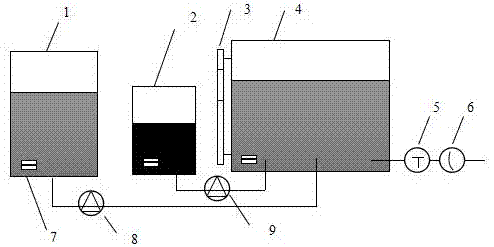

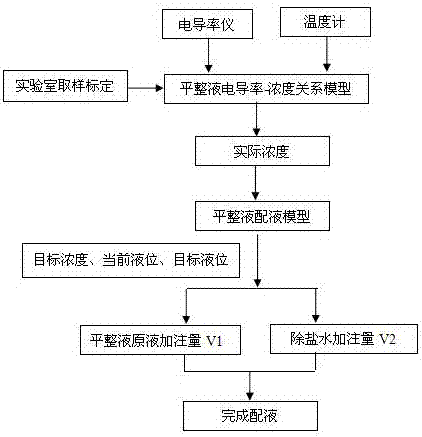

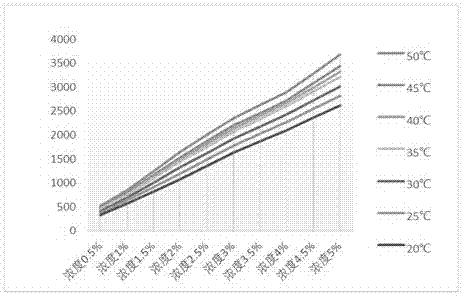

Automatic tempering liquid dispensing method based on online conductivity measurement

InactiveCN107272755AStable concentrationSmall fluctuations in concentrationControlling ratio of multiple fluid flowsMaterial resistanceComputer scienceElectrical resistivity and conductivity

The invention belongs to the tempering liquid dispensing technology field and particularly relates to an automatic tempering liquid dispensing method based on online conductivity measurement. The automatic tempering liquid dispensing method comprises steps of a tempering liquid conductivity-concentration relationship model, online conductivity detection, a tempering liquid dispensing model and a dispensing execution device. The method is advantaged in that tempering liquid maintenance efficiency is substantially improved, and manpower cost is reduced.

Owner:SD STEEL RIZHAO CO LTD

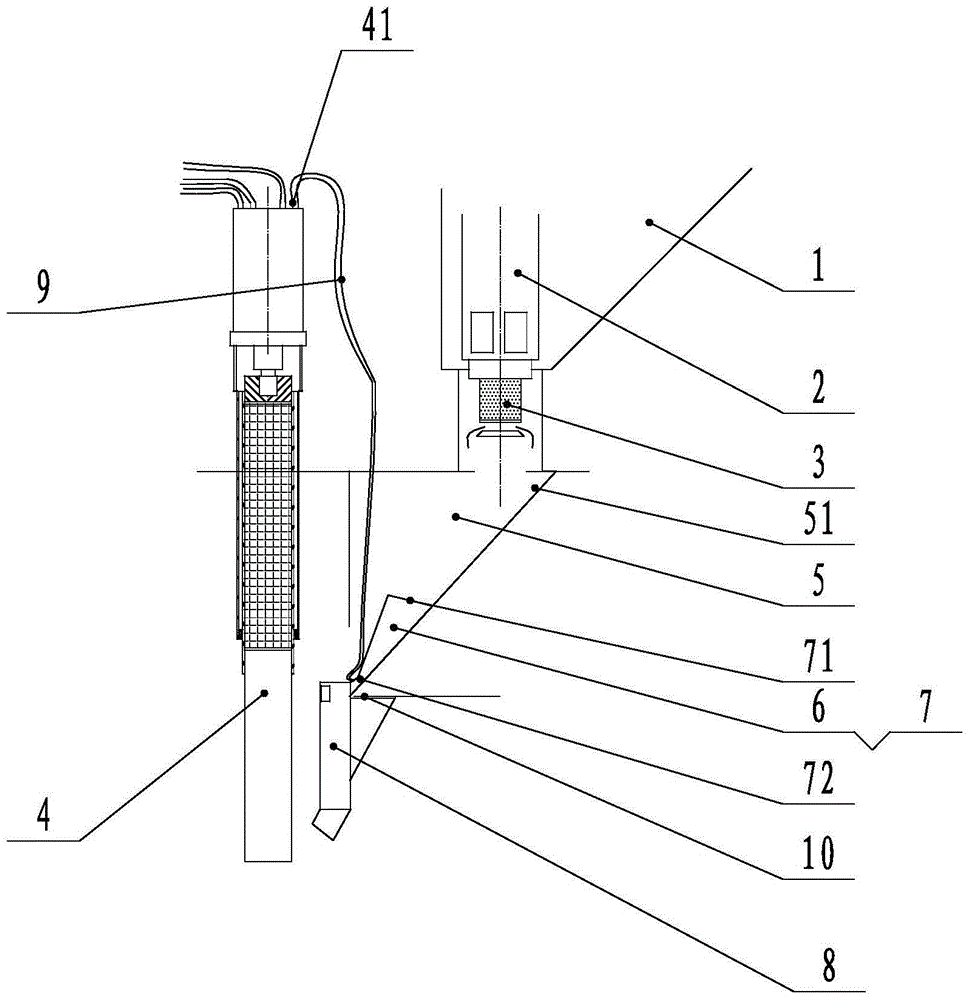

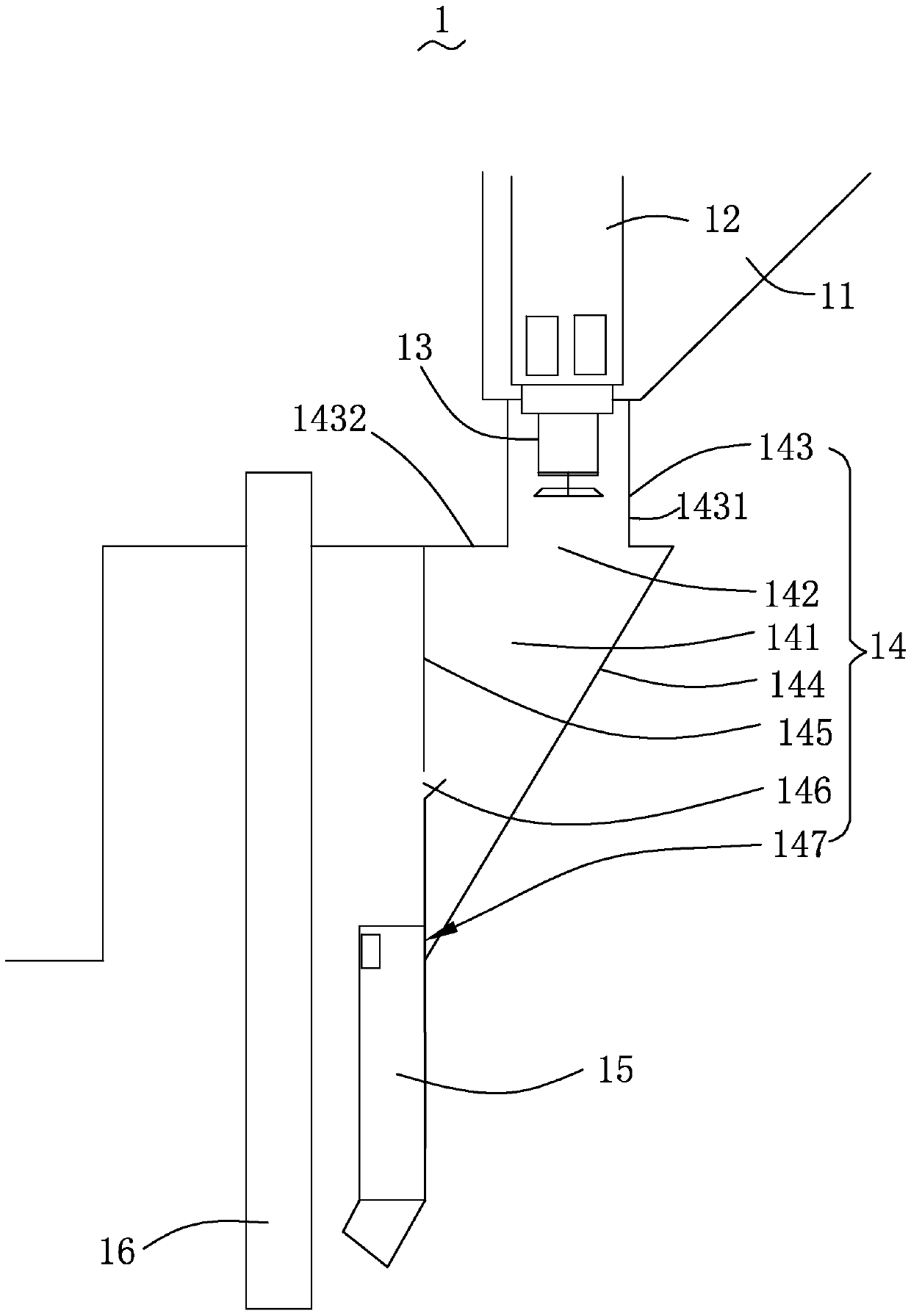

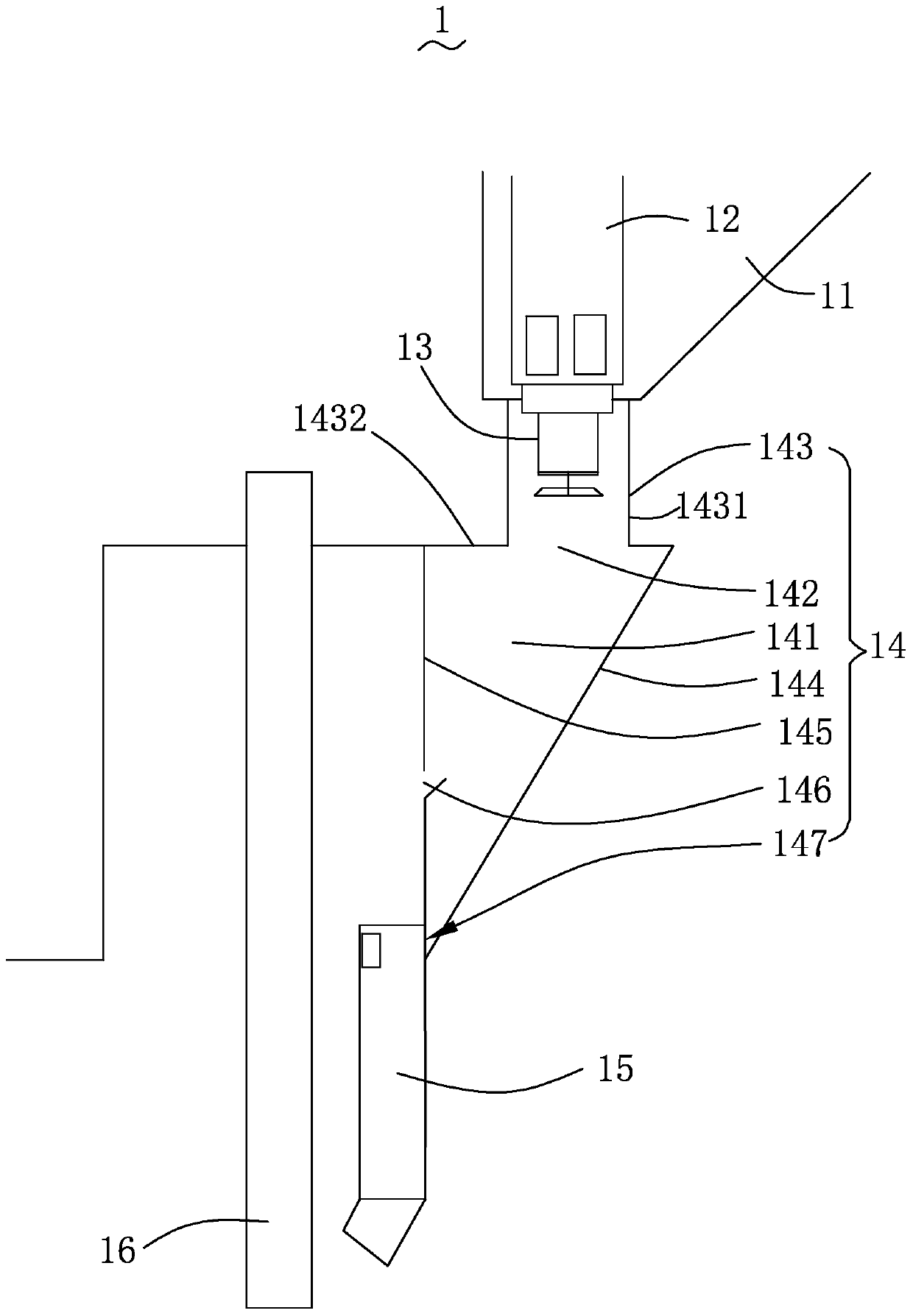

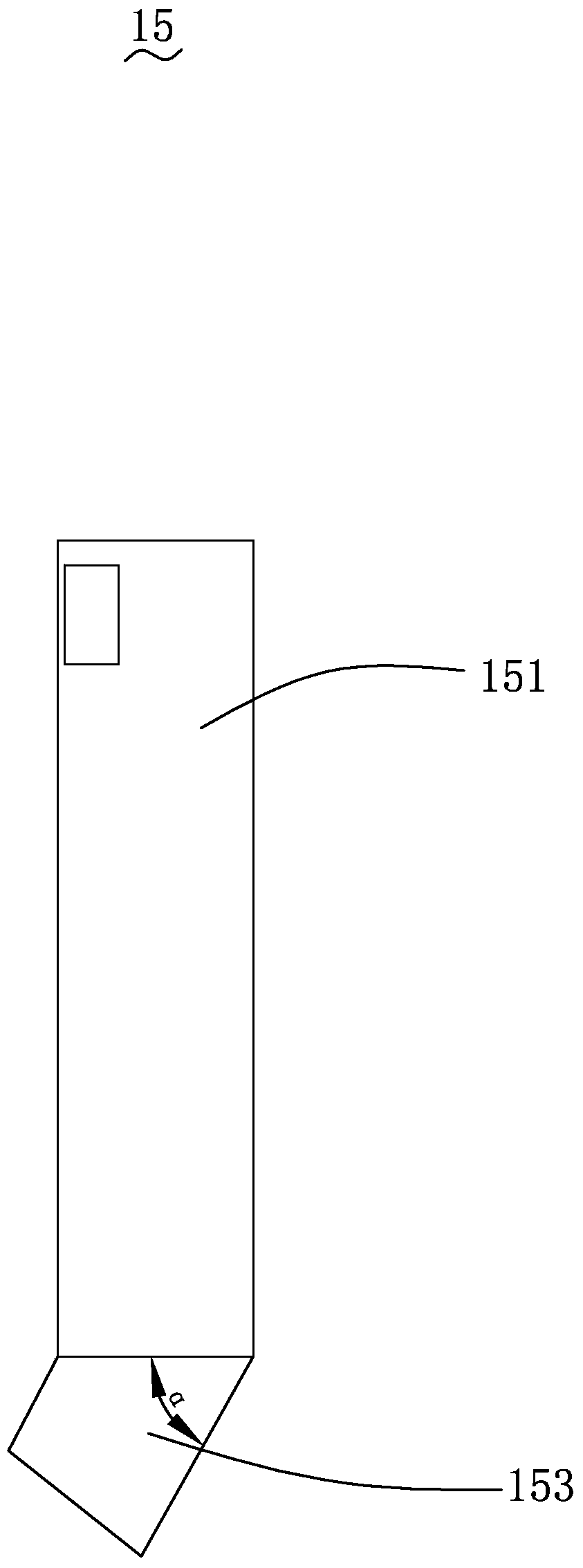

Continuous aluminum oxide feeding equipment

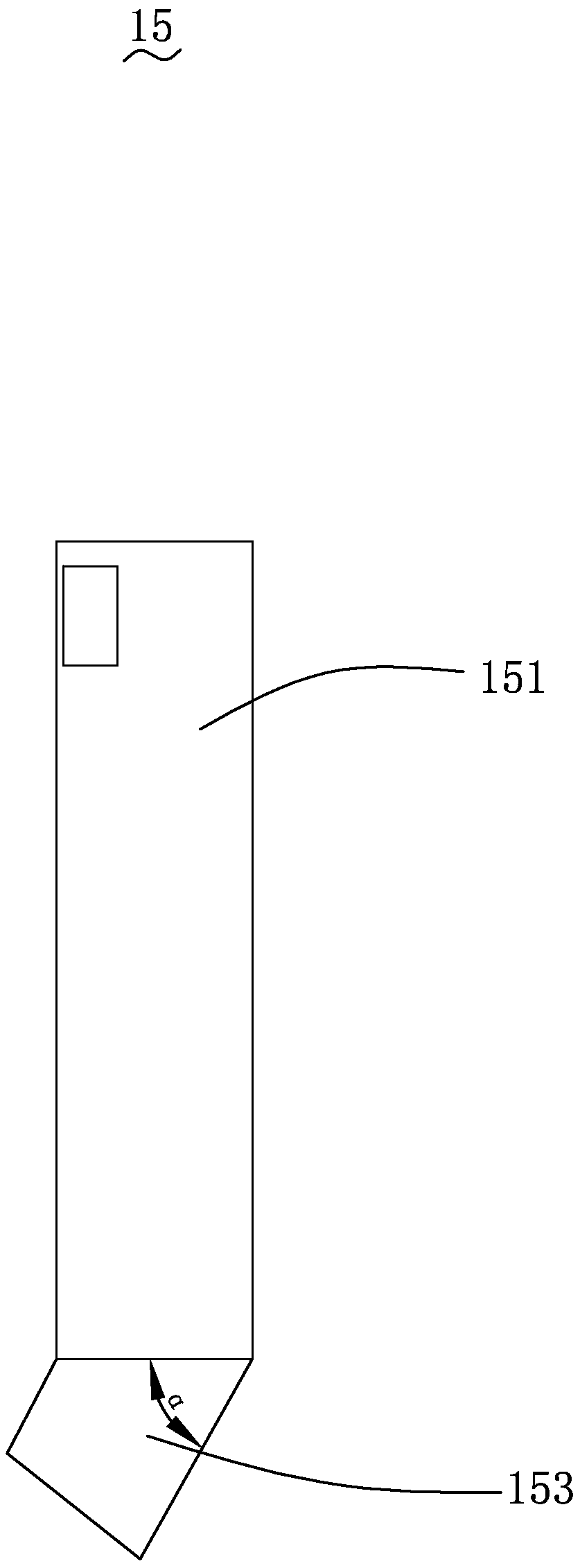

ActiveCN105671594AReduce temperature and alumina concentration fluctuationsImprove current efficiencyComposite materialOxide

The invention discloses continuous aluminum oxide feeding equipment which comprises a material box, a feeding air cylinder, a fixed container, a crust breaking head, a material passing frame, an oblique plate, a buffer and a feeding pipe. The feeding pipe is led to the bottom of the crust breaking head. The continuous aluminum oxide feeding equipment further comprises an air pipe which is arranged at a buffer outlet and used for blowing air to the buffer outlet. Compared with the prior art, the continuous aluminum oxide feeding equipment has the beneficial effects that (1) aluminum oxide is made to enter an electrolyte slowly, and the temperature fluctuation of an electrolytic cell and the concentration fluctuation of the aluminum oxide are reduced, so that the current efficiency is improved, and energy consumption is reduced; (2) the aluminum oxide is made to have enough time to be melted into the electrolyte, so that sediment at the furnace bottom is reduced, the pressure drop at the furnace bottom is reduced, and energy consumption is reduced; (3) the aluminum oxide is made to enter the electrolyte slowly through a pipeline, and the crust breaking head is prevented from being impacted so that the aluminum oxide can be prevented from being dispersed, the actual amount of materials entering the electrolytic cell is increased, and the effect coefficient is decreased; and (4) large particles in the aluminum oxide are blown away through the gas reverse blowing principle, so that blockage is eliminated, and the hole blockage phenomenon can be effectively prevented.

Owner:SNTO TECH GRP

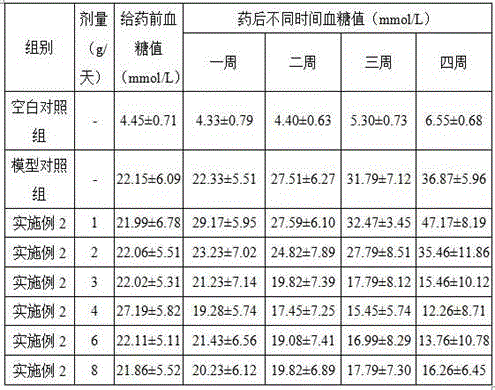

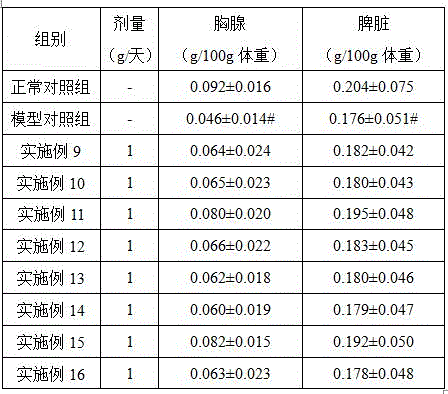

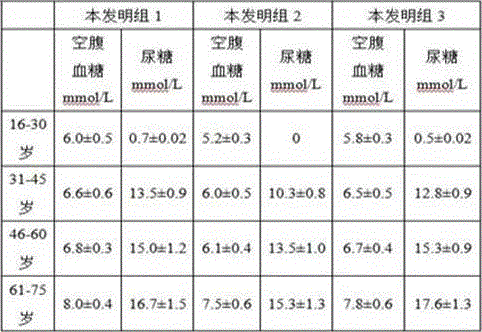

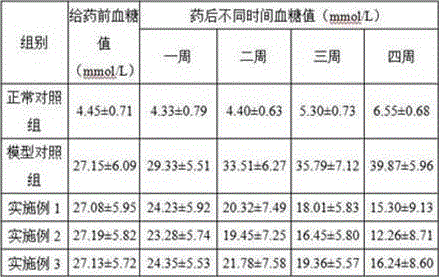

Medicine used for treating diabetes mellitus

PendingCN105641681ALower blood sugarSmall fluctuations in concentrationOrganic active ingredientsPeptide/protein ingredientsAcute hyperglycaemiaSide effect

The invention provides medicine used for treating diabetes mellitus and complications thereof. The medicine is glycoprotein, or a mixture of polysaccharide and protein, or polypeptide or protein. The medicine has an obvious effect of reducing blood glucose of a rat diabetes model, and in the four weeks after the medicine is taken, the blood glucose of a rat is reduced from 27.06-27.19 mmol / L to 11.26-23.41 mmol / L. The medicine is used for treating diabetes mellitus continuously for four weeks, the result shows that a blood glucose value can be reduced obviously, the content of urine protein and the content of urea nitrogen in serum are reduced, the content of triglyceride in the serum is reduced, and the thymus indexes of the rat are increased. The medicine has the obvious effect of reducing the blood glucose and urine sugar of patients with the diabetes mellitus; meanwhile, the medicine has a function of adjusting hyperglycemia, hypertension, hyperlipidemia and high blood viscosity threatening the diabetes mellitus severely. The medicine has the advantages of being safe, efficient and free of side effects, and has the obvious effects of reducing the blood glucose, cholesterol and triglyceride.

Owner:徐宝贞

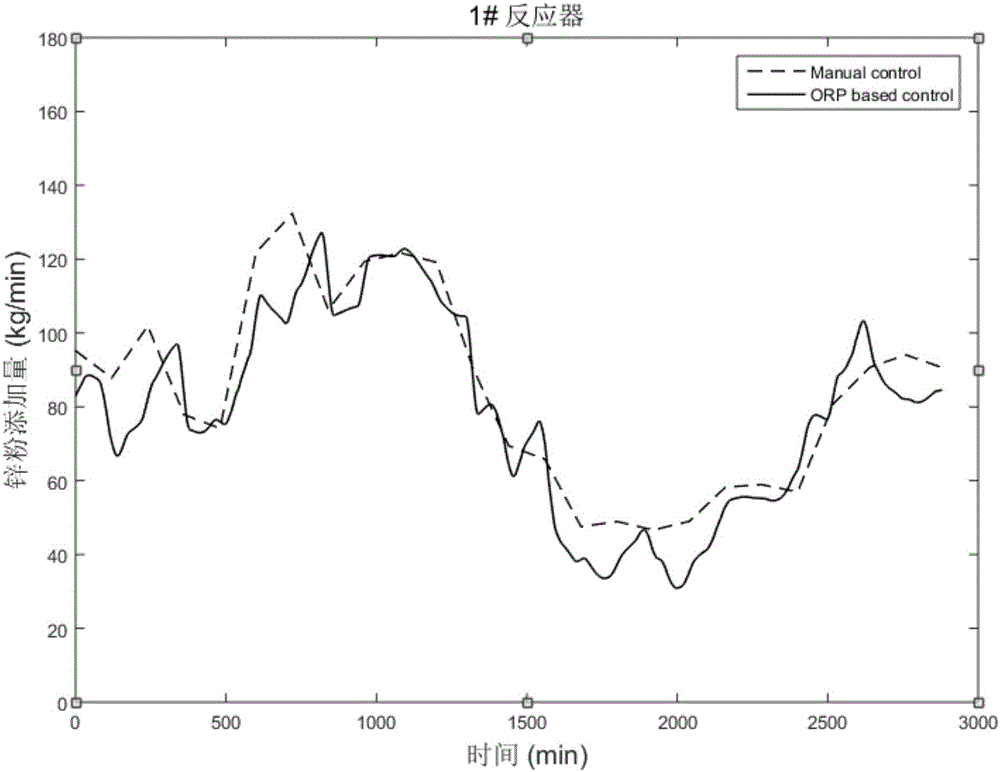

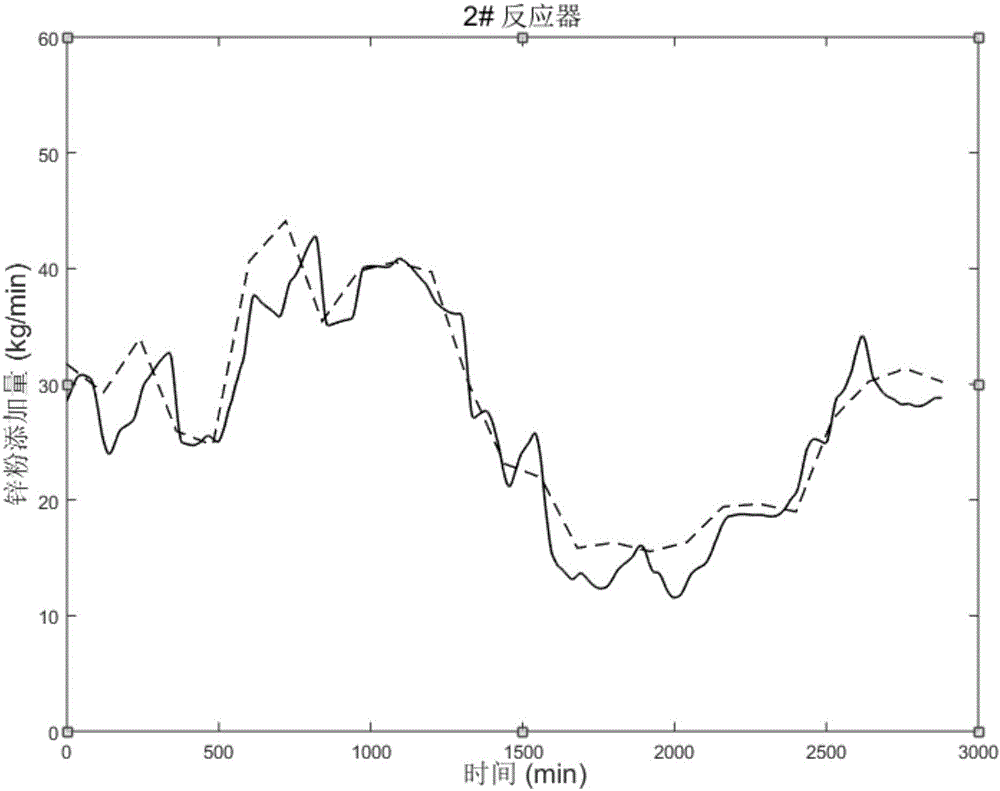

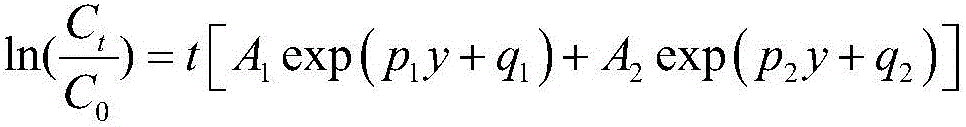

Optimal control method based on oxidation-reduction potential and used for liquid zinc purification and copper removal process

ActiveCN105950866APlay a guiding roleStable productionProcess efficiency improvementAdaptive controlRelational modelPhysical chemistry

The invention discloses an optimal control method based on an oxidation-reduction potential and used for the liquid zinc purification and copper removal process. Firstly, a relational model of the oxidation-reduction potential (ORP) and the copper ion concentration and a zinc powder adding amount control model are established and subjected to parameter identification; secondly, during zinc powder adding control, field liquid zinc flow, the ion concentration at a reactor inlet and ORP data are collected and compared with data used for parameter identification, and adjusting instructions are determined according to the comparison result; and thirdly, the zinc powder adding amount is determined according to relevant control rules according to the sent adjusting instructions, so that adding of zinc powder is controlled.

Owner:CENT SOUTH UNIV

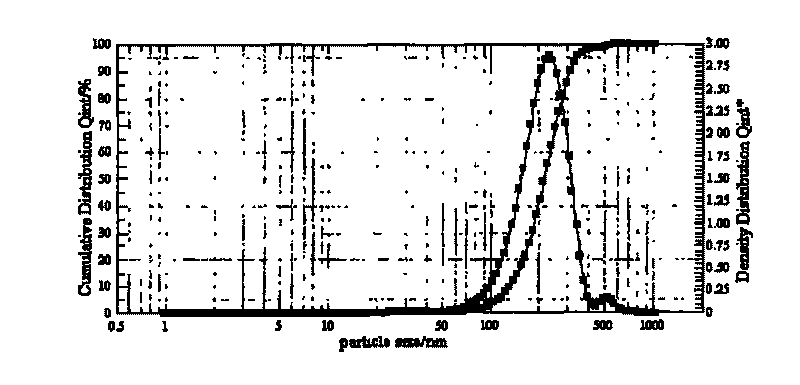

Full-automatic high-efficiency filter leakage detection system

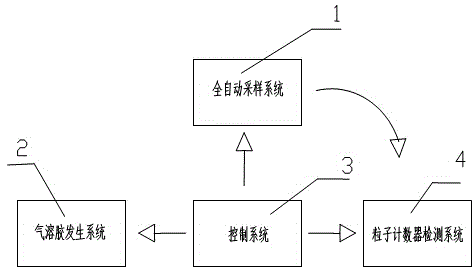

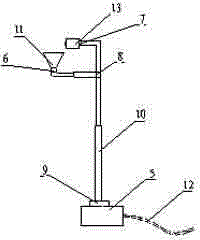

InactiveCN105319027ASmall fluctuationLabor savingDetection of fluid at leakage pointNon-electrical signal transmission systemsEngineeringControl system

The invention discloses a full-automatic high-efficiency filter leakage detection system, which is composed of an aerosol generation system, a particle counter detection system, a full-automatic sampling system and a control system, wherein the full-automatic sampling system can realize accurate positioning and improves the reproducibility of a detection result, the control system can realize effective monitoring for the whole device, and the particle counter detection system improves the accuracy and the sensitivity of detection. The whole device has the characteristics of high automation degree, high precision and accuracy and good reproducibility.

Owner:QINGDAO LANNONGGU AGRI PROD RES & DEV

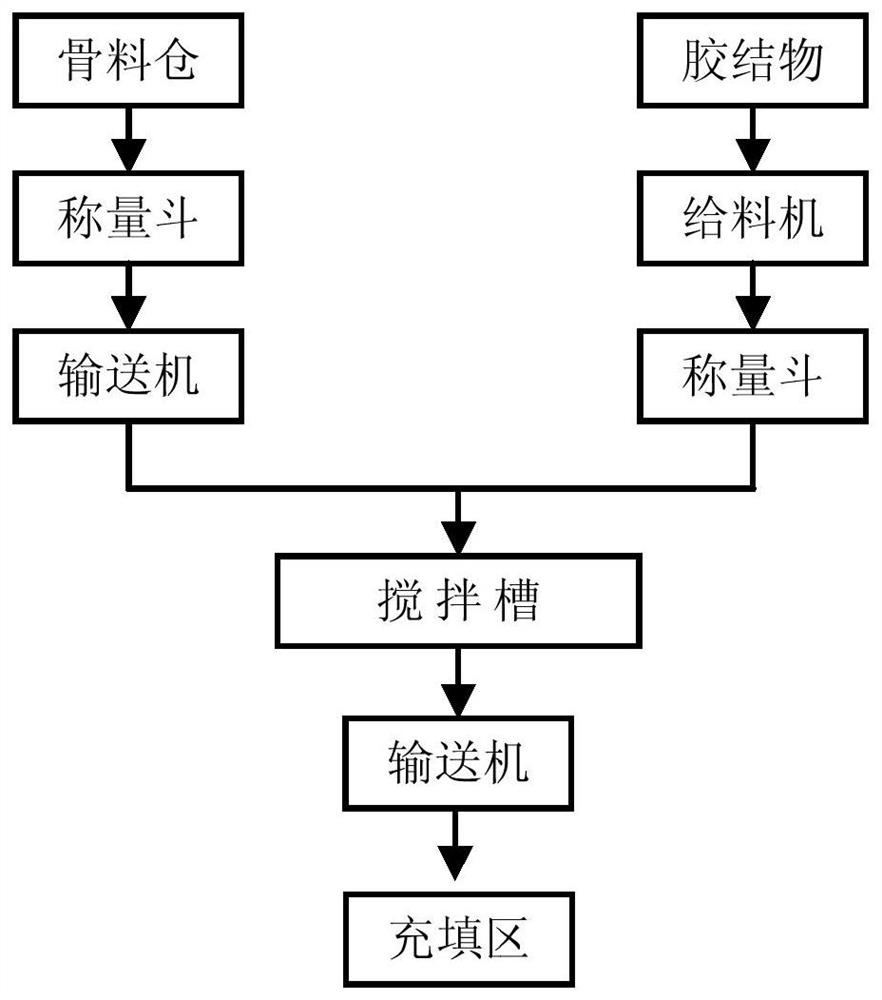

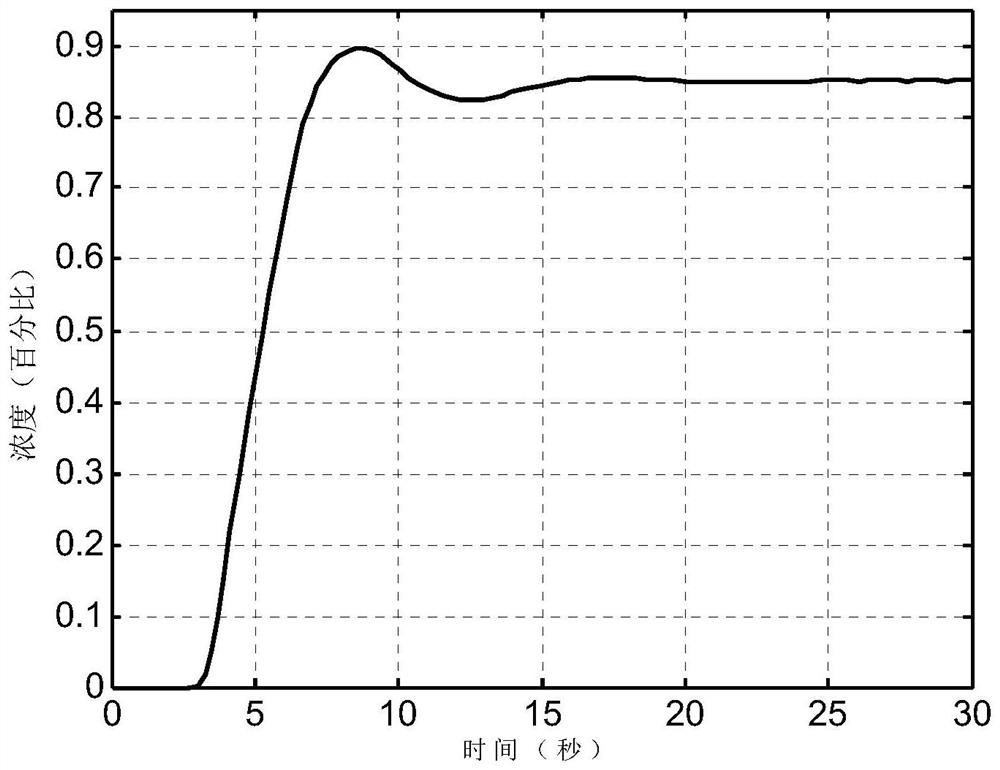

High-precision control method for mine filling slurry concentration

ActiveCN112130451AReduce fluctuations in concentrationStable concentrationControllers with particular characteristicsControl orientedControl theory

The invention relates to a high-precision control method for mine filling slurry concentration. The method comprises the following steps of: describing a slurry production process by adopting a third-order lag system, and decomposing the system into two small systems, namely an aggregate conveying process and an aggregate and cement stirring process; and establishing a control-oriented augmented error system without time lag in form by introducing errors and new variables. On the basis, a control law of the stirring process and a control law of the conveying process are designed by applying anoptimal control theory respectively. According to the method, the characteristics of the system and future information of an output target signal are fully utilized, so that the fluctuation of the slurry concentration can be effectively reduced, a guarantee is provided for high-quality filling, and the technical problem of control in the current mine filling slurry production process is solved. The method aims at engineering practical problems, and the achievement provides a theoretical reference for mine filling slurry production and has important application value for reducing the slurry concentration fluctuation and improving the filling quality.

Owner:宁夏烽火台数据信息技术有限责任公司

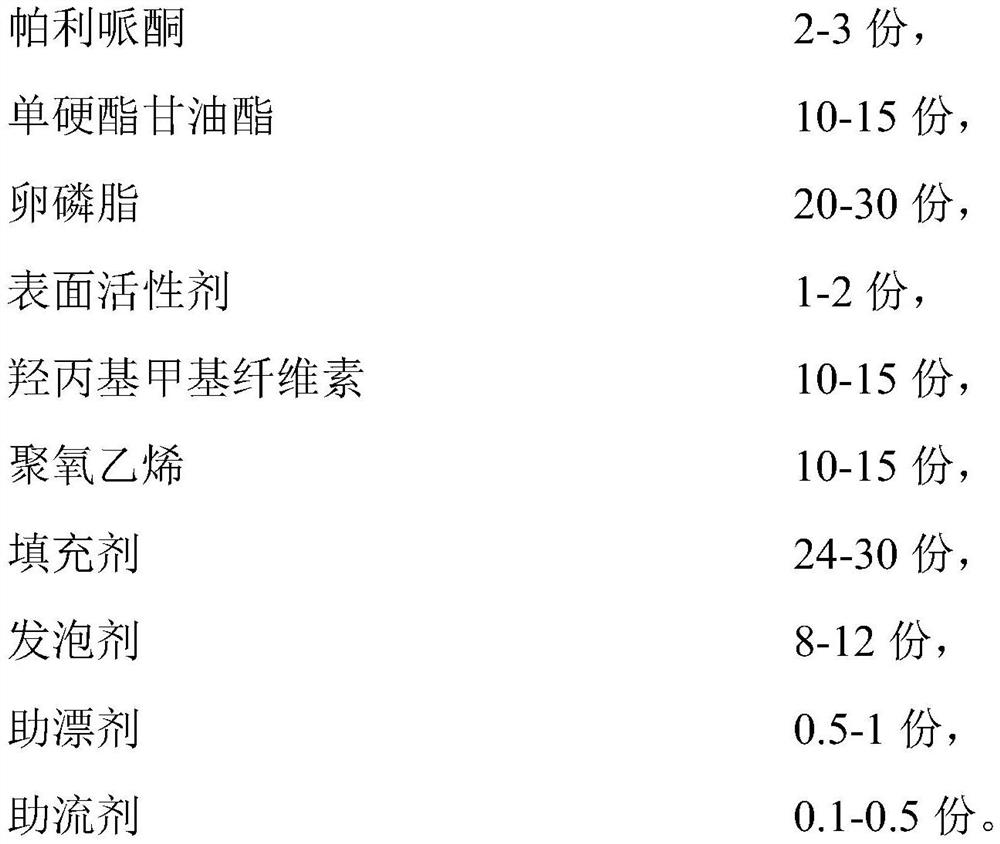

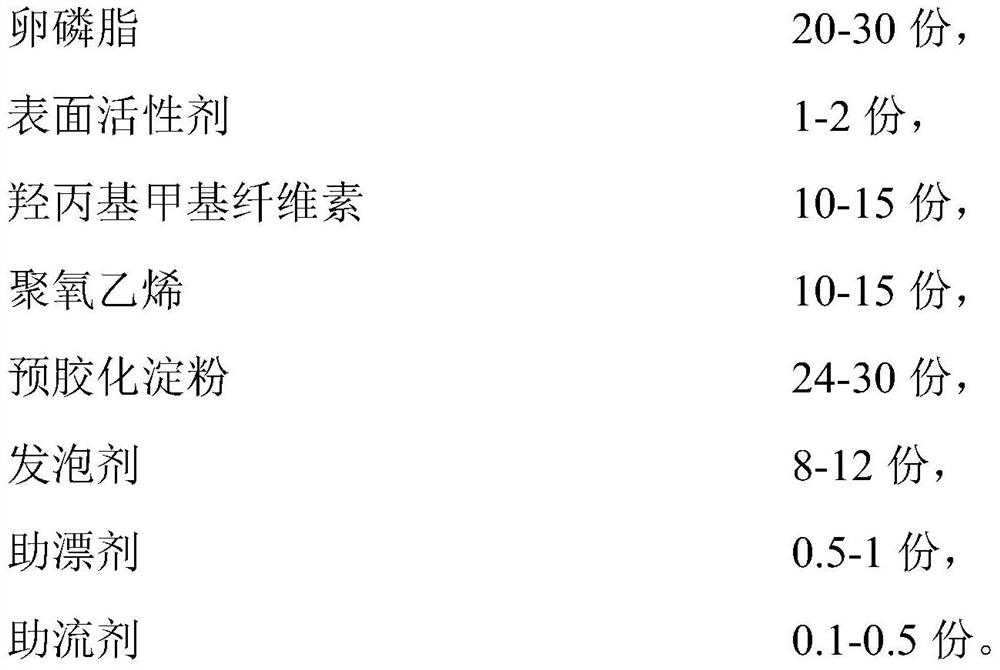

Paliperidone gastric retention tablet and preparation method thereof

ActiveCN112933055ASimple processSimple and fast operationOrganic active ingredientsNervous disorderCelluloseSurface-active agents

The invention belongs to the technical field of medicines, and particularly relates to a paliperidone gastric retention tablet and a preparation method thereof. The paliperidone gastric retention tablet is prepared from the following raw material components in parts by weight: 2-3 parts of paliperidone, 10-15 parts of glyceryl monostearate, 20-30 parts of lecithin, 1-2 parts of a surfactant, 10-15 parts of hydroxypropyl methyl cellulose, 10-15 parts of polyoxyethylene, 24-30 parts of a filling agent, 8-12 parts of a foaming agent, 0.5-1 part of a floating aid and 0.1-0.5 part of a flow aid. According to the paliperidone gastric retention tablet, through the synergistic effect of all the components, the medicine floats and is retained in gastric juice, the retention time of the paliperidone medicine in the gastric juice is prolonged, the medicine is slowly released, the release time of the medicine in the digestive tract is prolonged, absorption is enhanced, blood concentration fluctuation is reduced, and therefore the bioavailability is improved.

Owner:HONG KONG JOWA & HUAYUAN GRP CHUZHOU PHARMA CO LTD

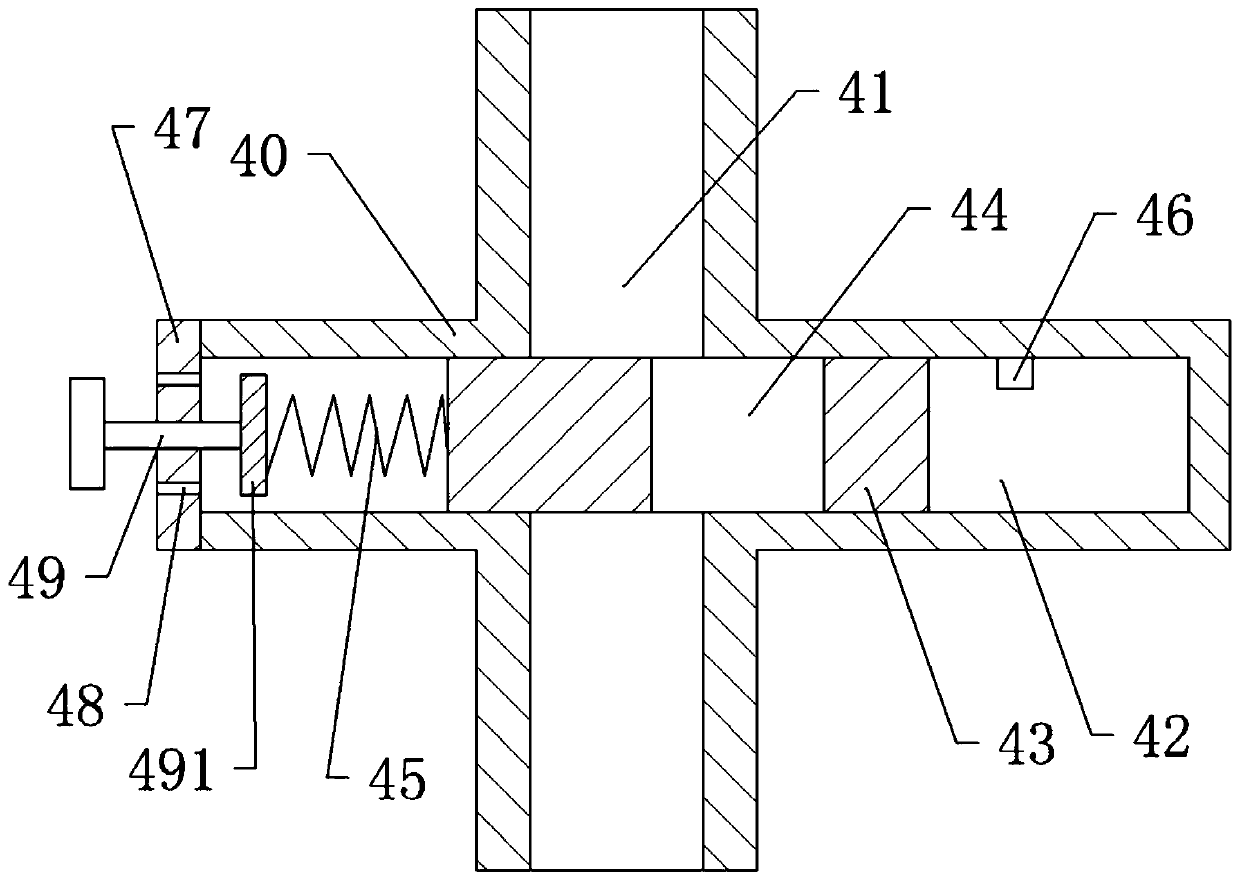

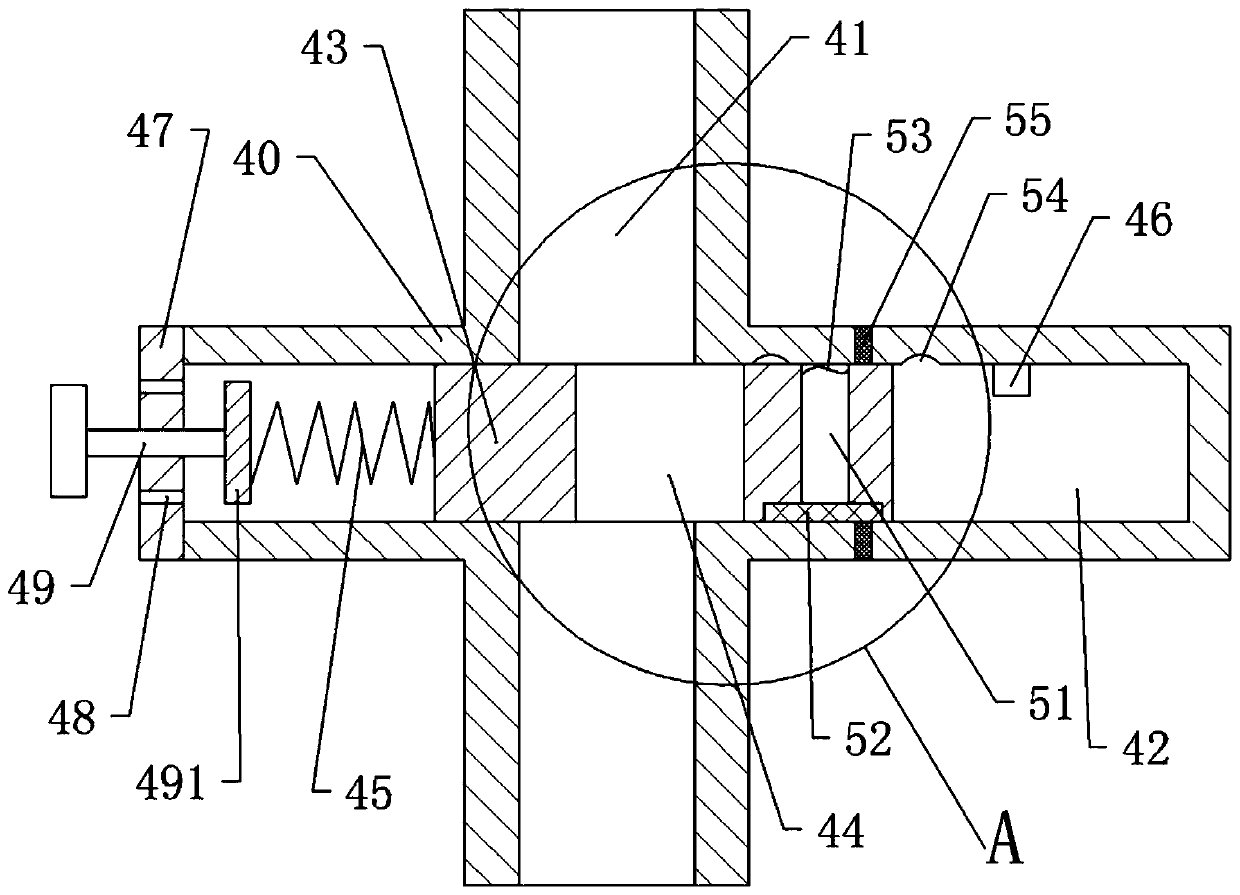

Heat sink of electrolytic tank

The invention specifically relates to a heat sink of an electrolytic tank, belonging to the technical field of electrolysis of sodium hypochlorite. The heat sink comprises the electrolytic tank, an electrode assembly, a cooling mechanism and a temperature controlling mechanism. The cooling mechanism comprises a cooling pipe immersed in brine; one end of the cooling pipe is connected with a coolingwater inlet, and the other end of the cooling pipe is connected with a cooling water outlet; the temperature controlling mechanism is connected with the cooling pipe in series and comprises a body which has a flow channel running through the body; two ends of the flow channel communicate with the cooling pipe; the body is further provided with a slideway which perpendicularly intersects with andcommunicates with the flow channel, a slide block is arranged in and slidably connected with a slideway; a flow hole cooperating with the flow channel is formed in the slide block; one end of the slideway is provided with a compression spring that abuts against the slide block; and the other end of the slideway is provided with a stop block. The heat sink of the invention carries out real-time adjustment of the temperature of the electrolytic tank, so the temperature of the electrolytic tank is always maintained in a stable range; and thus, an electrolysis rate is stable, and the concentrationfluctuation of a produced sodium hypochlorite solution is small.

Owner:贵州成黔科技开发有限公司

Continuous aluminum oxide blanking device

ActiveCN105506675ASmall fluctuations in concentrationGuaranteed the actual slot volumePower flowEnergy consumption

The invention provides a continuous aluminum oxide blanking device. The continuous aluminum oxide blanking device comprises an aluminum oxide material bin, a blanking channel, a constant volume device, a blanking tube and a crust breaking device, wherein the blanking channel is connected with the bottom of the aluminum oxide material bin and provided with a containing space, the constant volume device is contained in the containing space and communicated with the bottom of the aluminum oxide material bin, the crust breaking device is opposite to the blanking tube and the blanking channel in a spaced mode, the blanking tube comprises a feeding opening formed in the top of the blanking tube and a discharging opening formed in the bottom of the blanking tube, and the feeding opening is communicated with the bottom of the blanking channel. Compared with the prior art, according to the continuous aluminum oxide blanking device, intermittent blanking is changed into continuous blanking, aluminum oxide passes through the blanking channel and then slowly enters the blanking tube, blanking is conducted stably, fluctuation of the temperature of an electrolytic tank and the concentration of the aluminum oxide is reduced, electric current efficiency is further improved, and energy consumption is lowered.

Owner:SNTO TECH GRP

Multi-component gas simulation mixing system

PendingCN110865662AAvoid Concentration Distribution DeviationsAvoid condensationControlling ratio of multiple fluid flowsAnalysing gaseous mixturesThermodynamicsSystems design

The invention discloses a multi-component gas simulation mixing system, which belongs to the technical field of gas simulation mixing. After each component gas independently enters a rotary mixer, thecomponent gases are fully and uniformly mixed in an annular gas mixing chamber. Water vapor is added by a water vapor generation unit. After relevant parameters of multiple component gases and the water vapor are adjusted through data fed back by a monitoring unit, a simulated mixed gas is obtained and connected into a required system. The system is reasonable in design, wide in application range, easy and convenient to operate and high in efficiency. The concentration and flow velocity distribution uniformity of multiple component gases is improved, and accurate adjustment and control of moisture can be achieved.

Owner:HUANENG CLEAN ENERGY RES INST

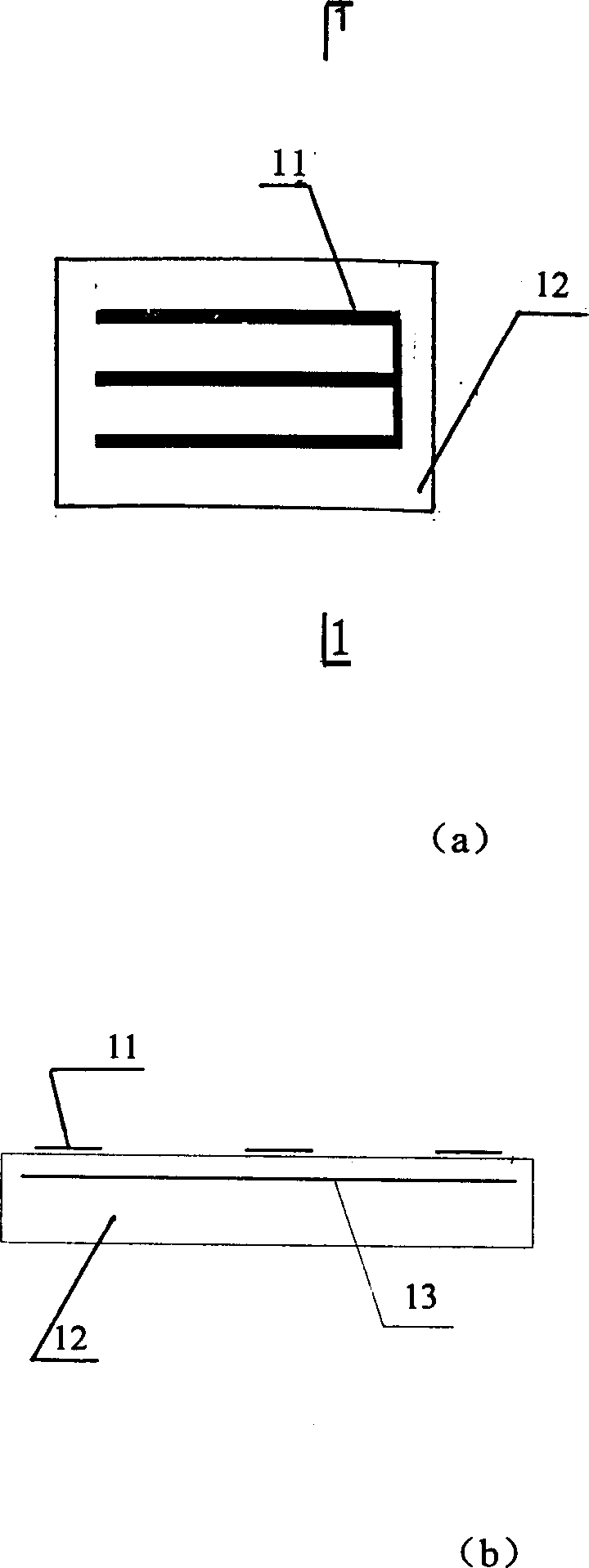

Production equipment for preparing semiconductor film on tubular base

InactiveCN103103503ADoes not affect growthReduce heating energy consumptionLiquid/solution decomposition chemical coatingSolid/suspension decomposition chemical coatingThermodynamicsProcess engineering

The invention discloses production equipment for preparing a semiconductor film on a tubular base. The production equipment adopts a single-slot multi-tube manner, heated liquid flows into the inner wall of the tubular base so as to heat the tubular base from inner side to heat a reaction solution through the tubular base, the reaction solution can exist in a normal temperature status and does not affect the growth of the semiconductor film, and the reaction can be carried out preferably on the outer wall of the tubular base so as to save the solution; high temperature heating liquid provided by an independent constant high-temperature heating box is taken as a heat source, so that the temperature of semiconductor film deposition is stable, and high repeatability of the semiconductor film deposition is realized; a manner of combination of an overflow structure and interior heating of the tubular base is also adopted; and the solution is updated at real time by adopting a reaction solution overflow circulatory system, the effect of concentration reduction on a reaction process at a later period is reduced, the waste liquor emission load is lowered, and the solution injection volume is reduced. The production equipment is applicable to industrial mass production of semiconductor films deposited on various tubular bases.

Owner:PEKING UNIV

Alkaline plant salt capable of decreasing blood sugar and preparation method thereof

InactiveCN105853787ALower blood sugarSmall fluctuations in concentrationOrganic active ingredientsMetabolism disorderBudHyperoside

The invention provides alkaline plant salt capable of decreasing blood sugar. The alkaline plant salt is prepared from saline land common seepweed herb plant salt, poria cocos extract, kudzuvine root extract, lotus root starch, kelp extract, sakura flowers, asparagus powder, hyperin, glucomannan and sophora flower bud extract. The invention further provides a preparation method of the alkaline plant salt. The alkaline plant salt has the effect of decreasing blood sugar and has the obvious effect of reducing blood sugar and urine sugar of diabetic patients in different age groups; after a drug made of the alkaline plant salt is withdrawn, two months later, the concentration fluctuation of blood sugar and urine sugar is small, for patients who are 16-45 years old, the blood concentration is raised by 2-3%, and urine sugar is not higher than 1.0 mmol / L; for patients who are 46-75 years old, the blood concentration is raised by 3-5%, and the urine sugar concentration is raised by 7-9%.

Owner:王胜

Method for controlling density ofsizing agent in hydrorefining work section of equipment of fine terephthalic acid

InactiveCN1539809ASmall fluctuations in concentrationReduce consumptionOrganic compound preparationCarboxylic compound preparationMotor speedControl set

A process for controlling the concentration of slurry in hydrorefining step of terephthalic acid refining equipment includes such steps as determining the relation between rotation speed of propeller's motor and TA mass flow, transforming the TA mass flow to slurry concentration at tank inlet, calculating current optimal control increment, transforming said slurry concentration to TA mass flow, transforming it to rotation speed of propeller's motor, under compensating static feedforward between slurry mass flow and TA mass flow, and adding the transformed feedforward and rotation speed increment to the PID control setting of motor speed.

Owner:SINOPEC YANGZI PETROCHEM +1

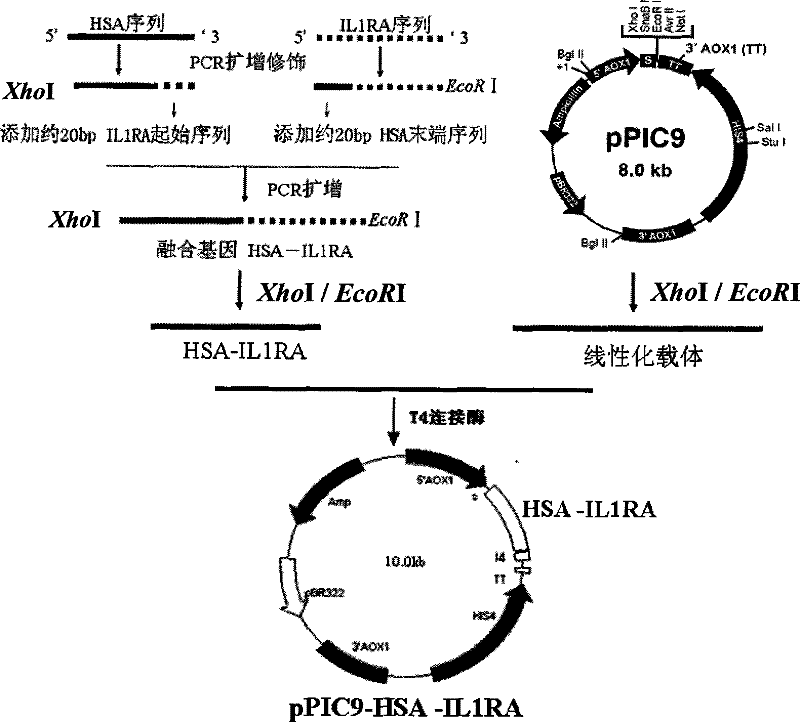

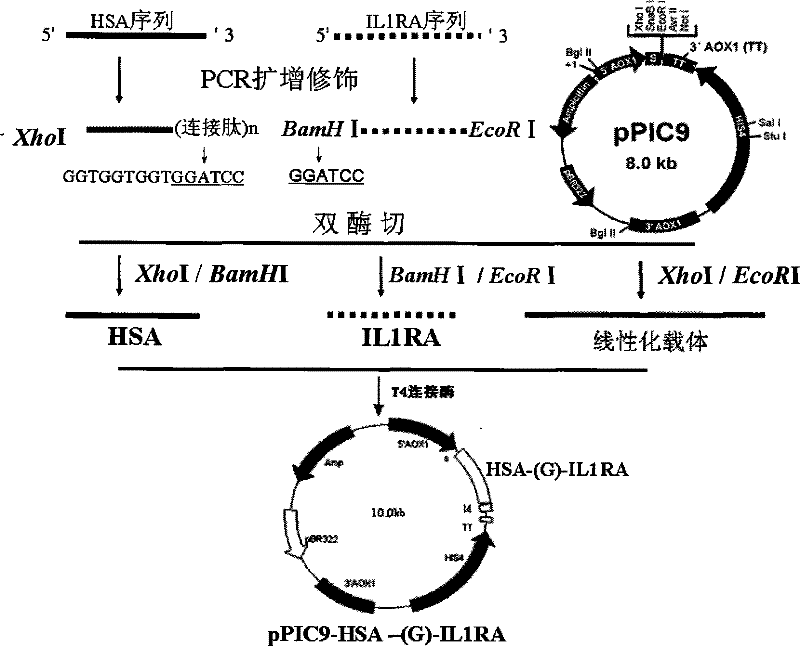

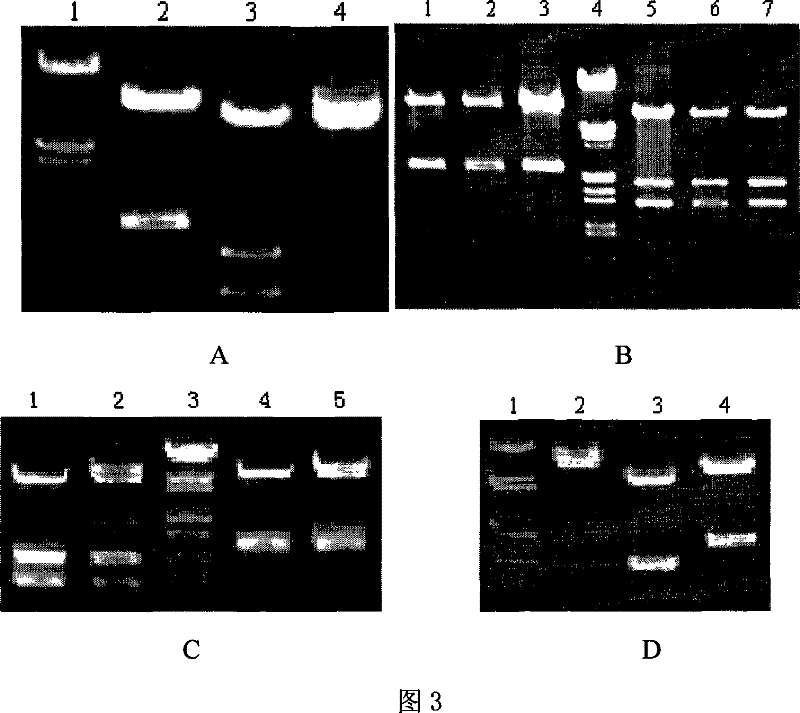

Fusion protein for serum albumin and interleukin 1 receptor antagonist and uses thereof

ActiveCN101255197BReduce clearanceExtended half-lifePeptide/protein ingredientsAntipyreticSide effectHalf-life

The invention provides a amalgamation albumen of serum albumin and interleukin 1 receptor antagonist, comprising human serum albumin HAS, peptide joint and human interleukin1 receptor antagonist IL1ra, wherein the peptide joint is 0-20 aminophenol long and exists between human HSA and human IL1ra, the construct is [GlyGlyGlyGlyser]<n>, n represents an integer from 0 to 4. The amalgamation albumen is obtained by constructing recombination pichia cell line, inducing expression of recombination amalgamation albumen in a growth culture medium and purifying. The amalgamation albumen, on the basis of original vivo and vitro biology function, reduces the clearance of IL1ra in vivo, prolongs the half-life of IL1ra in vivo, decreases dose and ejection frequency, make the maximum treat action, reduces the potential side effect of IL1ra or toxicity, improves safety and tolerance, is substantial an aid to treat moderate and bad rheumatoid arthritis, and can be used in the preparation of interleukin receptor antagonist.

Owner:HISUN BIORAY PHARMA CO LTD +1

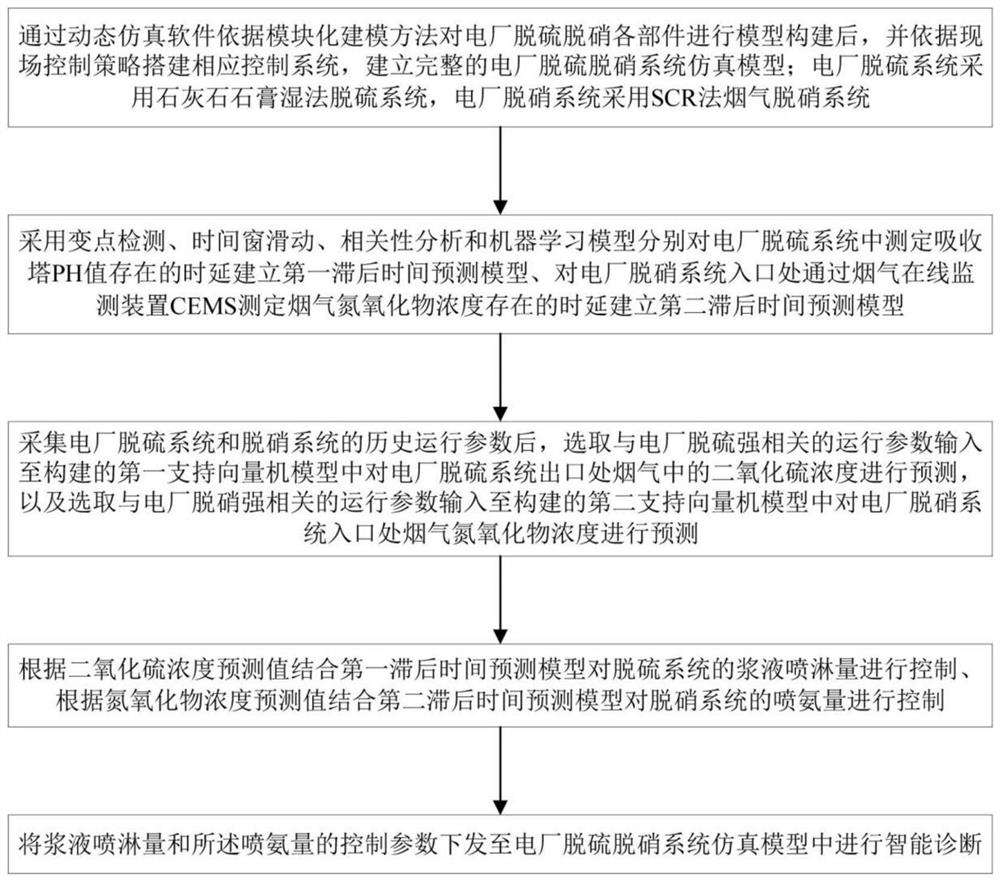

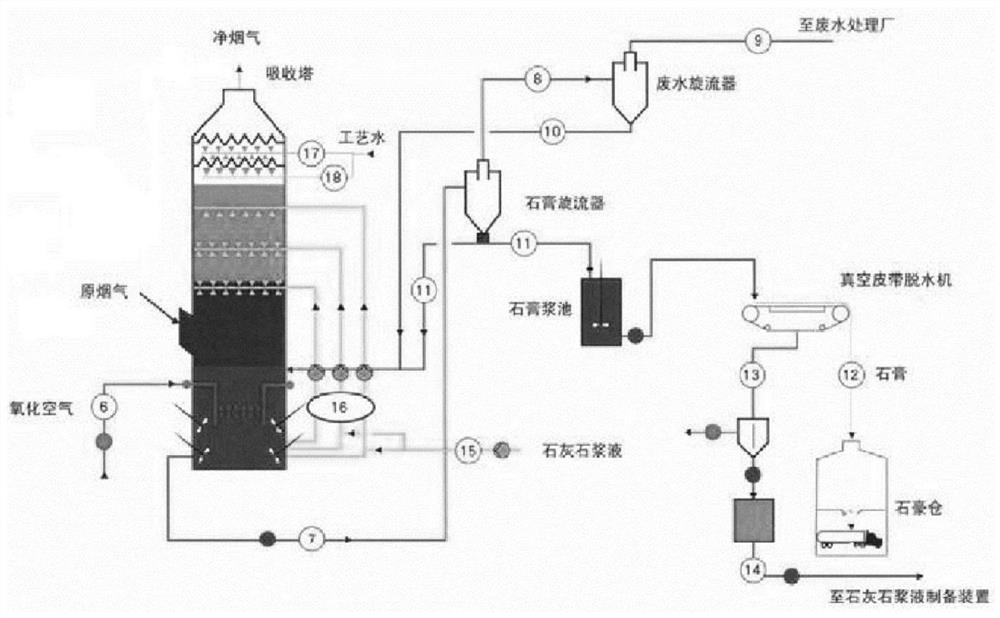

Flue gas desulfurization and denitrification optimization control method based on hysteresis model

PendingCN114225662AHigh precisionImprove accuracyDispersed particle separationSlurryControl parameters

The invention relates to a hysteresis model-based flue gas desulfurization and denitrification optimization control method, which comprises the following steps of: establishing a power plant desulfurization and denitrification system simulation model through dynamic simulation software according to modular modeling and a control strategy; establishing a first delay time prediction model for the time delay existing in the determination of the pH value of an absorption tower in the desulfurization system, and establishing a second delay time prediction model for the time delay existing in the determination of the concentration of flue gas nitrogen oxide at the inlet of the denitration system through a flue gas online monitoring device CEMS; predicting the concentration of sulfur dioxide at a desulfurization outlet and the concentration of nitrogen oxide at a denitration inlet by adopting a support vector machine model; controlling the slurry spraying amount according to the predicted value of the sulfur dioxide concentration in combination with a first lag time prediction model, and controlling the ammonia spraying amount according to the predicted value of the nitrogen oxide concentration in combination with a second lag time prediction model; and the control parameters are issued to the desulfurization and denitrification system simulation model for intelligent diagnosis.

Owner:STATE GRID HEBEI ENERGY TECH SERVICE CO LTD +2

Lipid prodrug of guanidinium-containing drug and drug plastid thereof

InactiveCN101723857BSolve the problem of low bioavailabilitySmall fluctuations in concentrationOrganic active ingredientsOrganic chemistryLipid formationLong chain fatty acid

The invention relates to a lipid prodrug of a drug containing guanidino and pharmacosome thereof. The lipid prodrug is a medicinal compound which is in covalent union with long-chain fatty acid with a single chain or double chains and contains guanidino. The pharmacosome is formed in such a way that the lipid prodrug disperses freely in a proper medium, is orderly arranged into a single-layer or double-layer structure, and is automatically assembled finally. The pharmacosome has biological targeting property, can effectively enhance the bioavailability of the drug and opens up a novel concept for solving the problems of poor transmembrane capability, low bioavailability and the like of a water soluble drug.

Owner:INST OF PHARMACOLOGY & TOXICOLOGY ACAD OF MILITARY MEDICAL SCI P L A

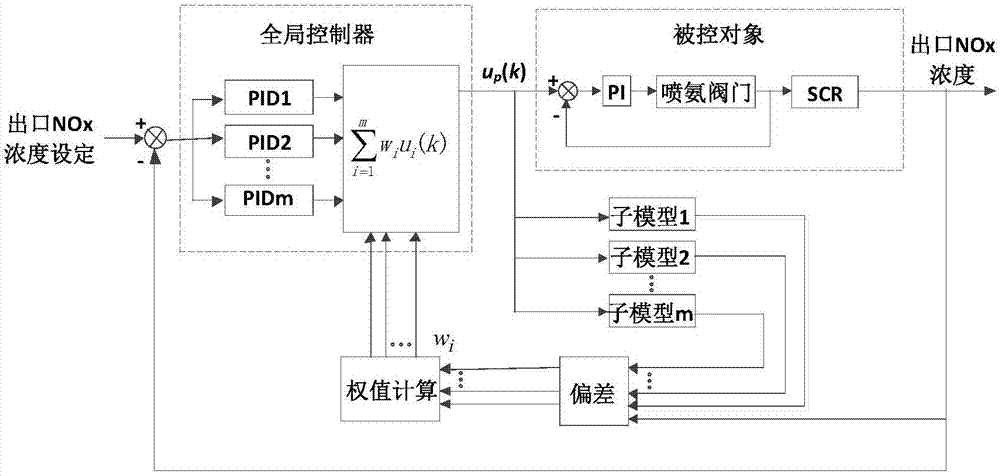

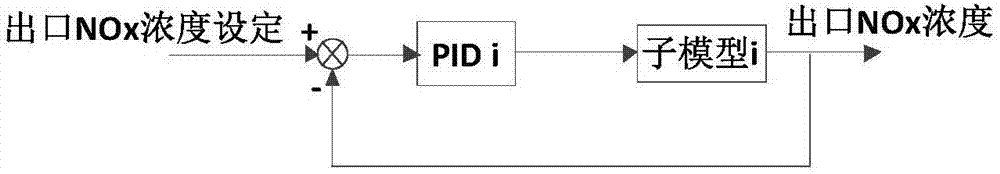

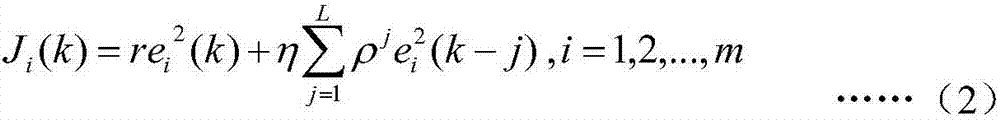

Multi-model adaptive control method for denitration control system

InactiveCN107272413ASmall fluctuations in concentrationGood control effectAdaptive controlControl systemOptimal control

The invention relates to a multi-model adaptive control method for a denitration control system. The method comprises steps that 1, sub models of a controlled object under different loads are established; 2, PID controllers are respectively designed according to the m sub models; output of the controlled object and output of each sub model are acquired through measurement; 4, deviation of output of the controlled object and output of each sub model is acquired; 5, a weight wi of each controller is solved; 6, control quantities u1(k) to um(k) of the controllers are weighted to output to acquire a global control quantity up(k); 7, the global control quantity is sent to the controlled object and the sub models for control; and 8, the process returns to the step 3. The method is advantaged in that a global controller can be made to output the optimal control quantity in real time under the changeable load condition, the purpose of adaptive load change is realized, change of an export NOx concentration can be timely tracked according to change of ammonia injection amount, export NOx concentration fluctuation of the denitration system can be effectively reduced, so the NOx concentration is stabilized to be in an index required by the environmental protection department, control thinking is simple, and the method is easy for realization in a power plant DCS.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

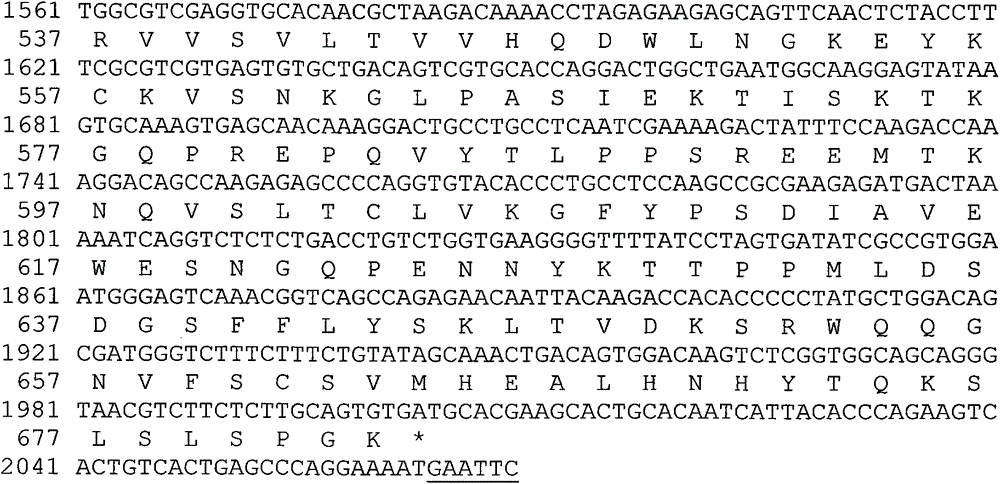

Pharmaceutical composition containing modified type human coagulation factor FVII-Fc fusion protein

InactiveCN103599527AIncrease productionEfficient and convenient purificationPeptide/protein ingredientsHydrolasesSide effectLysis

The invention discloses a recombined human coagulation factor FVII-Fc fusion protein, a preparation method thereof and applications thereof. The fusion protein successively comprises, from the N end to the C end, human FVII, a flexible peptide joint and an IgG2Fc mutant. The Fc mutant has no lysis property and exhibits very low bad Fc-mediated side effect. The fusion protein has similar or higher bioactivity than the human FVII, and prolonged the serum half time, thus improving pharmacokinetics and efficacy.

Owner:PHARMAB

Hydrochloric tamsulosin sustained-release capsule and its preparation method

ActiveCN101125134BOvercoming transfer time differencesLess irritatingOrganic active ingredientsPharmaceutical delivery mechanismSide effectFOOD EFFECT

The present invention provides a tamsulosin hydrochloride sustained-release capsule. The tamsulosin hydrochloride sustained-release capsule of the present invention can avoid the sudden release of the drug tablets and the performance differences generated from the gastric emptying differences, display minor food effect or do not display food effect, and obtain the stable curve of the plasma drug concentration and longer action time simultaneously, so as to reduce the occurrence of cardiovascular side effects, greatly improve the safety, effectiveness and compliance of the medication for the patients. The tamsulosin hydrochloride sustained-release capsule of the present invention can ensure the sustained and regular release of the main ingredient tamsulosin hydrochloride after the oral administration, and the present invention is characterized by convenient administration, durable function, stable efficacy, fewer side effects and so on.

Owner:CHANGZHOU NO 4 PHARMA FACTORY

Alumina continuous feeding device

ActiveCN105506675BSmall fluctuations in concentrationGuaranteed the actual slot volumePower flowEnergy consumption

The invention provides a continuous aluminum oxide blanking device. The continuous aluminum oxide blanking device comprises an aluminum oxide material bin, a blanking channel, a constant volume device, a blanking tube and a crust breaking device, wherein the blanking channel is connected with the bottom of the aluminum oxide material bin and provided with a containing space, the constant volume device is contained in the containing space and communicated with the bottom of the aluminum oxide material bin, the crust breaking device is opposite to the blanking tube and the blanking channel in a spaced mode, the blanking tube comprises a feeding opening formed in the top of the blanking tube and a discharging opening formed in the bottom of the blanking tube, and the feeding opening is communicated with the bottom of the blanking channel. Compared with the prior art, according to the continuous aluminum oxide blanking device, intermittent blanking is changed into continuous blanking, aluminum oxide passes through the blanking channel and then slowly enters the blanking tube, blanking is conducted stably, fluctuation of the temperature of an electrolytic tank and the concentration of the aluminum oxide is reduced, electric current efficiency is further improved, and energy consumption is lowered.

Owner:SNTO TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com