Alumina continuous feeding device

An alumina and feeding tube technology, applied in the field of aluminum electrolysis, can solve the problems of low current efficiency, poor stability of aluminum electrolytic cells, increased energy consumption, etc., and achieve the effects of improving current efficiency, reducing furnace bottom sedimentation, and reducing effect coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

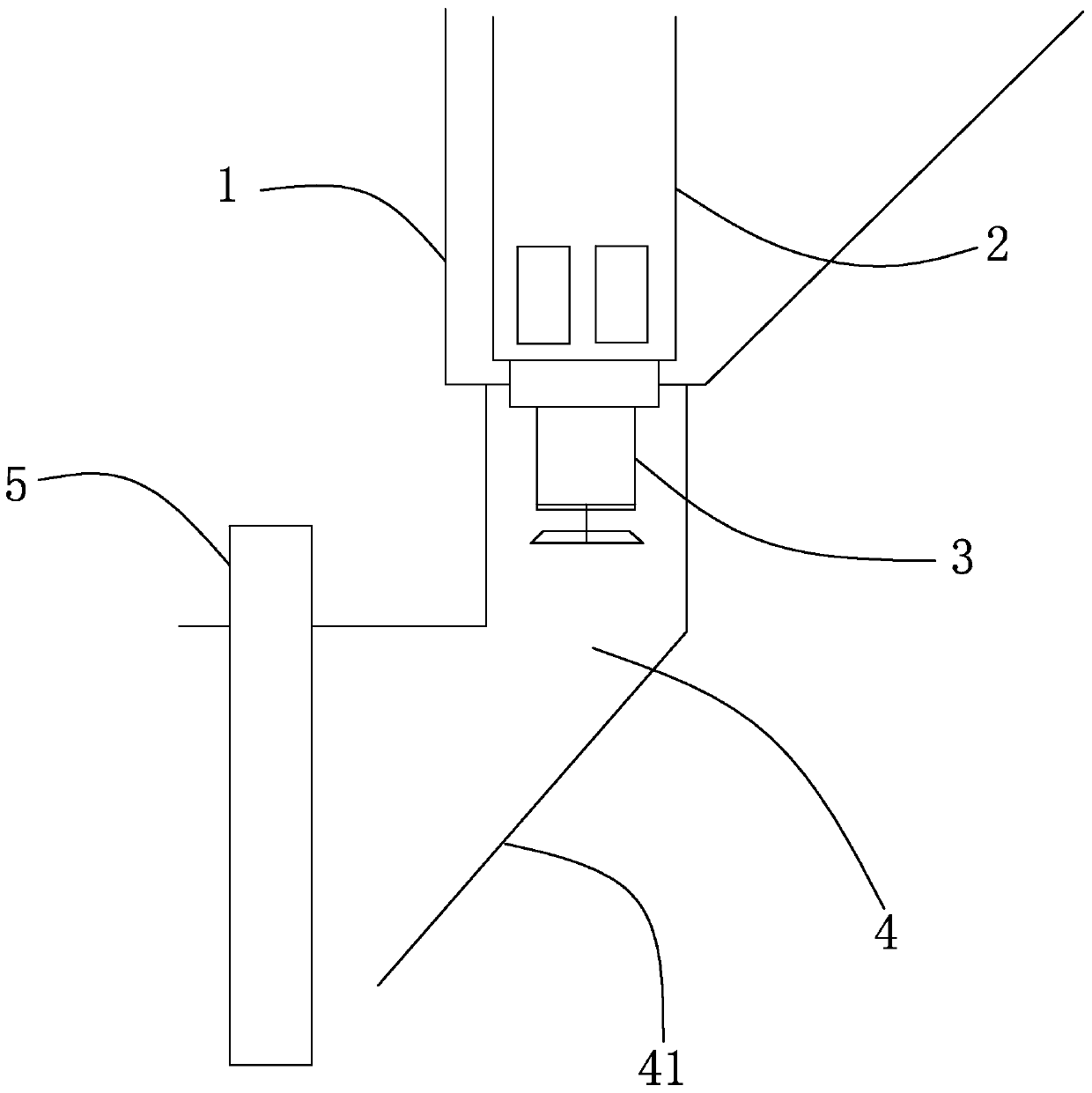

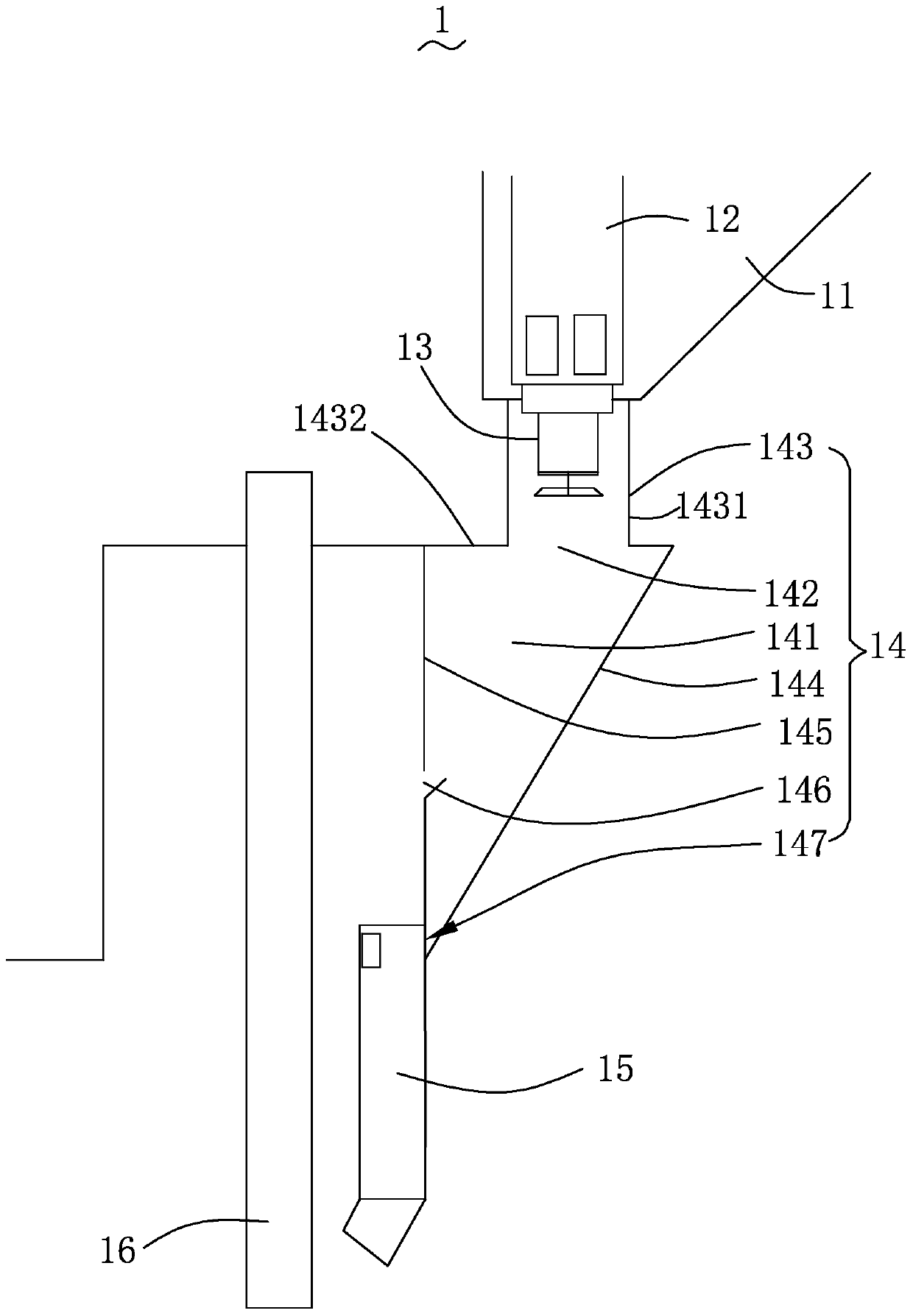

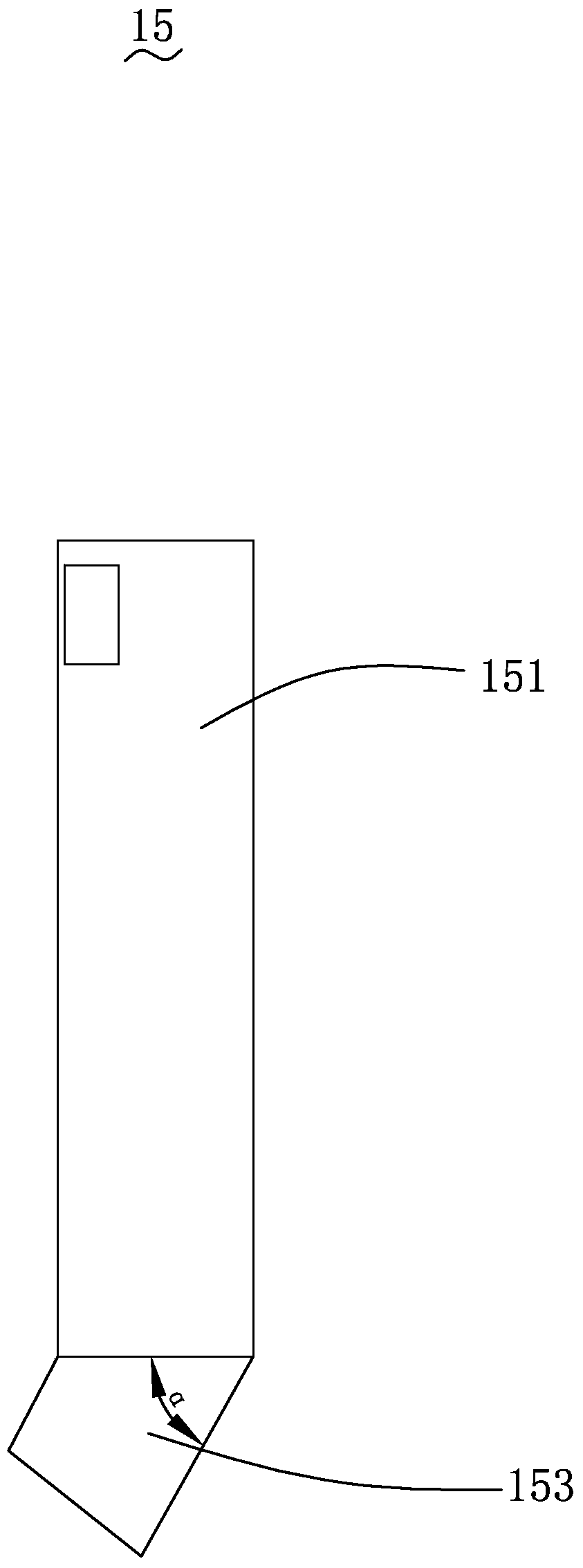

[0032] see figure 2 , is a schematic structural view of Embodiment 1 of the alumina continuous feeding device of the present invention. The alumina continuous feeding device 1 includes an alumina bin 11 , a feeding cylinder 12 , a fixed container 13 , a feeding channel 14 , a feeding pipe 15 and a shelling device 16 . The feeding cylinder 12 is arranged in the alumina material box 11 , and the fixed container 13 is connected to the bottom of the feeding cylinder 12 and is located in the feeding channel 14 . The shell breaking device 16 is located directly above the feed port (not shown) of the aluminum electrolytic cell, and is set opposite to the discharge channel 14 at intervals. The alumina material enters the feeding channel 14 through the fixed container 13, and then enters the aluminum electrolytic cell through the feeding pipe 15.

[0033] The feeding passage 14 includes a receiving space 141 , a feeding opening 142 , a connecting portion 143 , an inclined portion 14...

Embodiment 2

[0044] see Figure 6 , is a schematic structural view of Embodiment 2 of the alumina continuous feeding device of the present invention. The alumina continuous feeding device 2 includes an alumina bin 21 , a feeding cylinder 22 , a fixed container 23 , a feeding channel 24 , a feeding pipe 25 and a shelling device 26 . The structure and positional relationship of the alumina material box 21, the feeding cylinder 22, the fixed container 23 and the shelling device 26 are the same as those in the first embodiment.

[0045] The feeding passage 24 includes a receiving space 241 , a feeding opening 242 , a connecting portion 243 , an inclined portion 244 , a blocking portion 245 , an overflow opening 246 , a feeding opening 247 and a funnel device 248 . The fixed container 23 is accommodated in the accommodating space 241, and the structure and positional relationship of the material inlet 242, the connecting portion 243, the inclined portion 244, the blocking portion 245, the over...

Embodiment 3

[0052] see Figure 8 , is a schematic structural view of Embodiment 3 of the alumina continuous feeding device of the present invention. The alumina continuous feeding device 3 includes an alumina bin 31 , a feeding cylinder 32 , a fixed container 33 , a feeding channel 34 , a feeding pipe 35 and a shelling device 36 . The positional relationship of the alumina material box 31 , the feeding cylinder 32 , the constant container 33 and the shelling device 36 is the same as that of the first embodiment.

[0053] The discharge channel 34 includes a receiving space 341 , a connecting portion 342 , an inclined portion 343 , a blocking portion 344 , an overflow port 345 and a funnel device 346 , and the positional relationship of each component is the same as that of the second embodiment.

[0054] In this embodiment, the connection part 342 includes a first connection part 3421 and a second connection part 3422, the structure and location of which are the same as those in the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com