Method for extracting tungsten from scheelite

A technology of scheelite and phosphoric acid, applied in the direction of improving process efficiency, etc., can solve the problems of affecting decomposition rate, non-volatile, low corrosion, etc., and achieve the effect of simple leaching equipment, increasing liquid-solid ratio, and simplifying operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

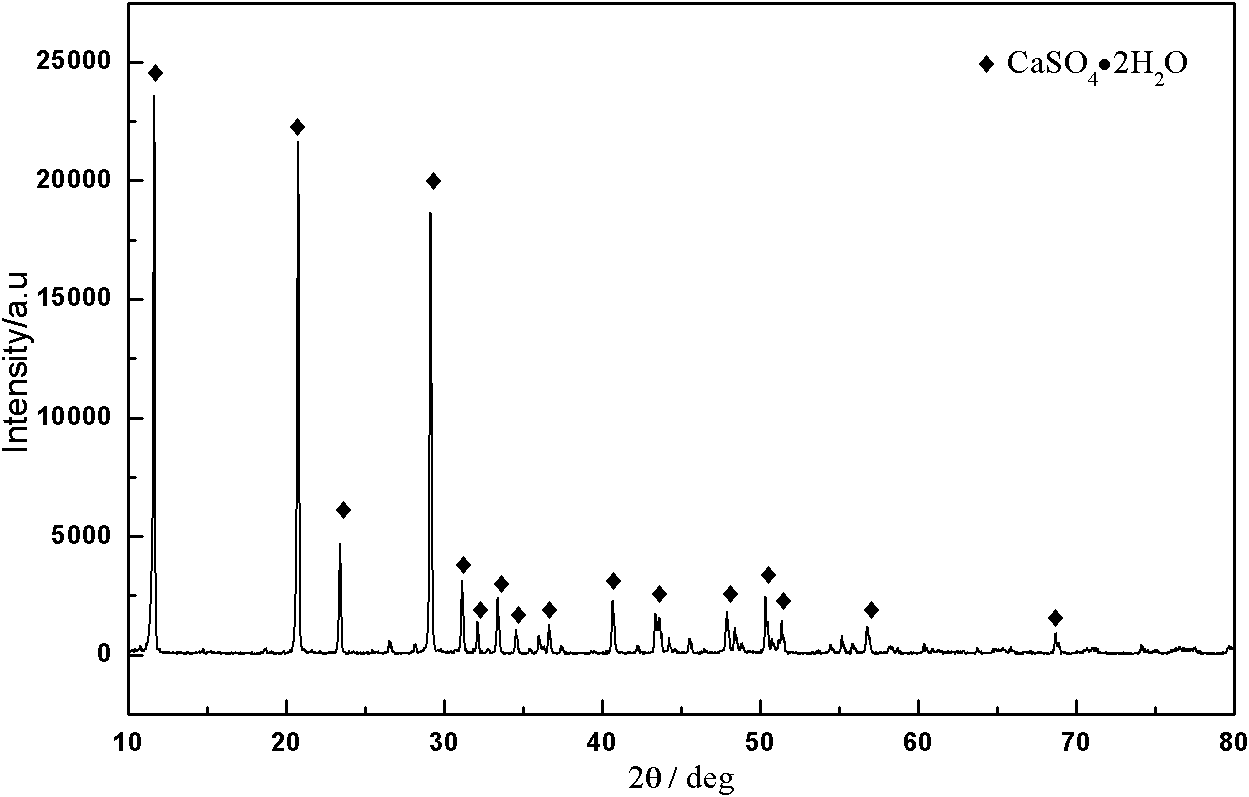

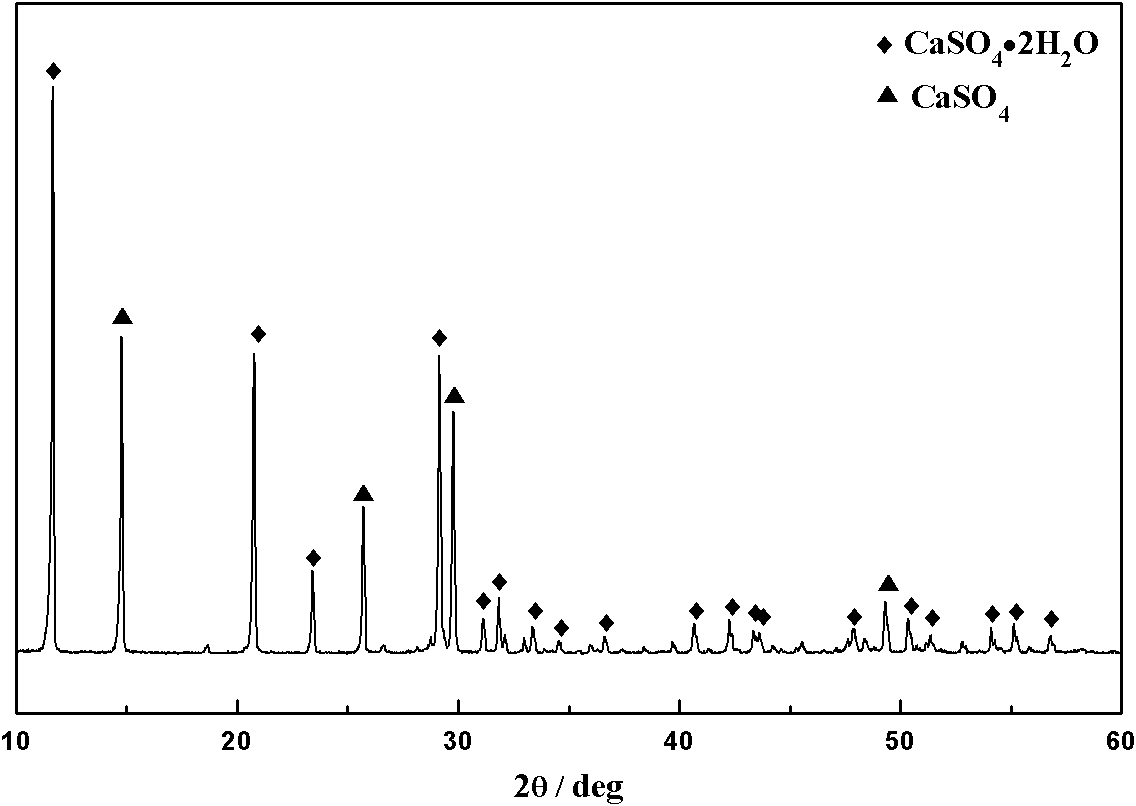

[0033] On the basis of using phosphoric acid and sulfuric acid mixed acid to decompose scheelite, by adding CaSO 4 2H 2 O seeds to reduce the supersaturation of the solution, and maintain a constant, relatively low reaction temperature to make the crystals grow uniformly, and at the same time increase the liquid-solid ratio of the leaching system to reduce the large concentration fluctuations caused by the consumption of sulfate ions, etc. Measures to obtain a single crystalline product, the experimental results are as follows.

[0034] Scheelite (including WO 3 70.6%) 1kg to prepare a mixed solution of phosphoric acid and sulfuric acid, P 2 o 5 Content is 20%, control SO 4 2- The concentration is 0.15g / ml, the amount of dihydrate gypsum seed crystals added is 50g, the liquid-solid ratio is 10:1, the reaction temperature is 60°C, and the reaction time is 6h. The leaching rate of tungsten is 99.4%. A Buchner funnel with a specification of 200mm is used to filter the slur...

Embodiment 2

[0039] Scheelite (including WO 3 70.6%) 1kg to prepare a mixed solution of phosphoric acid and sulfuric acid, P 2 o 5 Content is 25%, control SO 4 2- The concentration is 0.10g / ml, the amount of dihydrate gypsum seed crystal is 100g, the liquid-solid ratio is 12:1, the reaction temperature is 80°C, and the reaction time is 4h. The leaching rate of tungsten is 99.6%. A Buchner funnel with a specification of 200mm was used to filter the slurry, and the time required for filtration was 30 minutes. Then, the filter cake was washed with pure water three times, and the water consumption was 300ml each time. After washing, the filter cake contained P 2 o 5 down to 1.2%. The filtrate is adsorbed by secondary amine-based anion exchange resin, and the adsorption rate of tungsten is 99.1%. In the ion exchange process, phosphorus is lost in the form of phosphotungstic heteropolyacid and the total loss of entrainment is 3.7%. The mother liquor is added to the lost phosphoric acid an...

Embodiment 3

[0041] Scheelite (including WO 3 70.6%) 1kg to prepare a mixed solution of phosphoric acid and sulfuric acid, P 2 o 5 Content is 15%, control SO 4 2- The concentration is 0.20g / ml, the amount of dihydrate gypsum seed crystal is 1g, the liquid-solid ratio is 6:1, the reaction temperature is 50°C, and the reaction time is 8h. The leaching rate of tungsten is 99.0%. A Buchner funnel with a specification of 200mm is used to filter the slurry, and the time required for filtration is 1h, and then the filter cake is washed with pure water three times, and the water consumption is 300ml each time. After washing, the filter cake contains P 2 o 5 down to 3.4%. The filtrate is adsorbed by quaternary ammonium-based anion exchange resin, and the adsorption rate of tungsten is 98.9%. In the ion exchange process, phosphorus is lost in the form of phosphotungstic heteropoly acid and the total loss of entrainment is 3.1%. The mother liquor is added to the lost phosphoric acid and sulfur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com