Heat sink of electrolytic tank

A cooling device and electrolytic cell technology, applied in the electrolytic process, electrolytic components, cells, etc., can solve the problems that the concentration of sodium hypochlorite solution cannot be well controlled, the flow rate of cooling water cannot be controlled, and the temperature stability of the electrolytic cell is unfavorable. The effect of simple structure, good product quality and stable electrolysis rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

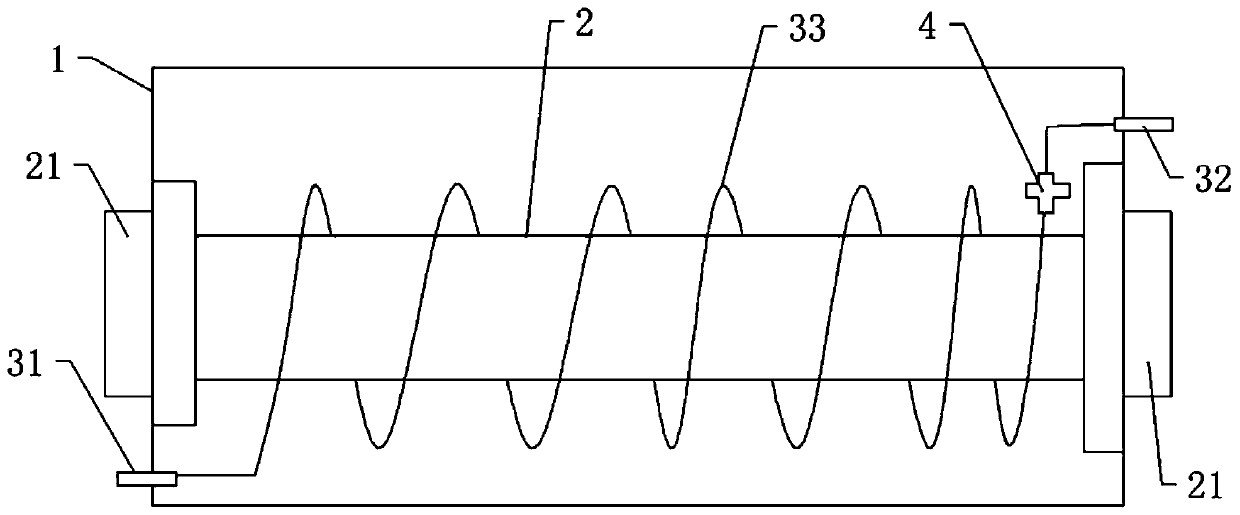

[0028] Embodiment one, such as figure 1 As shown, a cooling device for an electrolytic cell includes an electrolytic cell 1, an electrode assembly 2, a cooling mechanism and a temperature control mechanism 4. The electrolytic cell 1 is in a tubular shape, and the electrolytic cell 1 is filled with diluted brine. The connecting piece 21, the electrode assembly 2 is arranged in the electrolytic tank 1, the electrode assembly 2 includes a cathode plate and an anode plate, and the cathode plate and the anode plate are respectively connected with the conductive connecting pieces 21 at both ends of the electrolytic tank 1. The cooling mechanism includes a cooling pipe 33, a cooling water inlet 31 and a cooling water outlet 32, the cooling water inlet 31 and the cooling water outlet 32 are respectively arranged on the two end side walls of the electrolytic cell 1, the cooling pipe 33 is immersed in the diluted brine and the cooling pipe 33 It is evenly wrapped around the electrode ...

Embodiment 2

[0034] Embodiment 2 differs from Embodiment 1 in that: the cooling pipe 33 is arranged above the electrode assembly 2 in an S shape, and the temperature generated during electrolysis makes the water body heat up and flows upward, so that the temperature of the water body above the electrode assembly 2 is high. For the temperature of the water body below the electrode assembly 2 , it is beneficial to improve the heat exchange efficiency to arrange the cooling pipe 33 above the electrode assembly 2 .

Embodiment 3

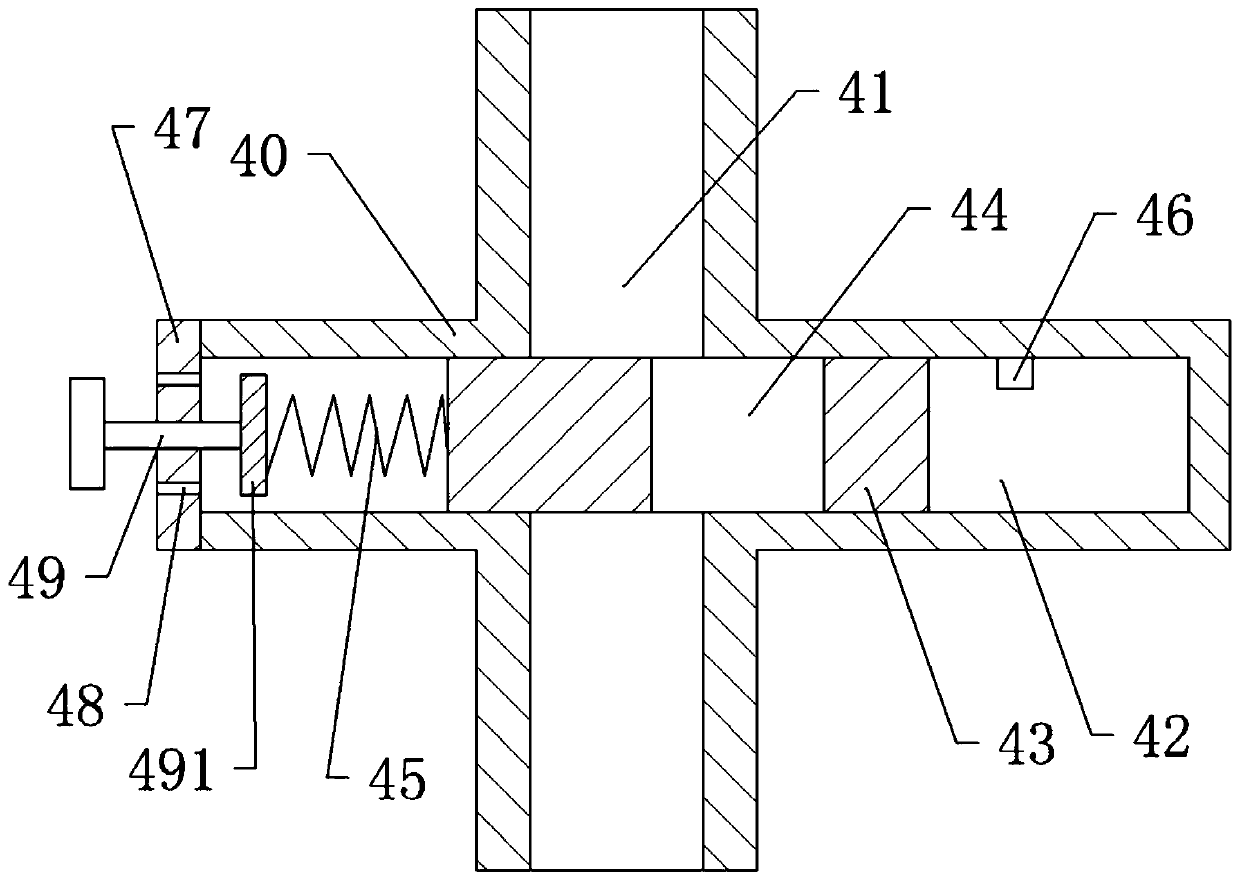

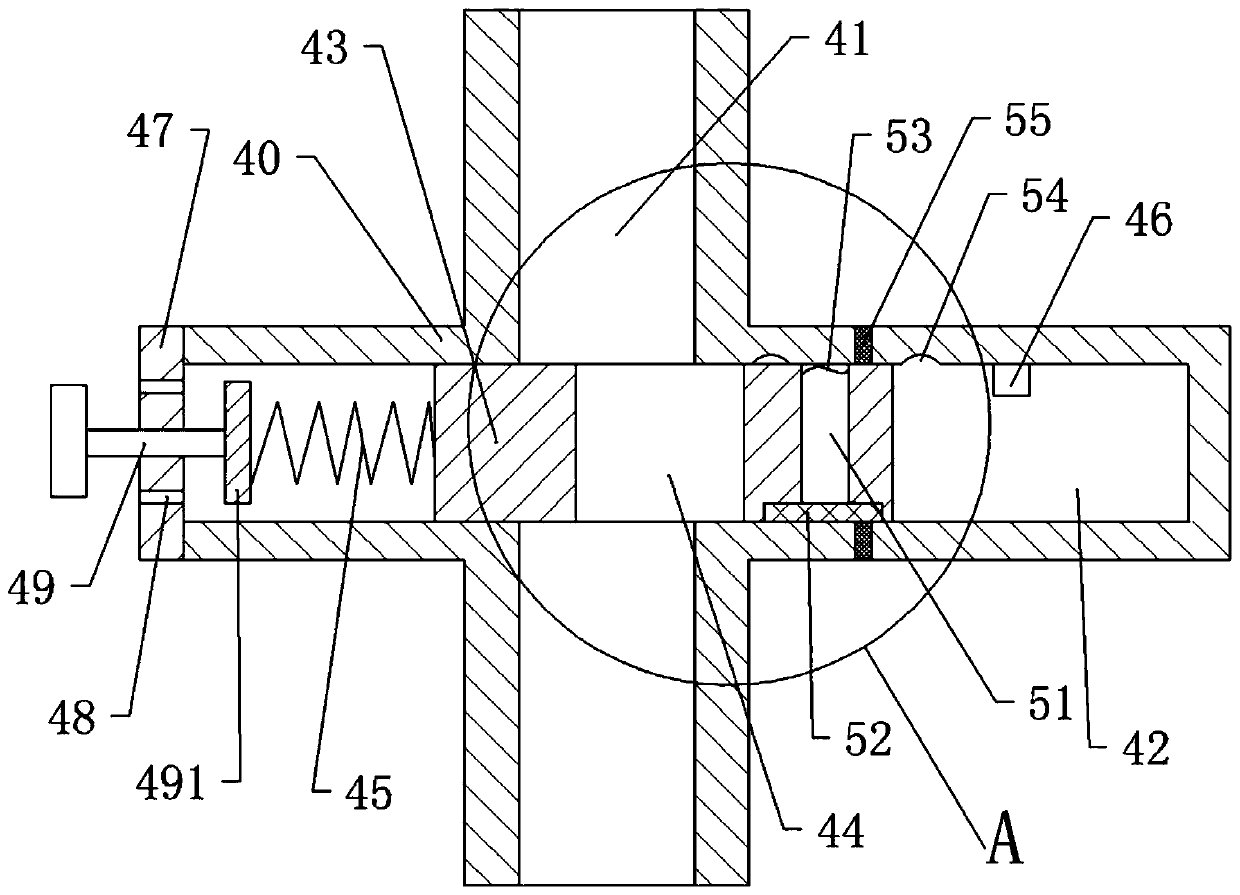

[0035] The third embodiment differs from the first embodiment in that: image 3 with Figure 4 As shown, in the slider body of the slider 43 close to the end of the stop block 46, a vertical through hole 51 that penetrates the slider 43 up and down is provided, and the bottom of the vertical through hole 51 is provided with a plug to block the bottom of the vertical through hole 51. In the heating block 52, the upper end of the vertical through hole 51 is provided with an elastic film 53 that blocks the upper end of the vertical through hole 51, and a heat insulating sheet 55 is provided along the circumference of the body of the slideway near the end of the limit block 46.

[0036] When the temperature in the electrolytic cell rises, the temperature of the inner chamber of the slideway near the end of the limit block 46 rises, causing the air pressure in the inner chamber to increase, and the pressure generated by the increased air pressure on the slider 43 makes the slider 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com