Method and equipment for continuous smelting of lead sulphide concentrate

A lead sulfide and concentrate technology, applied in the chemical industry, climate sustainability, sulfur trioxide/sulfuric acid, etc., can solve the problems of workers' health hazards, underutilization, and poor industrial hygiene conditions, and achieve SO2 The effect of small concentration fluctuation, obvious energy saving effect and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

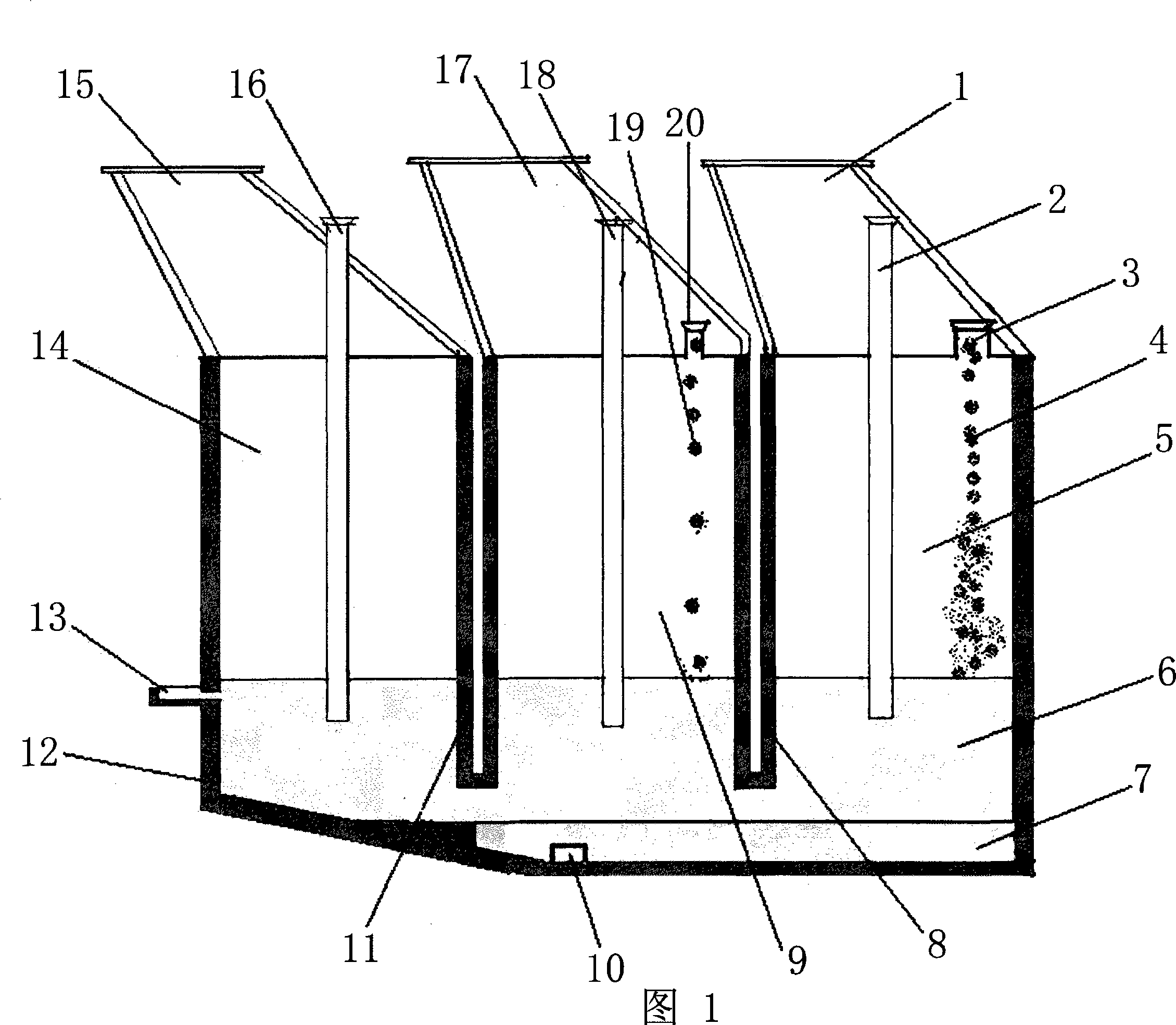

[0019] Referring to Fig. 1, in the liquid slag layer 6 of the molten pool of this lead sulfide concentrate continuous smelting furnace, partition walls 8 and 11 are arranged above the smelting space, and the part and the upper space of the liquid slag layer 6 are separated into mutually disconnected oxidation zones. Area 5, reduction area 9, and fuming area 14 are three areas, and the top of each area has its own flue gas outlet, that is, flue gas outlet 1 in the oxidation area, flue gas outlet 15 in the fuming area, flue gas outlet 17 in the reduction area, Each is equipped with spray guns 2, 16 and 18, the smelting material inlet 3 is set at the top of the oxidation zone 5, a siphon discharge port 10 is provided at the crude lead layer 7 at the bottom of the furnace body, and the slag discharge port 13 is provided at the fuming zone 14 6 places of the liquid slag layer. The fuming zone 14 at the bottom of the furnace body of the present invention is provided with a slope, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com