High-precision control method for mine filling slurry concentration

A slurry concentration and control method technology, applied in electric controllers, controllers with specific characteristics, etc., can solve problems affecting the improvement of system control performance, output fluctuations, and untimely control corrections, etc., to achieve improved control performance, The effect of overcoming output fluctuations and improving response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

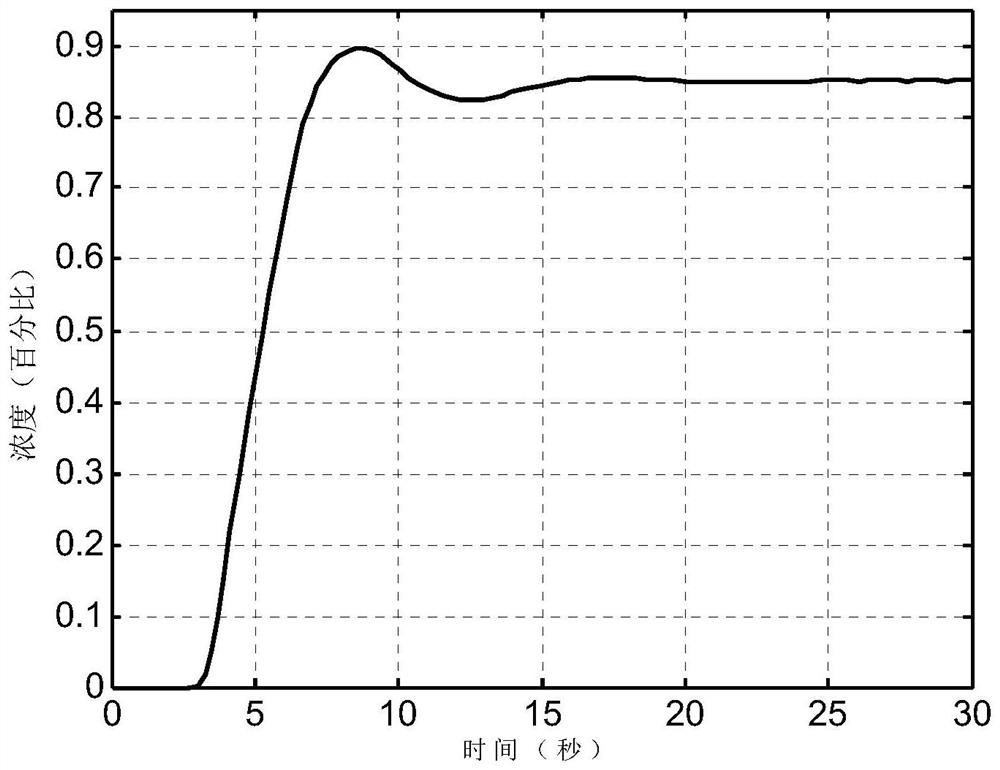

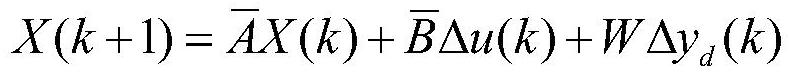

[0043] The content of slurry production process, model establishment, controller design and result analysis will be introduced below.

[0044] 1. Slurry production process

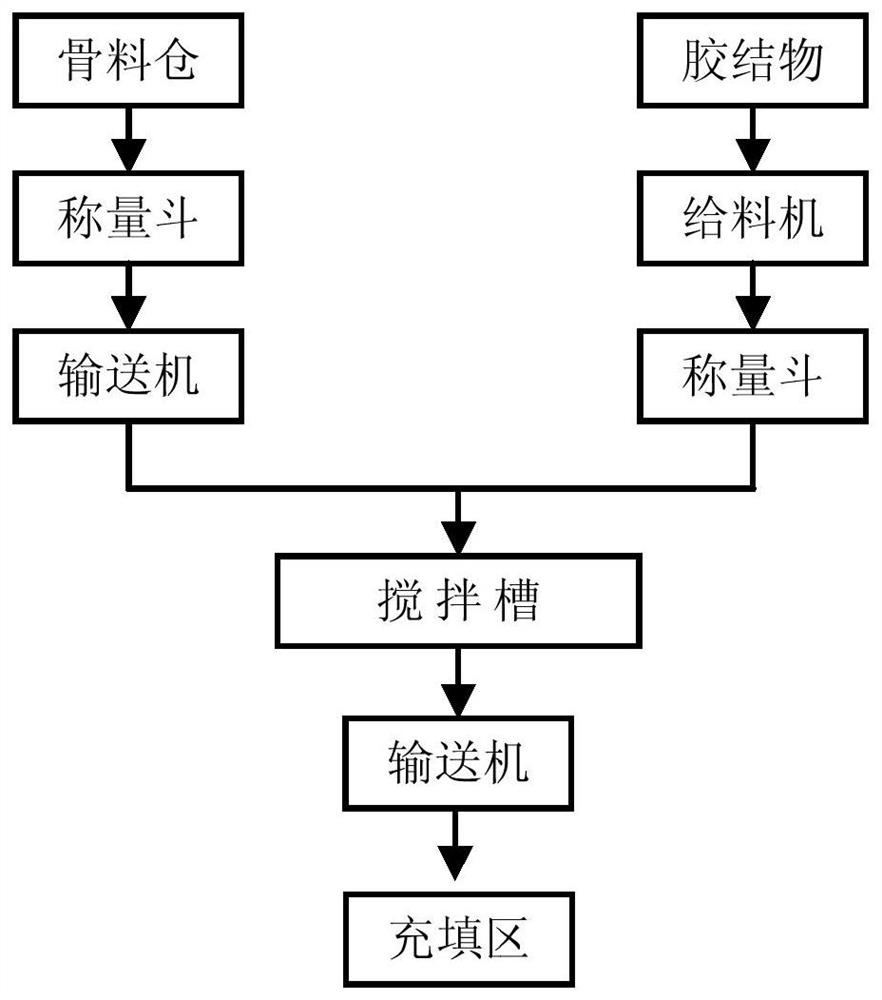

[0045] The aggregates considered in the present invention are mainly tailings. Before pulping, the aggregates need to be pretreated, such as crushing and filtering, to make them moderate in size and uniform in size. Cement and water are used as cement. Slurry production is to mix aggregate and cement according to a certain ratio to obtain a predetermined concentration of slurry. Finally, it is transported to the underground mined-out area through the pipeline for filling. The specific process such as figure 1 shown. Fromfigure 1 It can be seen that both the aggregate and the cement need to be weighed and then input to the mixing tank. In addition, it can also be seen from the process diagram that the production process requires a large space. The aggregate is usually stored far away from the mixing st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com