Feeding device and method for methanesulfonic acid electrotinning liquid additive

A methanesulfonic acid and feeding device technology, applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problem that the plating solution additives cannot be mixed quickly, and achieve the effect of reducing fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

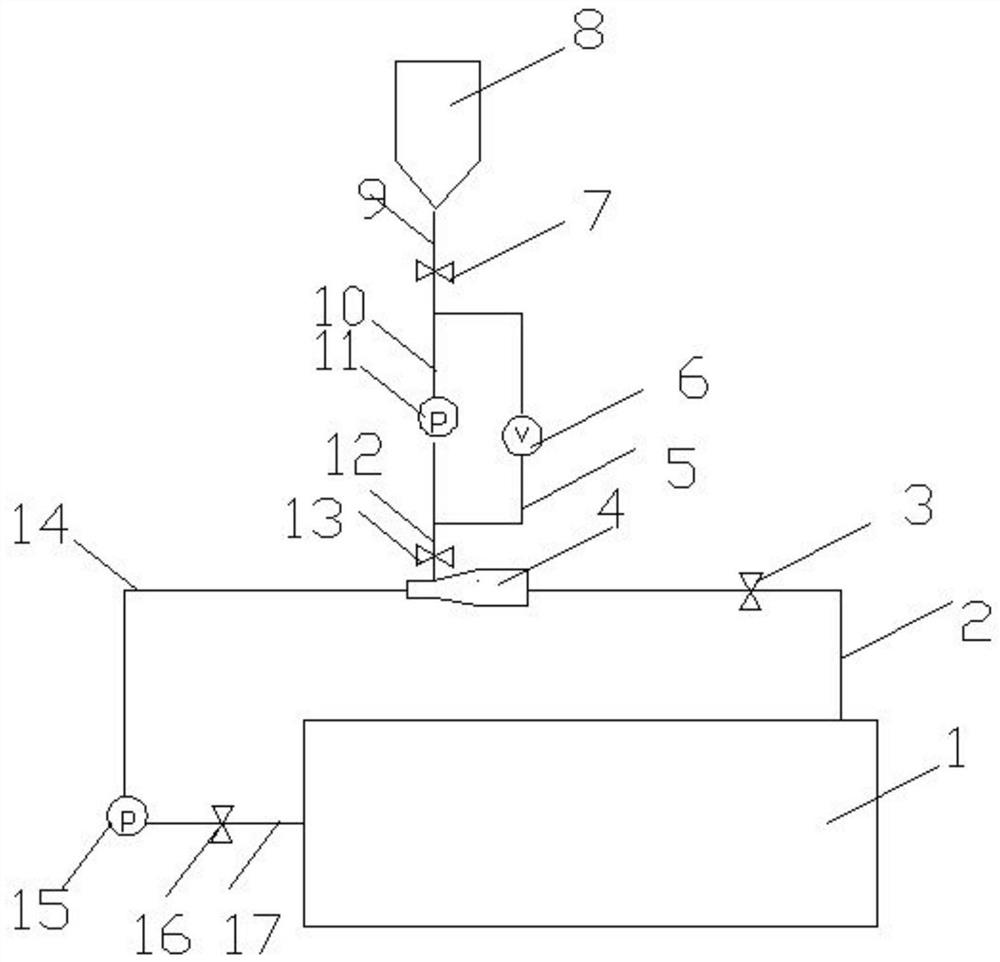

[0028] Embodiment 1, with reference to figure 1 , a feeding device for additives in methanesulfonic acid tin plating solution, comprising a plating solution self-circulation system and an additive feeding system, the plating solution self-circulation system comprising a plating solution circulation tank 1, a plating solution self-circulation pump 15 and a vacuum jet pump 4. The plating solution circulation tank 1 is connected to the liquid inlet of the plating solution self-circulation pump 15 through the plating solution self-circulation first pipeline 17, and the plating solution self-circulation pump inlet valve 16 is provided on the plating solution self-circulation first pipeline 17, and the vacuum jet The liquid inlet of the pump 4 is connected to the liquid outlet of the plating liquid self-circulation pump 15 through the second plating solution self-circulation pipe 14, and the liquid outlet of the vacuum jet pump 4 is connected to the plating solution circulation tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com