Purification device for organic waste gas

A purification device, a technology for organic waste gas, applied in chemical/physical/physical-chemical processes of energy application, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of low concentration, short residence time, large concentration fluctuation, etc. The regeneration process is simple to operate, the activated carbon filling amount is small, and the treatment process is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

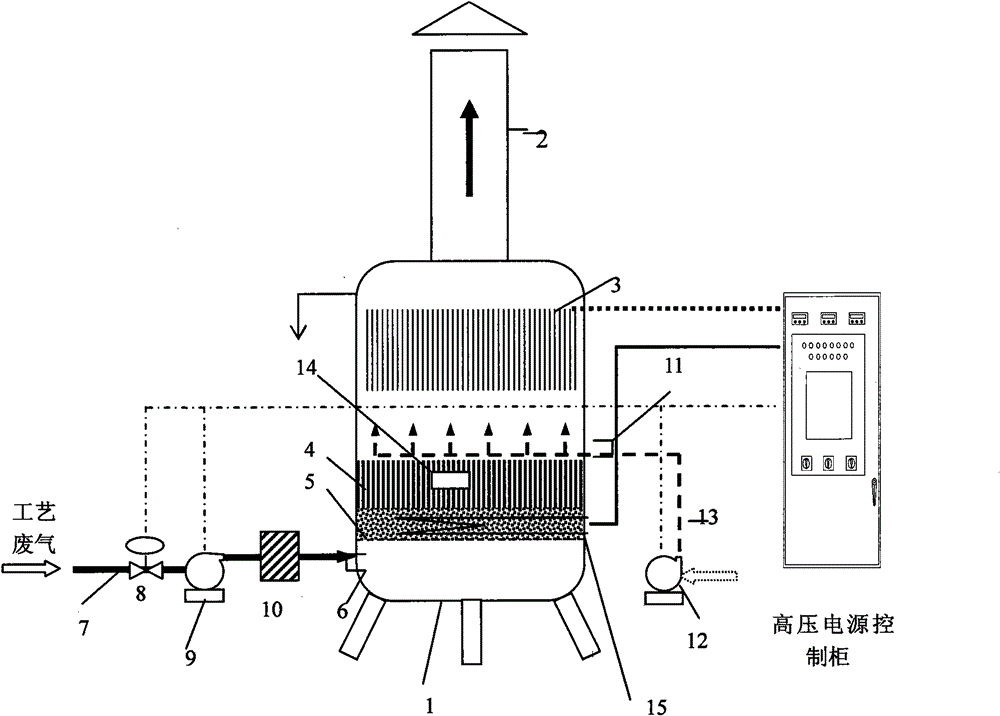

[0019] Such as figure 1 As shown, a purification device for organic waste gas includes a housing 1 of an exhaust gas purification tower, a concentrated exhaust tube 2 arranged on the housing 1, a plasma purifier 3 and a plasma purifier 3 arranged in the housing 1 The activated carbon adsorption bed 4 below is provided with a temperature measuring element 14 inside the activated carbon adsorption bed 4, and the temperature measuring element 14 is connected with an external temperature controller. The heating pipe 15 is provided with an exhaust gas inlet 6 on the housing 1, and the exhaust gas inlet 6 is connected to the air intake pipeline 7 outside the housing, and the air intake pipeline 7 is provided with an electric damper 8, an adsorption fan 9 and a filter 10 in sequence along the exhaust gas flow direction , the air inlet 11 on the shell of the exhaust gas purification tower 1 is connected with the external desorption fan 12 through the pipeline 13, the plasma purifier 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com