Method for controlling density ofsizing agent in hydrorefining work section of equipment of fine terephthalic acid

A technology of purified terephthalic acid and slurry concentration, which is applied in the preparation of carboxylate salts, chemical instruments and methods, and the preparation of organic compounds, and can solve problems such as unsatisfactory control quality, strong control effect, and difficulty in slurry concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

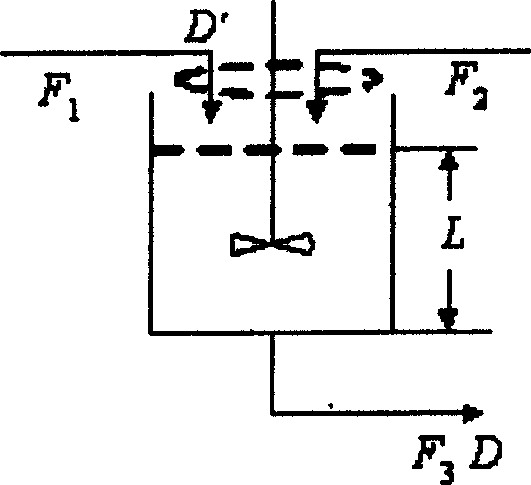

[0096] The control method of slurry concentration in this hydrorefining section takes the PTA device using the patented technology of Amoco Company as an example. In this device, the slurry tank ( figure 1 )'s main technical specifications are (outer diameter X height X wall thickness): Φ3600X5900X8, volume: 71.35m 3 . The specific implementation steps of the control method are:

[0097] 1. Under the condition of ensuring that the slurry concentration remains unchanged, the craftsman manually adjusts the speed of the two motors to calibrate the two screw propellers, and the screw propeller with the fastest material is used as the benchmark;

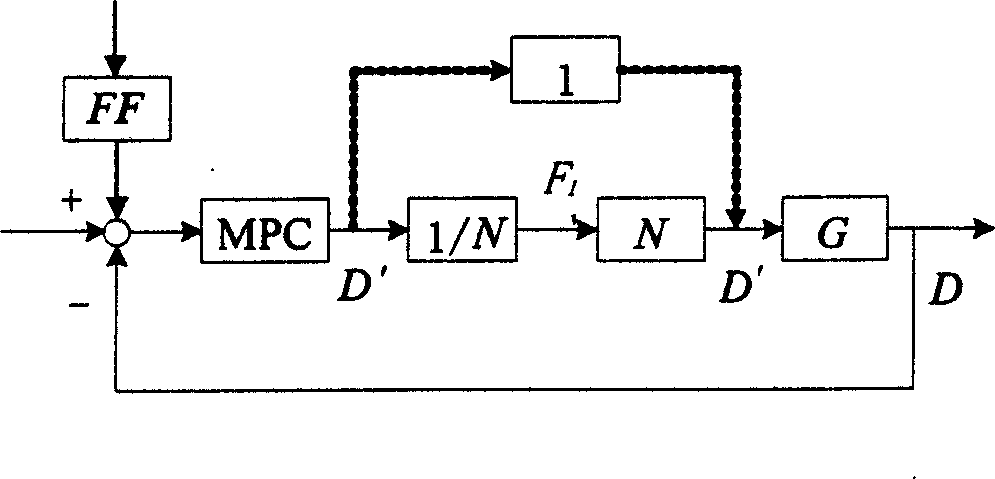

[0098] 2. After testing, it is determined that the speed coefficient of the reference screw propeller is 1.23, and the speed of the reference screw propeller motor is related to the mass flow rate of TA F 1 The coefficient N( figure 2) is 44.9;

[0099] 3. The speed of the reference propeller motor is changed in steps, and the transf...

Embodiment 2

[0109] The control method of the slurry concentration of the hydrorefining section, the PTA device and the parameters of each step are the same as those in Example 1.

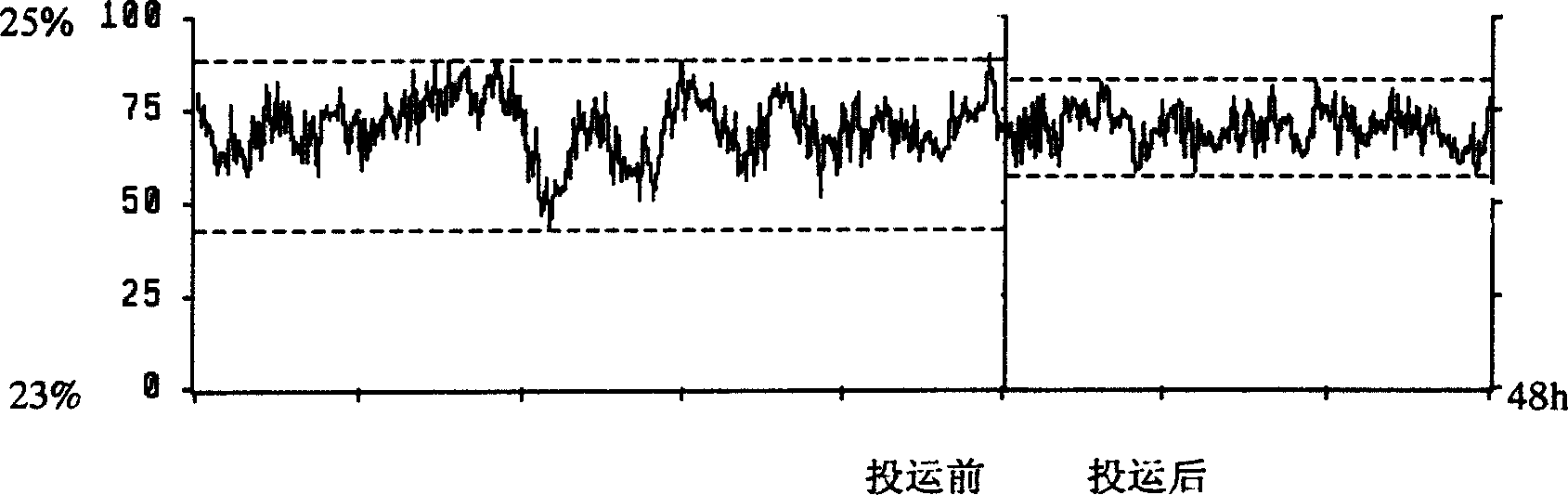

[0110] The real-time operation results in Fig. 3: Before the dividing line is the manually controlled slurry concentration fluctuation curve, and after the dividing line is the slurry concentration fluctuation curve after the operation of the control method.

[0111] exist Figure 3.2 Among them, before the operation of this control method, the fluctuation range of slurry concentration is 24.63-23.73 when manual control is adopted, and the average value of slurry concentration is 24.2. Because the average value of the concentration is low at this time, when the control method is running, the set value of the slurry concentration is increased to 24.5, and the actual operation effect is: the fluctuation range of the slurry concentration is 24.75 to 24.3, and the average value of the slurry concentration is 24.52,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com