Optimal control method based on oxidation-reduction potential and used for liquid zinc purification and copper removal process

A zinc liquid purification and process optimization technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problem of unqualified copper ion concentration at the outlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

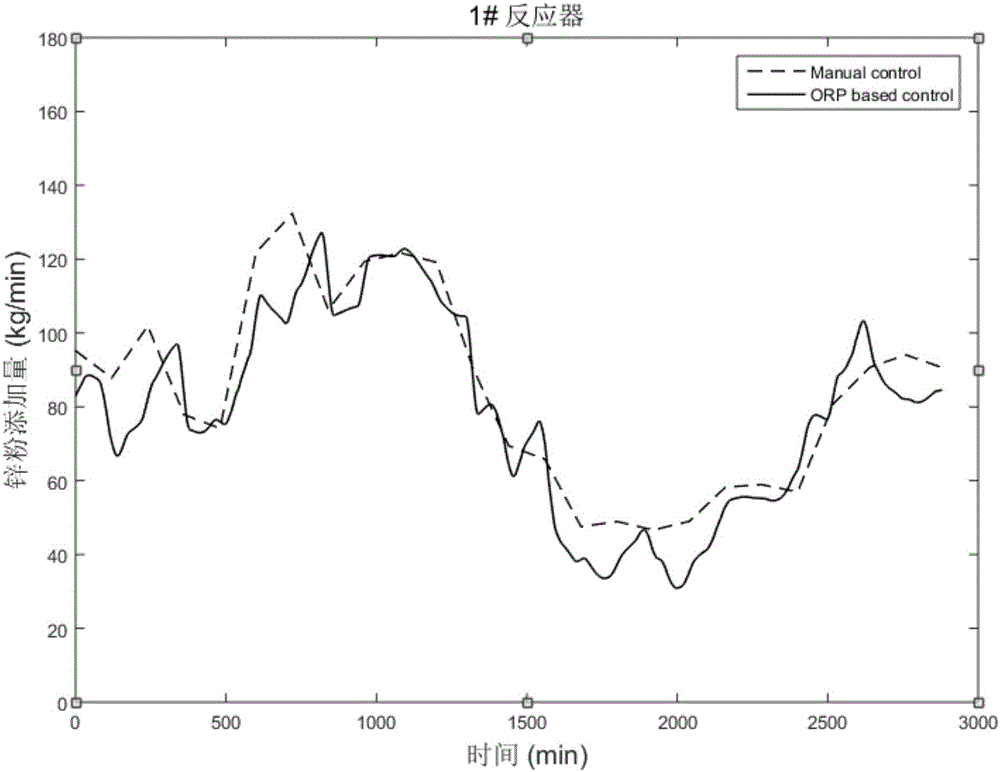

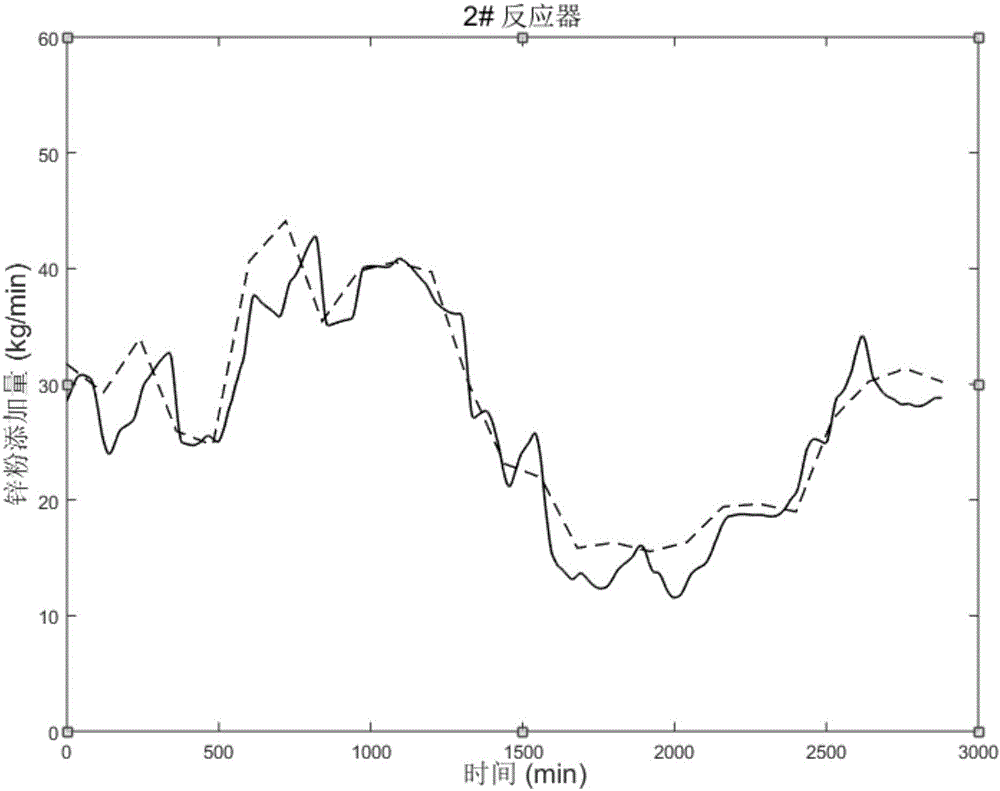

[0058] Embodiment 1: The copper removal process of the hydrometallurgy zinc smelting process in a certain lead-zinc factory is taken as an example to illustrate the superiority of the present invention.

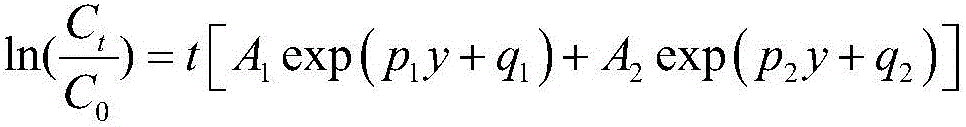

[0059] The first step is to establish the relationship model between redox potential and copper ion concentration in the copper removal process and the control model of zinc powder addition, and carry out parameter identification.

[0060] In the second step, the operating condition data is collected at time T and compared with the identification data, and the adjustment instruction is determined according to the comparison result.

[0061] The third step is to perform model retraining or controller selection according to the obtained adjustment instructions. The expert rules of the controller are as follows:

[0062] R i 1 : y T ∈ [ Y ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com