Automatic tempering liquid dispensing method based on online conductivity measurement

An automatic liquid preparation and leveling liquid technology, which is applied in various fluid ratio control, material resistance, etc., can solve the problems of heavy operator workload and large leveling liquid concentration fluctuations, so as to avoid temperature fluctuations, improve board surface quality, Effect of reducing concentration fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

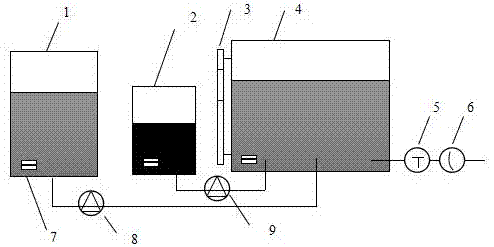

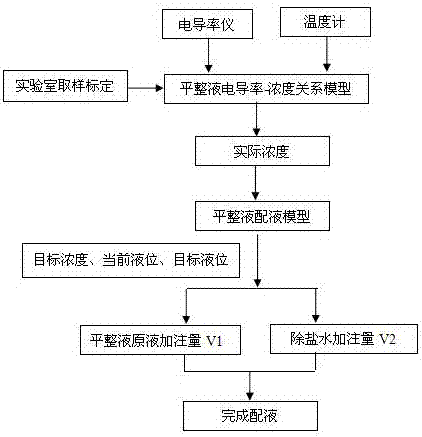

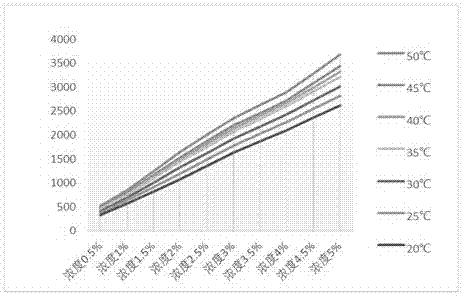

[0023] attached Figure 1-3 It is a specific embodiment of the present invention. The invention is an automatic leveling liquid dosing method based on online conductivity measurement, which includes the following steps: leveling liquid conductivity-concentration relationship model - online conductivity detection - leveling liquid dosing model - dosing execution device; The leveling liquid conductivity-concentration relationship model is described, which mainly characterizes the corresponding relationship between the leveling liquid conductivity and the concentration of different types of leveling liquids under different temperature conditions. It is obtained by regular sampling and testing in the laboratory. Liquid conductivity-concentration relationship curve, c(x)=f(T, K), where c(x)——x model leveling liquid concentration, T——leveling liquid temperature, K——leveling liquid conductivity; The online conductivity detection is to install a conductivity detector and a thermomete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com