Modified austenitic stainless steel surfacing electrode and preparation method thereof

A technology of austenitic stainless steel and surfacing electrodes, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of maintenance time delay, pressure vessel maintenance difficulty, high maintenance cost, etc., and achieve the effect of improving physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

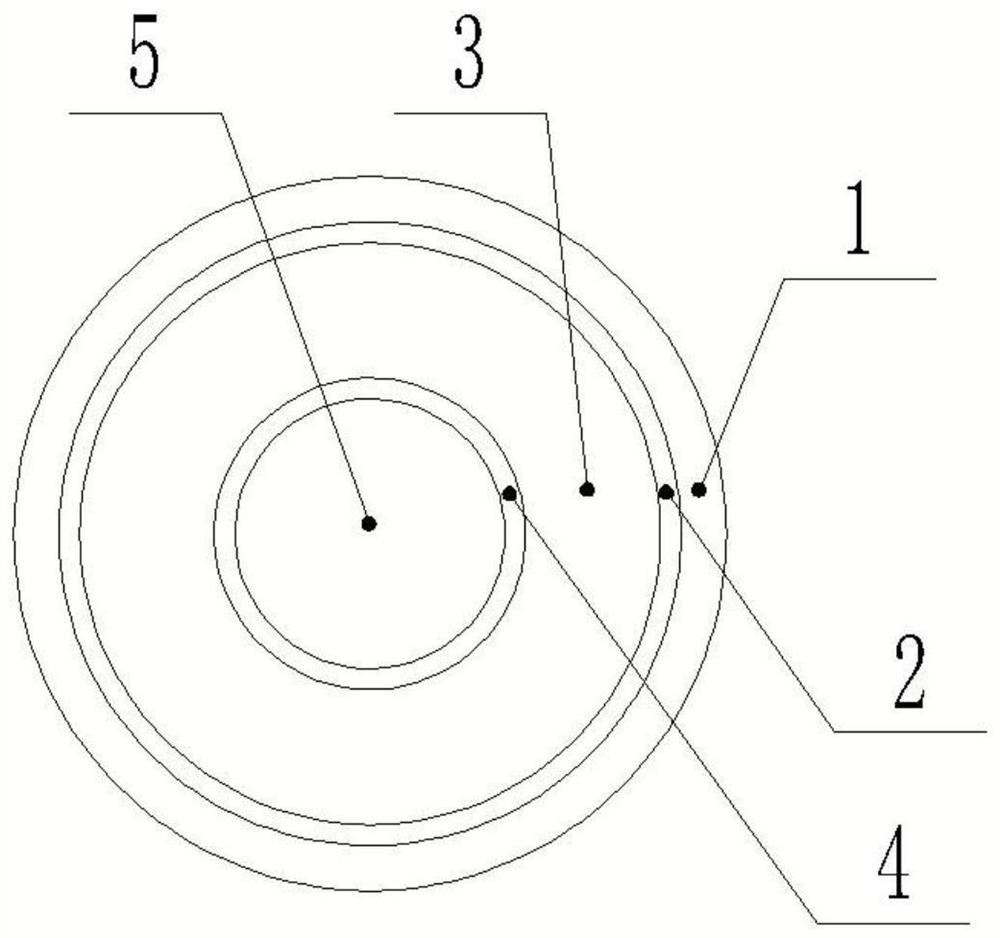

[0035] Such as figure 1 As shown, a modified austenitic stainless steel surfacing electrode includes a coating 1 and a welding core; the welding core includes a second interlayer 2, an outer layer of the welding core 3, a first interlayer 4 and an inner layer of the welding core from outside to inside 5. The inner layer 5 of the welding core includes metal chromium powder and graphite; the outer layer 3 of the welding core includes nickel powder, silicon powder, manganese powder and iron powder; the weight percentage of each component in the inner layer 5 of the welding core and the outer layer 3 of the welding core is: metal Chromium powder 22.26-24.73%, graphite 0.05-0.12%, nickel powder 9.89-13.6%, silicon powder 0.93%, manganese powder 2.47% and iron powder 58.15-64.4%; the materials of the first interlayer and the second interlayer are both No. 10 steel.

[0036] The above-mentioned modified austenitic stainless steel surfacing electrode changes the traditional electrod...

Embodiment 2

[0038] Such as figure 1 As shown, a modified austenitic stainless steel surfacing electrode includes a coating 1 and a welding core; the welding core includes a second interlayer 2, an outer layer of the welding core 3, a first interlayer 4 and an inner layer of the welding core from outside to inside 5. The inner layer 5 of the welding core includes metal chromium powder and graphite; the outer layer 3 of the welding core includes nickel powder, silicon powder, manganese powder, rare earth element oxides and iron powder; The weight percentage is: metal chromium powder 22.26-24.73%, graphite 0.05-0.12%, nickel powder 9.89-13.6%, silicon powder 0.93%, manganese powder 2.47%, rare earth oxide powder 2.47%-6.18% and iron powder 51.97-61.93% %.

[0039] For the above-mentioned modified austenitic stainless steel surfacing electrode, rare earth element oxides are added to the outer layer 3 of the welding core. Under the action of molten pool reflow during the welding process, the...

Embodiment 3

[0041] Such as figure 1 As shown, a modified austenitic stainless steel surfacing electrode includes a coating 1 and a welding core; the welding core includes a second interlayer 2, an outer layer of the welding core 3, a first interlayer 4 and an inner layer of the welding core from outside to inside 5. The inner layer 5 of the welding core includes metal chromium powder, graphite and molybdenum powder; the outer layer 3 of the welding core includes nickel powder, silicon powder, manganese powder, rare earth element oxide and iron powder; the inner layer 5 of the welding core and the outer layer 3 of the welding core The weight percentage of each component is: metal chromium powder 19.78-22.56%, graphite 0.043%, molybdenum powder 2.47-3.71%, nickel powder 9.89-13.6%, silicon powder 0.93%, manganese powder 2.47%, rare earth oxide powder 2.47%- 6.18% and iron powder 50.51-61.95%.

[0042] The above-mentioned modified austenitic stainless steel surfacing welding electrode adds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com