Polyethylene terephthalate composite material and preparation method thereof

A technology of polyethylene terephthalate and composite materials, applied in the field of engineering plastics, can solve problems such as poor repeatability, high cost, and harsh conditions for continuous fiber reinforcement, so as to improve interface adhesion and improve mechanical properties. The effect of performance and thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

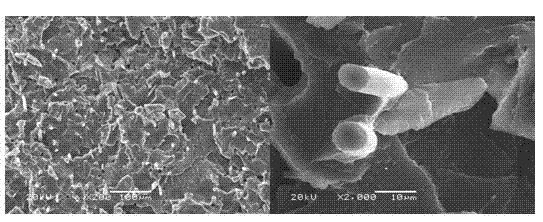

Image

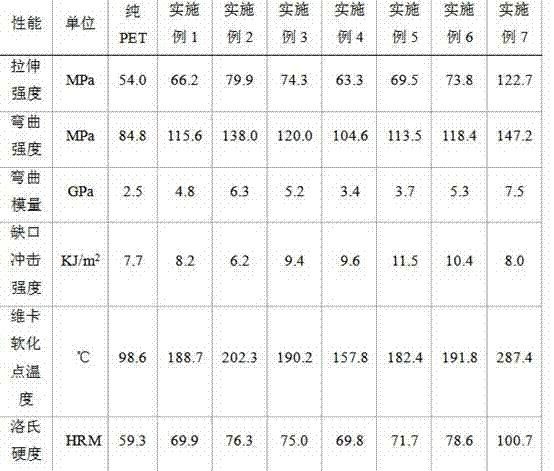

Examples

Embodiment 1

[0026] ①The weight percentage of PET is 89%, chopped carbon fiber without surface treatment 10%, tetrakis (β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester 0.05%, three ( 2,4-di-tert-butylphenyl) phosphite 0.05%, dry-mixed at room temperature for 5 minutes in a high-speed mixer;

[0027] ②The twin-screw extruder is melt-extruded and granulated to make composite materials. The heating zones of the screw are: Zone 1 245°C, Zone 2 255°C, Zone 3 260°C, Zone 4 265°C, Zone 5 270°C, the head temperature is 260°C; the screw speed is 50 rpm; the feeding speed is 15 rpm.

Embodiment 2

[0029] ①The weight percentage of PET is 84%, chopped carbon fiber without surface treatment 15%, tetrakis (β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester 0.05%, three ( 2,4-di-tert-butylphenyl) phosphite 0.05%, dry-mixed at room temperature for 5 minutes in a high-speed mixer;

[0030] ②The twin-screw extruder is melt-extruded and granulated to make composite materials. The heating zones of the screw are: Zone 1 245°C, Zone 2 255°C, Zone 3 260°C, Zone 4 265°C, Zone 5 270°C, the head temperature is 260°C; the screw speed is 50 rpm; the feeding speed is 15 rpm.

example 3

[0032] ①At a temperature of 100°C, after immersing the carbon fiber in sulfuric acid for 1 hour, spray a titanate coupling agent on the surface of the carbon fiber;

[0033] ②The weight percentage of PET is 89%, the chopped carbon fiber after treatment is 10%, tetrakis (β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester 0.5%, three (2, 4-di-tert-butylphenyl) phosphite 0.5% and dry-mixed at room temperature for 5 minutes in a high-speed mixer;

[0034] ③The twin-screw extruder is melt-extruded and granulated to make composite materials. The heating zones of the screw are: Zone 1 245°C, Zone 2 255°C, Zone 3 260°C, Zone 4 265°C, Zone 5 270°C, the head temperature is 260°C; the screw speed is 50 rpm; the feeding speed is 15 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com