Antistatic, wear-resistant and high-performance PS composite material and preparation method thereof

A composite material and high-performance technology, which is applied in the field of antistatic and wear-resistant high-performance PS composite materials and its preparation, can solve problems that have not been reported and limit the application of PS composite materials, and achieve improved mechanical properties, strong three-dimensional protection, The effect of preventing reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the wear-resistant high-performance PS composite material of any one of the above, comprising the following steps:

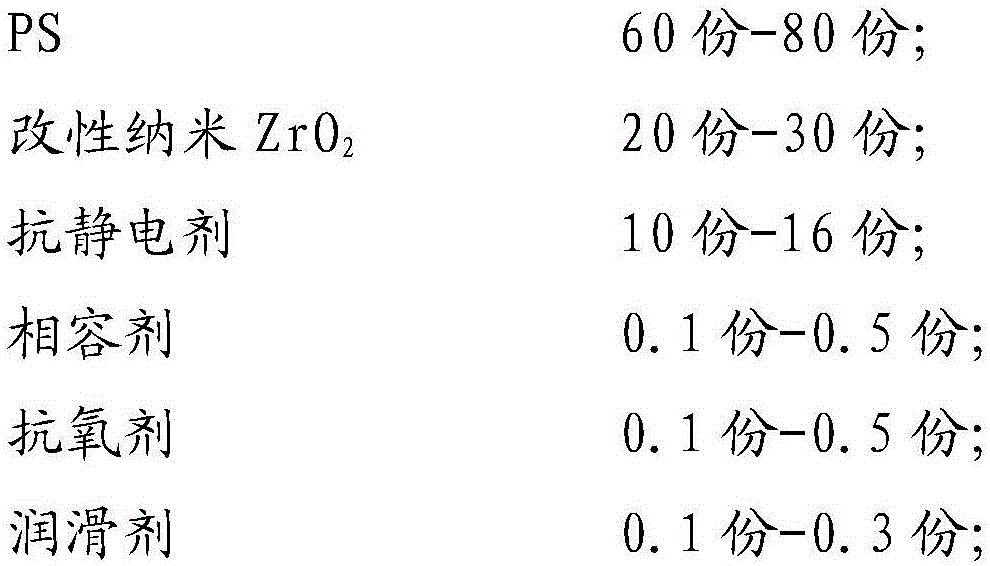

[0039] (1) Weigh 60-80 parts of PS, 20-30 parts of modified nano-ZrO 2 , 0.1-0.5 parts of MAH-SEBS, 0.1-0.5 parts of antioxidant, 0.1-0.3 parts of lubricant are mixed and stirred evenly to obtain a mixture;

[0040] (2) Extruding and granulating the mixture obtained in step (1) to obtain a PS composite material.

[0041] Preferably, the step (2) specifically includes: putting the mixture obtained in the step (1) into the hopper of a twin-screw extruder to extrude and granulate to obtain a PS composite material, wherein the twin-screw extruder The output machine includes six temperature zones arranged in sequence, the temperature of the first zone is 140-180°C, the temperature of the second zone is 190-230°C, the temperature of the third zone is 190-230°C, the temperature of the fourth zone is 190-230°C, and the temperature of th...

preparation example 1

[0048] Modified Nano ZrO 2 , its preparation method is as follows:

[0049] (1) Weigh a certain amount of butyl acrylate (BA), nano ZrO 2, potassium persulfate (KPS), aluminum sulfate, sodium dodecylbenzenesulfonate; BA, nano ZrO 2 , Potassium persulfate (KPS), aluminum sulfate, and sodium dodecylbenzenesulfonate have a mass ratio of 10:30:0.3:1:0.1; nanometer ZrO 2 The diameter is 40-80nm.

[0050] (2) KPS, sodium dodecylbenzenesulfonate, BA, nano ZrO 2 Put it into a three-necked flask, react in an oil bath at 160-180°C for 6-12 hours, then add aluminum sulfate to break the emulsion for 6-10 hours, filter and wash to obtain modified nano-ZrO 2 .

preparation example 2

[0052] Modified Nano ZrO 2 , its preparation method is as follows:

[0053] (1) Weigh a certain amount of butyl acrylate (BA), nano ZrO 2 , potassium persulfate (KPS), aluminum sulfate, sodium dodecylbenzenesulfonate; BA, nano ZrO 2 , Potassium persulfate (KPS), aluminum sulfate, and sodium dodecylbenzenesulfonate have a mass ratio of 10:40:0.7:3:0.3; nanometer ZrO 2 The diameter is 40-80nm.

[0054] (2) KPS, sodium dodecylbenzenesulfonate, BA, nano ZrO 2 Put it into a three-necked flask, react in an oil bath at 160-180°C for 6-12 hours, then add aluminum sulfate to break the emulsion for 6-10 hours, filter and wash to obtain modified nano-ZrO 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com