Preparation method of in-situ micro-nano particle-reinforced Al-Cu-Mg-Si alloy sheet in melt

An al-cu-mg-si, micro-nano particle technology, applied in the field of alloy sheet preparation, can solve the problems of restricting the development and application of aluminum alloys, poor creep resistance, low high temperature strength, etc. Large, improved mechanical properties, large number of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

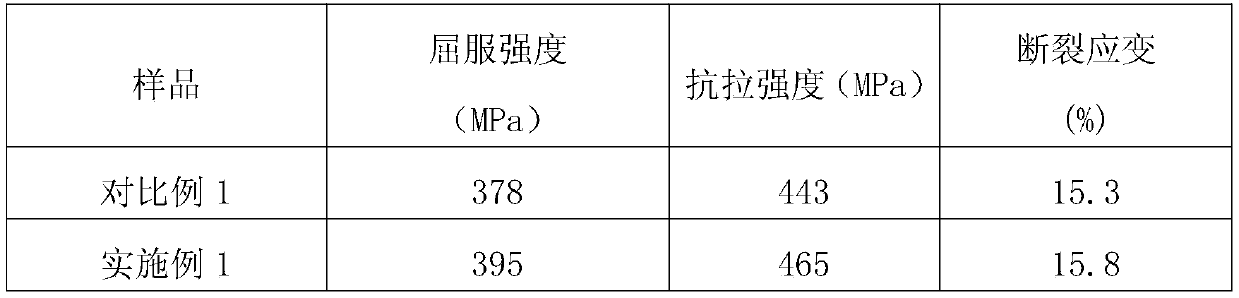

Examples

Embodiment 1

[0050] A method for preparing an Al-Cu-Mg-Si alloy sheet strengthened by in-situ micro-nano particles in a melt, the specific method is as follows:

[0051] Step 1, prepare Al-Ti-B 4 C system compact:

[0052] (1)B 4 Ball milling activation pretreatment of C powder: the particle size is 2.6μmB 4 C powder is put into the ball mill tank; the ball-to-material ratio is 100:1, and ball milled for 3 hours at a ball milling speed of 200r / min;

[0053] (2) Al alloy powder with a particle size of 45 μm, Ti powder with a particle size of 25 μm and B after ball milling 4 C powder mixed into 100g, Al alloy powder: 70.3wt.%; Ti powder: 21.4wt.%; B 4 C powder: 8.3wt.%; put 100g of the mixed powder into the ball mill tank in the mixer, and mix for 36 hours at a speed of 60r / min;

[0054] Among them, in addition to aluminum Al, the composition of the aluminum alloy powder is: copper Cu: 4.2%; magnesium Mg: 0.7%; silicon Si: 1%; zinc Zn: 0.15%; manganese Mn: 0.6%; titanium Ti: 0.1%; Nick...

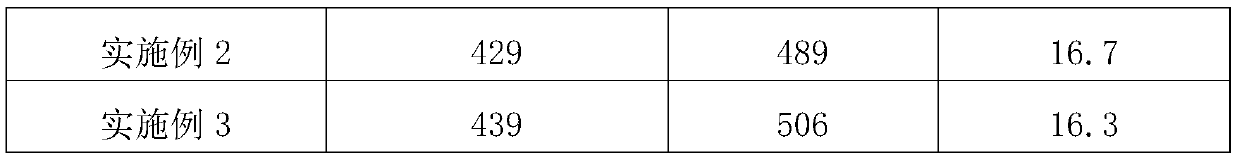

Embodiment 2

[0072] A method for preparing an Al-Cu-Mg-Si alloy sheet strengthened by in-situ micro-nano particles in a melt, the specific method is as follows:

[0073] Step 1, prepare Al-Ti-B4 C system compact:

[0074] (1)B 4 Ball mill activation pretreatment of C powder: the particle size is 1.2μmB 4 C powder is put into the ball mill jar; the ball-to-material ratio is 100:1, and ball milled for 1.5 hours at a ball milling speed of 260r / min;

[0075] (2) Al alloy powder with a particle size of 60 μm, Ti powder with a particle size of 15 μm and B after ball milling 4 C powder mixed to 3.86kg, Al alloy powder: 74.1wt.%; Ti powder: 18.7wt.%; B 4 C powder: 7.2wt.%; put 3.86kg of mixed powder into the ball mill tank in the mixer, and mix for 8 hours at a speed of 30r / min;

[0076] Among them, in addition to aluminum Al, the composition of the aluminum alloy powder is: Copper Cu: 4.4%; Magnesium Mg: 0.6%; Silicon Si: 0.7%; Zinc Zn: 0.2%; Manganese Mn: 0.6%; Titanium Ti: 0.1%; Nickel Ni:...

Embodiment 3

[0094] A method for preparing an Al-Cu-Mg-Si alloy sheet strengthened by in-situ micro-nano particles in a melt, the specific method is as follows:

[0095] Step 1, prepare Al-Ti-B 4 C system compact:

[0096] (1)B 4 Ball milling activation pretreatment of C powder: the particle size is 2.9μmB 4 C powder is put into the ball mill tank; the ball-to-material ratio is 100:1, and ball milled for 2 hours at a ball milling speed of 300r / min;

[0097] (2) Al alloy powder with a particle size of 15 μm, Ti powder with a particle size of 45 μm and B after ball milling 4 C powder mixed into 505g, Al alloy powder: 80.2wt.%; Ti powder: 14.3wt.%; B 4 C powder: 5.5wt.%; put 505g of the mixed powder into the ball mill tank in the mixer, and mix for 24 hours at a speed of 80r / min;

[0098] Among them, in addition to aluminum Al, the composition of the aluminum alloy powder is: Copper Cu: 3.9%; Magnesium Mg: 0.5%; Silicon Si: 1.1%; Zinc Zn: 0.8%; Manganese Mn: 0.9%; Titanium Ti: 0.12%; Ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com