Method for improving compactness of silicon dioxide coating layer on surface of titanium dioxide

A technology of silica and titanium dioxide, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of limited improvement of coating uniformity and compactness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

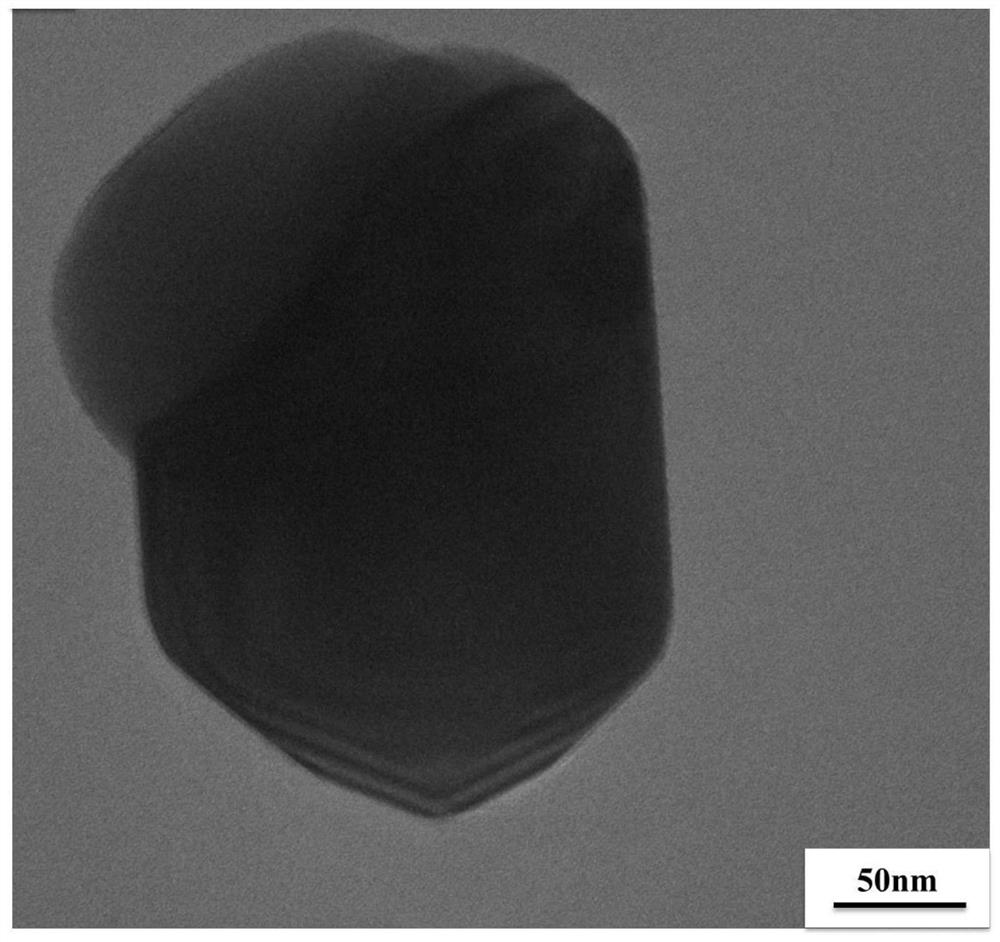

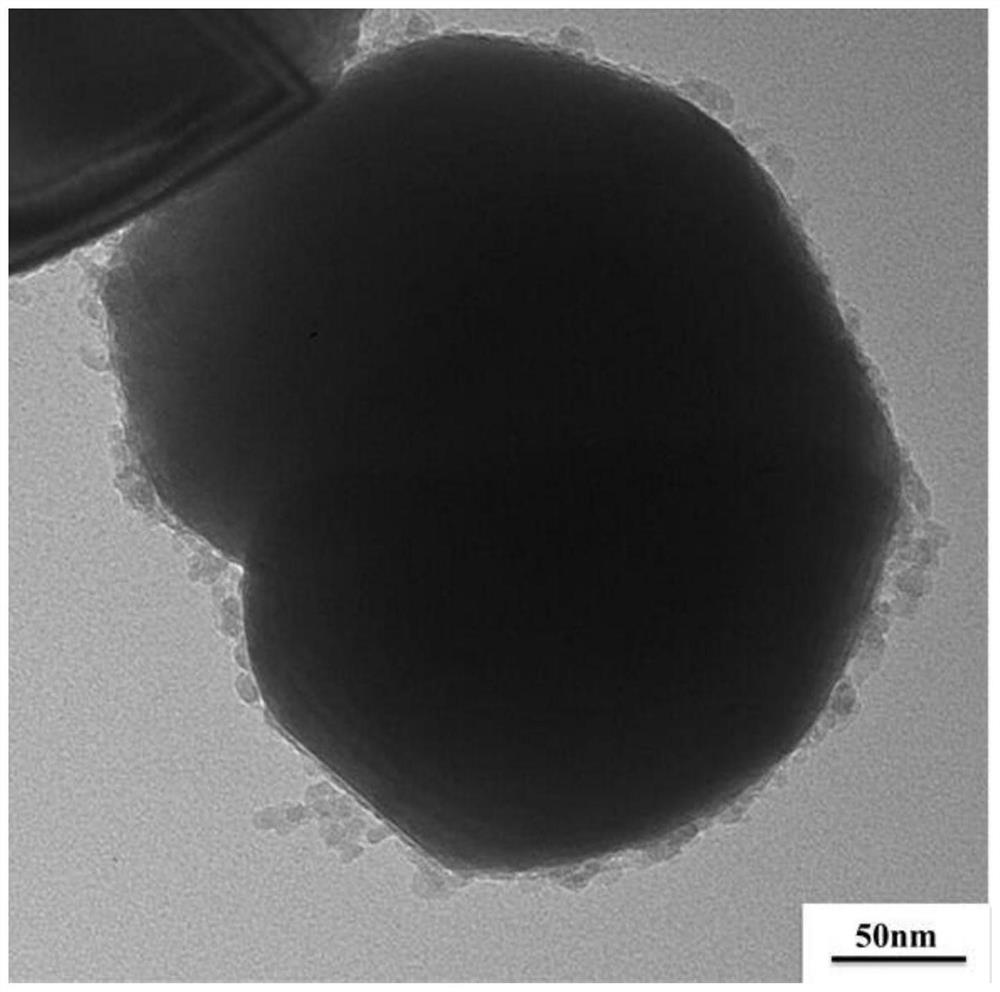

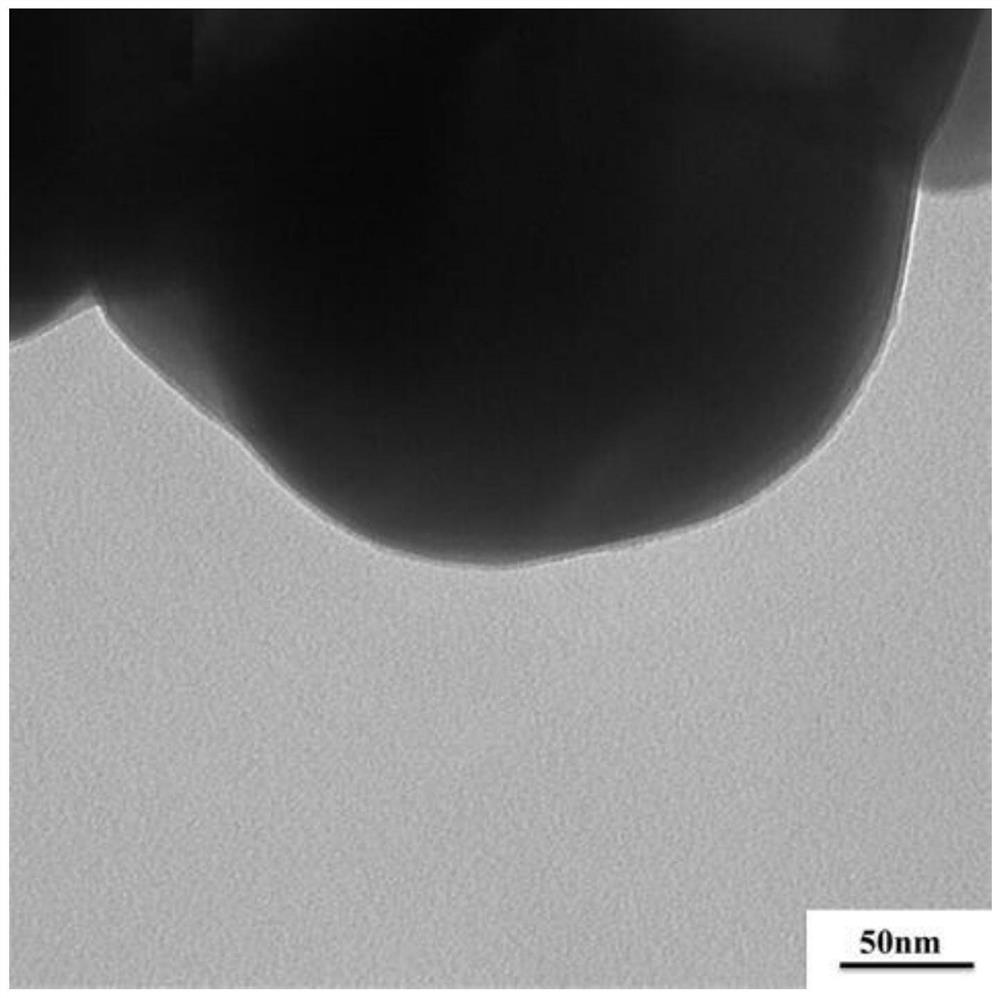

Image

Examples

Embodiment 1

[0026] (1) Get 200g of titanium dioxide and disperse it in water, configure the initial slurry of titanium dioxide with a mass concentration of 40%;

[0027] (2) Set the reaction temperature to 90°C, and keep the temperature constant during the titanium dioxide coating process;

[0028] (3) Under the action of stirring, trisodium citrate accounting for 0.05% of the mass of titanium dioxide and NaCl solid accounting for 8% of the mass of titanium dioxide are added to the titanium dioxide slurry;

[0029] (4) adjust slurry pH value to be 11 with NaOH solution;

[0030] (5) Use a peristaltic pump to drop sodium silicate and flow-coat dense SiO 2 coating layer, the addition of the sodium silicate is SiO 2 accounted for 4.0% of the mass of titanium dioxide, while maintaining a pH value of 11 with NaOH solution, and aging for 2 hours;

[0031] (6) Wash the mature slurry obtained in step (5), then dry and steam powder treatment to obtain dense SiO 2 coated with titanium dioxide. ...

Embodiment 2

[0033] (1) Get 200g of titanium dioxide and disperse it in water, configure the initial slurry of titanium dioxide with a mass concentration of 40%;

[0034] (2) Set the reaction temperature to 90°C, and keep the temperature constant during the titanium dioxide coating process;

[0035] (3) Add 0.1% trisodium citrate by mass of titanium dioxide and 8% NaCl solids by mass of titanium dioxide into the titanium dioxide slurry under stirring;

[0036] (4) adjust slurry pH value to be 11 with NaOH solution;

[0037] (5) Use a peristaltic pump to drop sodium silicate and flow-coat dense SiO 2 coating layer, the addition of the sodium silicate is SiO 2 accounted for 4.0% of the mass of titanium dioxide, while maintaining a pH value of 11 with NaOH solution, and aging for 2 hours;

[0038] (6) Wash the mature slurry obtained in step (5), then dry and steam powder treatment to obtain dense SiO 2 coated with titanium dioxide.

Embodiment 3

[0040] (1) Get 200g of titanium dioxide and disperse it in water, configure the initial slurry of titanium dioxide with a mass concentration of 40%;

[0041] (2) Set the reaction temperature to 90°C, and keep the temperature constant during the titanium dioxide coating process;

[0042] (3) Add 0.15% trisodium citrate by mass of titanium dioxide and 8% NaCl solids by mass of titanium dioxide into the titanium dioxide slurry under stirring;

[0043] (4) adjust slurry pH value to be 11 with NaOH solution;

[0044] (5) Use a peristaltic pump to drop sodium silicate and flow-coat dense SiO 2 coating layer, the addition of the sodium silicate is SiO 2 accounted for 4.0% of the mass of titanium dioxide, while maintaining a pH value of 11 with NaOH solution, and aging for 2 hours;

[0045] (6) Wash the mature slurry obtained in step (5), then dry and steam powder treatment to obtain dense SiO 2 coated with titanium dioxide.

[0046] The coated product obtained after pre-dispersi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com