Preparation method, product and application of BiOI/WO3 heterojunction efficient photoelectrocatalysis electrodes

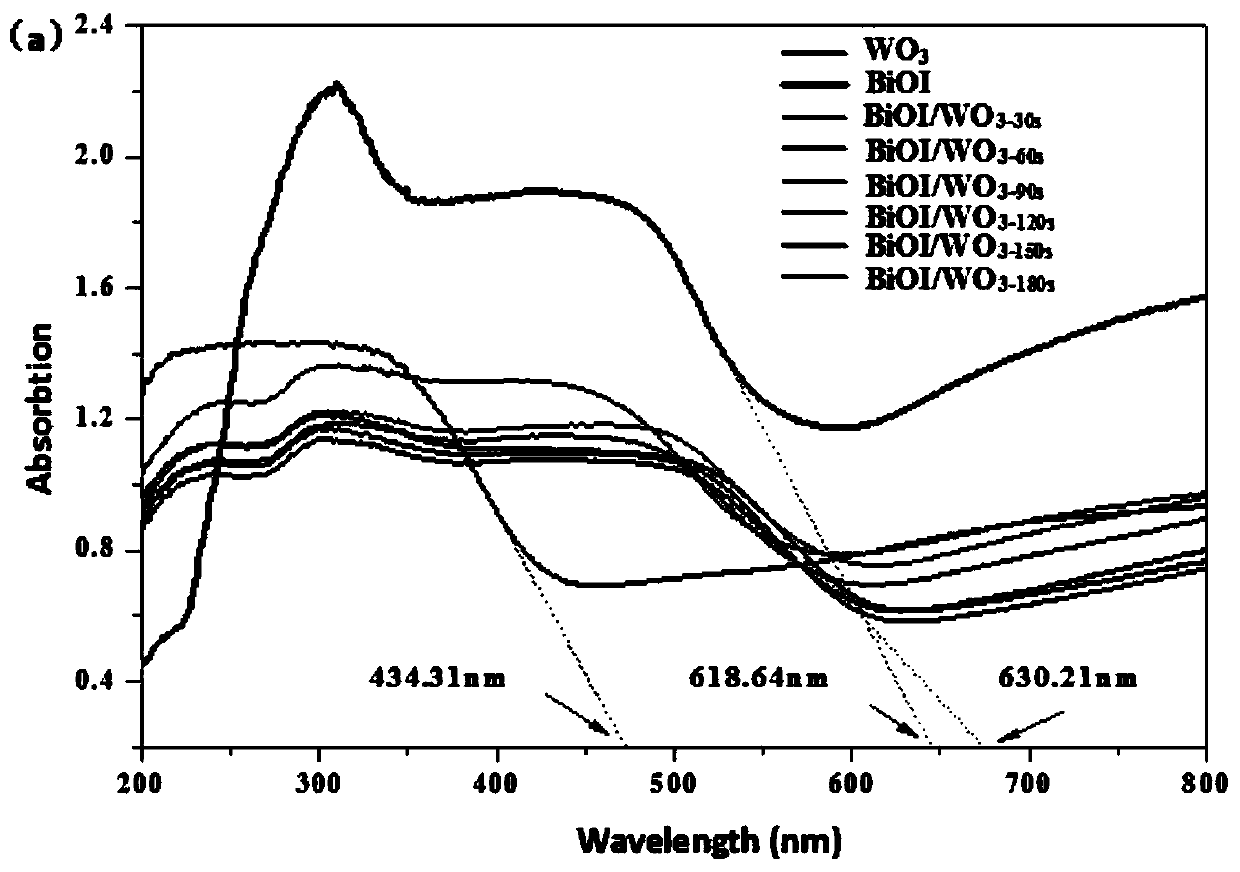

A photoelectric catalysis, heterojunction technology, applied in chemical instruments and methods, physical/chemical process catalysts, water/sludge/sewage treatment, etc. The problem of high hole-pair recombination rate, to achieve the effect of broadening the light absorption range, broadening the visible light response wavelength, and excellent electron mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

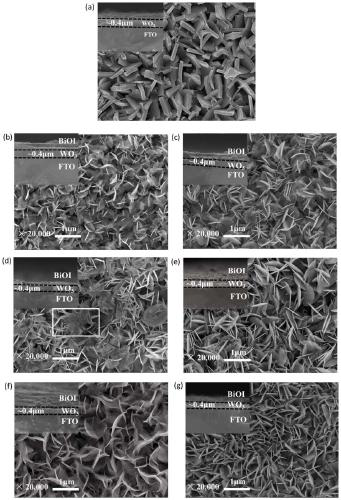

[0036] Step 1: WO 3 Preparation of photoelectrocatalytic electrodes

[0037] 0.231g Na 2 WO 4 ·H 2 O was dissolved in 30ml of deionized water and continuously magnetically stirred to make it evenly mixed, and 10ml of 3mol / L HCl solution was added dropwise to the solution, and 0.2g (NH 4 ) 2 C 2 o 4 , continue to stir for 10 minutes, add 30ml of deionized water again, stir magnetically for 30 minutes, place the FTO conductive glass in the hydrothermal reaction kettle with the above solution, transfer the hydrothermal reaction kettle to the oven, and control the hydrothermal reaction temperature to 120°C , stop the reaction after 2h, and after the hydrothermal reactor is cooled to room temperature, WO will grow 3 The FTO conductive glass was taken out, washed with deionized water, dried in an oven at 60°C for 20min, and then calcined in a muffle furnace at 500°C for 1h to obtain WO 3 Photoelectrocatalytic electrodes.

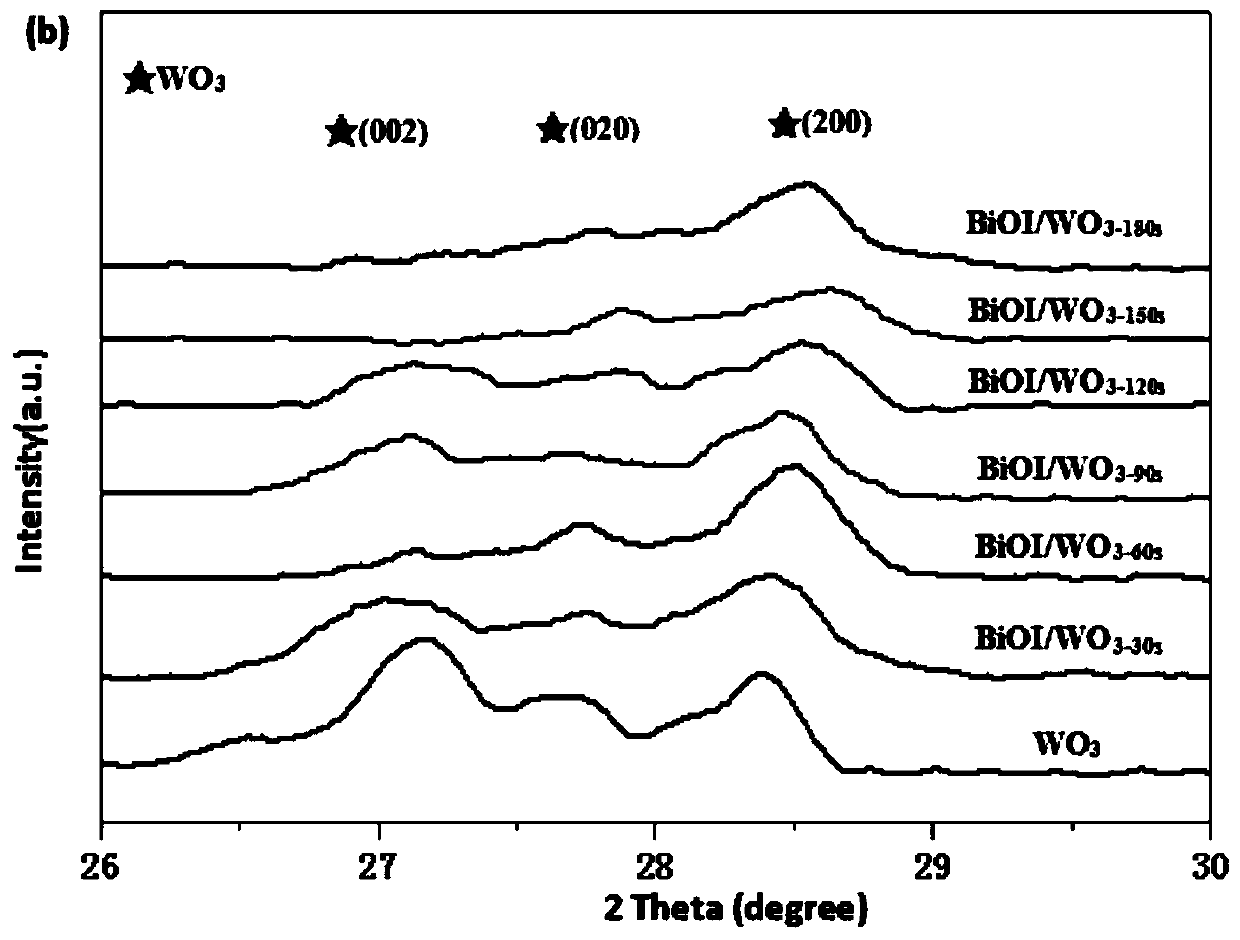

[0038] Step 2: BiOI / WO 3 Preparation of Heterojunc...

Embodiment 2

[0041] The preparation process is the same as in Example 1, the difference is that the electrodeposition time is 60s, and BiOI / WO 3-60S Heterojunction photocatalytic electrodes.

Embodiment 3

[0043] The preparation process is the same as in Example 1, the difference is that the electrodeposition time is 90s, and BiOI / WO 3-90S Heterojunction photocatalytic electrodes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com