Antibacterial and high-performance PS composite material and preparation method thereof

A composite material, high-performance technology, applied in the field of antibacterial high-performance PS composite material and its preparation, can solve the problems of poor compatibility between mica powder and PS matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

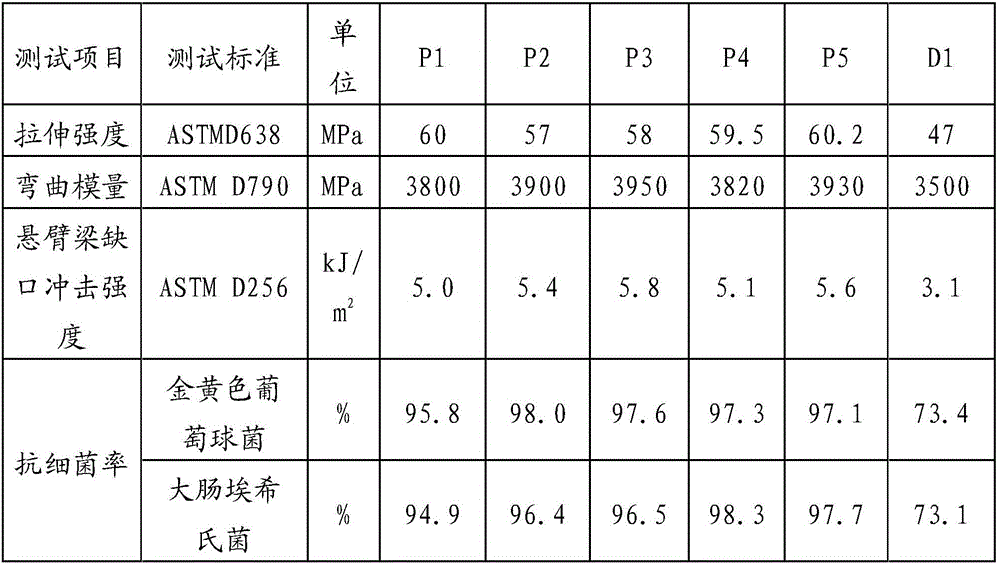

Examples

preparation example Construction

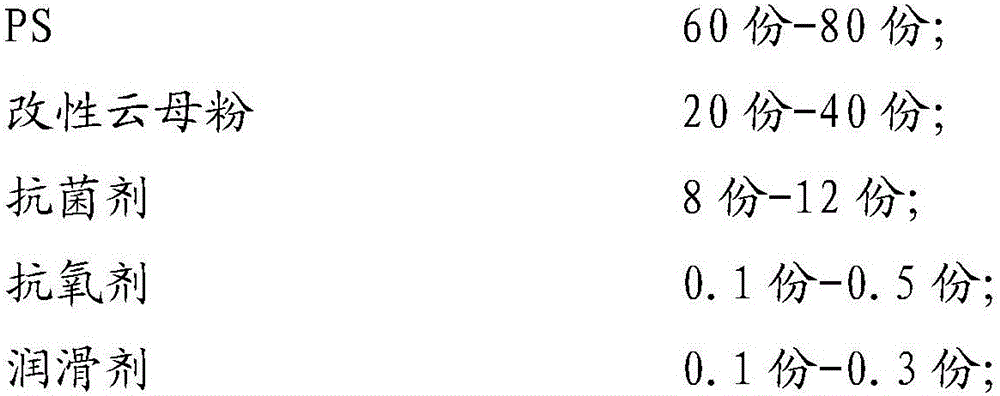

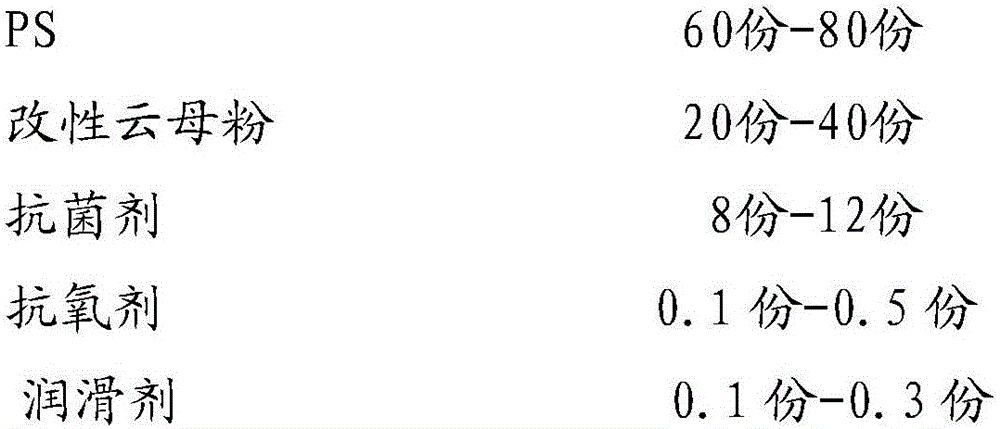

[0041] The preparation method of above-mentioned any antibacterial high-performance PS composite material, comprises the following steps:

[0042] 1) Weigh 60-80 parts of PS, 20-40 parts of modified mica powder, 8-12 parts of antibacterial agent, 0.1-0.5 parts of antioxidant, 0.1-0.3 parts of lubricant, mix and Stir evenly to obtain a mixture;

[0043] 2) extruding and granulating the mixture obtained in step 1), to obtain the PS composite material.

[0044] Preferably, the step 2) specifically includes: putting the mixture obtained in the step 1) into the hopper of a twin-screw extruder for extrusion and granulation to obtain a PS composite material, wherein the twin-screw extruder Including six temperature zones arranged in sequence, the temperature of the first zone is 160-180°C, the temperature of the second zone is 200-240°C, the temperature of the third zone is 200-240°C, the temperature of the fourth zone is 200-240°C, and the temperature of the fifth zone is 200-240°C...

preparation example 1

[0051] Described modified mica powder, its preparation method is as follows:

[0052] 1) Weigh a certain amount of mica powder, acetone, dibenzoyl peroxide (BPO), and acrylic acid (AA); the mica powder is phlogopite, with a particle size of 5 μm-10 μm. The mass ratio of mica powder, acetone, BPO, and AA is 60:240:1:4, and BPO acts as an initiator.

[0053] 2) Add mica powder into a three-necked flask filled with acetone, add AA and BPO under rapid stirring, react at 60-80°C for 2-4h, filter the reaction product, and dry in an oven at 80-100°C for 6-8h , the obtained mica powder A after acrylic surface modification.

[0054] 3) Add A and polyethylene wax into the extruder according to a certain mass ratio to extrude and granulate to obtain the modified mica powder. The mass ratio of A and polyethylene wax is 40:6.

[0055] The extruder includes six temperature zones arranged in sequence, the temperature of the first zone is 140-160°C, the temperature of the second zone is 180-...

preparation example 2

[0057] Described modified mica powder, its preparation method is as follows:

[0058] 1) Weigh a certain amount of mica powder, acetone, dibenzoyl peroxide (BPO), and acrylic acid (AA); the mica powder is phlogopite, with a particle size of 5 μm-10 μm. The mass ratio of mica powder, acetone, BPO, and AA is 80:360:3:8, and BPO acts as an initiator.

[0059] 2) Add mica powder into a three-necked flask filled with acetone, add AA and BPO under rapid stirring, react at 60-80°C for 2-4h, filter the reaction product, and dry in an oven at 80-100°C for 6-8h , the obtained mica powder A after acrylic surface modification.

[0060] 3) Add A and polyethylene wax into the extruder according to a certain mass ratio to extrude and granulate to obtain the modified mica powder. The mass ratio of A and polyethylene wax is 60:12.

[0061] The extruder includes six temperature zones arranged in sequence, the temperature of the first zone is 140-160°C, the temperature of the second zone is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com