Preparation method of composite positive material with multi-level conductive network of lithium ion battery

A composite cathode material, lithium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of reducing the volume energy density of materials, processing and coating performance, etc., to improve electrochemical performance, easy nucleation, and improved Effects of Conductivity and Structural Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

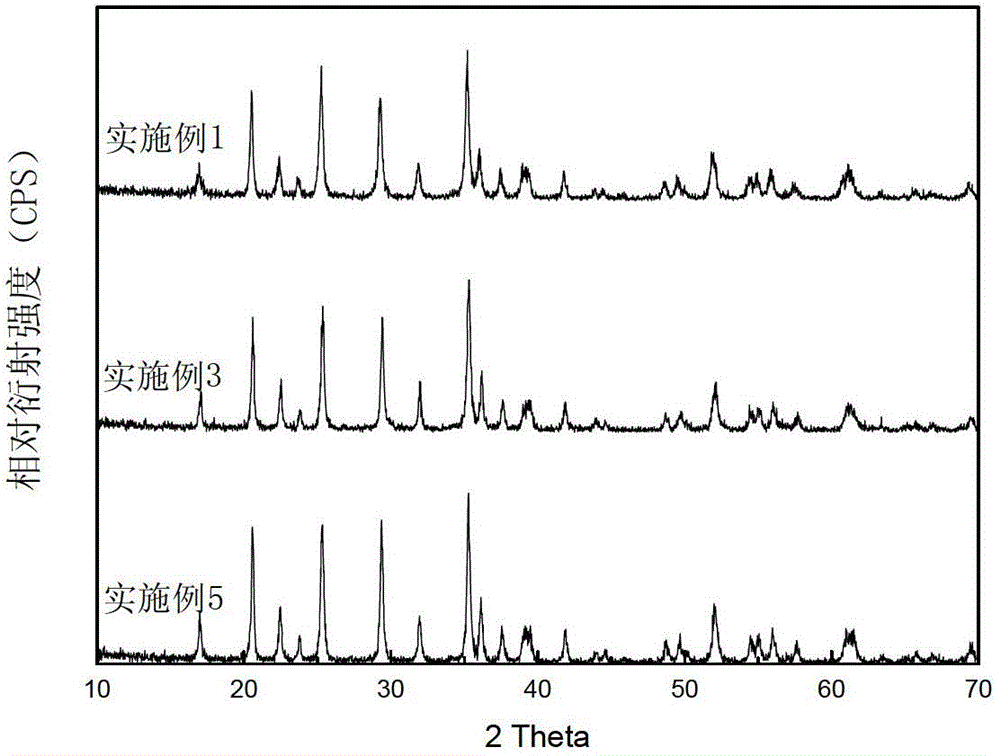

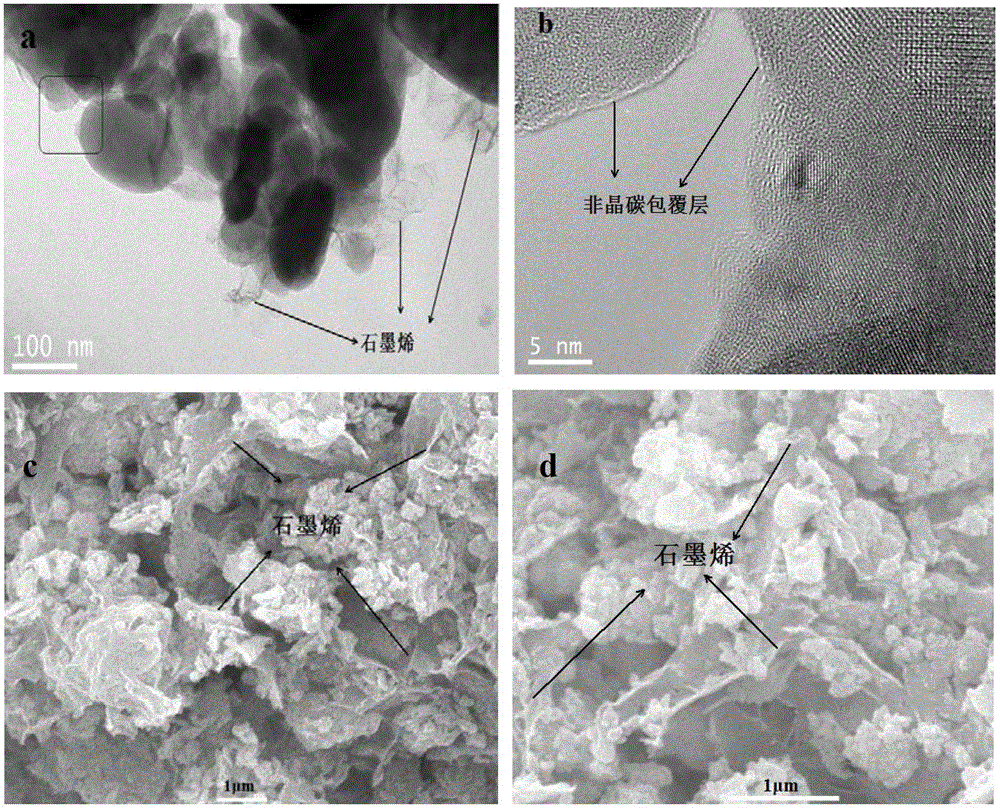

Embodiment 1

[0026] Weigh lithium dihydrogen phosphate and manganese powder according to the molar ratio of 1:1. And choose the theoretical target product LiMnPO 4 5 wt% graphite oxide and lithium dihydrogen phosphate are dispersed in deionized water medium, and the concentration of lithium dihydrogen phosphate is 1mol / L. The manganese powder was added into the lithium dihydrogen phosphate solution dispersed with graphite oxide, and the precursor slurry was obtained by mechanical activation liquid phase precipitation after high-energy ball milling for 4 hours. Since graphite oxide is rich in polar functional groups and has good hydrophilicity and delamination properties, the newly formed phosphate precipitation nuclei under mechanochemical action can be adsorbed on graphite oxide sheets to achieve in-situ growth using graphite oxide as a template. This facilitates the subsequent hydrothermal treatment to synthesize LiMnPO composited in situ. 4 / graphene material. Add an appropriate amo...

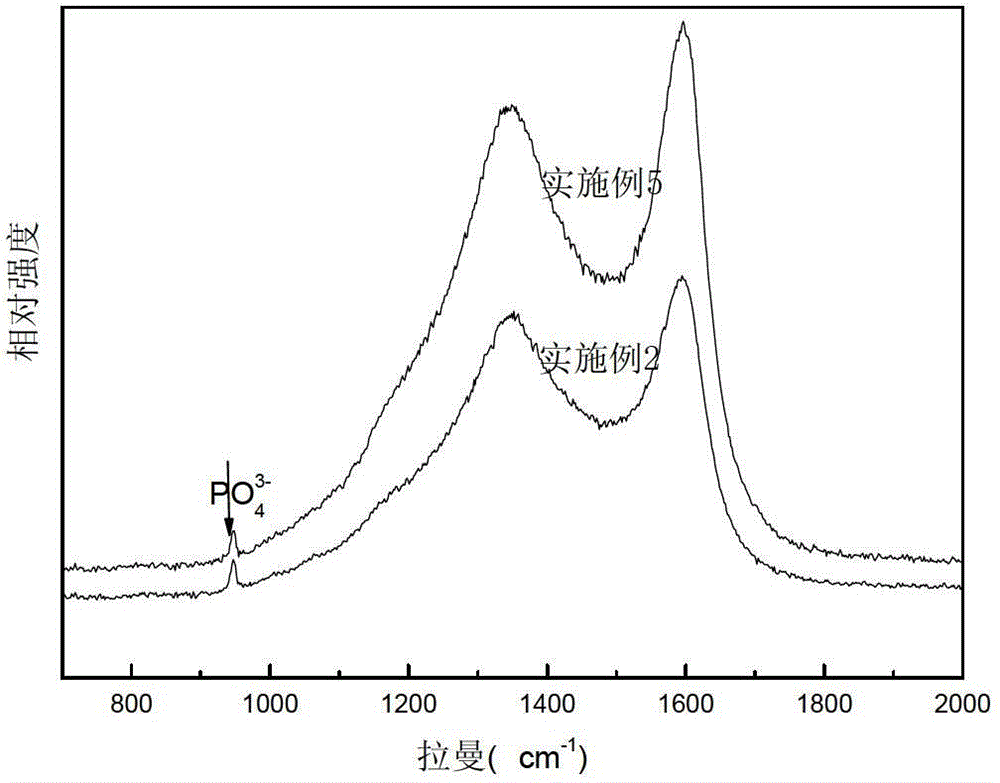

Embodiment 2

[0028] Select the theoretical target product LiMnPO 4 Graphite oxide and manganese nitrate of mass 2% are dispersed in dehydrated alcohol, and preparation manganese ion concentration is the mixed solution of 2mol / L, puts ultrasonic dispersion 1h behind, obtains the manganese salt solution that is dispersed with graphene oxide; The above-mentioned obtained The manganese salt solution dispersed with graphene oxide and concentrated phosphoric acid (85wt%) were added to the reactor with stirring according to the ratio of the amount of substances Mn:P=1:3, and the temperature was controlled to 40°C for 3 hours to obtain milk turbid liquid, the emulsion obtained above was filtered and washed to obtain the manganese phosphate / graphite oxide precursor. Due to the electrostatic force, Mn ions are adsorbed on the graphene oxide sheets, and phosphoric acid is added to react with Mn ions to produce a precipitation reaction, so that the generated manganese phosphate precipitates on the gra...

Embodiment 3

[0031] Select the theoretical target product LiMnPO 4 Disperse graphite oxide and manganese sulfate with 8% mass in deionized water, prepare a mixed solution with a manganese ion concentration of 1mol / L, and then place it in ultrasonic dispersion for 1h to obtain a manganese salt solution dispersed with graphite oxide; the prepared concentration is 1mol / L NH 4 h 2 PO 4 solution. Add the manganese salt solution dispersed with graphite oxide and the ammonium dihydrogen phosphate solution obtained above into the reactor with stirring according to the ratio of the amount of substances Mn:P-=1:1.02, and at the same time use a concentration of 1mol / L of ammonium aqueous solution to adjust the pH of the reaction feed liquid to 9, control the temperature to 80 ° C for 3 hours to obtain an emulsion, filter and wash the emulsion obtained above to obtain NH 4 PPML 4 / graphite oxide precursor; the resulting NH 4 PPML 4 / The graphite oxide precursor and lithium hydroxide were mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com