SiC film preparation device and method for preparing SiC film at low vacuum degree

A thin-film preparation and low-vacuum technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of high deposition temperature, high energy consumption and high cost of thermal CVD, and achieve lower deposition temperature, The effect of increasing the deposition rate and promoting safety and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

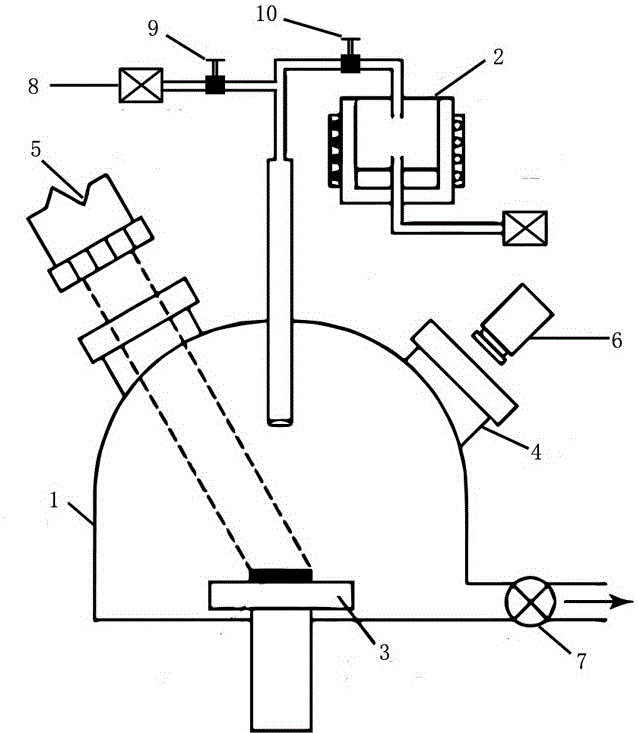

[0040]A SiC thin film preparation device, comprising a CVD reaction furnace 1 and a precursor furnace 2, the CVD reaction furnace 1 is provided with a heating table 3 for heating a boron nitride substrate, and the side wall of the CVD reaction furnace 1 is provided with two quartz windows 4 , CVD reaction furnace 1 is equipped with a laser emitter 5 and a pyrometer 6 respectively at the positions corresponding to two quartz windows 4, an air inlet is arranged on the top of CVD reaction furnace 1, a vacuum pump 7 is connected to the bottom of CVD reaction furnace 1, and CVD reaction furnace 1 The gas inlet of the gas inlet is respectively connected to the argon source 8 and the precursor furnace 2 through the nozzle and the pipeline, and a control valve I9 is set on the pipeline connected to the argon source 8, and a control valve I9 is set on the pipeline connected to the precursor furnace 2. Valve II 10.

[0041] A method for rapidly preparing SiC thin films under low...

Embodiment 2

[0057] A method for rapidly preparing SiC thin films under low vacuum, comprising the following steps:

[0058] Step (1): Cleaning preparation before SiC membrane preparation:

[0059] a. Put the boron nitride substrate into acetone and ultrasonically clean it for 10 minutes to remove the oil on the surface of the substrate.

[0060] b. Then use alcohol ultrasonic cleaning for 2 minutes to wash away the acetone, and then rinse with deionized water.

[0061] c. Then in volume ratio NH 3 ?H 2 O:H 2 o 2 :H 2 O=1:1:5 in the cleaning solution, ultrasonic cleaning at a temperature of 80 ° C for 10 minutes, and then in the volume ratio HF:H 2 Ultrasonic cleaning in O=1:50 mixture for 2 minutes, and finally rinsed with deionized water;

[0062] Step (2): Equipment adjustment before SiC film preparation:

[0063] a. Put the cleaned boron nitride substrate (8×8mm) into the laser-loaded cold-wall chemical vapor deposition (CVD) reaction chamber, adjust the position of the bor...

Embodiment 3

[0073] A method for rapidly preparing SiC thin films under low vacuum, comprising the following steps:

[0074] Step (1): Cleaning preparation before SiC membrane preparation:

[0075] a. Put the boron nitride substrate into acetone and ultrasonically clean it for 10 minutes to remove the oil on the surface of the substrate.

[0076] b. Then use alcohol ultrasonic cleaning for 2 minutes to wash away the acetone, and then rinse with deionized water.

[0077] c. Then in volume ratio NH 3 ?H 2 O:H 2 o 2 :H 2 O=1:1:5 in the cleaning solution, ultrasonic cleaning at a temperature of 80 ° C for 10 minutes, and then in the volume ratio HF:H 2 Ultrasonic cleaning in O=1:50 mixture for 2 minutes, and finally rinsed with deionized water;

[0078] Step (2): Equipment adjustment before SiC film preparation:

[0079] a. Put the cleaned boron nitride substrate (8×8mm) into the laser-loaded cold-wall chemical vapor deposition (CVD) reaction chamber, adjust the position of the bor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com