Heat exchanger and refrigeration cycle device using the same

a technology of heat exchanger and cycle device, which is applied in the field of heat exchanger, can solve the problems of increasing thermal conduction loss, difficult to use such a structure of heat exchanger, and inability to use refrigerant types, so as to improve heat exchanger pressure resistance, improve heat exchanger performance, and reduce heat loss at the inl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

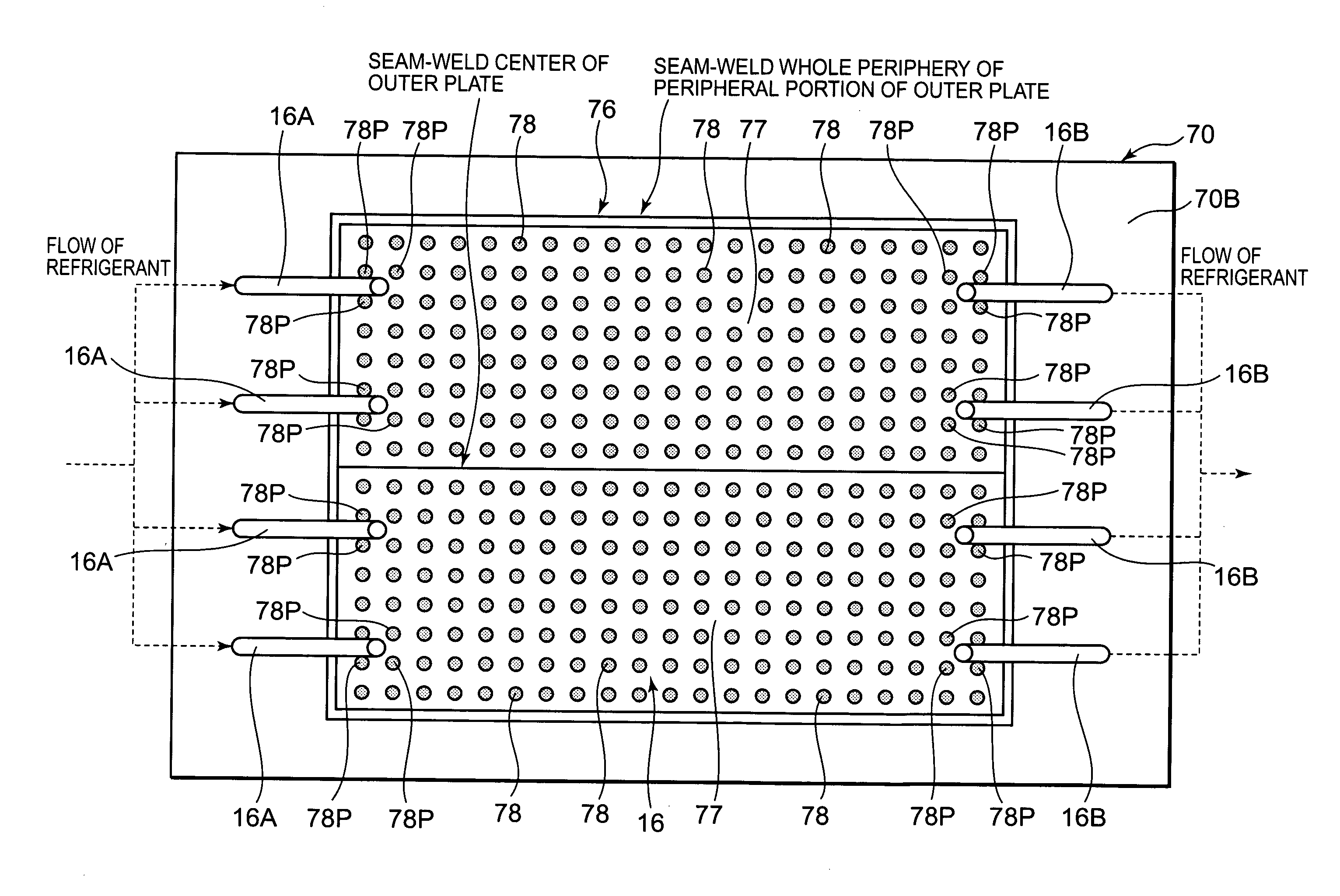

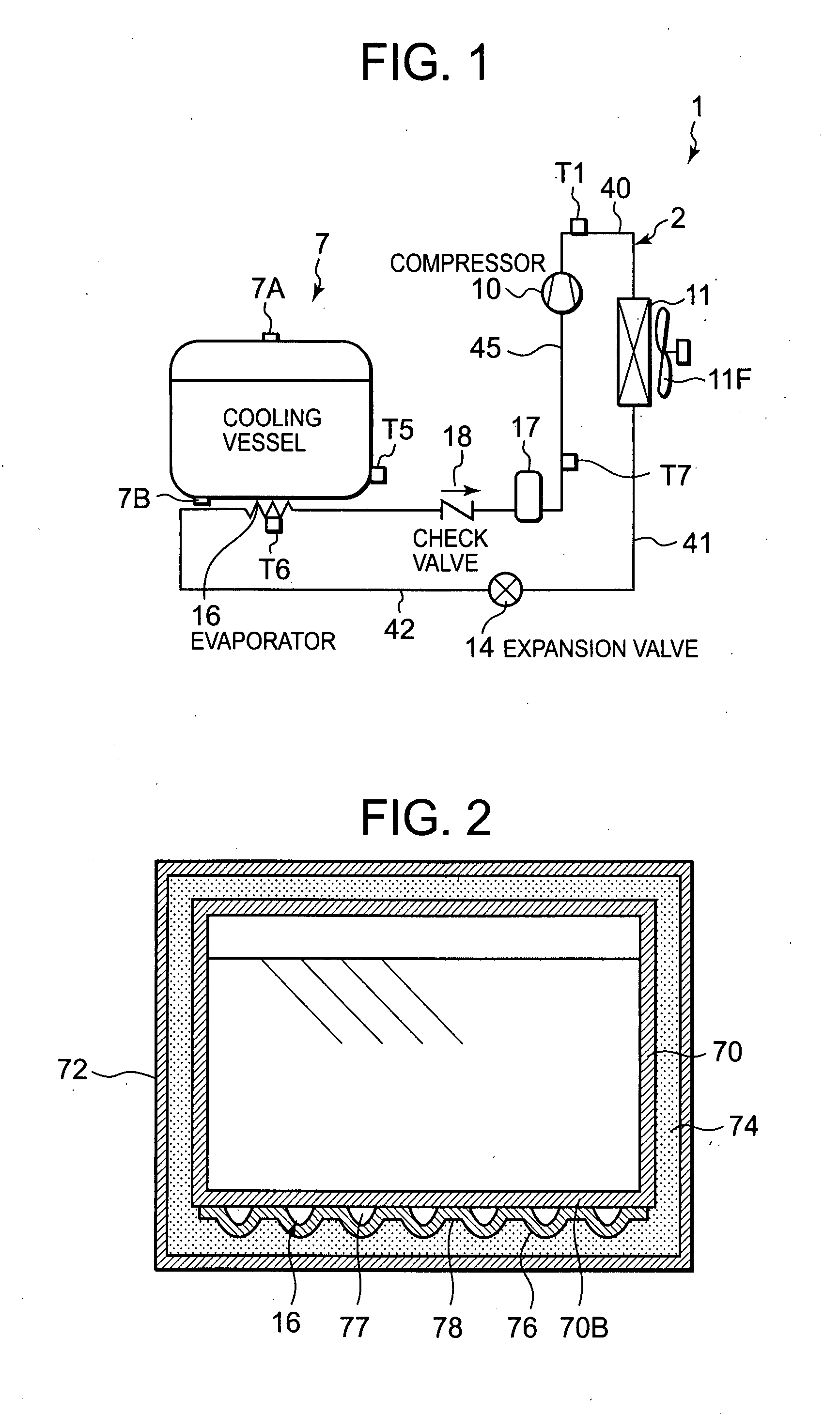

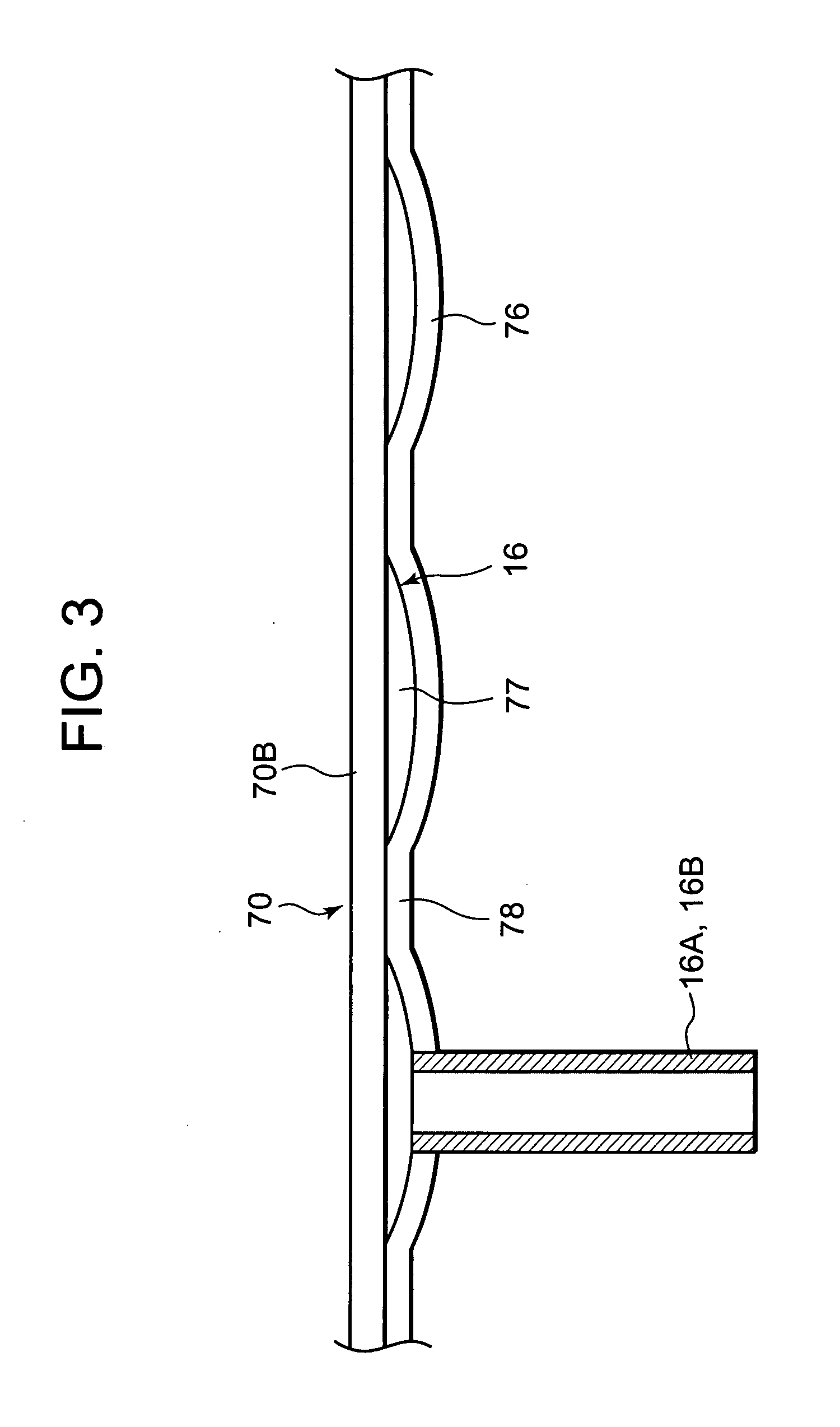

[0025] A refrigeration cycle device of the present embodiment is one example applied to a device which cools and insulates milk immediately after drawn until the milk is shipped. FIG. 1 is a schematic constitution diagram of the refrigeration cycle device of one embodiment to which the present invention is applied. A refrigeration cycle device 1 of the present embodiment is provided with a refrigerant circuit 2 constituted by connecting a compressor 10, a condenser (condensing heat exchanger or gas cooler or gas cooling heat exchanger) 11, an expansion valve 14 as a throttling means and an evaporator 16 in an annular form via pipes so as to form a closed circuit. That is, a high-pressure refrigerant pipe 40 connected to the compressor 10 on a discharge side is connected to an inlet of the condenser 11. The condenser 11 is a heat exchanger which performs heat exchange between a refrigerant and a heat medium to release heat of the refrigerant to the heat medium. It is assumed in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com