Vehicle-mounted lens sealing test device

A test device and sealing technology, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, by measuring the increase and decrease rate of fluid, etc., can solve the problems of long test period, cumbersome operation steps, and easy to suffer from pressure loss, etc. To achieve the effect of eliminating pressure loss, simplifying the detection steps and shortening the test cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

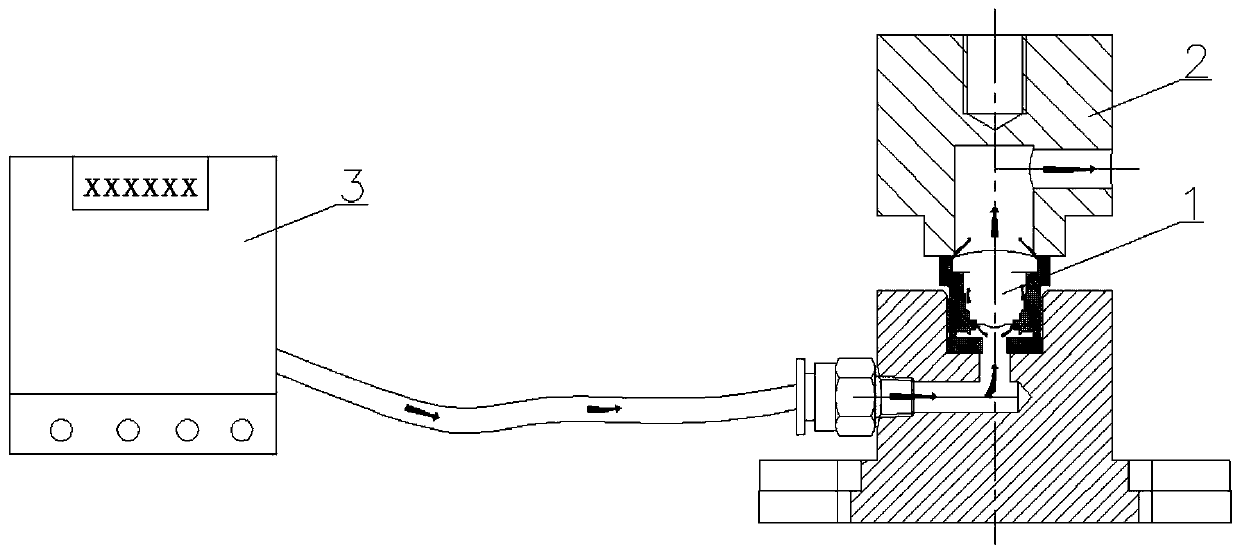

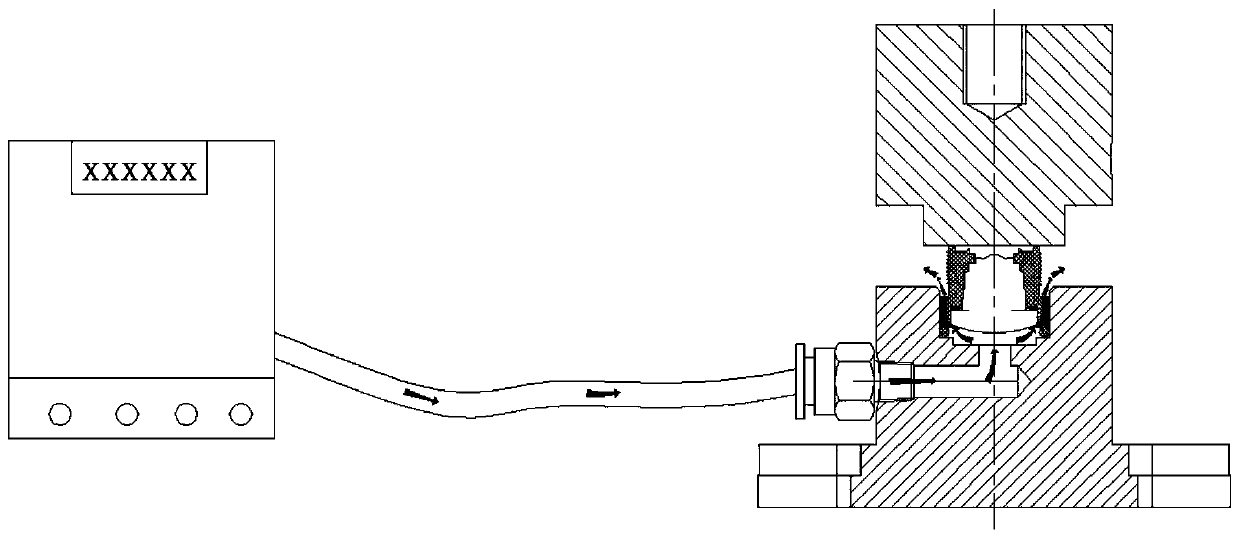

Method used

Image

Examples

Embodiment Construction

[0028] In the description of the present invention, it should be understood that the orientation or positional relationship indicated by the terms "inner", "outer", "upper", "lower" etc. is based on the orientation or positional relationship shown in the drawings, and is only for It is convenient to describe the present invention and simplify the description, but does not indicate or imply that the device or element referred to must have a specific orientation, be constructed and operate in a specific orientation, and thus should not be construed as limiting the present invention.

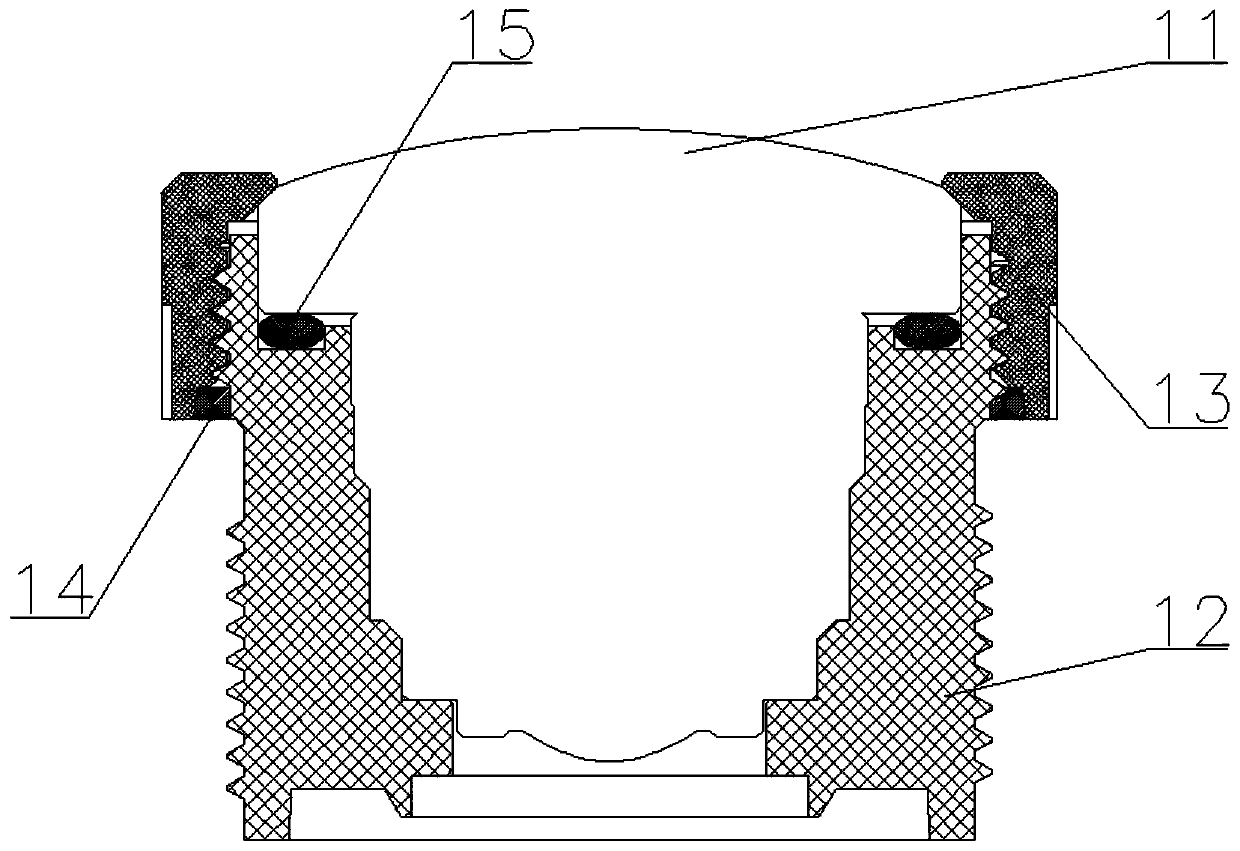

[0029] In order to facilitate those skilled in the art to understand the sealing test device disclosed in the present invention, before proceeding to the formal description, the structure of the vehicle-mounted lens 1 is first briefly described, specifically as follows: the vehicle-mounted lens 1 is composed of a lens 11, a lens base 12 and The lens gland 13 is composed of several parts, wherein the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com