Gas pressure wave generator for regenerative type refrigerator

A technology of gas pressure and wave generator, which is applied in refrigerators, refrigeration and liquefaction, irreversible cycle compressors, etc. It can solve the problems of high consumption of high-purity gas, low compression efficiency, and difficulty in manufacturing compressors, etc., to achieve Effect of shortening processing cycle, improving compression efficiency, reducing gap sealing loss and shuttle loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

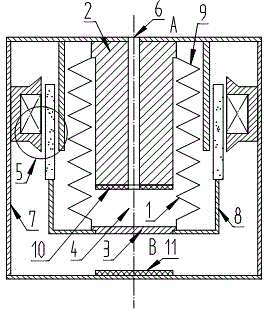

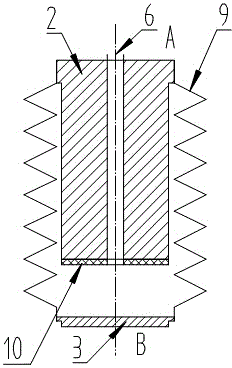

[0021] like Figure 1-Figure 2 A gas pressure wave generator for a regenerative refrigerator includes a motor 5 , a bellows assembly 1 and a fixed casing 7 . The motor 5 and the bellows assembly 1 are located in the fixed casing 7 . The motor 5 includes a stator part, a mover part and soft magnets. The bellows assembly 1 includes a bellows 9, a base 2 and a blind plate 3 fixedly connected to both ends of the bellows 9, respectively. The base body 2 is located in the bellows 9, and the base body 2 is provided with an exhaust port 6. The base body 2 , the blind plate 3 and the inner wall of the bellows 9 form a compression chamber 4 . One end of the bellows 9 fixed to the base body 2 is fixedly connected with the stator part through the fixed shell 7; The bellows 9 and the fixed end of the mover part reciprocate along the axial direction of the bellows 9 under the drive of the mover part, thereby driving the gas volume in the compression chamber 4 to change periodically, so ...

Embodiment 2

[0026] The motor 5 is a rotary motor, and the connecting frame 8 is a crank linkage mechanism. Through the crank linkage mechanism, the rotation angle of the rotary motor is converted into a linear displacement. Furthermore, end B of the corrugated tube 9 is driven to reciprocate along the axial direction of the corrugated tube 9 by the mover part of the motor 5 .

[0027] Others are with embodiment 1.

[0028] Concrete work process of the present invention is:

[0029] (1) Connect a three-way valve at the exhaust port 6 of the base body 2, so that the pressure wave generator of the one-way valve is inside the pressure wave generator of the two-way valve, and the three-way valve evacuates the pump. The gas pressure wave load can be a Stirling expander or a pulse tube refrigerator, and the gas filled in the refrigerator is high-purity helium.

[0030] (2) First open the one-way valve and the three-way valve, close the two-way valve, and evacuate and inflate the inside of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com