Intelligent corrosion-resistant anti-interference vortex precession flowmeter and processing and assembling process

A vortex flowmeter and assembly process technology, applied in the direction of measuring device, measuring flow/mass flow, liquid/fluid solid measurement, etc., can solve the problems of surface hardness, not easy to demould, affect corrosion resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

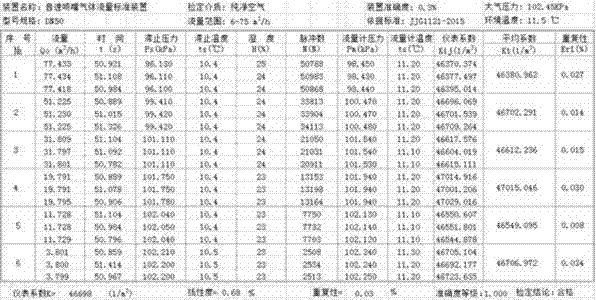

Image

Examples

Embodiment 1

[0053] The present invention provides an intelligent anti-corrosion and anti-interference swirling vortex flowmeter, which includes a precessing vortex housing, a vortex generator, a sensor, and a control system. The vortex generator is placed inside the precessing vortex housing, and the The sensor is fixed on the outside of the precession vortex shell and is electrically connected to the vortex generator, the sensor is electrically connected to the control system, the vortex generator is manufactured by a compound casting process, and the precession vortex shell The body cavity of the body and the vortex generating body are all treated with surface hardening and corrosion resistance. The control module of the sensor adopts a 16-bit MSP430F5438A single-chip microcomputer, and the MSP430F5438A single-chip microcomputer adopts the IARWorkbench system that the compiler can provide C language standard characteristics, and the program of the control system The software is written i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com