A kind of multi-principal alloy powder and method for preparing coating by laser cladding on die steel

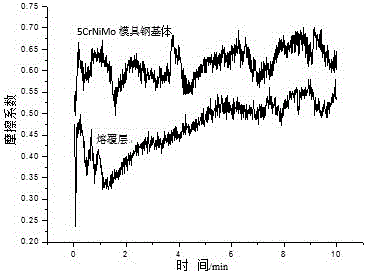

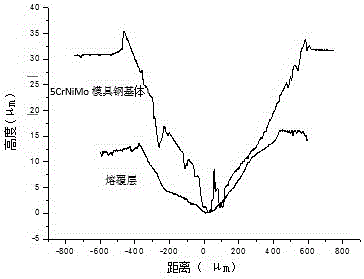

A multi-principal alloy and laser cladding technology, which is applied in the field of material surface treatment and strengthening, can solve the problems of low manufacturing precision and standardization, poor quality reliability and stability, and low service life of molds, and achieve wear resistance and Improved corrosion resistance, reduced friction coefficient, and smooth wear profile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. A multi-principal alloy powder, in molar fractions, comprising the following components: 30 parts of Co, 30 parts of Cr, 30 parts of Al, 30 parts of Mn and 30 parts of Ni, and the particle size of the multi-principal alloy powder is 100 ~300 mesh; the purity of the Co, Cr, Al, Ni, Mn are all ≥99%.

[0024] Two, the above-mentioned multi-principal alloy powder is used for the method for preparing cladding layer on die steel, comprises the steps:

[0025] 1) Use electronic balance FA2004N to prepare multi-principal alloy powder according to the above formula, put the prepared multi-principal alloy powder into a ball mill and mix for 4 h;

[0026] 2) Grind off the oxide film on the surface of the 5CrNiMo mold steel with metallographic sandpaper, and clean the polished mold steel with absolute ethanol or acetone;

[0027] 3) Prepare a polyvinyl alcohol solution with a mass concentration of 0.3%, and heat it in a water bath to completely dissolve the polyvinyl alcohol; m...

Embodiment 2

[0031] 1. A multi-principal alloy powder, in molar fractions, comprising the following components: 20 parts of Co, 20 parts of Cr, 20 parts of Al, 20 parts of Mn, 20 parts of Ni and 10 parts of Fe; the multi-principal alloy The particle size of the powder is 100-300 mesh; the purity of the Co, Cr, Al, Ni, Mn and Fe are all ≥99%.

[0032] Two, the above-mentioned multi-principal alloy powder is used for the method for preparing cladding layer on die steel, comprises the steps:

[0033] 1) Use the electronic balance FA2004N to prepare multi-principal alloy powder according to the above formula, put the prepared multi-principal alloy powder into a ball mill and mix for 5 hours;

[0034] 2) Grind off the oxide film on the surface of the 5CrNiMo mold steel with metallographic sandpaper, and clean the polished mold steel with acetone;

[0035] 3) Prepare a polyvinyl alcohol solution with a mass concentration of 0.4%, and heat it in a water bath to completely dissolve the polyvinyl ...

Embodiment 3

[0039] 1. A multi-principal alloy powder, in molar fractions, comprising the following components: 10 parts of Fe, 10 parts of Co, 10 parts of Cr, 10 parts of Al, 10 parts of Mn and 10 parts of Ni; the multi-principal alloy The particle size of the powder is 100-300 mesh; the purity of the Co, Cr, Al, Ni, Mn and Fe are all ≥99%.

[0040] Two, the above-mentioned multi-principal alloy powder is used for the method for preparing cladding layer on die steel, comprises the steps:

[0041] 1) Use the electronic balance FA2004N to prepare multi-principal alloy powder according to the above formula, put the prepared multi-principal alloy powder into a ball mill and mix for 6 h;

[0042] 2) Grind off the oxide film on the surface of the 5CrNiMo mold steel with metallographic sandpaper, and clean the polished mold steel with acetone;

[0043] 3) Prepare a polyvinyl alcohol solution with a mass concentration of 0.5%, and heat it in a water bath to completely dissolve the polyvinyl alco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com