Ultrasonic solid-state lithium battery with built-in ultrasonic waves

An ultrasonic and solid-state lithium technology, applied in the field of batteries, can solve the problems of reducing the structure of ultrasonic batteries, unable to work normally, low charging and discharging efficiency, etc., and achieves the effect of reducing power storage performance, shortening service life, and promoting molecular motion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

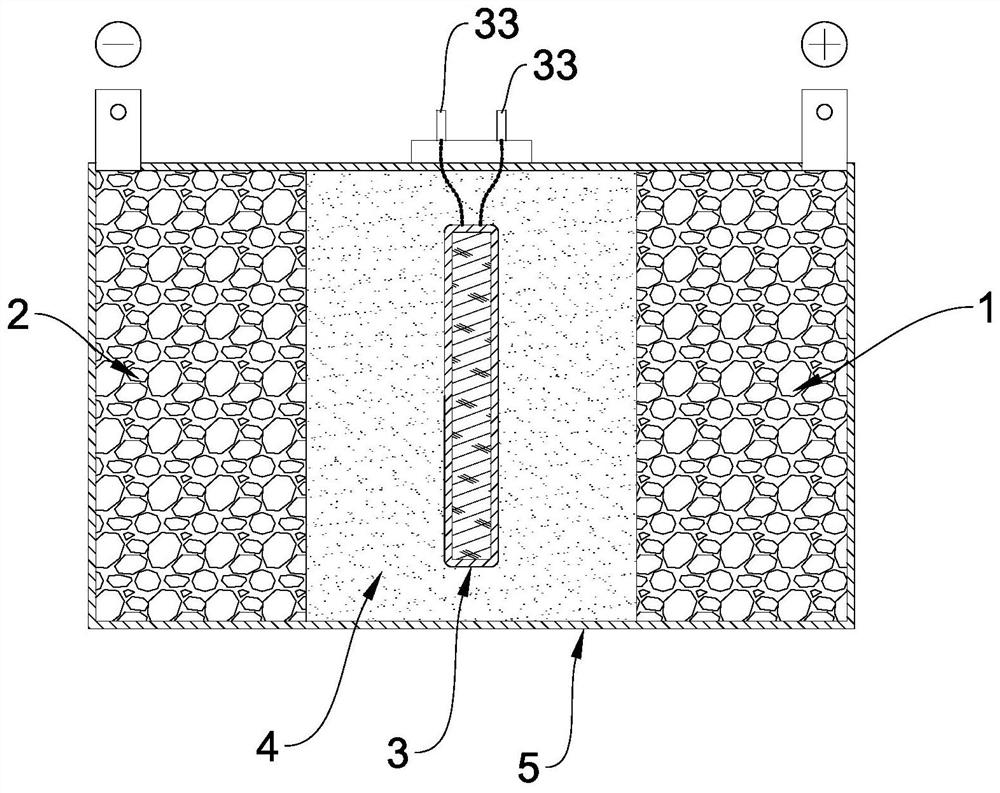

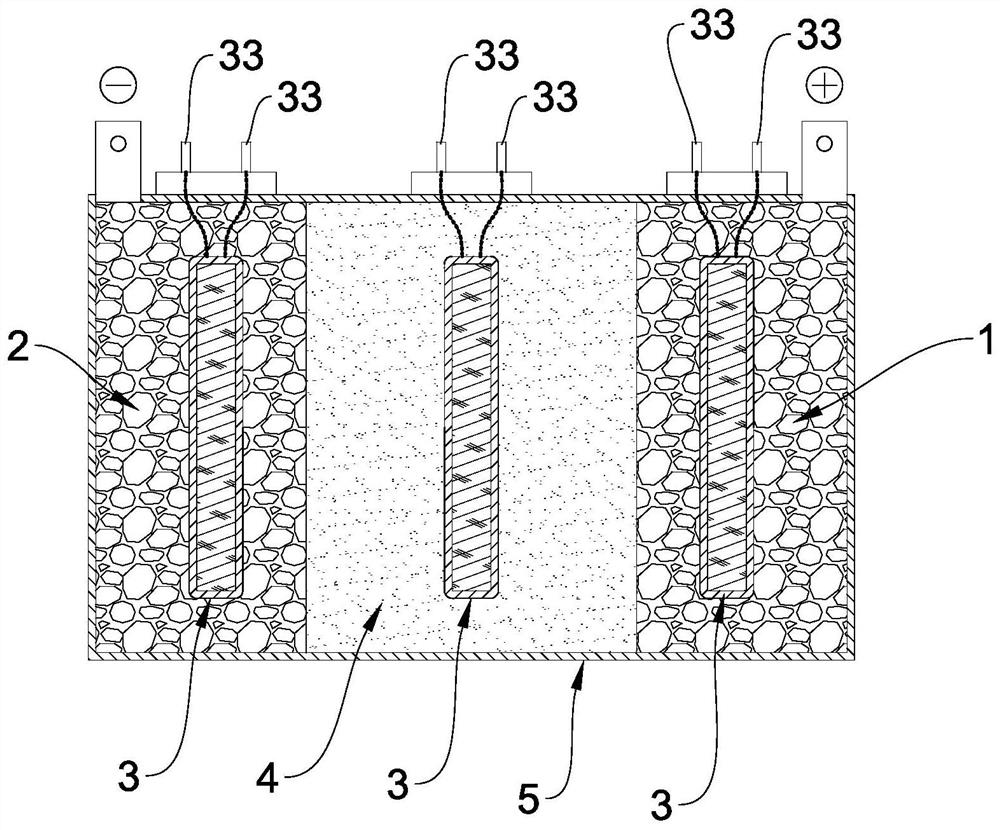

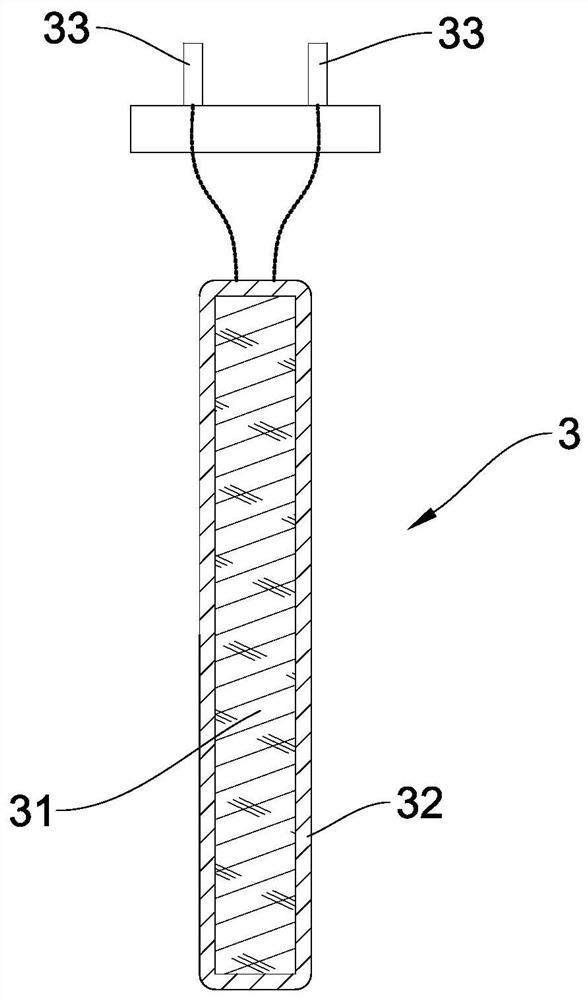

[0017] Such as Figure 1 to Figure 3 As shown, an ultrasonic solid-state lithium battery with a built-in ultrasonic wave according to the present invention includes a positive electrode body 1, a negative electrode body 2, a solid electrolyte 4, etc. on which a battery case 5 is installed on the battery case 5; in order to achieve the purpose of the present invention, this The invention also includes an ultrasonic vibration module 3 built into the positive electrode body 1 and / or the negative electrode body 2 and / or the solid electrolyte 4. The ultrasonic vibration module 3 includes an ultrasonic vibration element 31 and an insulating material coated on the surface of the ultrasonic vibration element 31. The material layer 32 is also provided with connection terminals 33 electrically connected to the ultrasonic vibrating element 31 on or outside the top of the positive electrode body 1 and / or the negative electrode body 2 and / or the solid electrolyte 4 . Specifically, as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com