Patents

Literature

63results about How to "Speed up molecular motion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

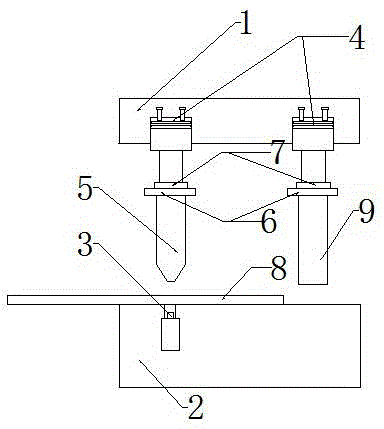

Deburring and punching integrated mold

InactiveCN104959457ASpeed up molecular motionConvenient punching and formingShaping toolsPerforating toolsPunching

The invention discloses a deburring and punching integrated mold. The deburring and punching integrated mold comprises an upper mold base, a lower mold base for placing a product, a punching component positioned on the upper mold base, a deburring component positioned on the upper mold base, and a heating piece positioned in the lower mold base and corresponding to the punching component. The invention provides punching equipment; the punching equipment heats a part beforehand to accelerate the molecule movement before the punching, and then performs the punching; the mode is convenient to punch and mold; the punching and the deburring are continuously finished; and after the punching is finished, a mounting hole is transferred to the position of a deburring punch for punching before the part is cooled, so that the design improves the product quality, and improves the production efficiency.

Owner:昆山—邦泰汽车零部件制造有限公司

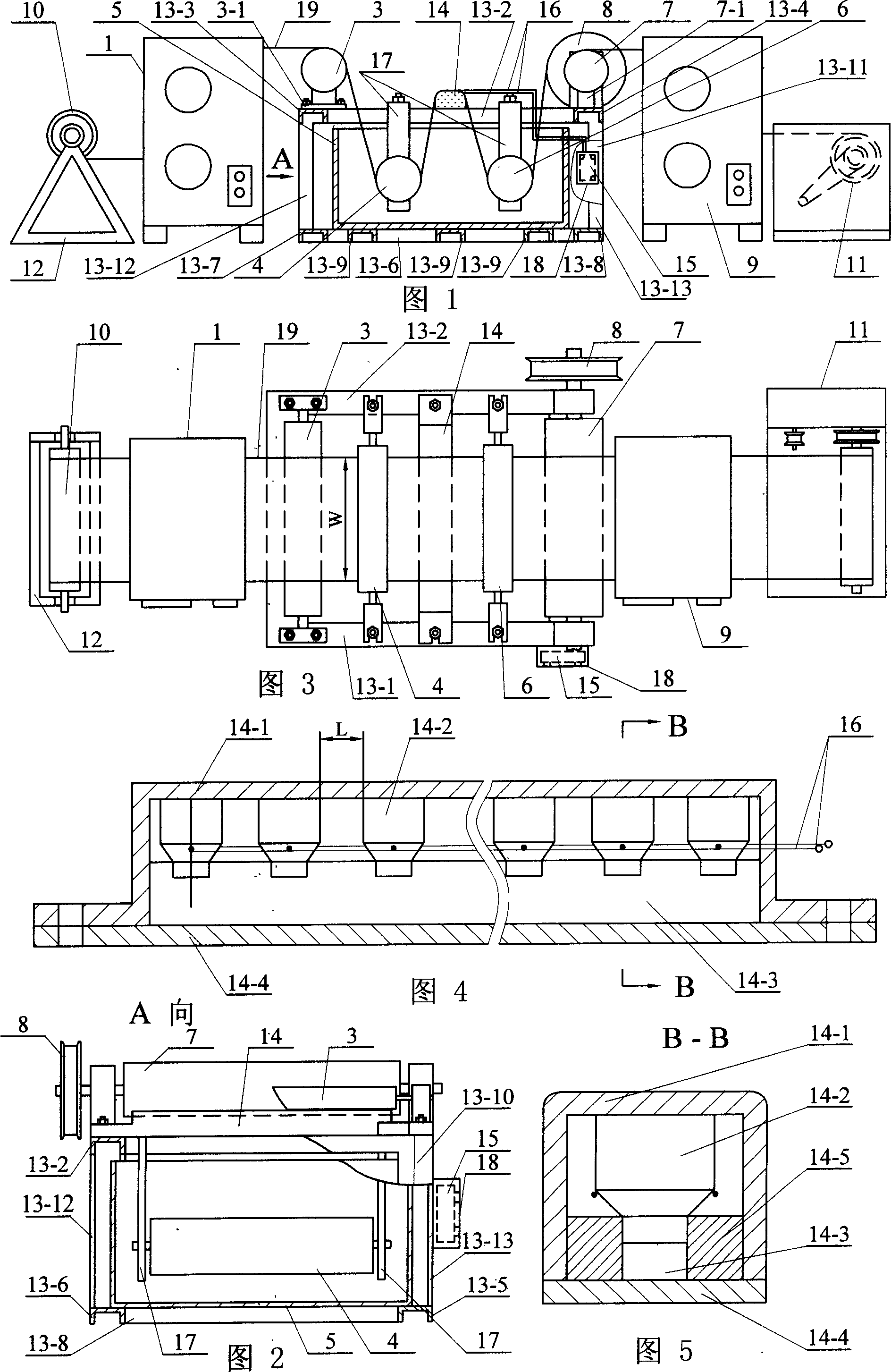

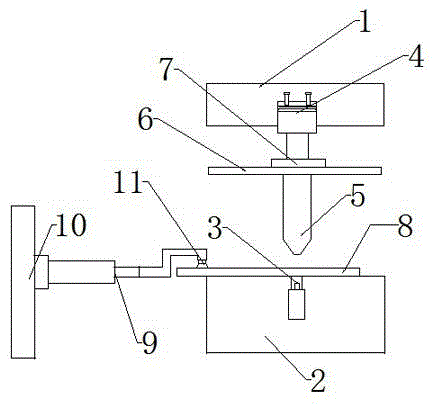

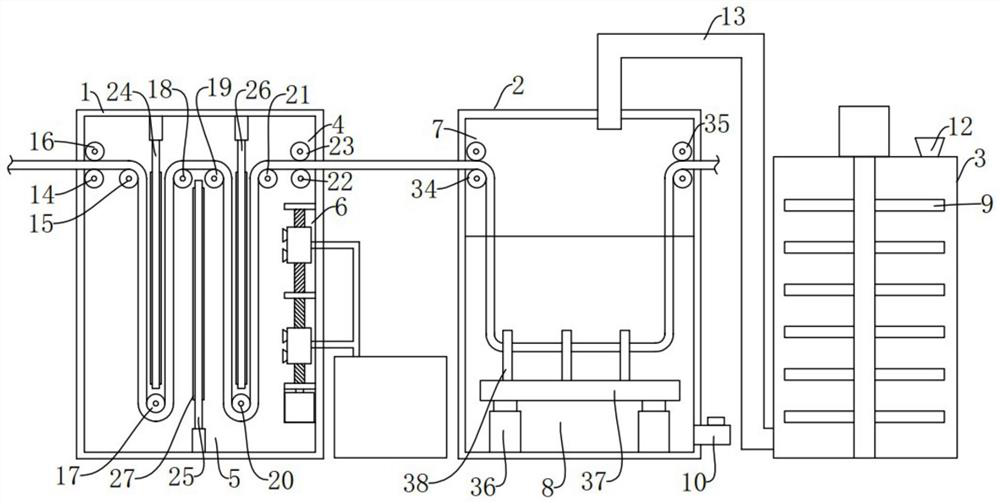

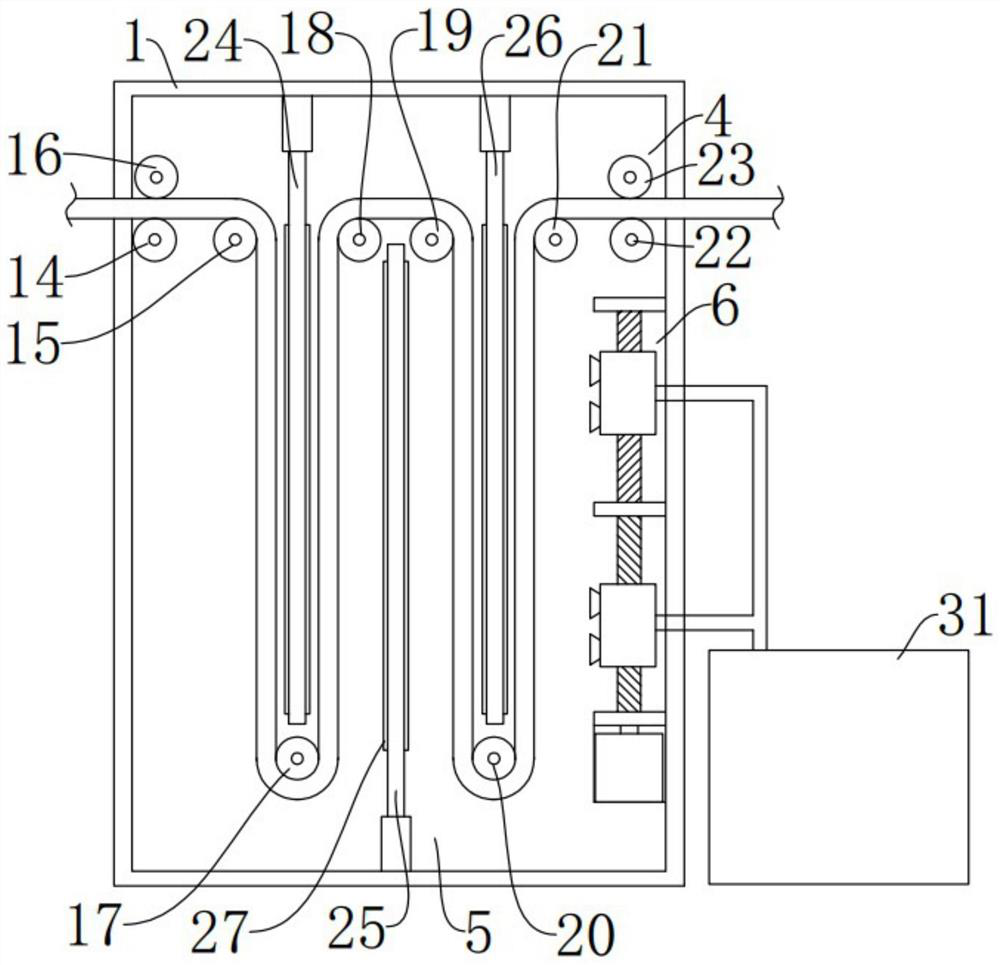

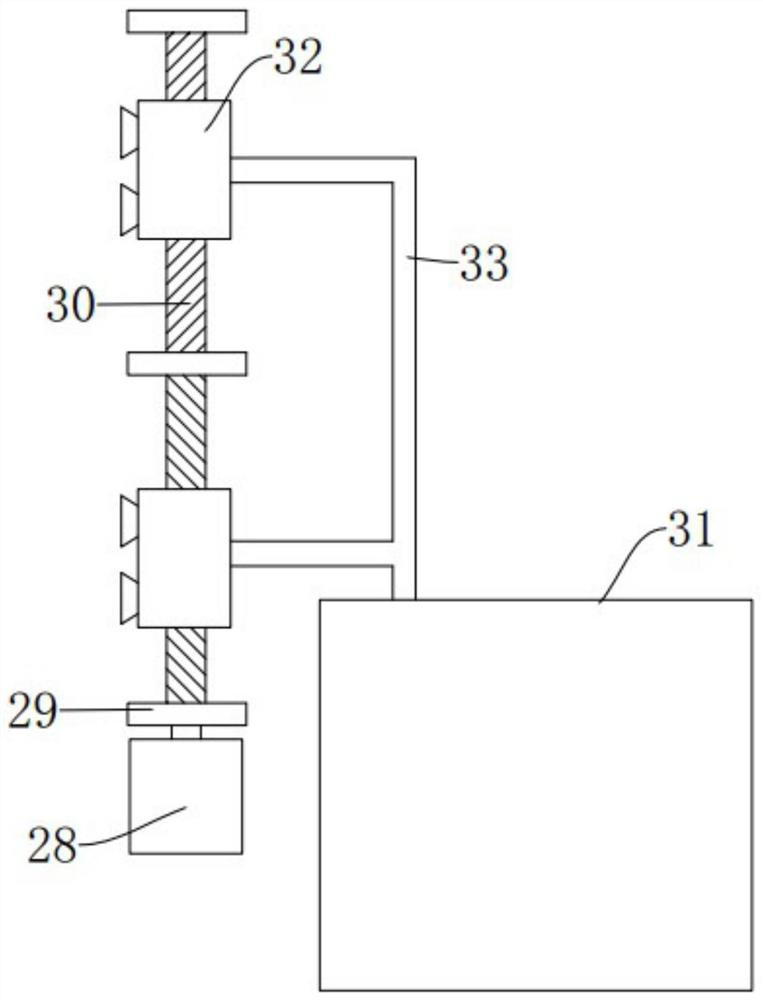

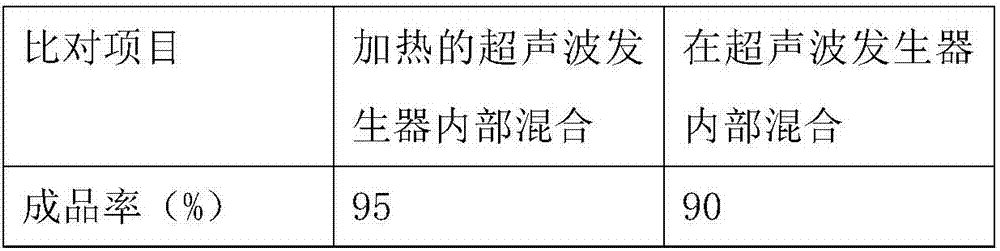

Method and device for improving wettability of broad width presoaking material

ActiveCN1734003ALow viscositySpeed up molecular motionUltrasonic/sonic fibre treatmentVibration treatmentFiberTransformer

A process and apparatus for improving the width prepreg soakage property relates to a process and apparatus for improving the prepreg soakage property. This invention solves the following problems in the prepeg production, using the fiber improved technology can't improve the soakage property of the prepreg; using the ultrasonic vibration technology can't fit for the thermosetting tar; using the ultrasonic soakage narrowband technology can't realize the width fiber soakage disposal. The method of this invention as follows: digging the dried fiber cloth 19 into the thermosetting tar, then going through the compound transformer 14 which is under the control of the ultrasonic power 15, and then drying, rolling and bundling, wherein the width of the fiber cloth 19 W is 0.1-1.5m; the device of this invention as follows: the first drying stove 1 and the rolling roller 10 are mounted at the left of the frame, the second drying stove 9 and the curling machine 11 are mounted at the right of the frame, the upper face of the frame fixes with the compound transformer 14, and the ultrasonic power 15 fixes on the frame. Using this device and the method of this invention can improve the width prepreg soakage property greatly.

Owner:HARBIN INST OF TECH

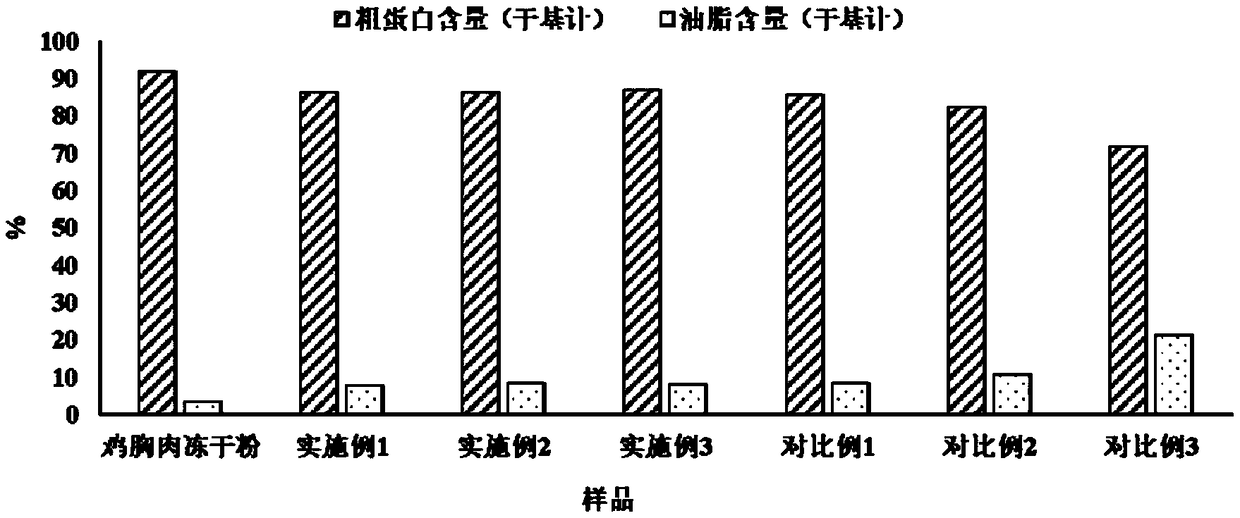

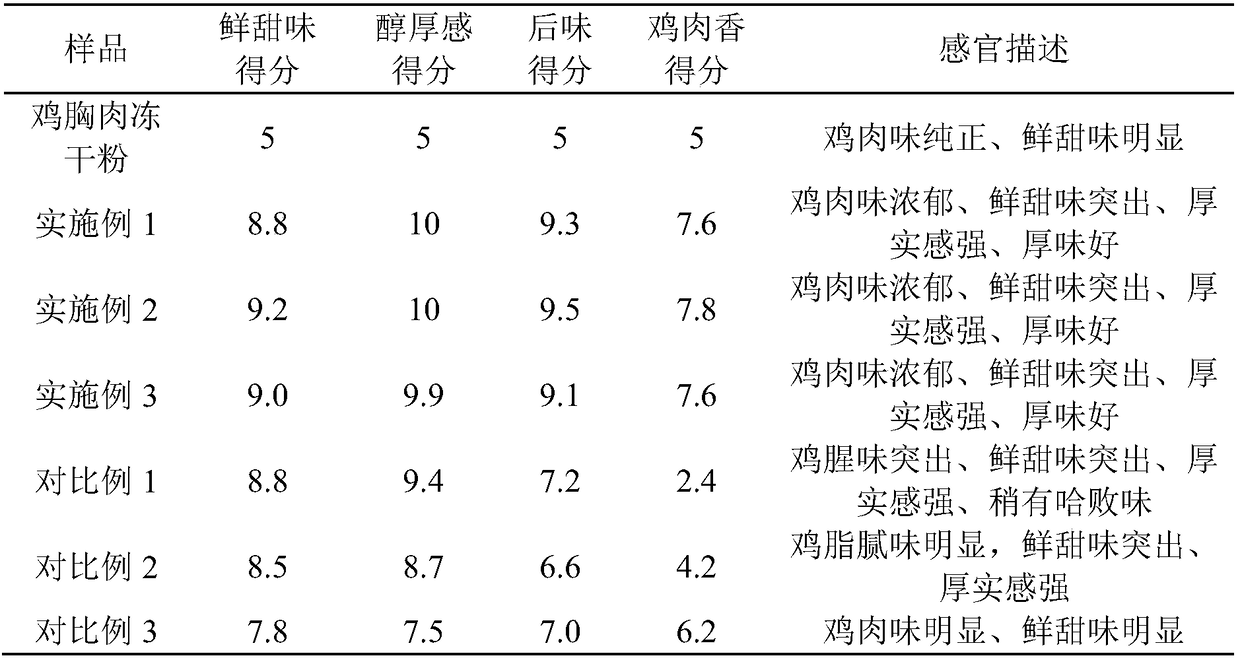

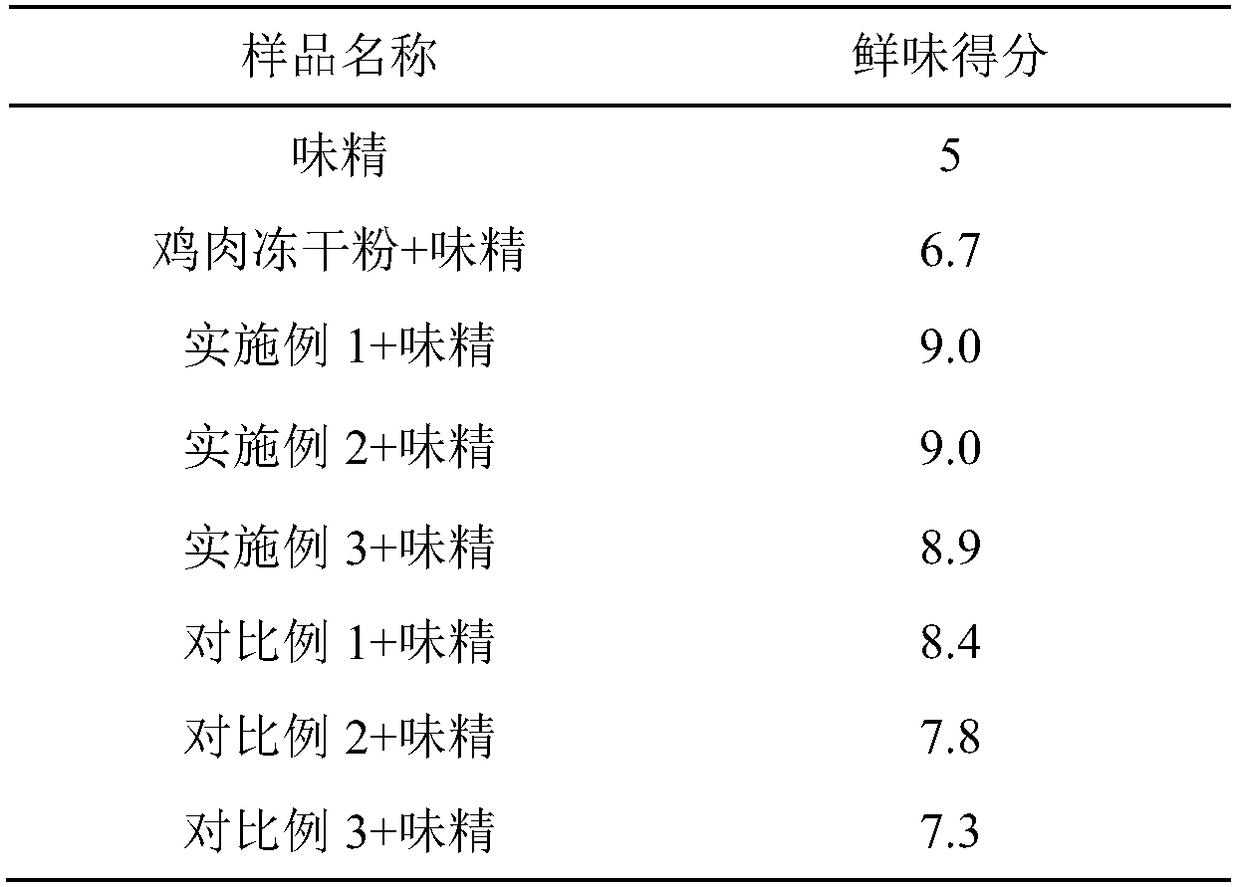

Chicken meat flavored peptide as well as preparation method and application thereof

ActiveCN109430513AGood flavor substancesEasy to separateProtein foodstuffs working-upProtein composition from meatProteinase activityTrypsin

The invention discloses chicken meat flavored peptide as well as a preparation method and application thereof. The method comprises the following steps of mincing a whole chicken, adding water, protease and spice powder, performing enzymolysis, and taking permeating liquid namely chicken meat enzymatic hydrolysate, wherein the protease is papain and / or alkali protease; then adding an emulsifying agent, protease, lipase and reducing sugar to the chicken meat enzymatic hydrolysate, performing emulsifying and enzymolysis treatment, then raising the temperature to 90-100 DEG C, performing heat-preservation stirring for 2-3 hours, and collecting a solution so as to obtain chicken meat flavored peptide liquid, wherein the protease is trypsin or flavored protease; and performing concentration orfreeze drying on the chicken meat flavored peptide liquid so as to obtain the chicken meat flavored peptide. The technology is simple to operate, low in production cost and free from any pollution, and the prepared chicken meat flavored peptide is outstanding in palatable taste and obvious in meat taste and is a superior flavor development base material.

Owner:厦门友和邦生物科技有限公司

Agricultural products storage insecticide and its production method and purpose

InactiveCN1631160AResidue reductionEasy to useBiocideEdible seed preservationAgricultural scienceEmulsion

The invention discloses an agricultural products storage insecticide and its production method and use, which is the emulsifying agent of methylpyrimitate or aqueous emulsion of methylpyrimitate. The advantages include high performance, broad spectrum, low toxicity, low residual, and environmental protection. The insecticide is suitable for the prevention and cure of grain and agricultural product warehouse insects.

Owner:岳阳粮神生物科技有限公司

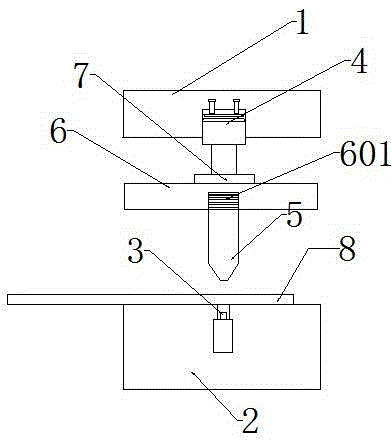

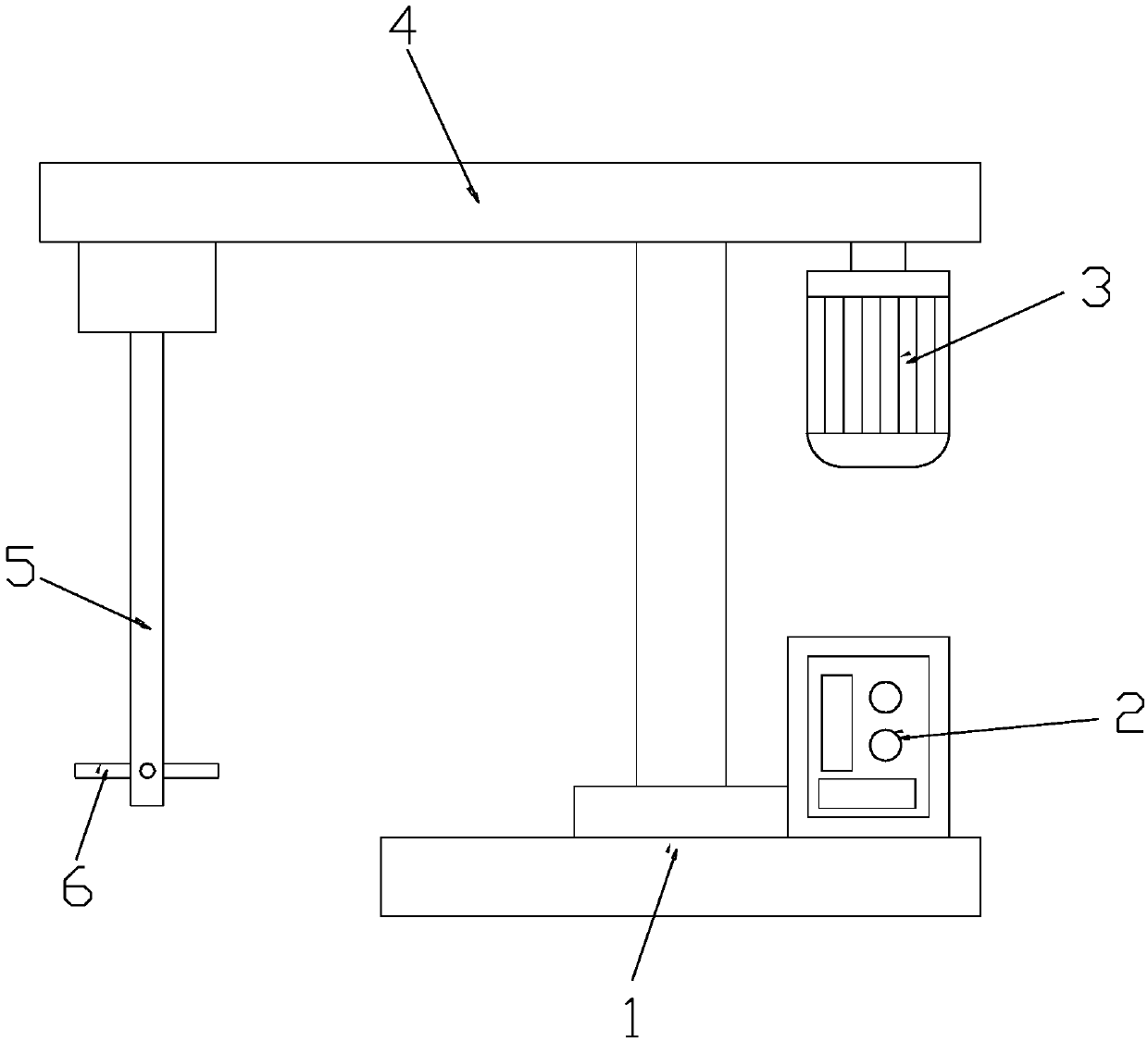

Punching equipment

The invention discloses punching equipment. The punching equipment comprises an upper die base, a lower die base where a product is placed, a stamping assembly arranged on the upper die base, and a heating piece which is arranged in the lower die base and corresponds to the stamping assembly. The stamping assembly comprises a nitrogen spring fixed to the upper die base, a punch detachably connected to the nitrogen spring, and a connection plate fixed between the nitrogen spring and the punch, and a threaded groove used for fixing the punch is formed in the connection plate. According to the punching equipment, a part is preheated before punching so as to accelerate molecular movement, and then punching is conducted. In this way, punching and formation are facilitated. The punch is of the detachable design and can be replaced with a deburring punch after punching is completed, and deburring stamping is completed before the part is cooled. By means of the design, the product quality is improved, and meanwhile the production efficiency is improved.

Owner:昆山—邦泰汽车零部件制造有限公司

A method of extracting taurine from scallop skirt

InactiveCN105523966APromote dissolutionMild sourceOrganic chemistryOrganic compound preparationCavitationSolvent

A method of extracting taurine from scallop skirt is provided. The method adopts scallop skirt leftovers as raw materials, and prepares the taurine by steps of cleaning, homogenizing, ultrasonic enzymolysis, enzyme deactivation, decoloring, concentration, cooling and crystallization. The method combines ultrasonic smashing and stepped enzymolysis to prepare the taurine. Cavitation effects and mechanical functions of ultrasonic waves in an extracting solvent can effectively smash cells so that effective components are in an isolated state and are dissolved into the extracting solvent, and can accelerate molecule movements of the extracting solvent so that the extracting solvent and the taurine molecules are brought into rapid contact, dissolved and mixed with each other, taurine digestion is facilitated and the extracting efficiency is increased. The method is mild in reaction conditions, wide in raw material sources, low in cost and simple in operation, can be used for industrial production and has high economic value.

Owner:广西钦州市绿源天然食品加工有限公司

Preparation process of blood-sugar-reducing and lipid-lowering potentilla discolor medicinal granules

InactiveCN103054971AEasy to operateReduce extraction timeMetabolism disorderAntinoxious agentsDrugWater soluble

The invention discloses a preparation process of blood-sugar-reducing and lipid-lowering potentilla discolor medicinal granules, which belongs to the field of processing of Chinese herbal medicine dietary therapy health-care products. The process comprises the steps of preparation of medicinal material extracts and the medicinal granules. The process is simple, easy to operate and low in cost, and can ensure that medicinal ingredients can be effectively maintained without being lost. The potentilla discolor extractant prepared by the method is high in water solubility and tasty and refreshing to drink, and as a new source food and a health-care product, the health-care medicinal granules without any additive and with effects of natural herbal medicines has high application and development values and wide market prospect.

Owner:HENAN UNIV OF SCI & TECH

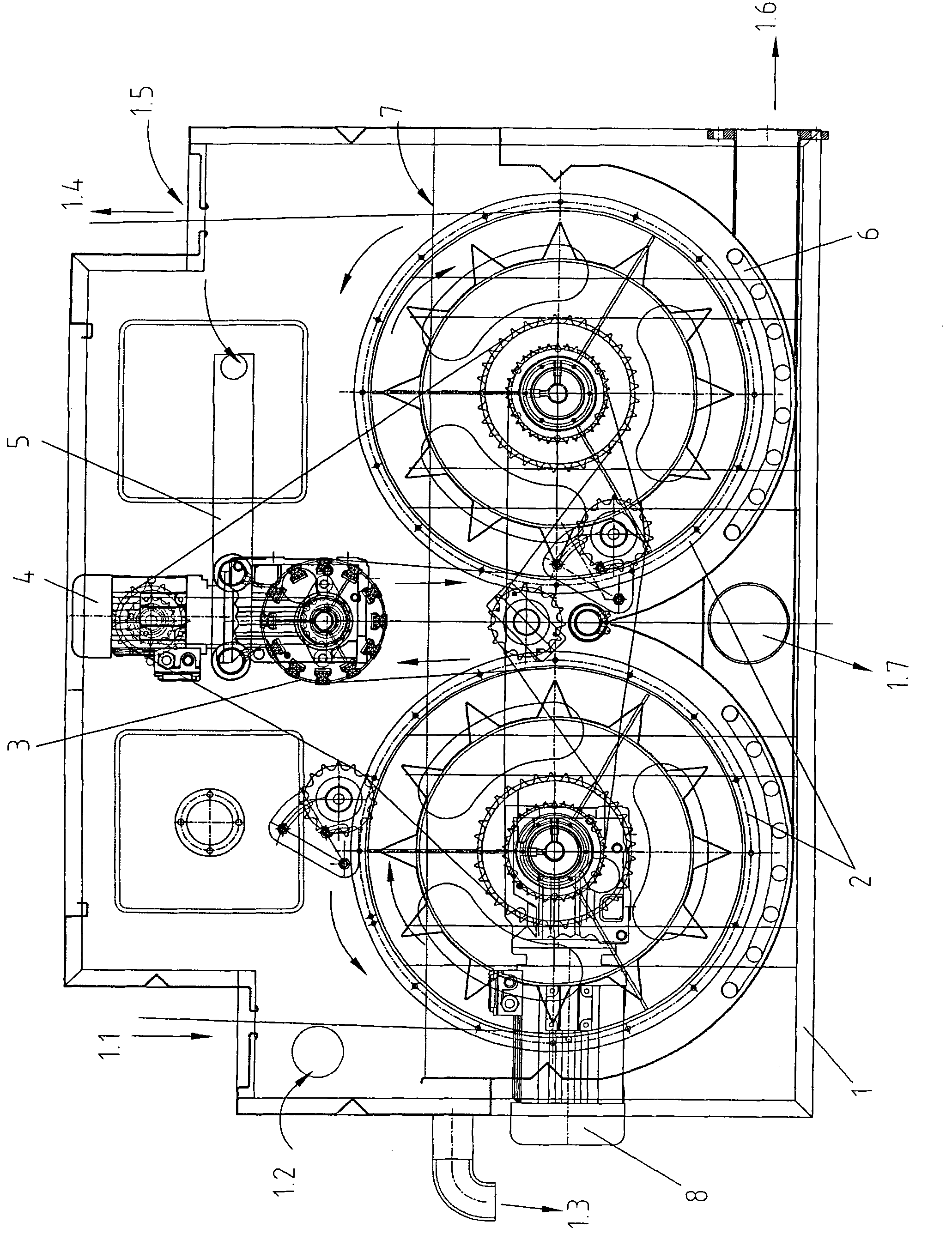

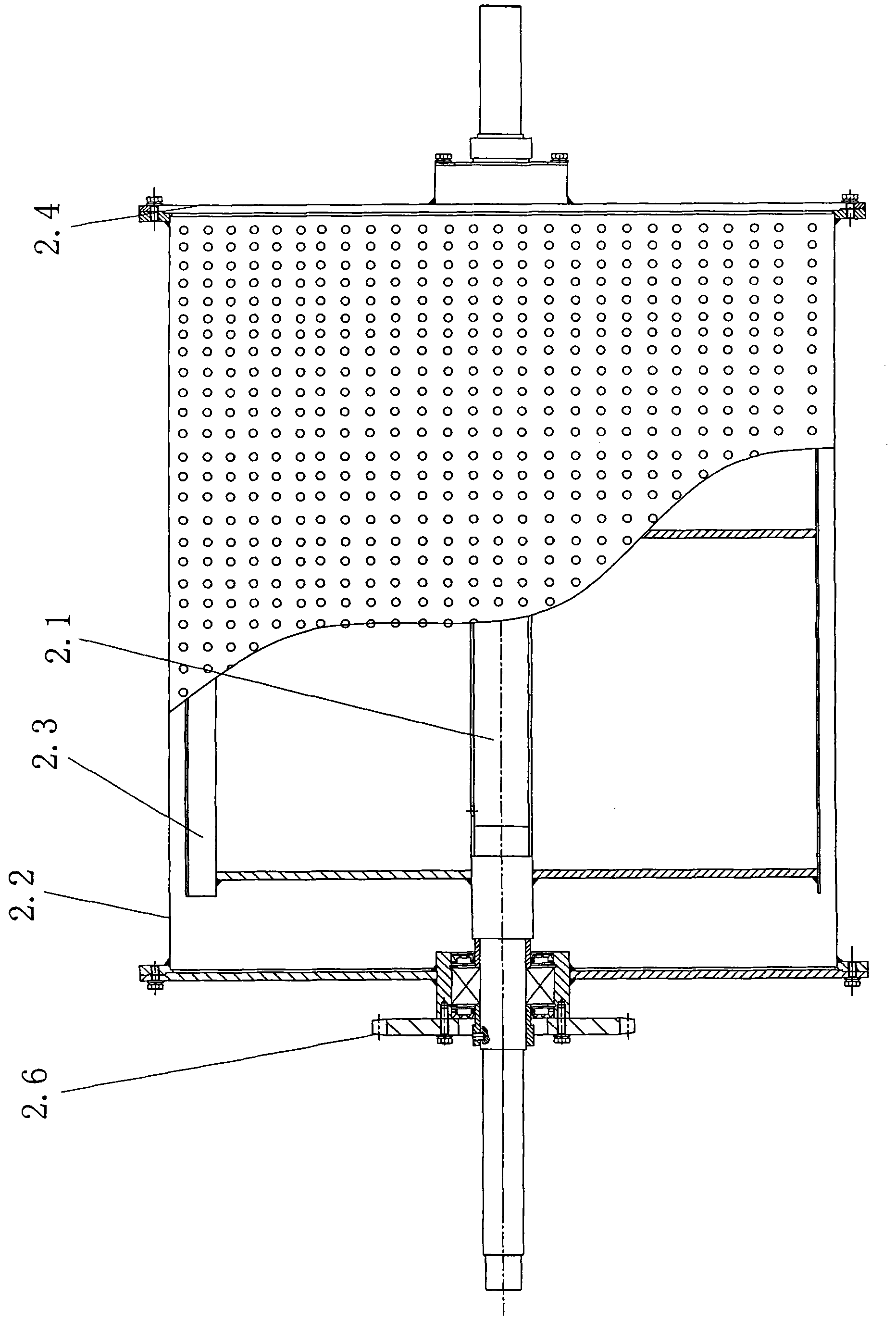

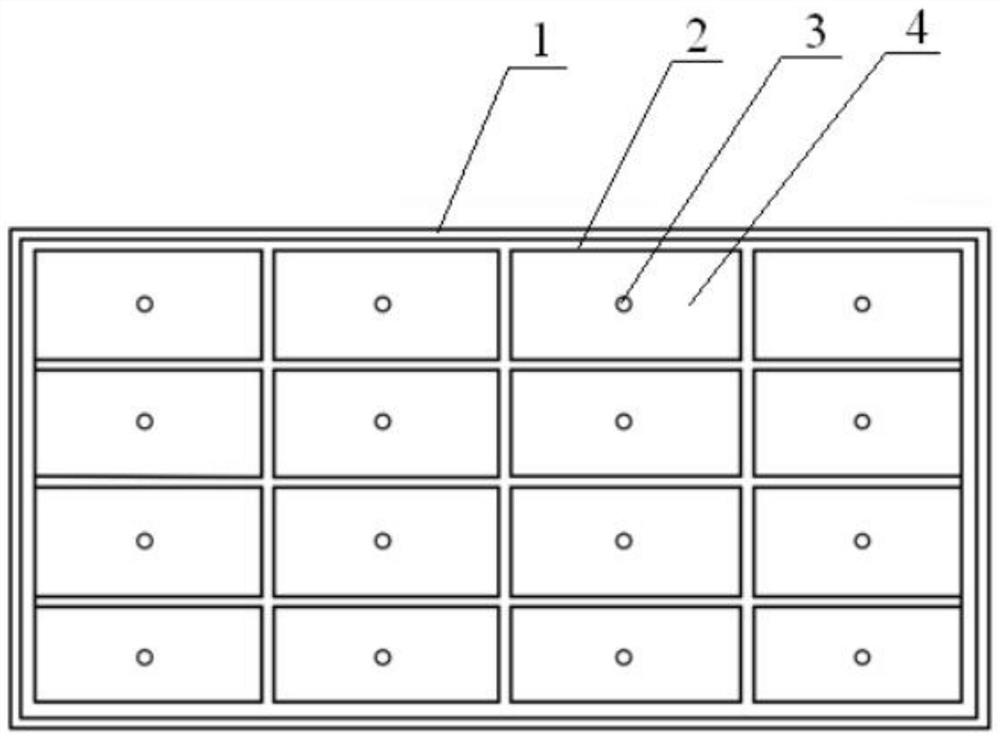

Tension-free overflow water washing tank

ActiveCN101892567ASpeed up molecular motionNo scratchesTextile treatment containersTextile treatment by spraying/projectingPolyesterDyeing

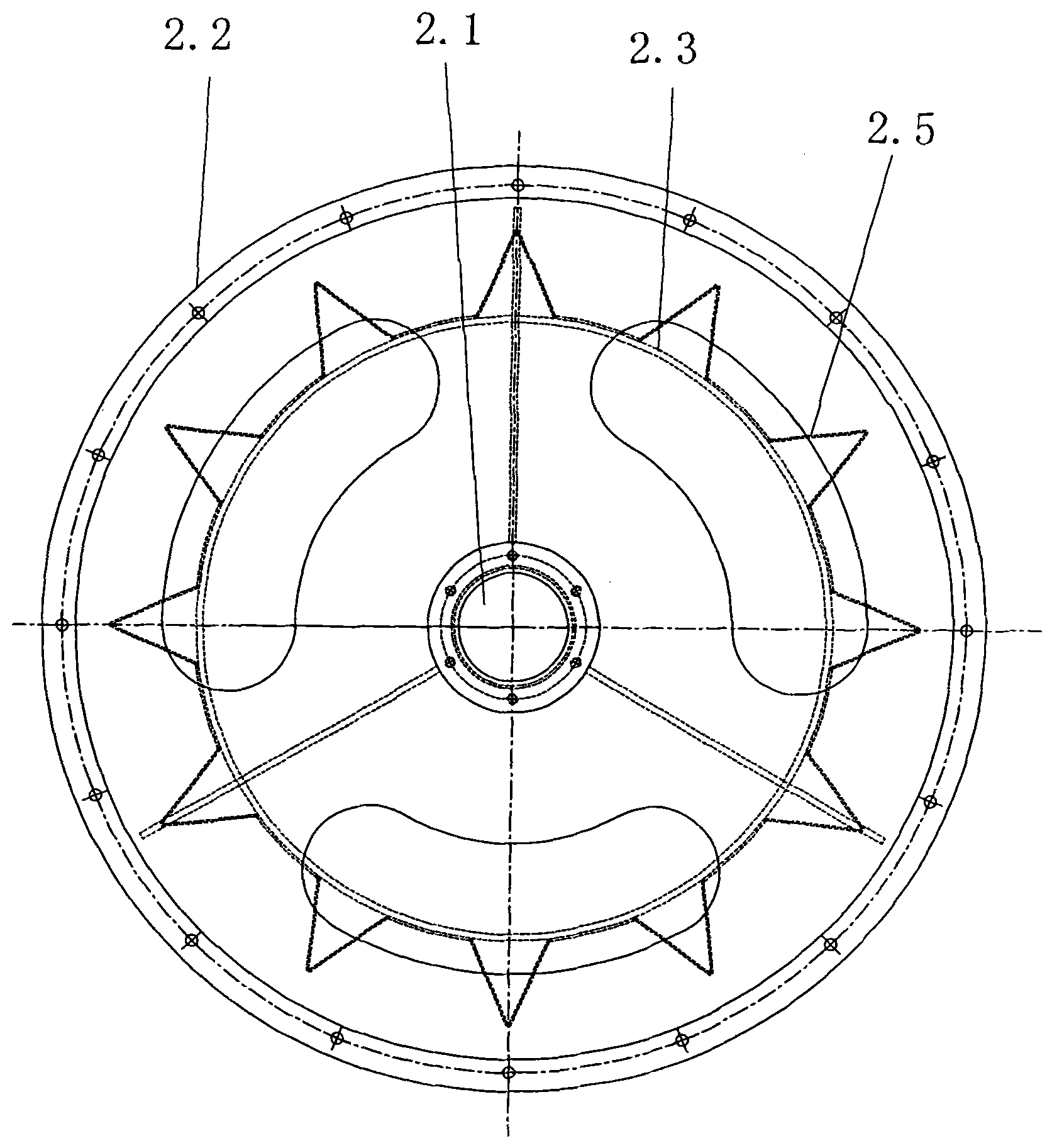

The invention relates to a tension-free overflow water washing tank, which is mainly applicable to water washing and dyeing of pure cotton and cotton and polyester blended fabric after cold pad-batch pretreatment, stacking and steaming, and water washing after printing. The tension-free overflow water washing tank comprises a tank body (1) and rotary drums (2), the number of the rotary drums (2) is two, the two rotary drums (2) are arranged at the left and the right in the tank body (1) in parallel, and the tension-free overflow water washing tank is characterized in that a water inlet (1.2), a water outlet (1.7) and an overflow port (1.3) are arranged on the tank body, the rotary drums (2) are arranged at the lower half part in the tank body (1), a cloth-crossing roller (3) is arranged in the tank body (1) above the two rotary drums (2), and a spraying device (5) is arranged above the cloth-crossing roller (3) and the right rotary drum (2) in the tank body (1); and each rotary drum (2) comprises an outer mesh cylinder (2.2) and inner mesh cylinder (2.3) which are coaxially arranged at the interior and the exterior, a plurality of convex edges (2.5) are axially arranged on the outer edge of each inner rotary cylinder (2.3), and the rotation directions of the outer mesh cylinders (2.2) and the inner rotary cylinders (2.3) are reverse. The adoption of the water washing tank has the advantages of being difficult to scratch the surface of the fabric, not producing grinding marks and having thorough and good cleaning effect.

Owner:江阴福汇纺织有限公司

Cutoff filter

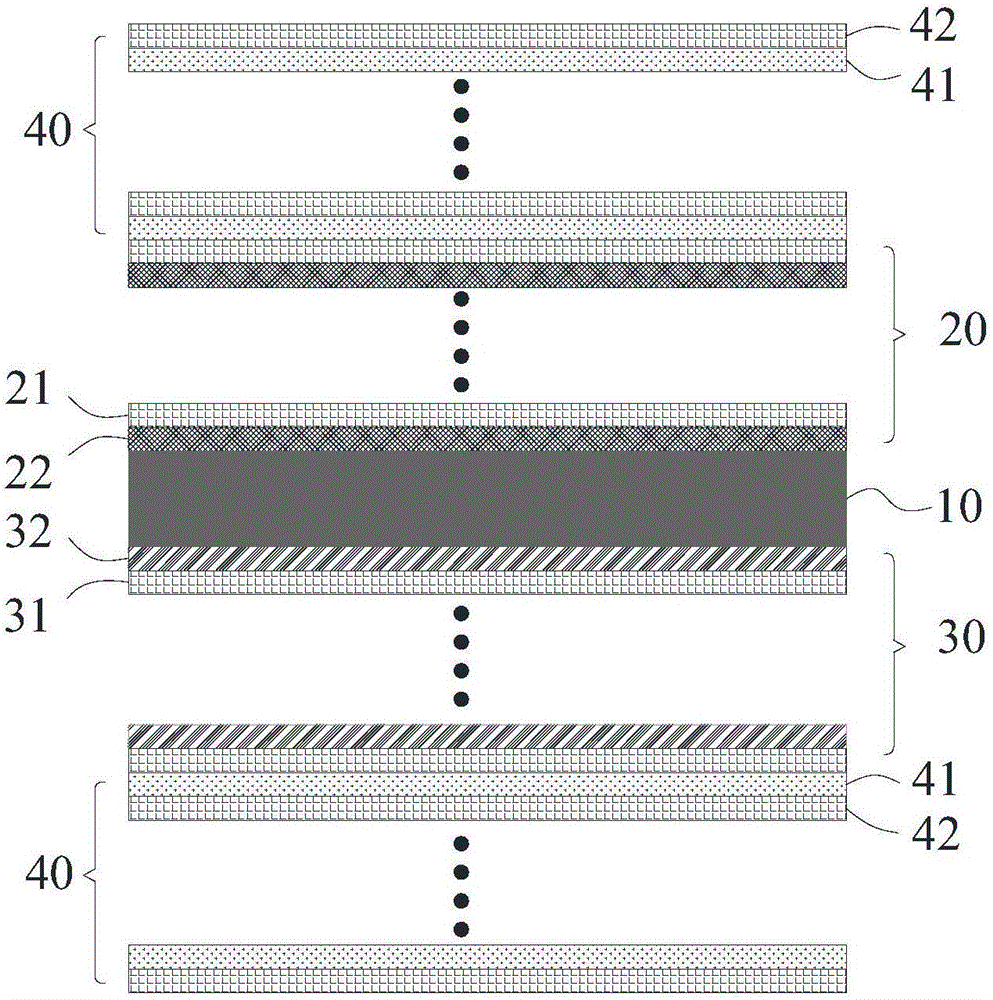

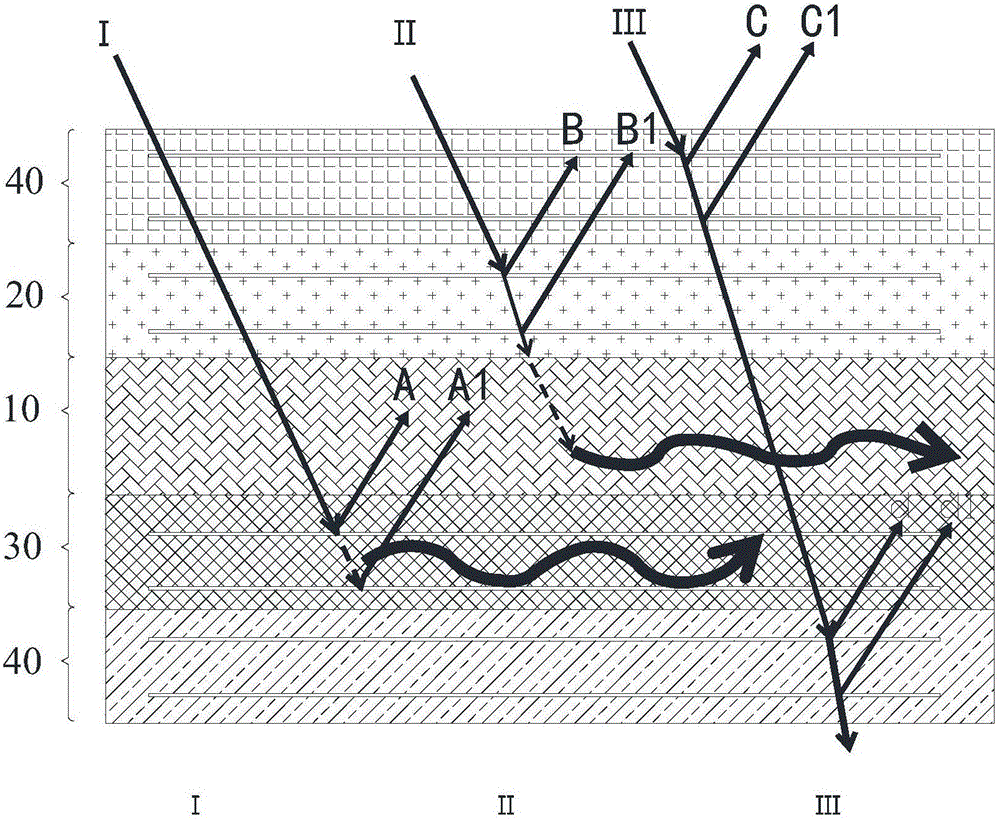

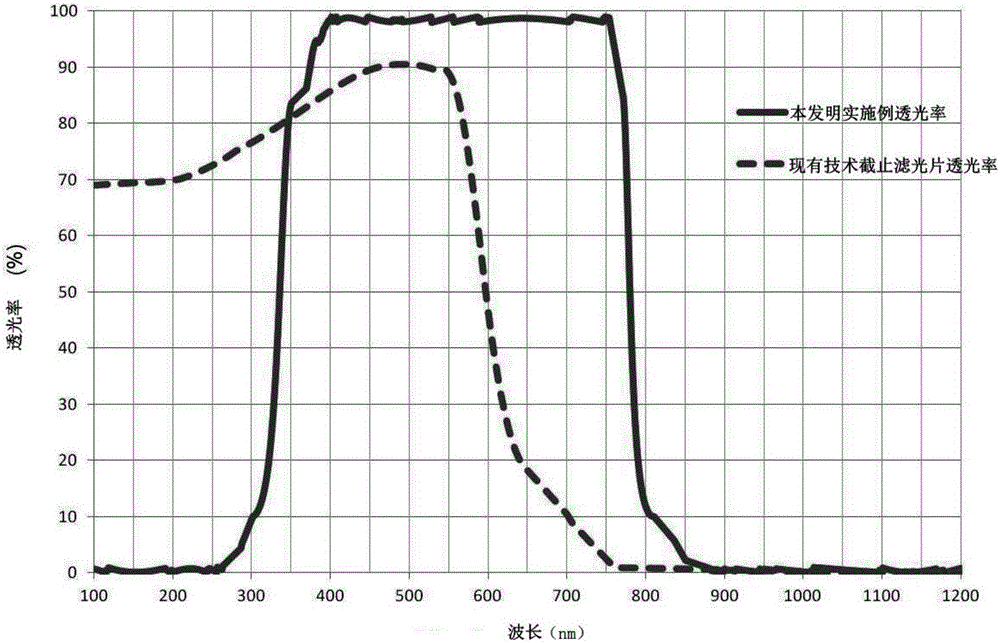

InactiveCN105738995AReduce thicknessGood light transmissionOptical filtersUltraviolet lightsRefractive index

The invention provides a cutoff filter which comprises a blue glass substrate, an infrared cutoff membrane stack and an ultraviolet cutoff membrane stack which are arranged at two sides of the blue glass substrate. The infrared cutoff membrane stack is formed through stacking a first high-refractivity film layer with a first refractivity and a second low-refractivity film layer with a second refractivity. The ultraviolet cutoff membrane stack is formed through stacking a third high-refractivity film layer with a third refractivity and a fourth low-refractivity film layer with a fourth refractivity, wherein the first refractivity is larger than the second refractivity; the third refractivity is larger than the fourth refractivity; and the infrared cutoff membrane stack and the ultraviolet cutoff membrane stack are deposited on the blue glass substrate in a megnetron sputtering manner. According to the cutoff filter, infrared light is cut off through the infrared cutoff membrane stack and the blue glass substrate and the ultraviolet light is cut off through the ultraviolet cutoff membrane stack; and the infrared cutoff membrane stack and the ultraviolet cutoff membrane are deposited on the blue glass substrate in a megnetron sputtering manner, thereby reducing thickness of the cutoff filter.

Owner:SHENZHEN LEAGUER OPTRONICS

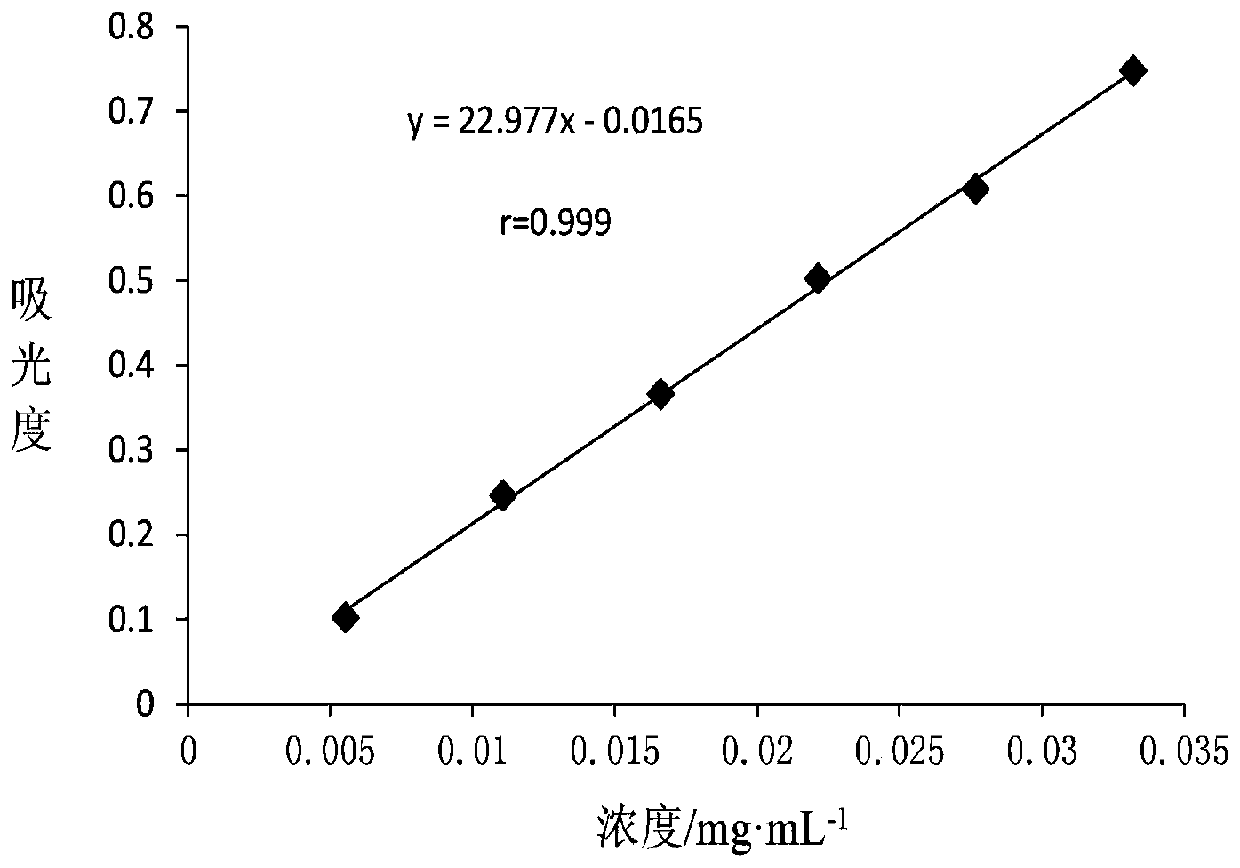

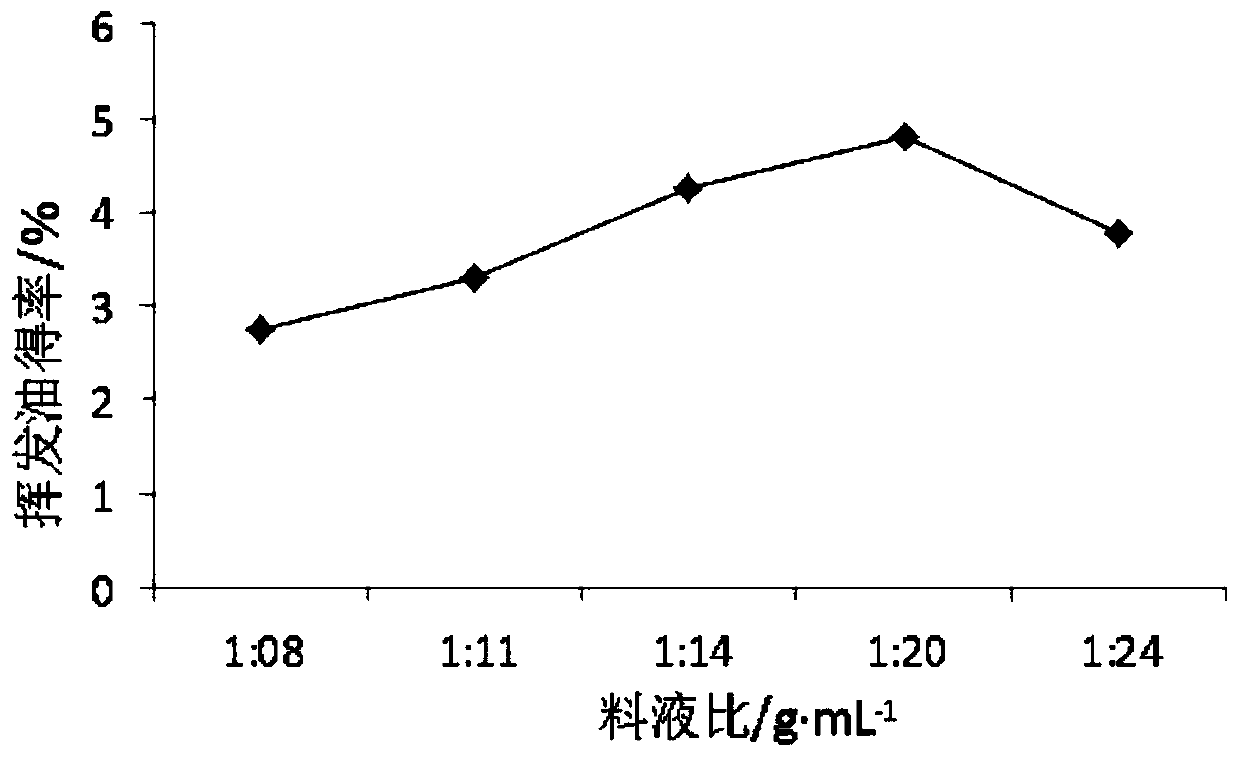

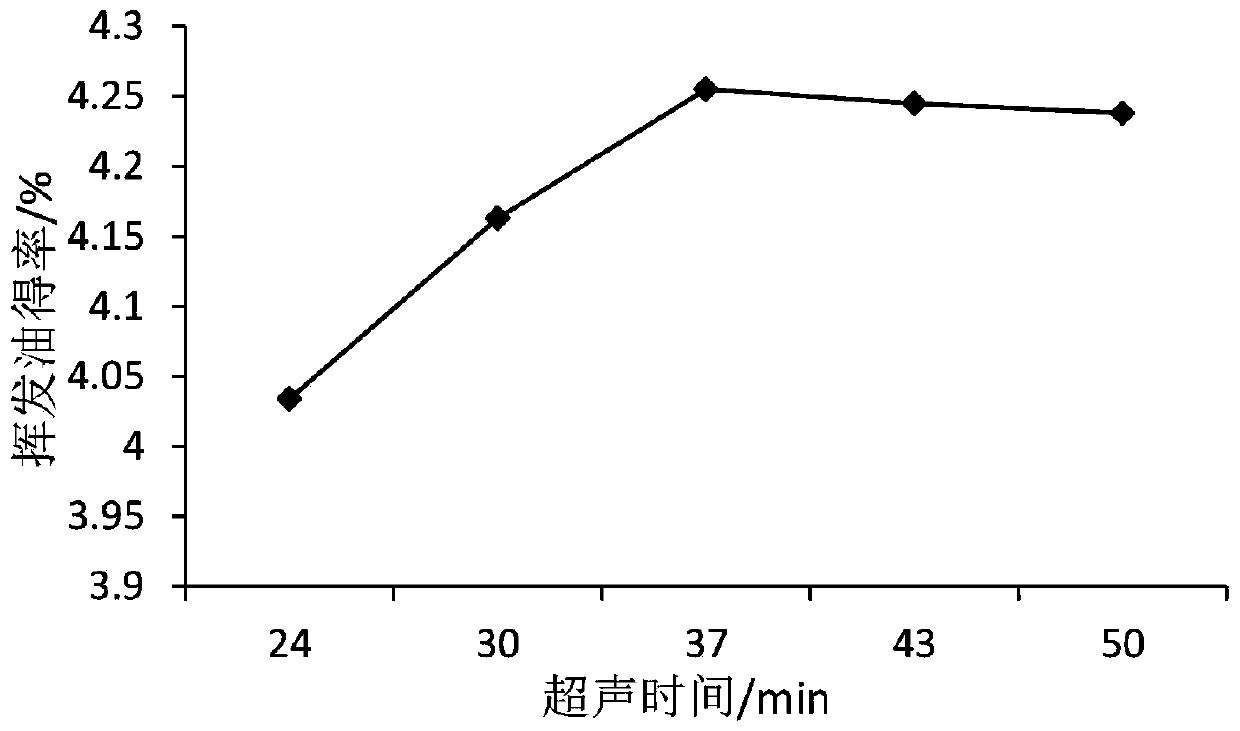

Extraction method and purification method of acorus gramineus volatile oil

ActiveCN110302289AReasonable designSimple processEssential-oils/perfumesPlant ingredientsSolventChemistry

The invention relates to the technical field of traditional Chinese medicine extraction, and discloses an extraction method and a purification method of acorus gramineus volatile oil. The extraction method of the acorus gramineus volatile oil includes the steps of pre-treatment, ultrasonic extraction, vacuum suction filtration, rotary evaporation and other steps; and the purification method of theacorus gramineus volatile oil is to obtain the high-purity refined acorus gramineus volatile oil through ethanol immersion, vacuum and suction filtration and rotary evaporation carrying on the acorusgramineus volatile oil. The extraction method of the acorus gramineus volatile oil is reasonable in design and simple in technology, an ultrasonic extraction method is adopted, the extraction methodhas the advantages of being short in extraction time, mild in extraction conditions, high in product yield, high in active ingredient content of the obtained acorus gramineus volatile oil, no residualin solvent extraction, energy saving and environmental protection, and the purification method of the acorus gramineus volatile oil has the advantages of being simple in operation, high in purification efficiency, high in product active ingredient content and no residual in solvent.

Owner:SHANXI UNIV OF CHINESE MEDICINE

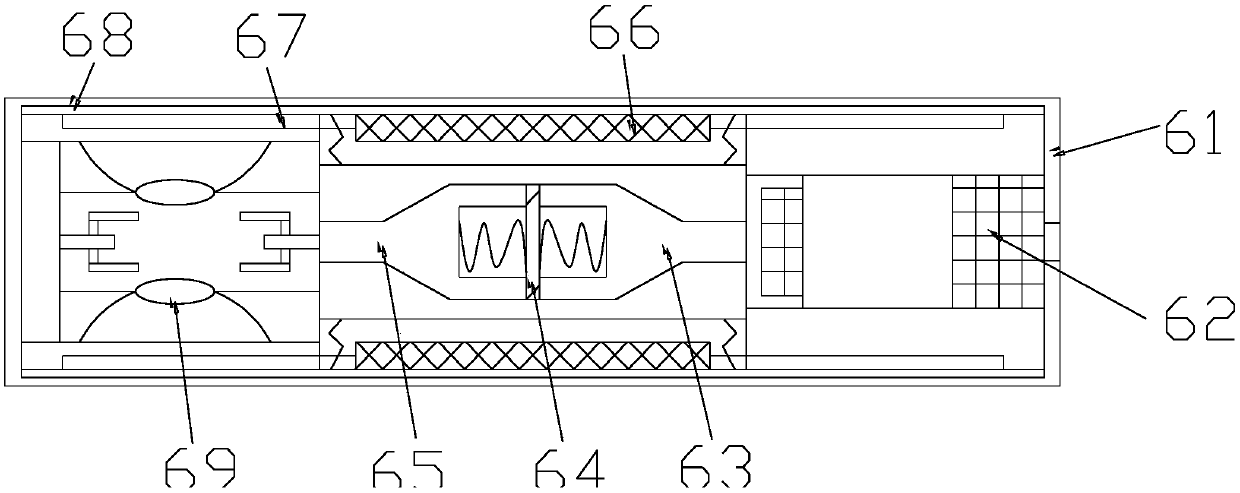

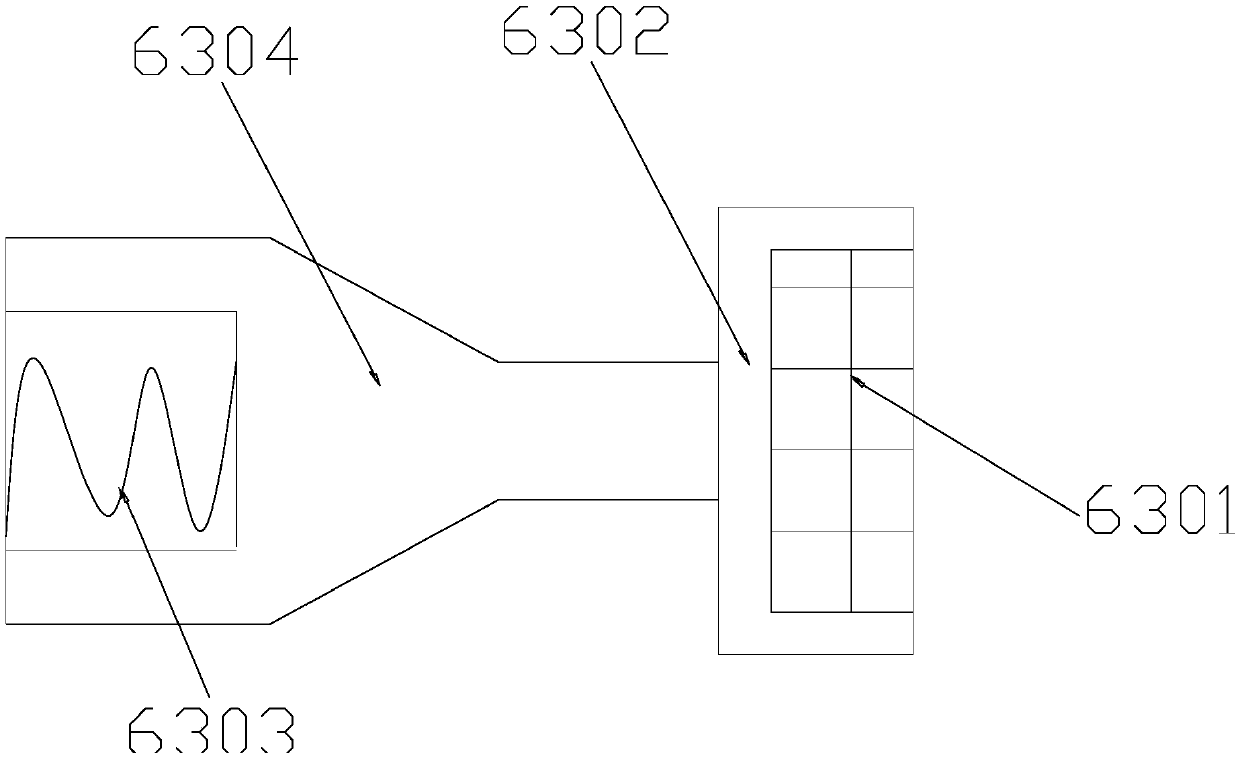

Punching equipment

InactiveCN104959454AExtended service lifeSpeed up molecular motionShaping toolsMetal-working feeding devicesPunchingManufacturing engineering

The invention discloses punching equipment. The punching equipment comprises an upper die base, a lower die base where a product is placed, a stamping assembly arranged on the upper die base, a heating piece which is arranged in the lower die base and corresponds to the stamping assembly, and a movement assembly which is fixed to the product and drives the product to move. The movement assembly comprises a suction piece fixed to the product, a transverse movement piece fixed to the suction piece, and a vertical movement piece fixed to the transverse movement piece. According to the punching equipment, a part is preheated before punching so as to accelerate molecular movement, and then punching is conducted. In this way, punching and formation are facilitated, burs are reduced, and the product quality is improved. Meanwhile, the service life of a punch is prolonged. Due to the fact that the punching equipment is provided with the movement assembly for fixing products, full-automatic positioning for punching is realized, and all the punching work is completed. The production efficiency is improved. Labor is saved.

Owner:昆山—邦泰汽车零部件制造有限公司

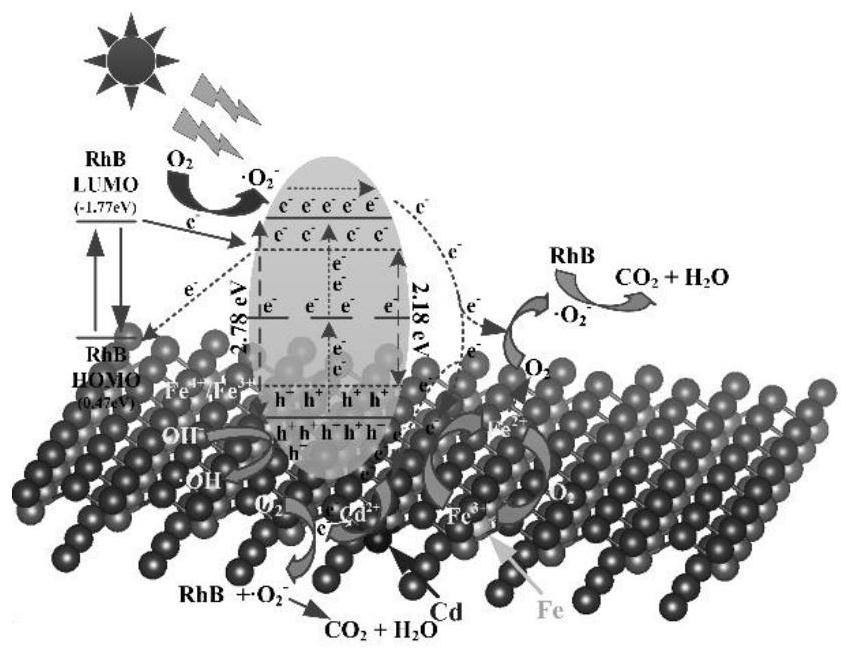

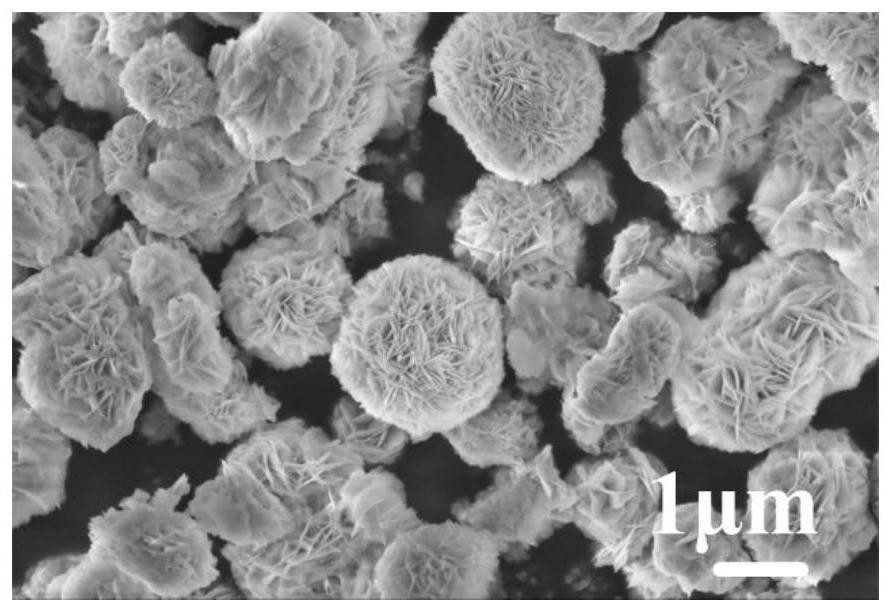

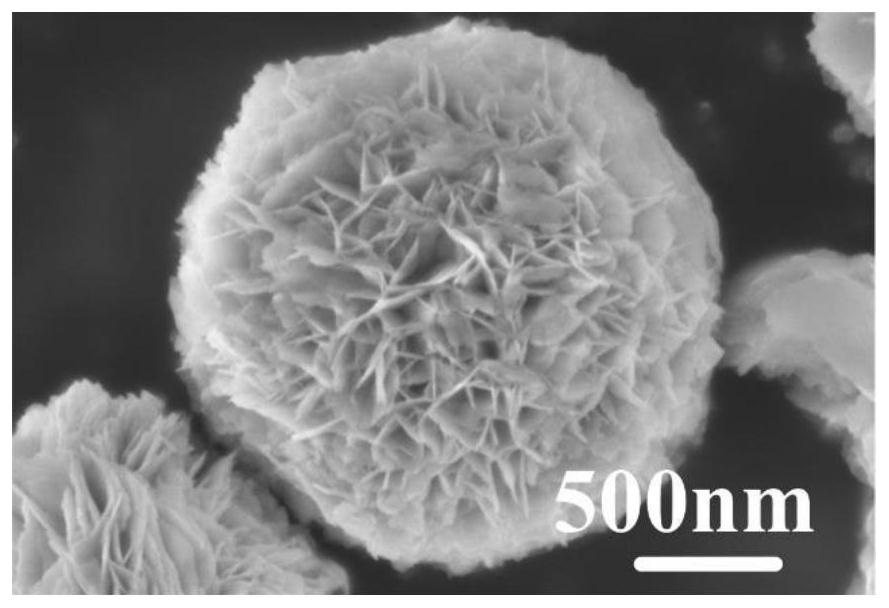

Metal ion co-doped BiOBr microsphere as well as preparation method and application thereof

ActiveCN111686770AFacilitated releaseReduced band gapWater/sewage treatment by irradiationWater treatment compoundsMicrosphereOrganosolv

The invention discloses a metal ion co-doped BiOBr microsphere as well as a preparation method and application thereof. The microsphere is specifically prepared from Bi < 1-x-y > Cd < x > Fe < y > OBr, wherein x = y = 0.02, or Bi<1-x> Cd<x>OBr, x = 0.02, or Bi<1-x> Fe<x>OBr, and x = 0.02, the preparation method comprises the following steps: respectively dissolving a bismuth source and CTAB in anorganic solvent, carrying out ultrasonic treatment, and carrying out magnetic stirring; mixing to obtain a mixed solution, adding metal ions, transferring an obtained product into a high-pressure kettle, adding a rupture disk, and carrying out microwave hydrothermal reaction; and after the reaction is finished, cooling a product to room temperature, washing with deionized water for multiple times,fully washing with ethanol, and drying. The preparation method disclosed by the invention is mild in condition and simple in process, and organic pollutants such as dyes and antibiotics in sewage canbe efficiently degraded under simulated sunlight irradiation.

Owner:YANAN UNIV

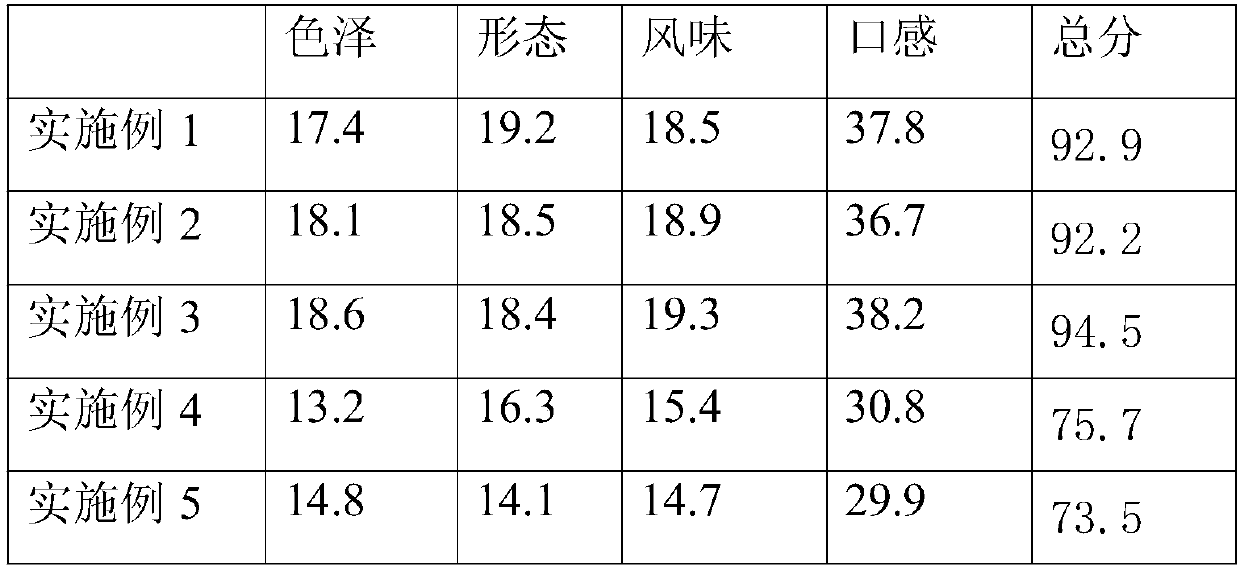

Preparation method of chili sauce

InactiveCN107668659AInhibit the activity of polyphenolaseMaintain colorFood thermal treatmentMaterials preparationFlavor

The invention belongs to the technical field of food processing, and particularly relates to a preparation method of a chili sauce. The method comprises the following steps of material preparation, pretreatment, beating, mixing and fermentation. According to the chili sauce prepared by the invention, the total acid content of the chili sauce is controlled by special hot soup treatment and a special fermentation process, and the total acid content can reach up to 0.88% at a minimum. If the total acid content is too high, product is not safe. The flavor of chili is ensured, and finally the chilisauce has a natural red color, is bright and glossy, and has little juice, poor fluidity, moderate viscosity, fine and uniform texture, no layering, a strong fermentation flavor, coordinating smells,no peculiar smell, fine taste, mild sourness, spiciness and saltiness, and soft sourness.

Owner:代浩

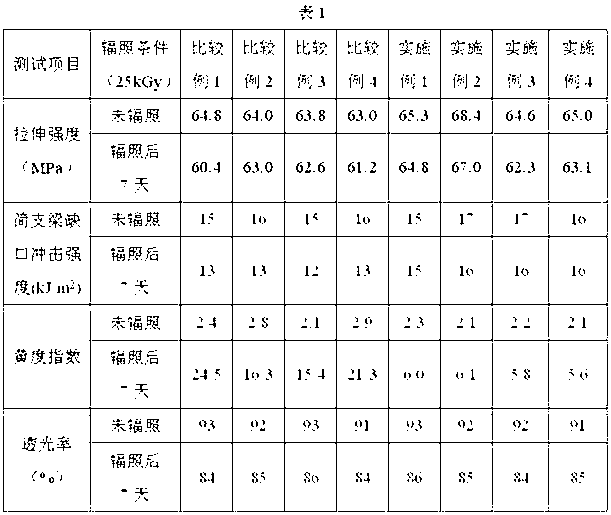

Radiation resistant polycarbonate material, preparation method and application thereof

The invention discloses a medical radiation resistant polycarbonate material comprising polycarbonate, a radical stabilizer, epoxy diluents and a plasticizer, wherein the masses of the components in the formula are as follows: the polycarbonate is 100 parts, the radical stabilizer is 0.1-1.0 part, the epoxy diluents are 0.1-2.0 parts and the plasticizer is 0.1-2.0 parts. The invention further discloses a preparation method and application of the material. The color of the prepared polycarbonate material after being radiated by high-energy electron accelerator beams or 60Co gamma-ray (the dose is not more than 40KGy) does not turn yellow, the good mechanical properties and transparency can be guaranteed, and the requirements of the medical polycarbonate material can be met. The medical radiation resistant polycarbonate material can be applied to the preparation of artificial kidney dialyzers, artificial lungs, blood oxygenation apparatus, blood separators, anesthesia evaporation equipment or other pieces of medical equipment which need to be operated at transparent and audio-visual conditions and need to be radiated.

Owner:UNIV OF JINAN +2

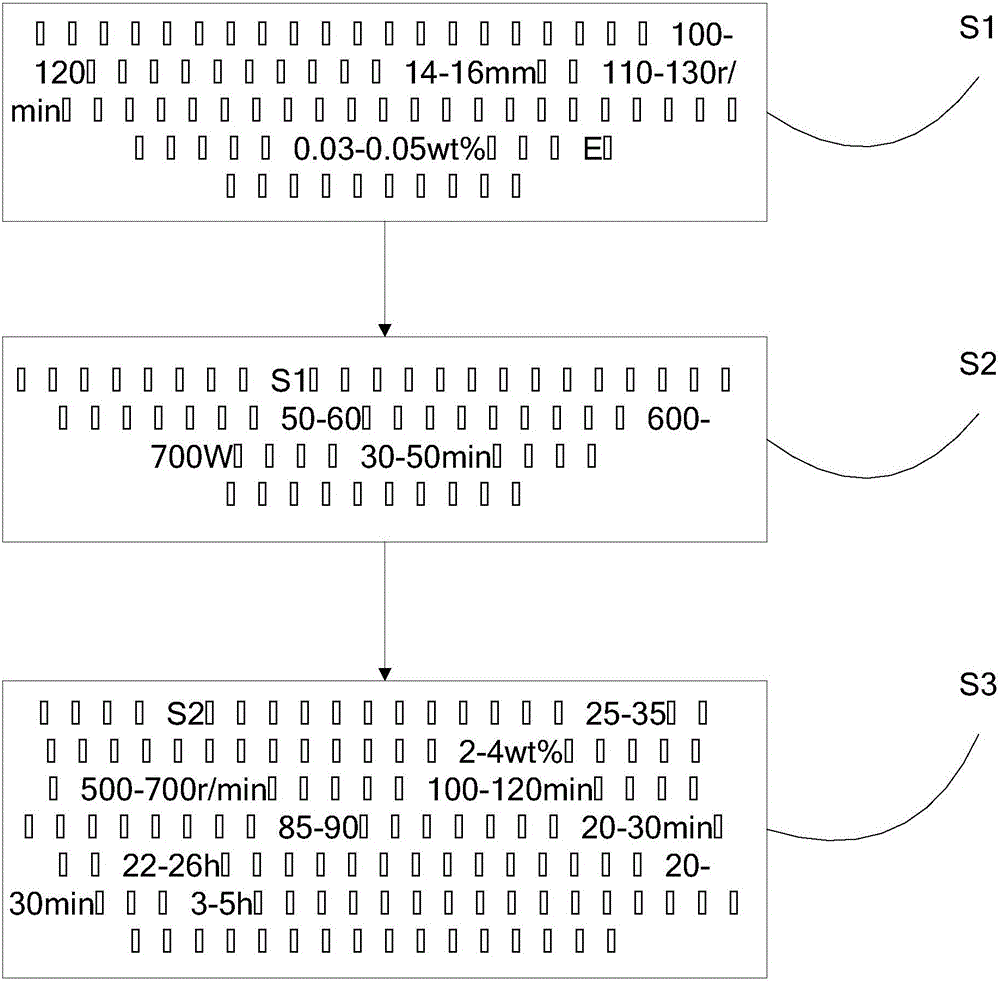

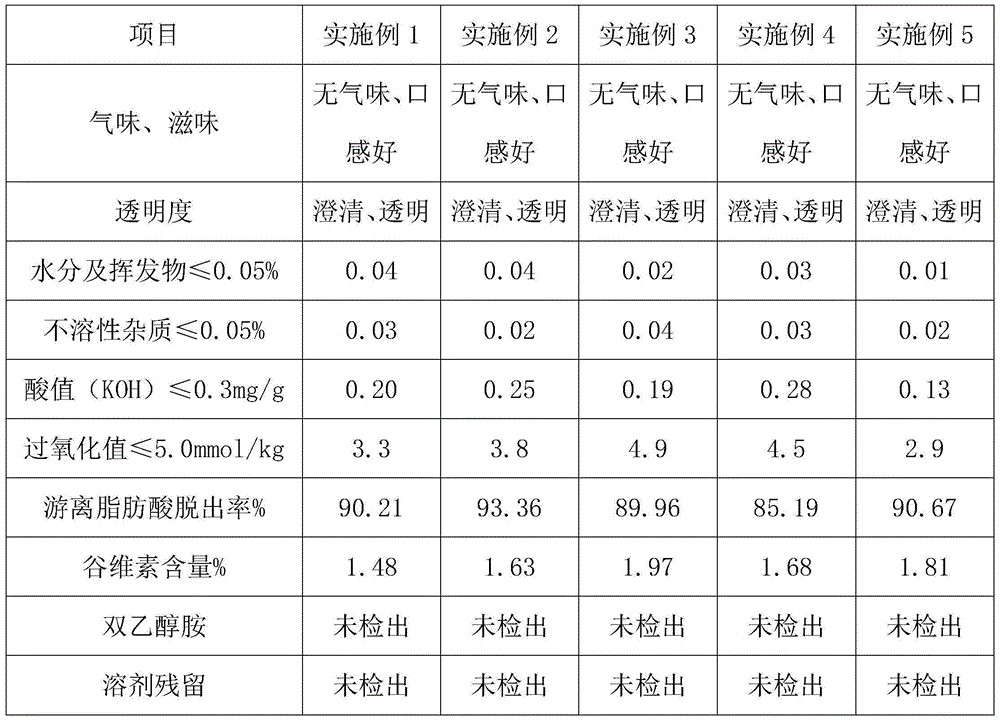

Preparation method for high-quality rice bran oil

InactiveCN105087136AImprove antioxidant capacityHigh oil extraction rateFatty-oils/fats refiningFatty-oils/fats productionWater bathsRoom temperature

The invention discloses a preparation method for high-quality rice bran oil. The method comprises the following steps: S1, rice bran preservation: a step of placing rice bran in an extrusion-expansion machine, carrying out heating to 100 to 120 DEG C, wherein a diameter of an extrusion film hole is 14 to 16 mm, then carrying out extrusion and expansion with a speed of 110 to 130 r / min, carrying out cooling to room temperature, spraying 0.03 to 0.05 wt% of vitamin E with rice bran weight as datum, and carrying out uniform mixing so as to obtain preserved rice bran; S2, crude rice bran oil extraction: a step of adding the preserved rice bran obtained in the S1 into a solvent, carrying out water bath heating to 50 to 60 DEG C, carrying out ultrasonic treatment under an ultrasonic power of 600 to 700 W for 30 to 50 min, then carrying out filtering and rotary evaporation so as to obtain crude rice bran oil; and S3, refining: a step of subjecting the crude rice bran oil obtained in the S2 to degumming, deacidifying, dewaxing, decolorizing and deodorizing so as to obtain the high-quality rice bran oil. The preparation method for the high-quality rice bran oil provided by the invention has the advantages of high oil quality, high oil extraction rate, high free fatty acid removal efficiency and simple operation.

Owner:BENGBU QIONGHUAI GRAIN & OIL

Degradable film and preparation method thereof

The invention discloses a degradable film and a preparation method thereof. The degradable film comprises the following raw materials: polyethylene, polylactic acid, corn starch, polynaphthalene formaldehyde sulfonate, fatty alcohol polyoxyethylene ether ammonium sulfate, acrylate and water. The degradable film is prepared by the steps: carrying out burdening, mixing and uniform stirring to prepare a mixed material A; modifying the mixed material A to prepare a modified mixed material, and blowing the modified mixed material by using a plastic film blowing machine. The preparation method disclosed by the invention is simple in preparation process, and the degradable film disclosed by the invention is good in water resistance, high in biodegradability and good in toughness.

Owner:长沙浩然医疗科技有限公司

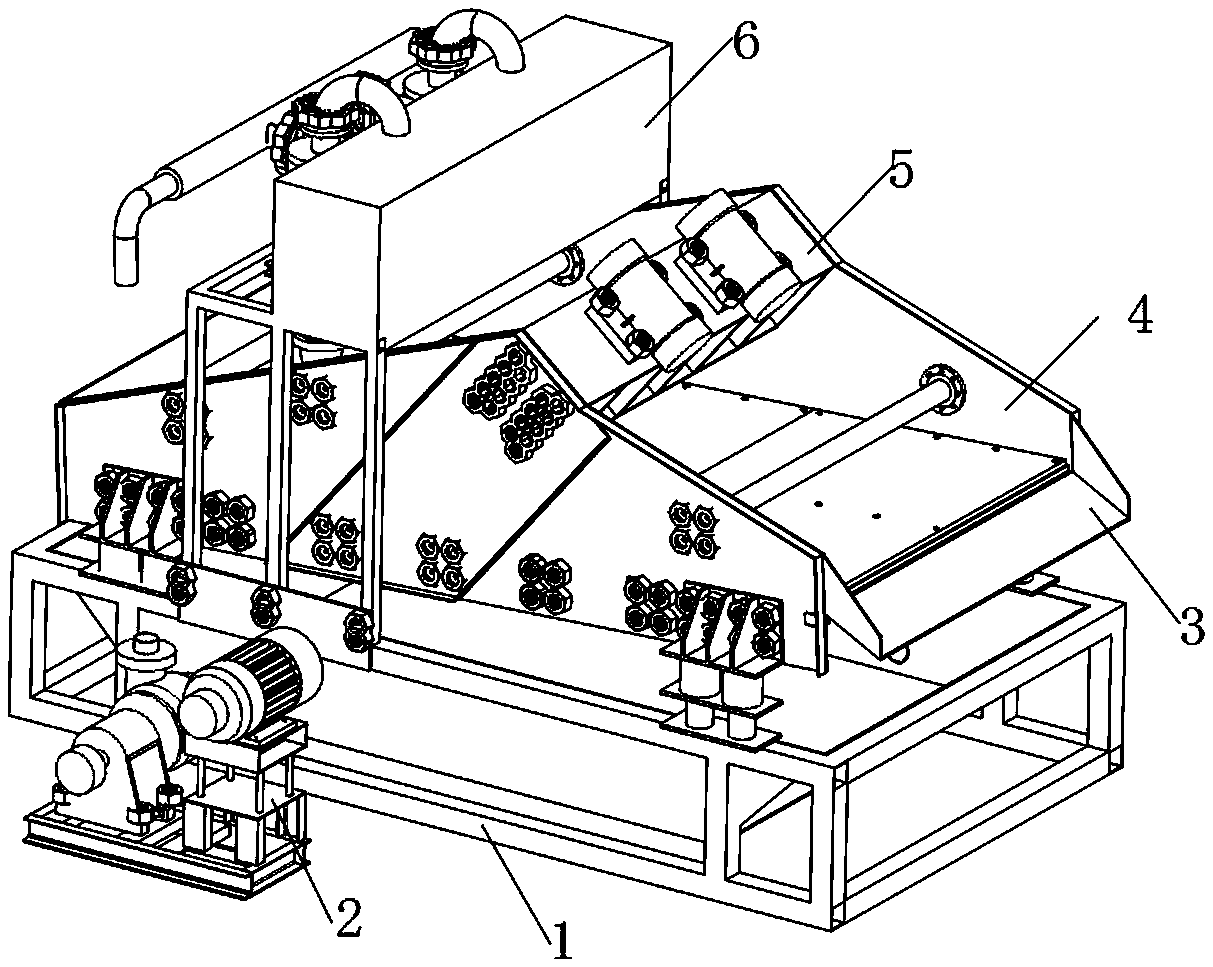

Pigment mixing equipment for sound wave heating resonance anti-adhesion printing packaging

InactiveCN109621778ASpeed up molecular motionEasy to cleanTransportation and packagingRotary stirring mixersSolubilityTuning fork

The invention discloses pigment mixing equipment for sound wave heating resonance anti-adhesion printing packaging. Th equipment structurally comprises a base, a controller, a motor, a connector, a rotation rod and a stirring device. Under the effect of a current generation device and an electric heating wire, an arch movement block moves upwards to extrude a dielectric substance to form current,the current is introduced into the electric heating wire through a wire for heating a shell, the water contact solubility of the external phase of the shell is improved, the molecular motion of pigment attached to the shell is improved, and accordingly the pigment can be better cleaned; under the effect of a sound wave resonance device, sound waves generated by impact of the shell and the water flow are collected through reflection of a sound returning plate, a vibration insulation film vibrates and collides a vibration tuning fork, the vibration tuning fork gives out sound waves so that a resonance tuning fork can be subjected to resonance, a resonance plate is subjected to resonance, the shell is driven to vibrate to form bubbles, impact waves are generated when the bubbles are closed, and the aim of cleaning and purifying the shell is achieved.

Owner:赣州惠彩印刷有限公司

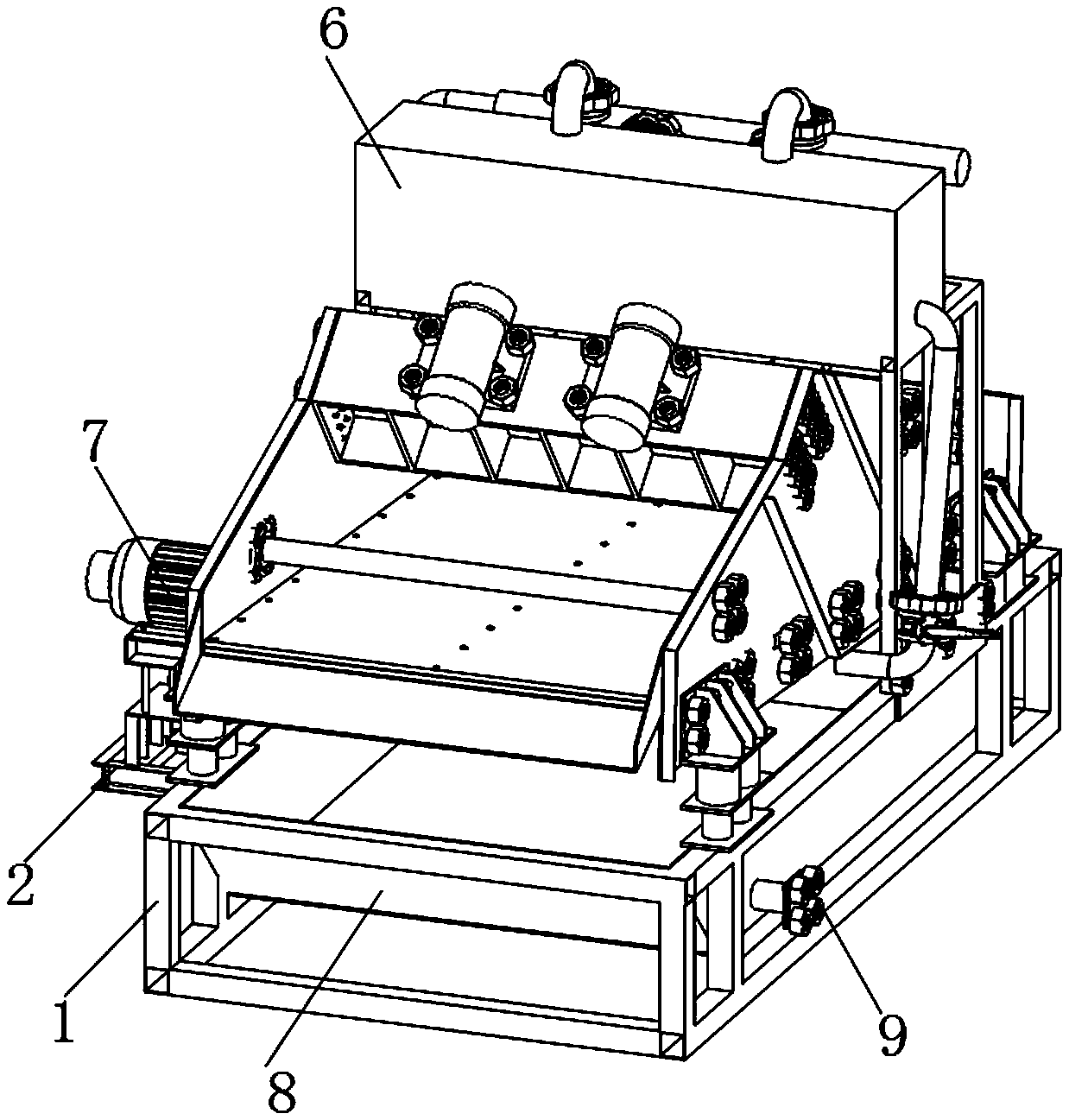

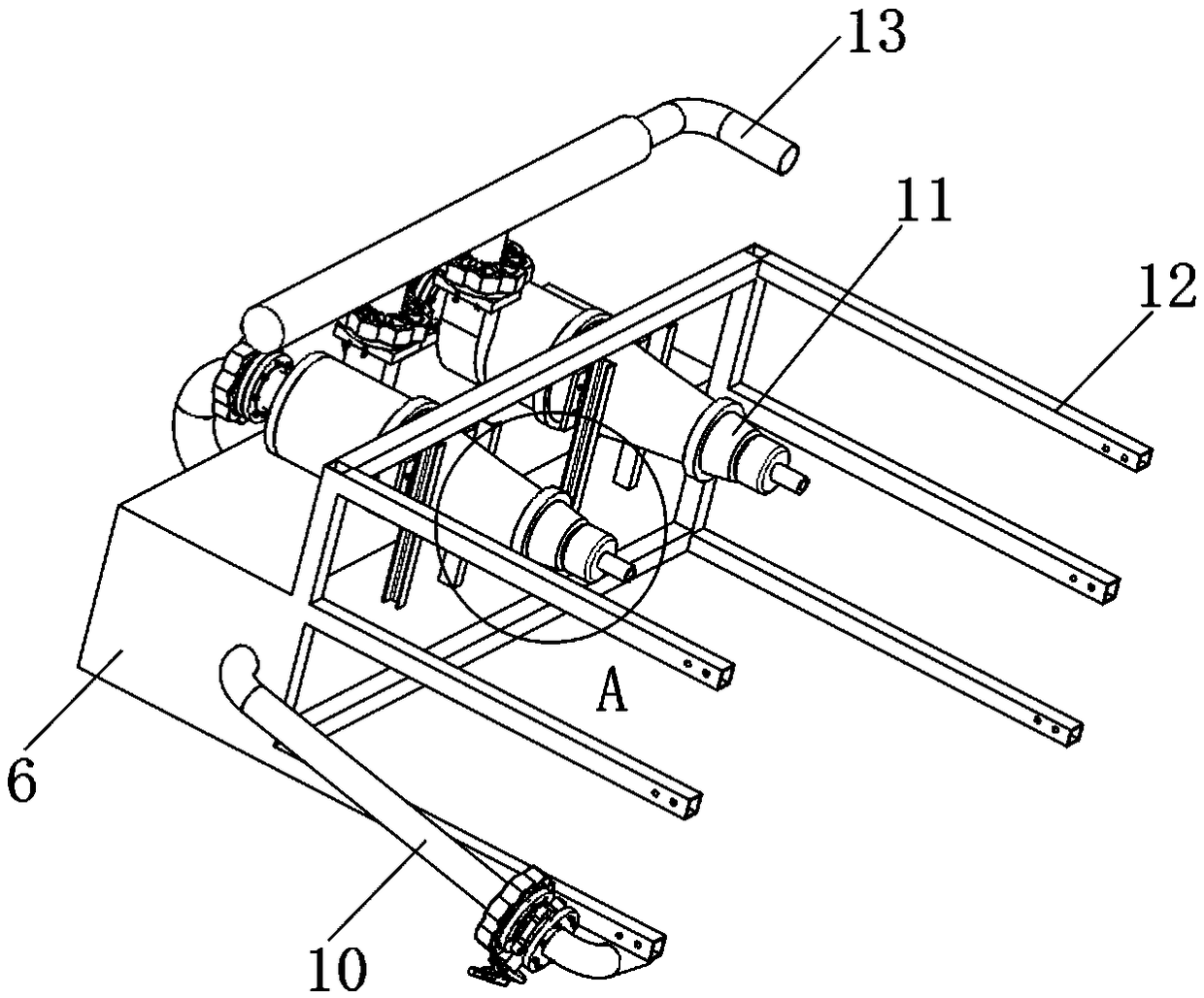

Fabricated sewage treatment device and treatment process thereof

ActiveCN109485199AAvoid easy cloggingExtended service lifeMultistage water/sewage treatmentTransverse planeEngineering

The invention discloses a fabricated sewage treatment device and a treatment process thereof. The fabricated sewage treatment device comprises a base, a loading box and a purification box, wherein thepurification box is arranged inside the top end of the base; the loading box is horizontally arranged on the top of the base; side plates which are longitudinally arranged are welded at both sides ofthe loading box; a screen mesh is slantwise arranged at the upper part of the loading box; a sediment box is fixedly arranged on the top end of the middle part between the two side plates through a support; one end of the sediment box is connected to a water inlet pipe; a plurality of first conveying pipes are arranged at one side of the sediment box; the other side of the sediment box is connected to a transverse plate; a plurality of second conveying pipes are arranged at one side of the transverse plate; and the two ends of the transverse plate are welded on the side surfaces of the side plates. The fabricated sewage treatment device is convenient to use, simple in operation and long in service life, has a high safety performance, a good purification effect and strong treatment ability, can adapt to different working occasions and fully purifies sewage; and the interior of the fabricated sewage treatment device is unlikely to be blocked.

Owner:江苏瑞盛环境科技有限公司

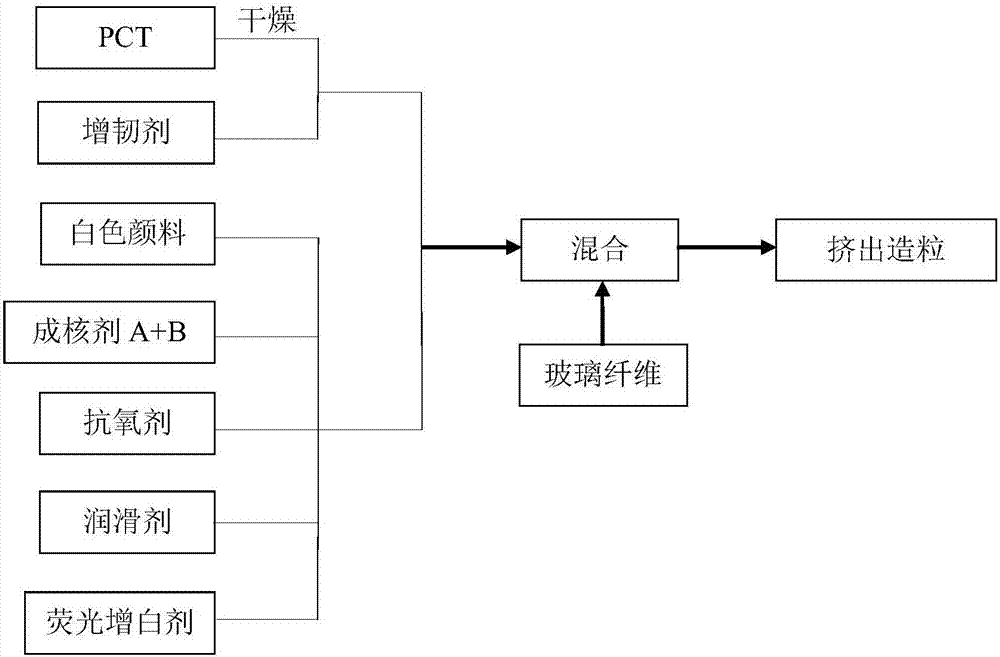

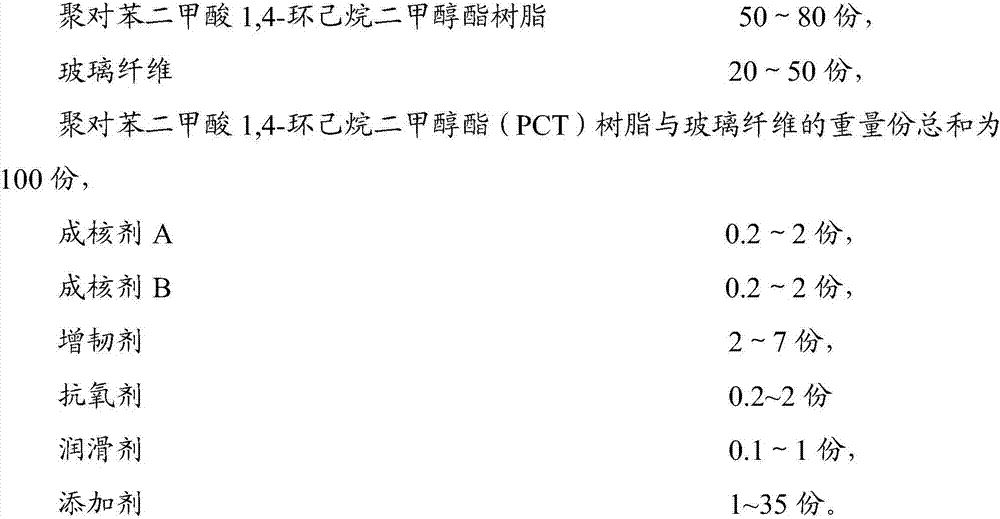

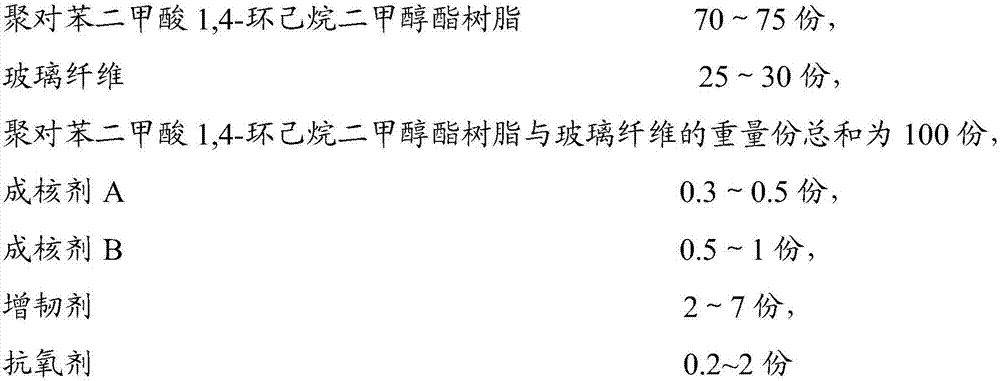

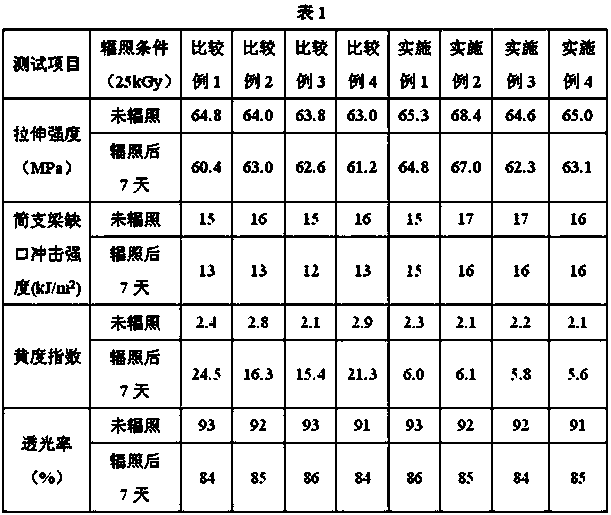

Polyester composition and preparation method thereof

The invention relates to a polyester composition and a preparation method thereof; the polyester composition is prepared from poly-1,4-cyclohexane dimethylene terephthalate (PCT) resin, glass fiber, nucleating agent A, nucleating agent B, a flexibilizer, an antioxidant, a lubricant and an additive. The poly-1,4-cyclohexane dimethylene terephthalate (PCT) resin has number-average molecular weight of 25000 to 30000; the nucleating agent A is sodium carboxylate organic small-molecular nucleating agent, having molecular weight of 100-200 g / mol; the nucleating agent B is an ionic polymer salt nucleating agent. The polyester composition has higher crystallizing rate so that a material takes short time to form, time cost of product processing is saved, crystallizing rate is largely increased, and the comprehensive properties of the material, such as impact property, bending performance, and thermal deformation temperature tolerance, can be better improved.

Owner:SINOPLAST NEW MATERIAL

Radiation resistant polycarbonate material, preparation method and application thereof

The invention discloses a medical radiation resistant polycarbonate material comprising polycarbonate, a radical stabilizer, epoxy diluents and a plasticizer, wherein the masses of the components in the formula are as follows: the polycarbonate is 100 parts, the radical stabilizer is 0.1-1.0 part, the epoxy diluents are 0.1-2.0 parts and the plasticizer is 0.1-2.0 parts. The invention further discloses a preparation method and application of the material. The color of the prepared polycarbonate material after being radiated by high-energy electron accelerator beams or 60Co gamma-ray (the dose is not more than 40KGy) does not turn yellow, the good mechanical properties and transparency can be guaranteed, and the requirements of the medical polycarbonate material can be met. The medical radiation resistant polycarbonate material can be applied to the preparation of artificial kidney dialyzers, artificial lungs, blood oxygenation apparatus, blood separators, anesthesia evaporation equipment or other pieces of medical equipment which need to be operated at transparent and audio-visual conditions and need to be radiated.

Owner:UNIV OF JINAN +2

Mixed gas for LED bulbs and filling method of mixed gas

InactiveCN104501113ALumen highWon't breakPoint-like light sourceLighting heating/cooling arrangementsKryptonHydrogen

Disclosed are mixed gas for LED bulbs and a filling method the mixed gas. The mixed gas is made from, by volume, 90% to 92% of helium, 3% to 5% of hydrogen, 1% to 3% of krypton and 1% to 3% of nitrogen. Owing to movements of molecules of the mixed gas filling an LED bulb, heat in the LED bulb is evidently decreased, the temperature is lowered, the service life of the LED bulb is prolonged, and lumen of the LED bulb is improved. During filling, four inert gases are mixed and charged through an opening of a core post until reaching a standard atmospheric pressure; the LED bulb is never severely broken even after the LED bulb falls off, and injury by fragments is avoided.

Owner:HAINING DEKELONG ELECTRONICS

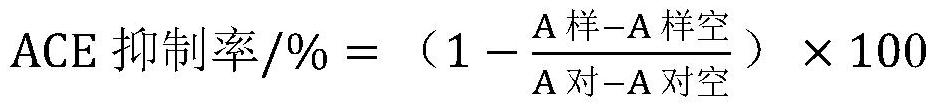

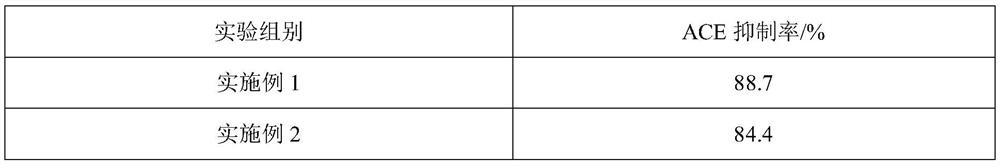

Chinese wolfberry glycopeptide oral liquid for assisting blood pressure reduction and preparation method thereof

PendingCN112971127AAdd flavorGreat tastePeptide preparation methodsFood ingredient as taste affecting agentFructoseGlycopeptide

The invention discloses a Chinese wolfberry glycopeptide oral liquid for assisting blood pressure reduction and a preparation method thereof, and belongs to the technical field of Chinese wolfberry glycopeptide bioactive substance extraction and product preparation. The oral liquid is prepared by mixing the following raw materials in parts by mass: 20-60 parts of Chinese wolfberry glycopeptide, 500-1000 parts of raspberry pulp and 20-50 parts of fructo-oligosaccharide, and the specific preparation method comprises the following steps: by using deionized water as a solvent, extracting a Chinese wolfberry glycopeptide crude extract through an ultrasonic-assisted method, and separating and purifying the obtained Chinese wolfberry glycopeptide crude extract by adopting an inorganic ceramic membrane; purified Chinese wolfberry glycopeptide is compounded and mixed with raspberry pulp and fructo-oligosaccharide, the oral liquid with the blood pressure reduction effect is obtained after packaging and sterilization. The preparation method is simple in process and low in production cost, and the novel Chinese wolfberry glycopeptide oral liquid for assisting blood pressure reduction with good flavor, taste and effect can be prepared.

Owner:SHAANXI RES INST OF AGRI PRODS PROCESSING TECH +1

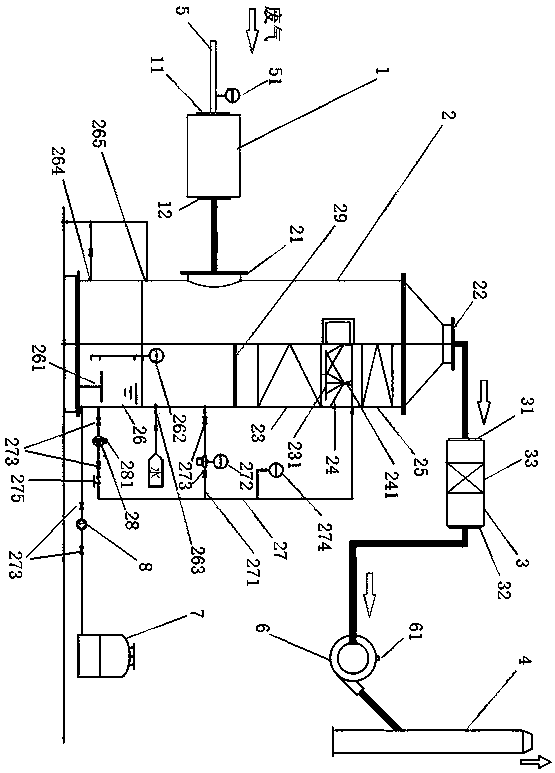

Laboratory exhaust gas treatment system

InactiveCN108421398AAvoid pollutionSimple structureGas treatmentDispersed particle separationSprinkler systemEngineering

The invention relates to a laboratory exhaust gas treatment system. The laboratory exhaust gas treatment system comprising a heating device, an exhaust gas purification tower, a filter device, an induced draft fan and a gas discharge part is characterized in that the heating device, the exhaust gas purification tower, the filter device, the induced draft fan and the gas discharge part are sequentially connected through a pipeline; from top to bottom, the inner portion of the exhaust gas purification tower is sequentially provided with a liquid storage part, a packing layer, s sprinkler systemand a defogging layer; the liquid storage part is connected with the sprinkler system through a circulating pipe and a circulating pump; the exhaust gas purification tower is connected with a dosing device through the pipeline; frequency conversion devices are respectively arranged on the induced draft fan and the circulating pump; a wind pressure transmitter is disposed on a laboratory exhaust gas collection pipeline connected with the heating device. The laboratory exhaust gas treatment system has the advantages that the arrangement of the heating device facilitates the reaction between exhaust gas and absorption treatment liquid, thus improving purification effect; with the arrangement of the wind pressure transmitter and the frequency conversion devices and with the power supply frequency of the induced draft fan and the circulating pump adjusted according to the wind pressure transmitter, while exhaust gas absorption is ensured to be of good effect, energy savings are maximized, and the effect of energy conservation and emission reduction is achieved.

Owner:苏州爱源环境科技有限公司

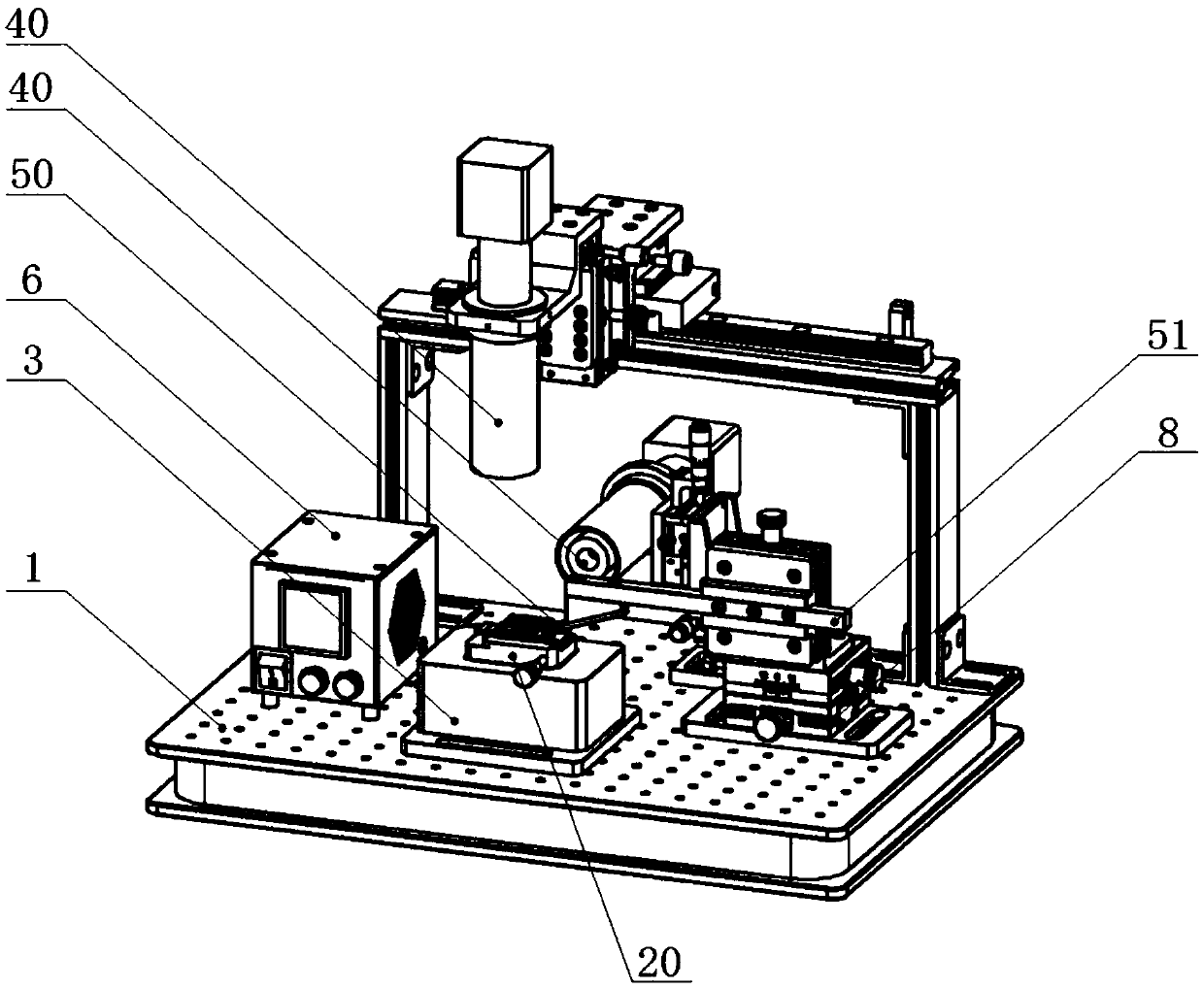

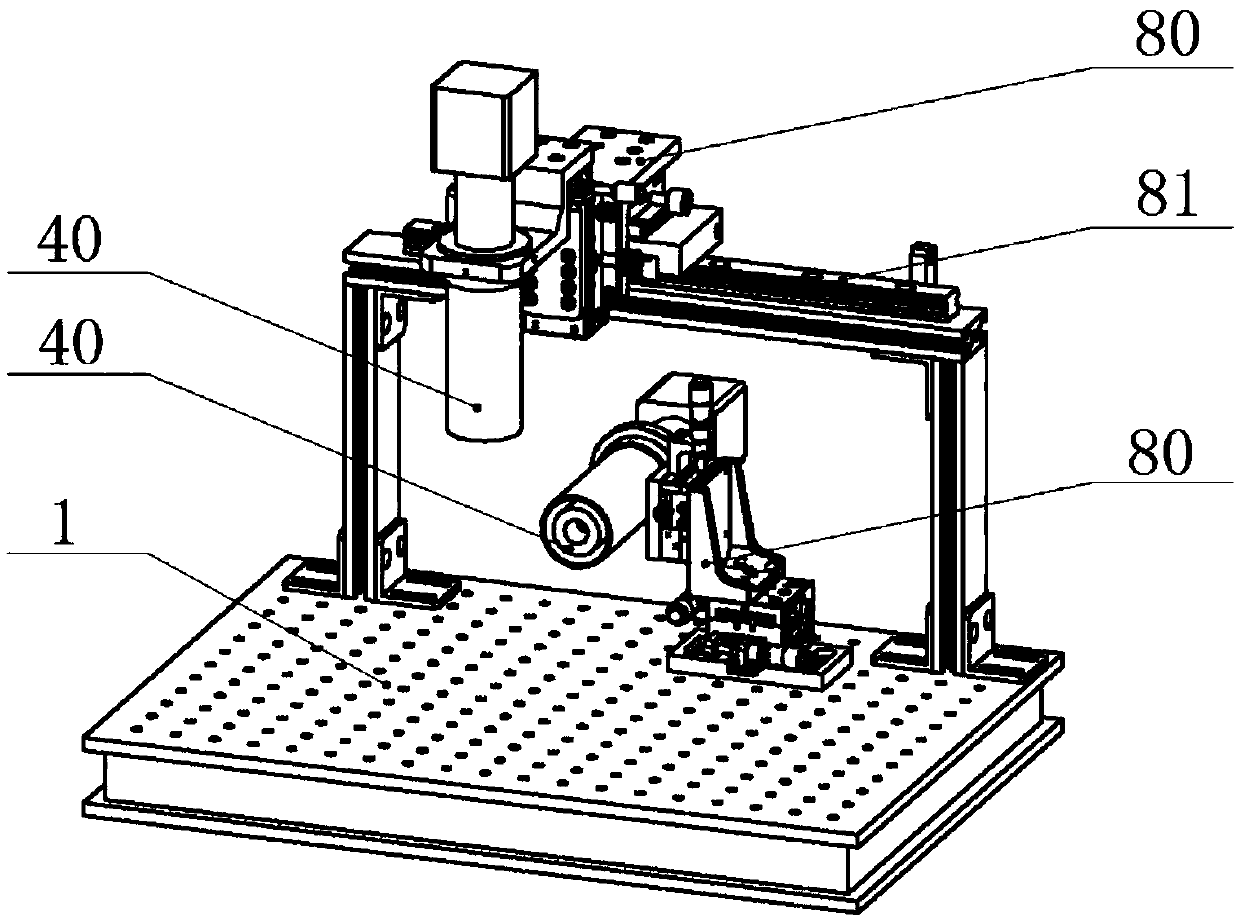

Reworking device for optical COB package

PendingCN109526197ASpeed up molecular motionReduce the degree of curingElectrical componentsEngineeringOptical communication

The invention relates to the technical field of optical communication and provides a reworking device for optical COB package. The device comprises a working platform on which a fixing component, a heating component, an observation component and a peeling component are installed. The fixing component is used for fixing a PCBA board, the heating component is used for heating the PCBA board, the observation component is used for monitoring the condition of the PCBA board in real time, and the peeling component is used for removing a PD chip that is heated and loosened on the PCBA board. According to the reworking device for optical COB package, the PCBA board fixed on the fixing component can be heated by the heating component, the heating can accelerate the molecular motion of glue betweenPD and PCBA to reduce the degree of curing between the PD chip and the PCBA board, so the PD chip is easily peeled from the PCBA board by the peeling component, the peeling process is observed in realtime under the observation component, the whole process is completed by mechanical components, which is more precise than pure manual, and the damage to chip components on the PCBA board is prevented.

Owner:LINKTEL TECH CO LTD

Heavy oil sludge treatment method

InactiveCN112479557AEffective stratificationImplement layeringBiological sludge treatmentDemulsifierOil sludge

The invention discloses a heavy oil sludge treatment method, which belongs to the field of heavy oil sludge harmless and resourceful treatment, and comprises chemical separation, air floatation oil removal and phytoremediation, and specifically comprises the following steps of heating a mixed solution obtained by diluting heavy oil sludge with water, adding sulfuric acid to adjust the pH value, adding a self-made demulsifier and a commercial coagulant, and carrying out chemical separation while stirring. After separation is completed, standing and layering are conducted, floating oil on the uppermost layer enters an oil storage tank, lower-layer water and sediment are separated through a centrifugal machine, centrifugate further enters air floatation oil removal, and mud cakes enter phytoremediation. And the oil content of the mud cake after phytoremediation is lower than 0.5%. According to the method, the heavy oil sludge is treated by combining a chemical method, a physical method and a biological method, and recycling and harmlessness of the heavy oil sludge are achieved.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Drying and bleaching device for textile production

InactiveCN113699720ARealize two-way multiple heating and dryingImprove uniformityLiquid/gas/vapor removalTextile treatment carriersProcess engineeringMoisture absorption

The invention discloses a drying and bleaching device for textile production. The drying and bleaching device comprises a drying box, a bleaching box, a bleaching liquid mixing box, a drying guide roller set, a heating mechanism, a moisture absorption mechanism, a bleaching guide roller set, a bleaching auxiliary mechanism and a mixing mechanism; the bleaching box is arranged between the drying box and the bleaching liquid mixing box; a liquid outlet is formed in the lower part of the side wall of the bleaching box; the drying guide roller set and the heating mechanism are arranged in the drying box; the moisture absorption mechanism is arranged on one side of the drying box; the bleaching guide roller set is arranged in the bleaching box; the bleaching auxiliary mechanism is arranged on the bottom wall of the bleaching box; the mixing mechanism is arranged in the bleaching liquid mixing box; a feeding opening is formed in the top wall of the bleaching liquid mixing box; a bleaching liquid conveying pipe is arranged on the lower portion of the side wall of the bleaching liquid mixing box; and the other end of the bleaching liquid conveying pipe is arranged in the bleaching box. The invention relates to the technical field of textile processing, and particularly provides the drying and bleaching device for textile production, which is high in drying efficiency and drying uniformity, high in bleaching speed and excellent in uniformity.

Owner:沛县宏宇纺织有限公司

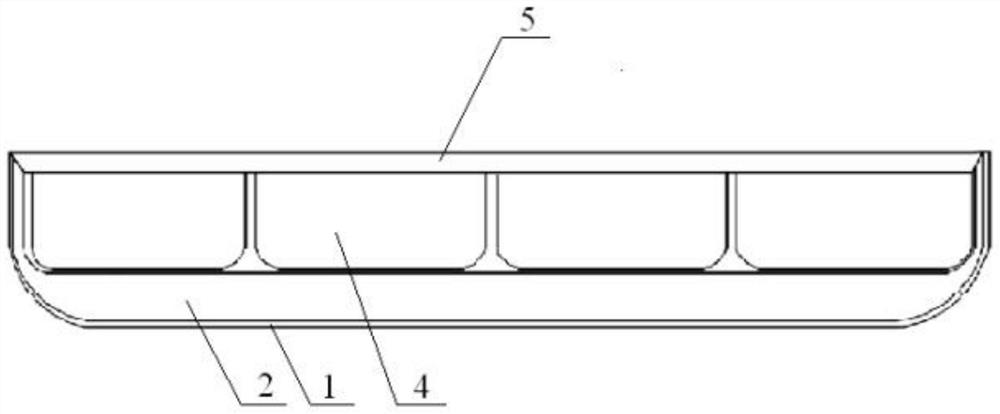

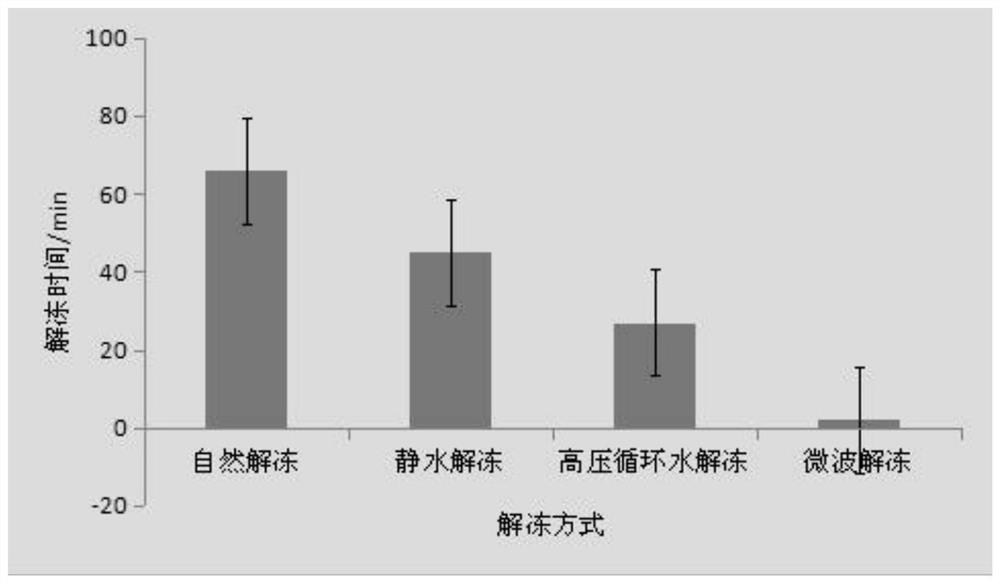

Microwave c seafood dumpling processing and non-freezing storage fresh-keeping method

PendingCN112042894AShorten thawing timeFacilitate conductionFood preservationFood coatingMicrowave ovenSpanish mackerel

The invention relates to a microwave spanish mackerel seafood dumpling processing and non-freezing storage fresh-keeping method, and provides a processing technology which is simple to operate and lowin cost by improving unfreezing, cleaning and sterilizing modes of spanish mackerel on the basis of an existing processing technology. Meanwhile, the invention provides a compound natural preservative formula and a special storage packaging box which is convenient and quick to use. The special storage packaging box has the following advantages and effects: (1) the unfreezing time is short; (2) cleaning and sterilizing efficiency is high; (3) flavoring and fishy smell removal are obvious; (4) non-freezing storage for one month is achieved; (5) the selected natural preservative is safer and healthier than a chemical preservative; and (6) the specially-made storage packaging box is novel in packaging design and can be directly put into a microwave oven for heating before eating, the interlayer design can prevent the dumpling box from being overheated after microwave heating, and the dumplings can be eaten after microwave heating for 3 minutes and is convenient and fast.

Owner:山东鲁海食品有限公司

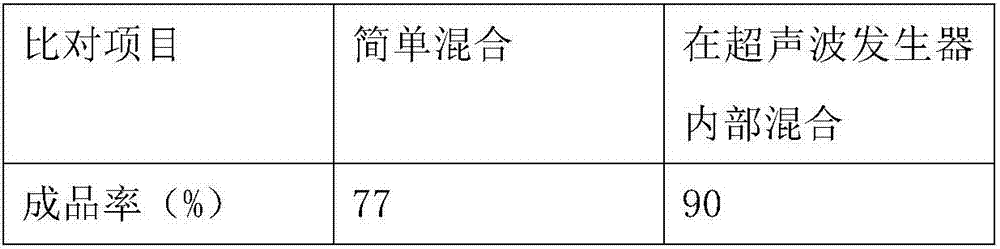

Method for preparing neodymium, iron and boron by means of bonding by aid of high-uniformity adhesive

InactiveCN107464646AAppropriate particle size distributionLow costTransportation and packagingMetal-working apparatusAdhesiveMixed materials

The invention discloses a method for preparing neodymium, iron and boron by means of bonding by the aid of high-uniformity adhesive. The method includes steps of carrying out particle size treatment on magnetic powder, and to be more specific, grinding the neodymium, iron and boron magnetic powder by the aid of special neodymium, iron and boron magnetic powder grinding machines until the neodymium, iron and boron magnetic powder can pass 90-mesh screen cloth; carrying out particle size treatment on auxiliaries, to be more specific, extracting gamma-aminopropyltriethoxysilane, water and isopropyl alcohol according to mass percents and matching the gamma-aminopropyltriethoxysilane, the water and the isopropyl alcohol with one another; drying materials, to be more specific, uniformly mixing the magnetic powder treated at the step 1 and the auxiliaries treated at the step 2 with one another inside set ultrasonic generators to obtain mixtures, pouring the mixtures into drying discs, drying the mixtures, and then allowing the mixtures to stand still after the mixtures are dried so as to obtain mixed materials; carrying out granulation, to be more specific, pouring nylon 12 and the mixed materials obtained at the step 3 into special neodymium, iron and boron granulators, granulating the nylon 12 and the mixed materials to obtain particles and then allowing the particles to stand still after the nylon 12 and the mixed materials are granulated; carrying out injection molding on the particles in magnetic fields by the aid of injection molding machines. The method has the advantages that the human input, the equipment input and the energy cost can be reduced, and accordingly large-scale production can be facilitated.

Owner:杭州天时亿科技有限公司

Active washing flake and preparation method thereof

InactiveCN106491413AHigh field effectHigh activityCosmetic preparationsHair cosmeticsExcited stateMedicine

The invention relates to active washing flake and a preparation method thereof, belonging to the field of daily necessities. The active washing flake comprises, by weight, 600 to 750 parts of fatty acid, 80 to 100 parts of plant gum and 21.37 to 23.74 parts of energy powder, wherein the energy powder is added with a certain amount of auxiliaries composed of calcium gluconate, Bian stone and fossilia ossis mastodi. The active washing flake can better stimulate the activity of each energy powder, so that the formation of energy field is consistent with the integrated energy field. The preparation method of the active washing flake is characterized in that a specific temperature of 520 DEG C to 580 DEG C is maintained during the grinding process of the energy powder added to the gelatin, and grinding at this temperature enables the energy field of each material to be ground and mixed in a specific excited state, resulting in a stronger field effect in the final washing flake product.

Owner:青岛首创嘉业工贸有限公司

Fiber master batch with infrared heat storage function and preparation method of fiber master batch

ActiveCN114539741AWashable and environmentally friendlySpeed up molecular motionMonocomponent polyolefin artificial filamentMonocomponent polyesters artificial filamentFiberThermodynamics

The invention provides a fiber master batch with an infrared heat storage function and a preparation method of the fiber master batch, and the fiber master batch comprises the following components in percentage by weight: 1-30wt% of a concentrated rare earth material and 70-99wt% of a high polymer material. The concentrated rare earth material provided by the invention can be proportionally mixed with different high polymer materials to prepare master batches, can be used for preparing various fibers, can be used for weaving infrared heat storage functional fabrics, and has the advantages of washability, environment friendliness and low cost compared with infrared warm-keeping clothes in the prior art.

Owner:TIANJIN BAOGANG RES INST OF RARE EARTHS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com