Tension-free overflow water washing tank

An overflow washing and tension-free technology, applied in textiles and papermaking, liquid/gas/steam textile material treatment, textile processing machine accessories, etc., can solve the problems of poor washing effect, incomplete cleaning and high water consumption of fabrics, etc. Achieve the effect of shortening cleaning time, improving washing effect, eliminating scratches and wear marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

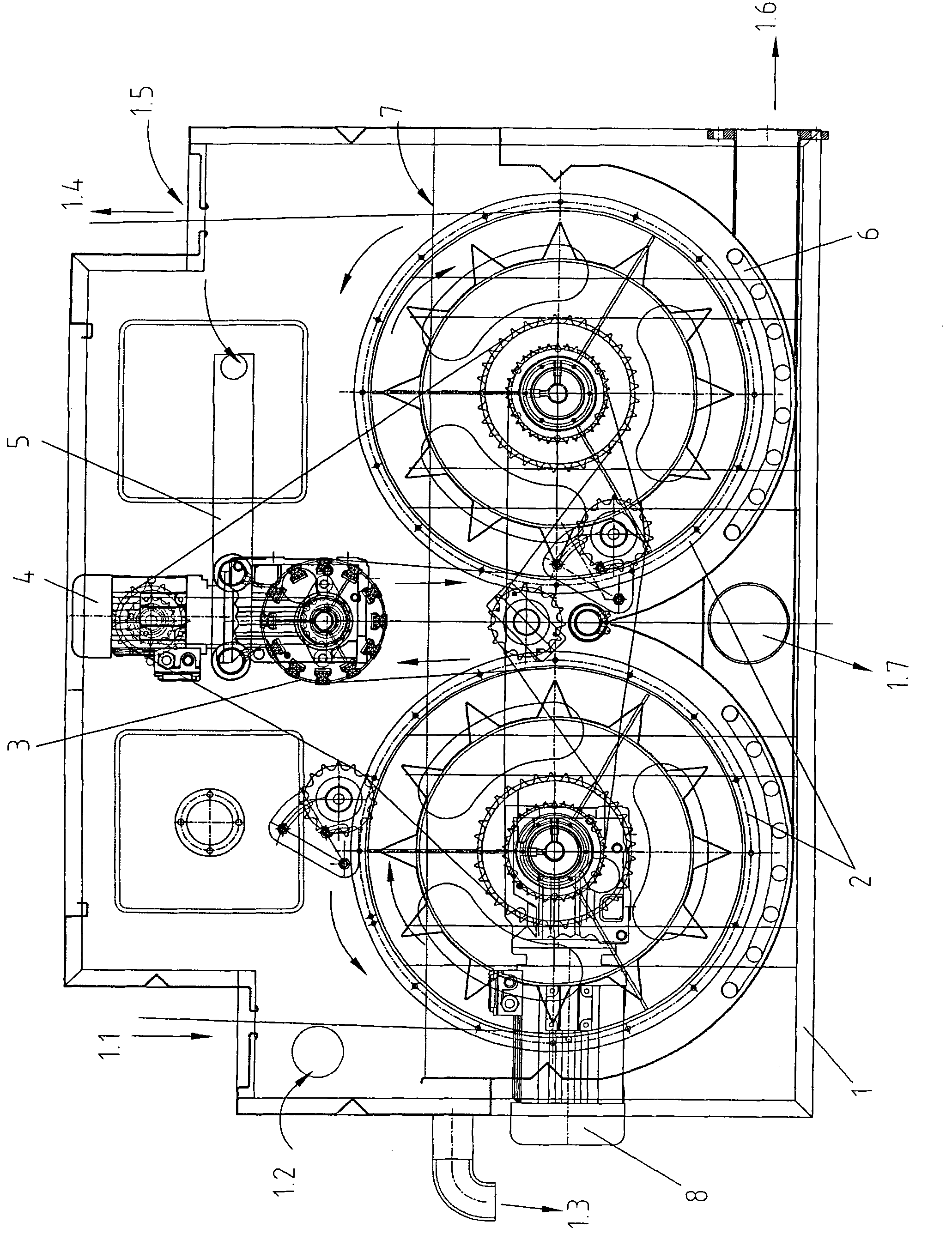

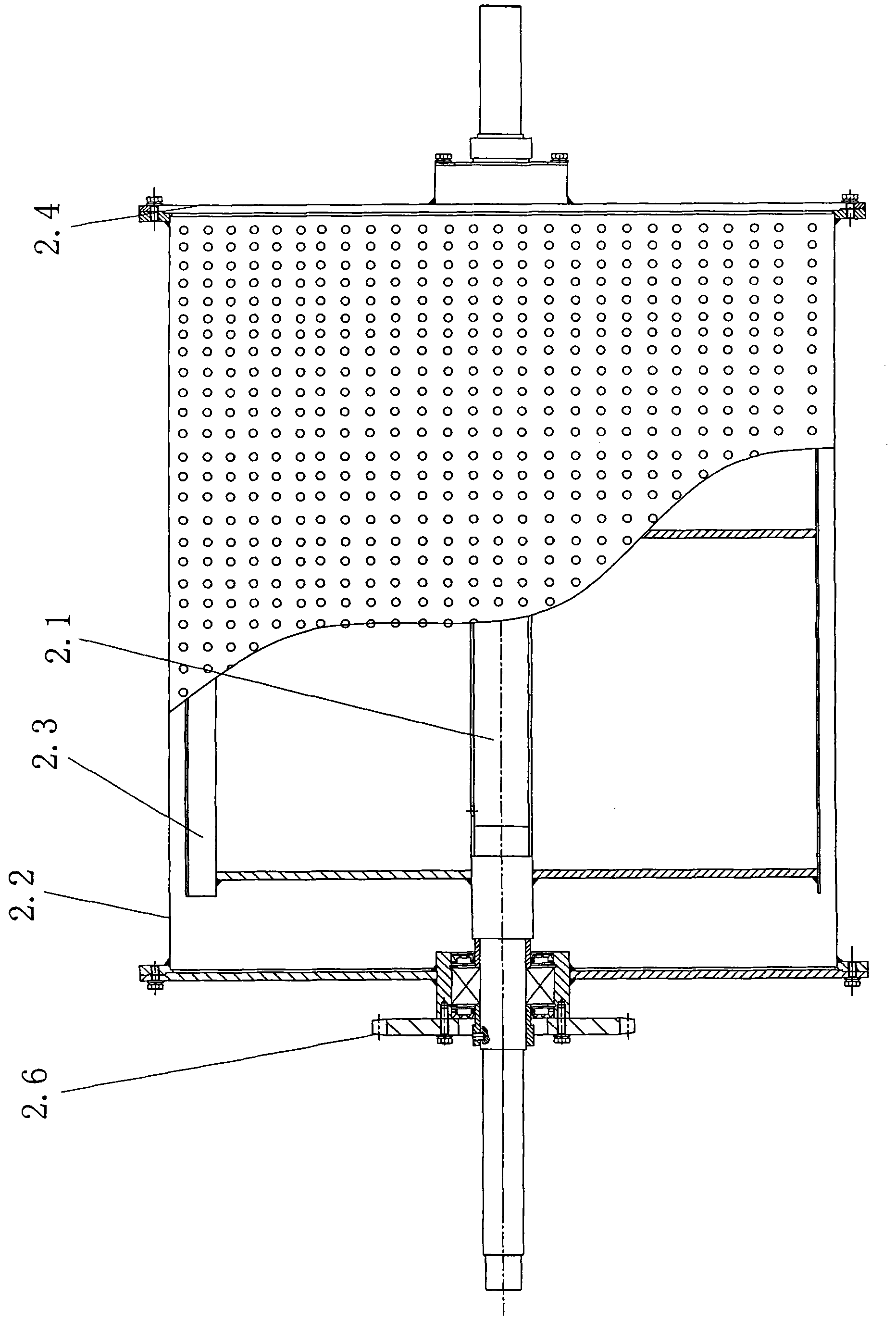

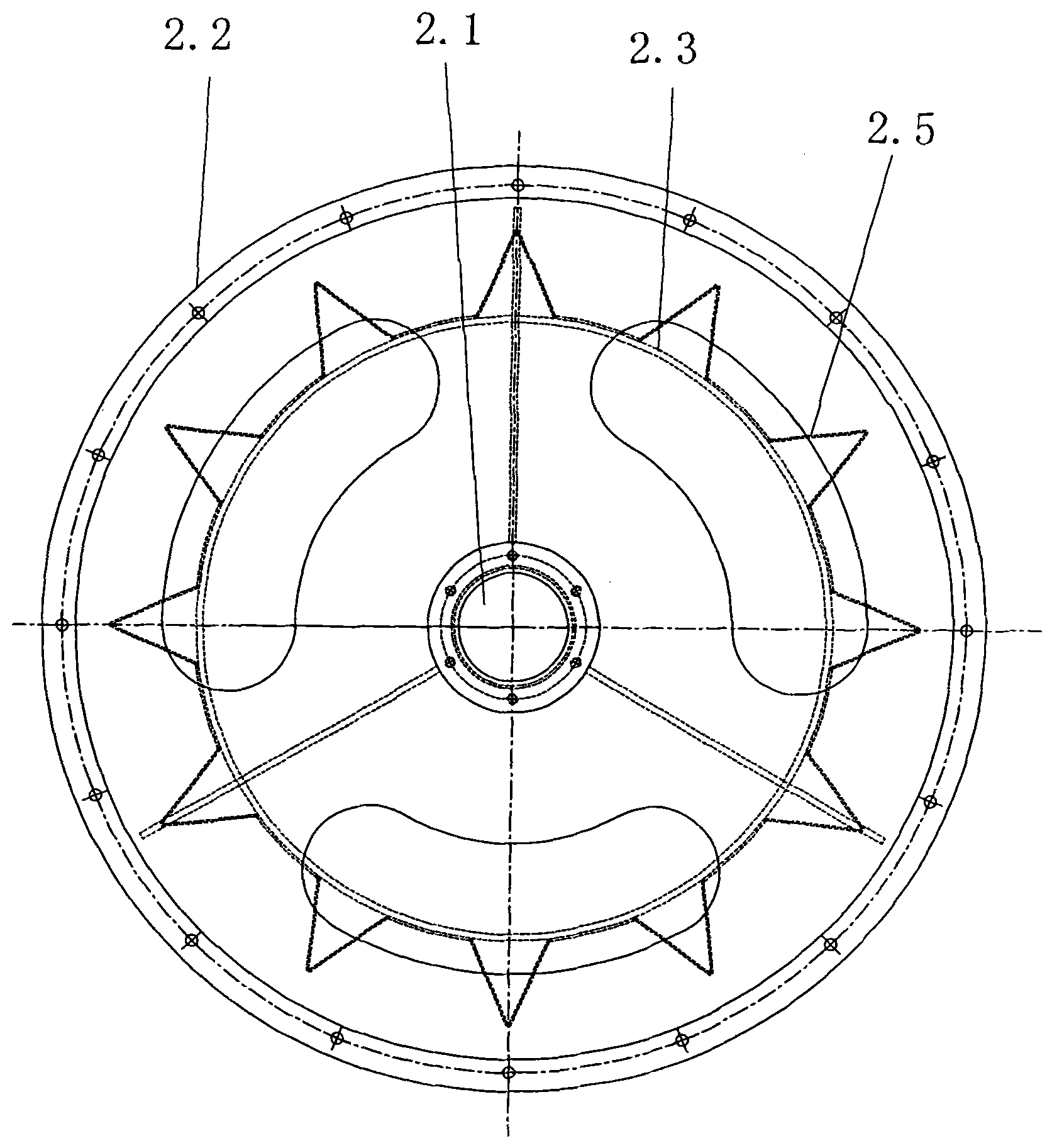

[0019] see figure 1 , figure 1 It is a schematic diagram of the overall structure of the tension-free overflow washing tank of the present invention. Depend on figure 1 It can be seen that the tension-free overflow washing box of the present invention includes a box body 1 , a rotating drum 2 , a cloth passing roller 3 , a first transmission device 4 , a second transmission device 8 , a spray device 5 and a heating device 6 . The left side of the top of the box 1 is provided with a cloth inlet 1.1, the right side of the top of the box 1 is provided with a cloth outlet 1.4, the left side of the box 1 is provided with a water inlet 1.2 and an overflow 1.3, and the right side of the box 1 is provided with other Water inlet 1.5 and water outlet 1.6, the bottom of box body 1 is provided with water outlet 1.7. The drum 2 has two pieces, and the two drums 2 are arranged in parallel in the box body 1 on the left and on the right, and are placed in the lower half of the box body 1 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com