Radiation resistant polycarbonate material, preparation method and application thereof

A polycarbonate and radiation-resistant technology, applied in the field of medical radiation-resistant polycarbonate materials and their preparation, can solve the problems of yellowing and poor mechanical properties, and achieve the advantages of accelerating elimination, increasing toughness and maintaining transparency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

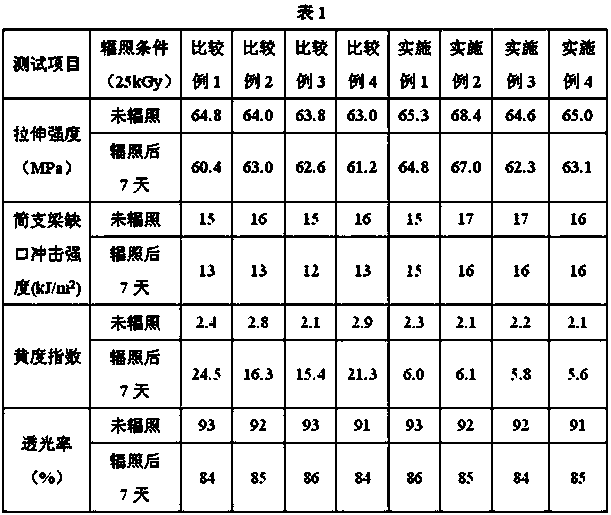

[0026] Weigh 100 parts of polycarbonate polycarbonate resin, 0.3 part of 2,5-di-tert-butyl hydroquinone, 0.3 part of allyl glycidyl ether, 0.4 part of polyoxypropylene glycol ether, and add them to the high-speed mixer Mix in the middle for 5 minutes to get the premix, then put the premix into the screw extruder for melt blending, the temperature of the extruder is 240-290°C along the direction from the feed port to the die, and the temperature of the die is 270-290°C , the screw speed is 40 rpm, the blend is extruded through a die, cooled, and pelletized to obtain a radiation-resistant polycarbonate material. The obtained above-mentioned materials were dried and injected into standard samples, and tested for mechanical properties and yellowness index before and after irradiation. The results are shown in Table 1.

Embodiment 2

[0028] Weigh 100 parts of polycarbonate polycarbonate resin, 0.3 part of hydroquinone dibenzyl ether, 0.1 part of propylene oxide phenyl ether, 0.3 part of epoxidized soybean oil, join in a high-speed mixer and mix for 5 minutes to obtain Premix, and then put the premix into the screw extruder for melt blending, the temperature of the extruder along the direction from the feed port to the die is 240-280°C, the temperature of the die is 270-280°C, and the screw speed is 60 rpm / min, the blend is extruded through a die, cooled, and granulated to obtain a radiation-resistant polycarbonate material. The obtained above-mentioned materials were dried and injected into standard samples, and tested for mechanical properties and yellowness index before and after irradiation. The results are shown in Table 1.

Embodiment 3

[0030]Weigh 100 parts of polycarbonate polycarbonate resin, 0.3 part of hydroquinone dibenzyl ether, 0.1 part of allyl glycidyl ether, 0.3 part of dibenzyl ether, 0.1 part of tri-n-butyl citrate, 0.3 part of poly Oxypropylene glycol ether, added to a high-speed mixer and mixed for 5 minutes to obtain a premix, then put the premix into a screw extruder for melt blending, and the temperature of the extruder along the direction from the feed port to the die is 230- 280°C, the die temperature is 275-285°C, the screw speed is 80 rpm, the blend is extruded through the die, cooled, and granulated to obtain a radiation-resistant polycarbonate material. The obtained above-mentioned materials were dried and injected into standard samples, and tested for mechanical properties and yellowness index before and after irradiation. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com