Metal ion co-doped BiOBr microsphere as well as preparation method and application thereof

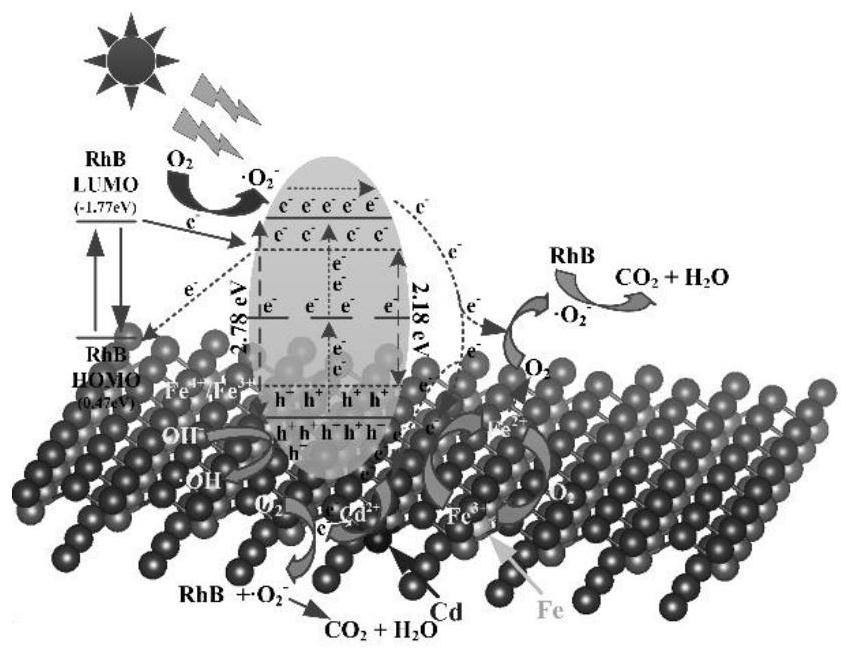

A metal ion and co-doping technology, applied in chemical instruments and methods, catalyst activation/preparation, water treatment of special compounds, etc., can solve problems such as limited effective reactions, achieve improved photocatalytic activity, promote reactions, and broaden visible light response range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

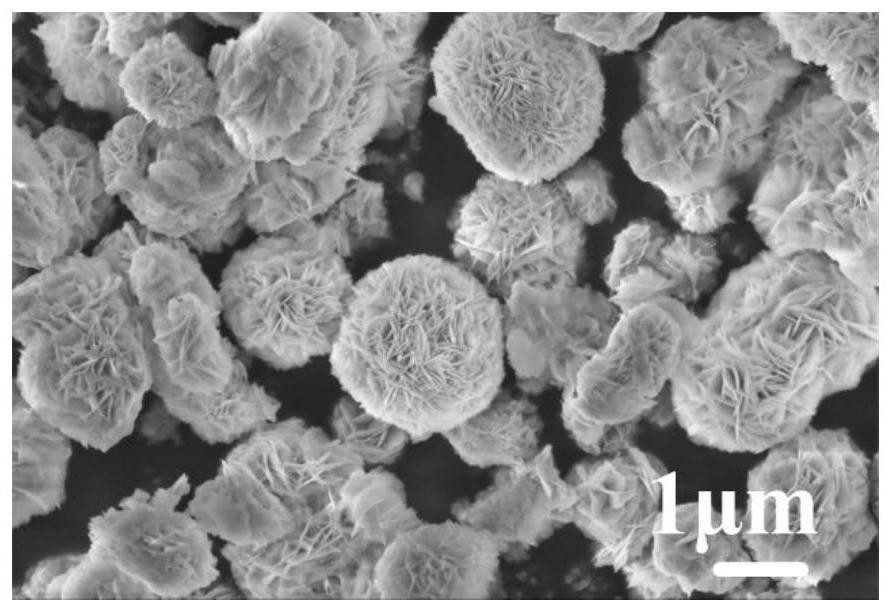

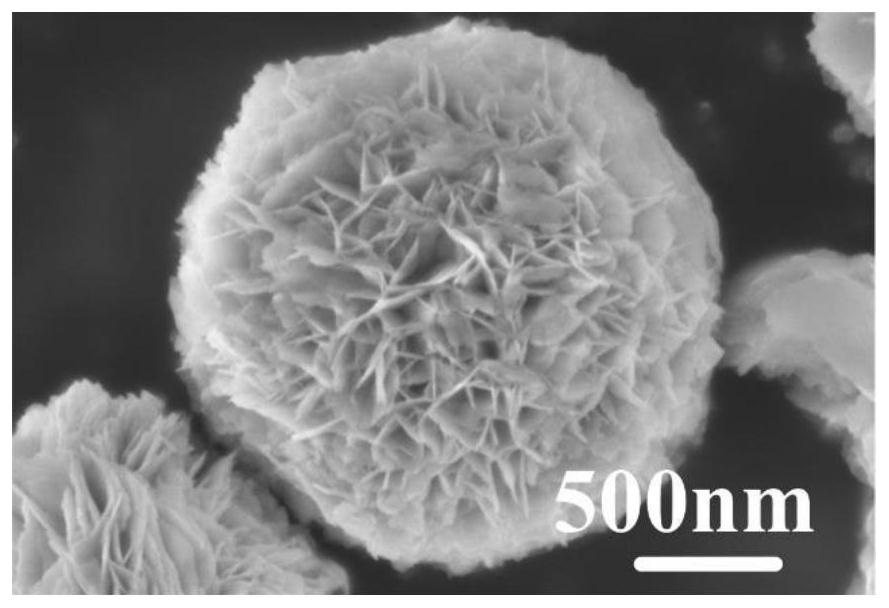

[0042] Bi(NO 3 ) 3 ·5H 2 O and CTAB were dissolved in 20ml of ethylene glycol (EG) at a molar ratio of 1:1 (4mmol), and sonicated for 15min. After 15 min of magnetic stirring, the above two solutions were mixed and stirred for 30 min to form a precursor solution, and then 2wt% Cd(NO 3 ) 2 4H 2 O (0.01542g) to obtain a mixed solution, then transfer the mixed solution to a microwave hydrothermal polytetrafluoroethylene lined autoclave, and add a bursting membrane, tighten the kettle body, and place it in a microwave hydrothermal reactor system , reacted at 180°C for 15min. After the reaction, the product was cooled to room temperature, washed several times with deionized water (DI), washed twice with ethanol, and dried at 60 °C for 12 h to synthesize Cd 2+ Doped BiOBr microspheres, named Bi 0.98 Cd 0.02 OBr. The Bi prepared in this example 0.98 Cd 0.02 SEM images of OBr at different magnifications are shown in figure 2 and image 3 .

Embodiment 2

[0044] Bi(NO 3 ) 3 ·5H 2 O and CTAB were dissolved in 20ml of ethylene glycol (EG) at a molar ratio of 1:1 (4mmol), and sonicated for 15min. After magnetic stirring for 15 min respectively, the above two solutions were mixed and stirred for 30 min to form a precursor solution, and then 2wt% Fe(NO 3 ) 3 9H 2 O (0.0202g), to obtain a mixed solution, then transfer the mixed solution to a microwave hydrothermal polytetrafluoroethylene lined autoclave, and add a bursting membrane, tighten the kettle body, and place it in a microwave hydrothermal reactor system , reacted at 180°C for 15min. After the reaction, the product was cooled to room temperature, washed several times with deionized water (DI), washed twice with ethanol, and dried at 60 °C for 12 h to synthesize Fe 3+ Doped BiOBr microspheres, named Bi 0.98 Fe 0.02 OBr. The Bi prepared in this example 0.98 Fe 0.02 The SEM images of OBr at different magnifications are shown in Figure 4 and Figure 5 .

Embodiment 3

[0046] Bi(NO 3 ) 3 ·5H 2 O and CTAB were dissolved in 20ml of ethylene glycol (EG) at a molar ratio of 1:1 (4mmol), and sonicated for 15min. After 15 min of magnetic stirring, the above two solutions were mixed and stirred for 30 min to form a precursor solution, and then 2wt% Cd(NO 3 ) 2 4H 2 O (0.01542g), to obtain a mixed solution, continue to add 2wt% Fe (NO 3 ) 3 9H 2 O (0.0202 g), the mixed solution was then transferred to a microwave hydrothermal Teflon-lined autoclave with a burst disk. It was placed in a microwave hydrothermal reactor system and reacted at 180° C. for 15 min. After the reaction, the product was cooled to room temperature, washed several times with deionized water (DI), washed twice with ethanol, and dried at 60°C for 12h. synthesized Cd 2+ / Fe 3+ Co-doped BiOBr microspheres, named Bi 0.96 Cd 0.02 Fe 0.02 OBr. The Bi prepared in this example0.96 Cd 0.02 Fe 0.02 The SEM images of OBr at different magnifications are shown in Figure 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com