Deburring and punching integrated mold

A deburring and punching technology, applied in the field of stamping equipment, can solve the problems of lower product quality, difficult molding, and undeveloped products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

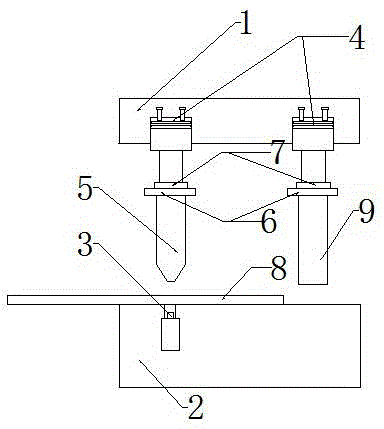

[0019] Deburring and punching integrated mold, including: upper die base 1, lower die base 2 for placing product 8, as for stamping components on upper die base 1, as for deburring components on upper die base 1, as for lower die base 2 Inside and corresponds to the heating element of the stamping assembly. The stamping assembly includes: a nitrogen spring 4 fixed on the upper die base 1, and a punch 5 connected under the nitrogen spring 4; the deburring assembly includes: a nitrogen spring 4 fixed on the upper die base 1, connected under the nitrogen spring 4 The deburring punch 9. After the punching process is completed, move the mounting hole to the deburring punch 9 times to complete the deburring process. When moving the product 8 for convenience, the mounting hole can be aligned with the deburring punch 9, and the central axis of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com