Preparation method for high-quality rice bran oil

A rice bran oil, high-quality technology, applied in the direction of fat oil/fat refining, fat oil/fat production, fat production, etc., can solve the problems of accelerating the quality of rice bran oil, deterioration of rice bran oil quality, and difficulty in short-term oil production, etc. Achieve the effects of increasing antioxidant capacity, increasing leaching rate, and accelerating molecular movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

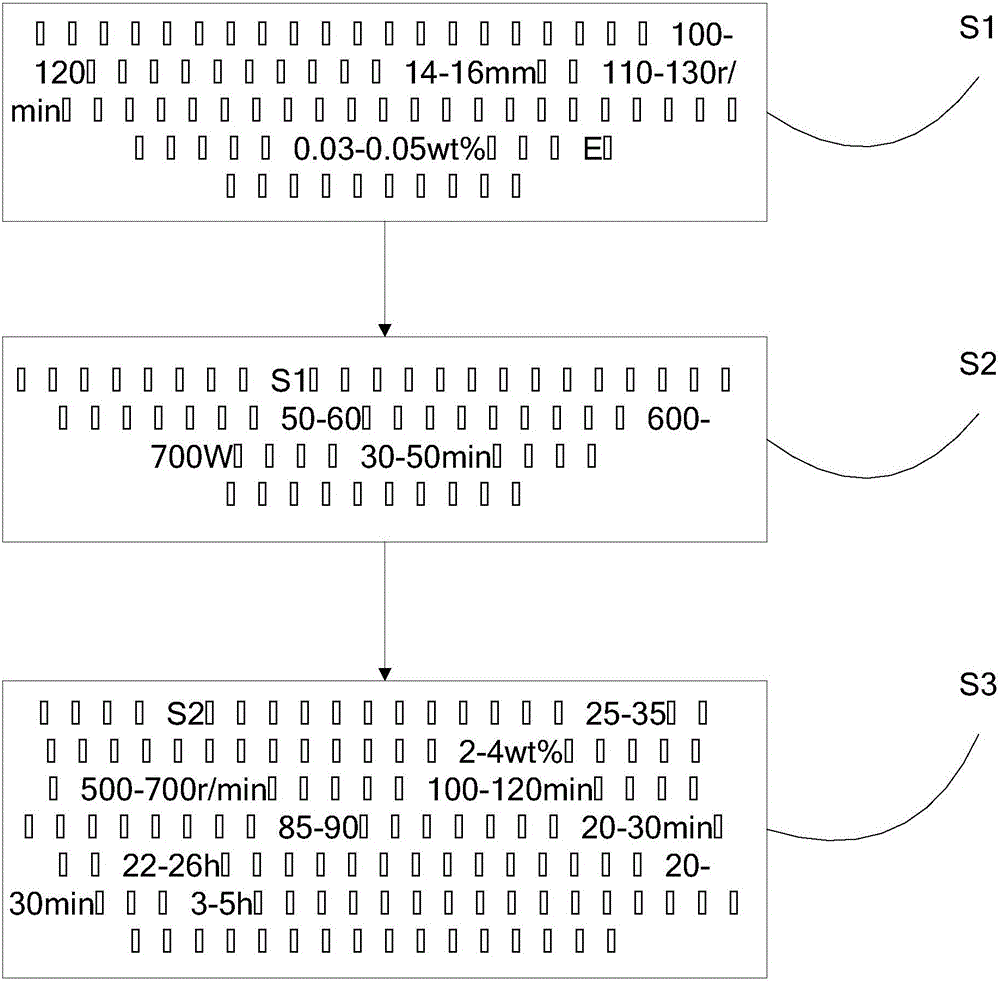

[0018] refer to figure 1 , a kind of preparation method of high-quality rice bran oil that the present invention proposes, comprises the steps:

[0019] S1. Fresh-keeping rice bran: put the rice bran in an extrusion extruder, heat up to 100-120°C, extrude the diameter of the film hole to be 14-16mm, extrude at a speed of 110-130r / min, cool to room temperature, Spraying 0.03-0.05wt% vitamin E based on the weight of rice bran, and mixing to obtain fresh-keeping rice bran;

[0020] S2. Extraction of crude rice bran oil: Add the fresh-keeping rice bran obtained in S1 into the solvent, raise the temperature in a water bath to 50-60°C, and ultrasonicate for 30-50min at an ultrasonic power of 600-700W, suction filter, and rotary evaporate to obtain rice bran crude oil;

[0021] S3. Refining: heat up the crude rice bran oil obtained in S2 to 25-35°C, add 2-4wt% diethanolamine based on the weight of the crude rice bran oil, stir at a speed of 500-700r / min for 100-120min, and centrifu...

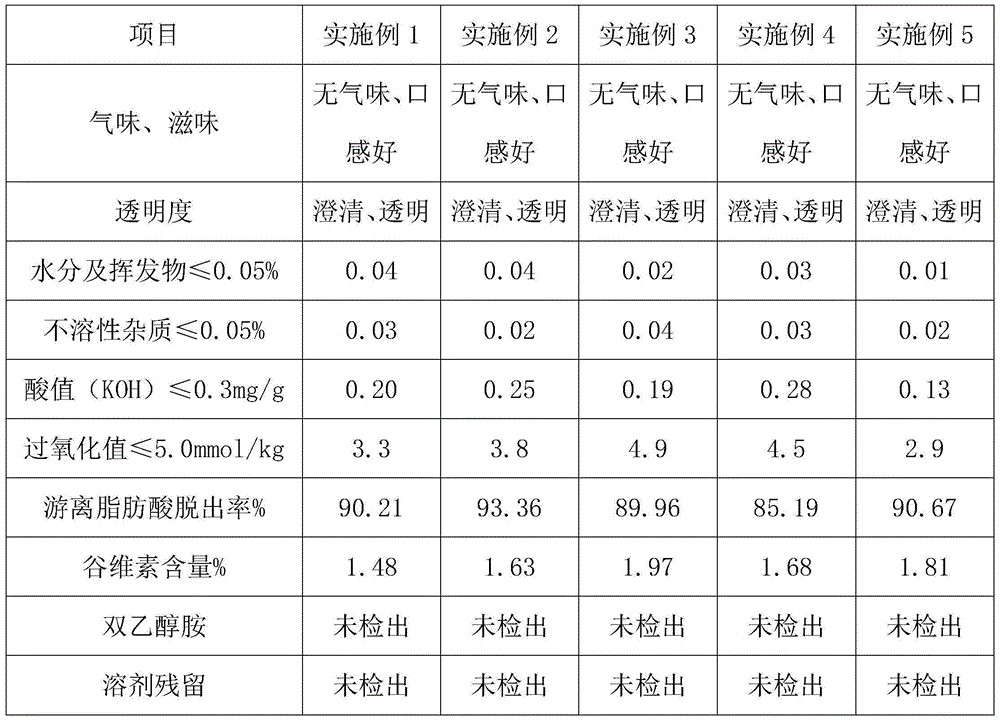

Embodiment 1

[0024] A preparation method of high-quality rice bran oil, comprising the steps of:

[0025] S1. Fresh-keeping rice bran: place the rice bran with a moisture content of 17wt% and 20 meshes in an extrusion extruder, heat up to 120°C, extrude the diameter of the film hole to be 14mm, extrude and expand at a speed of 130r / min, and cool to At room temperature, spray 0.03wt% vitamin E based on the weight of rice bran, and mix to obtain fresh-keeping rice bran;

[0026] S2. Extraction of crude rice bran oil: add the fresh-keeping rice bran obtained in S1 into isopropanol, raise the temperature in a water bath to 50° C., and ultrasonicate for 50 minutes at an ultrasonic power of 700 W, suction filter, and rotary evaporate to obtain crude rice bran oil, wherein , the weight-to-volume ratio of fresh-keeping rice bran to isopropanol is (g / ml) 1:5;

[0027] S3, refining: heat up the rice bran crude oil obtained in S2 to 35°C, add 2wt% diethanolamine based on the weight of rice bran crud...

Embodiment 2

[0029] A preparation method of high-quality rice bran oil, comprising the steps of:

[0030] S1. Fresh-keeping rice bran: place the rice bran with a moisture content of 14wt% and 40 meshes in an extrusion extruder, heat up to 100°C, extrude the diameter of the film hole to be 16mm, extrude and expand at a speed of 110r / min, and cool to At room temperature, spray 0.05wt% vitamin E based on the weight of rice bran, and mix to obtain fresh-keeping rice bran;

[0031] S2. Extraction of crude rice bran oil: Add the fresh-keeping rice bran obtained in S1 into ethanol, heat up to 60°C in a water bath, ultrasonicate for 30 minutes at an ultrasonic power of 600W, suction filter, and rotary evaporate to obtain crude rice bran oil. The weight-to-volume ratio of rice bran and ethanol is (g / ml) 1:7;

[0032]S3, refining: heat up the rice bran crude oil obtained in S2 to 25°C, add 4wt% diethanolamine based on the weight of rice bran crude oil, stir at a speed of 500r / min for 120min, and ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com