Method and device for improving wettability of broad width presoaking material

A prepreg and wettability technology, which is applied in the processing of textile materials, textiles and papermaking, vibration treatment, etc., can solve the problems of impregnation treatment of wide-width fiber cloth and improvement of wettability of prepreg, etc., to achieve Effect of improving wettability and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

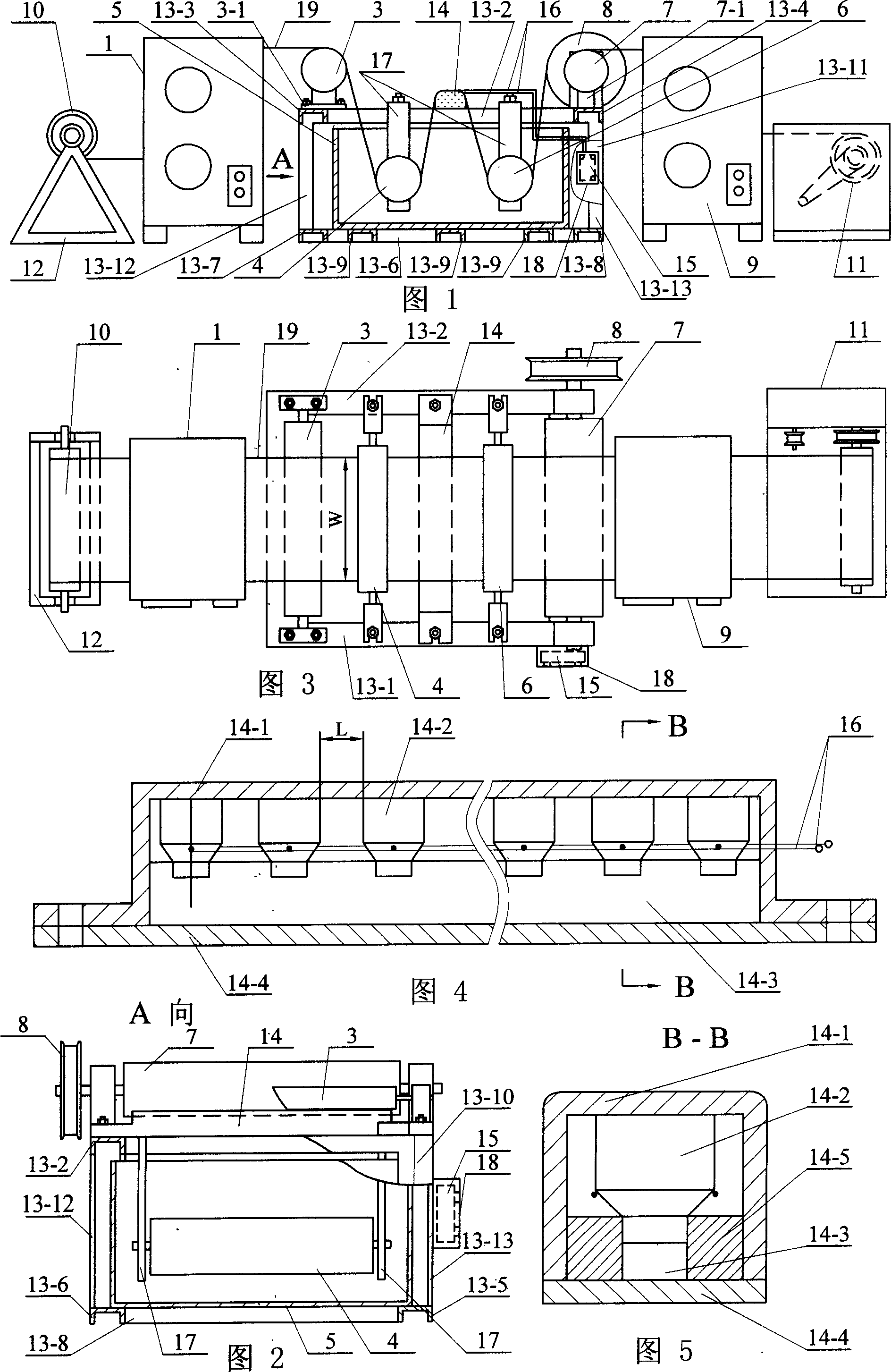

[0007] Embodiment 1: The method for improving the wettability of wide-width prepregs in this embodiment is accomplished as follows: After the dried fiber cloth 19 is immersed in thermosetting resin, it is dried again and rolled into bundles; The fiber cloth 19 passes on the vibrating plate 14-1 on the combined transducer 14 before drying, the vibrating frequency of the vibrating plate 14-1 is controlled by the ultrasonic power source 15, and the vibrating frequency of the vibrating plate 14-1 is 48 ± 1.5kHz, ultrasonic power of 20-700W, running speed of fiber cloth 19 of 40-120m / h, tension of fiber cloth 19 of 10-300N, width W of fiber cloth 19 of 0.1-1.5m.

specific Embodiment approach 2

[0008] Embodiment 2: The difference between this embodiment and Embodiment 1 is: after the fiber cloth 19 of this embodiment passes on the vibrating plate 14-1 on the combined transducer 14, it is soaked in thermosetting material again before drying. resin. The resin content on the fiber cloth 19 after ultrasonic treatment will decrease correspondingly, which will affect the quality of the fiber cloth 19. Therefore, before drying, the fiber cloth 19 impregnated with thermosetting resin will be impregnated with thermosetting resin again, which can make up for the above defects.

specific Embodiment approach 3

[0009] Specific embodiment three: the differences between this embodiment and specific embodiment one are: the vibration frequency of the vibrating plate 14-1 of this embodiment is 48kHz, the ultrasonic power is 30W, the running speed of the fiber cloth 19 is 60m / h, the fiber The tension of the cloth 19 was 145N, and the width W of the fiber cloth 19 was 1.0 m. Using the above technical parameters, the fiber cloth 19 with a width W of 1.0 m can be effectively ultrasonically treated, thereby improving the quality of the composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com