A method for preparing tissue engineering scaffold material by using degradable synthetic polymer material

A tissue engineering scaffold, a technology for synthesizing macromolecules, used in medical science, prostheses, etc., can solve problems such as poor connectivity, affecting cell activity, and being unsuitable for tissue engineering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing a tissue engineering scaffold material by using a degradable synthetic polymer material, comprising the following steps:

[0040] (1) The raw material used is polyglycolide with a crystallinity of 48%, and the flakes are prepared by hot pressing, and then placed in a high-temperature and high-pressure reactor;

[0041] (2) Using supercritical carbon dioxide (scCO 2 ) to replace the gas in the high-temperature and high-pressure reactor;

[0042] (3) Put the high-temperature and high-pressure reactor into an oil bath at 250°C, pressurize it to 25MPa, and saturate it for 1 hour;

[0043] (4) Rapidly cool down the oil bath to 220°C, and saturate the flakes in the reactor for 1 hour;

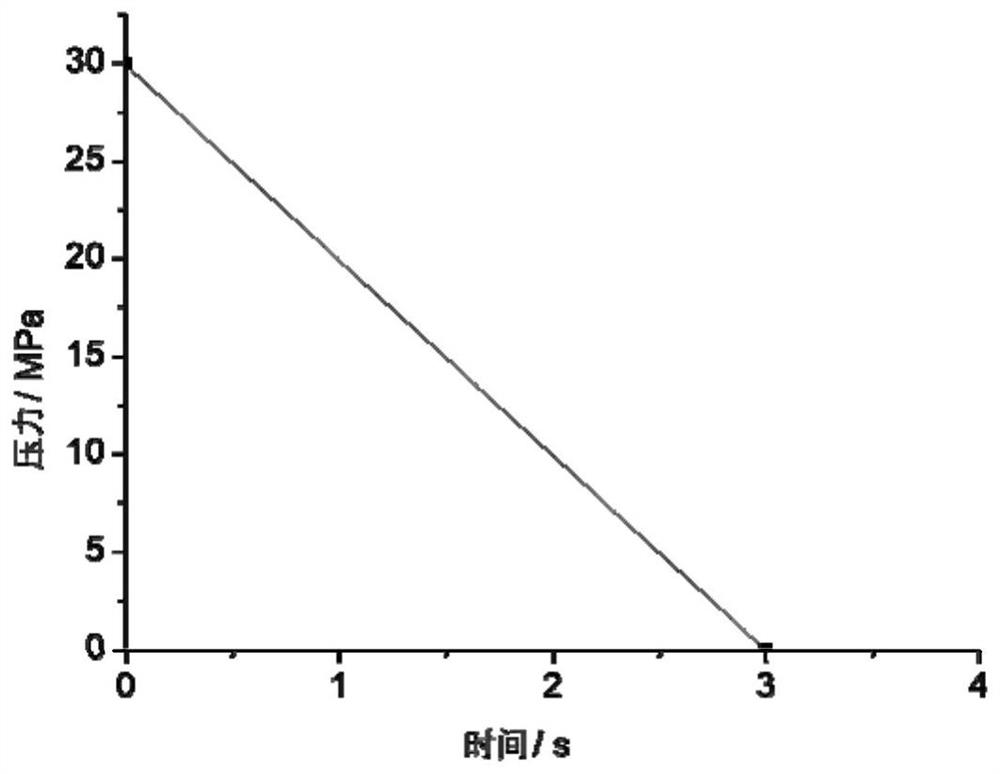

[0044] (5) According to the set pressure drop curve to release the pressure, the tissue engineering scaffold material can be obtained; the pressure drop curve of the pressure release is as follows: figure 1 shown.

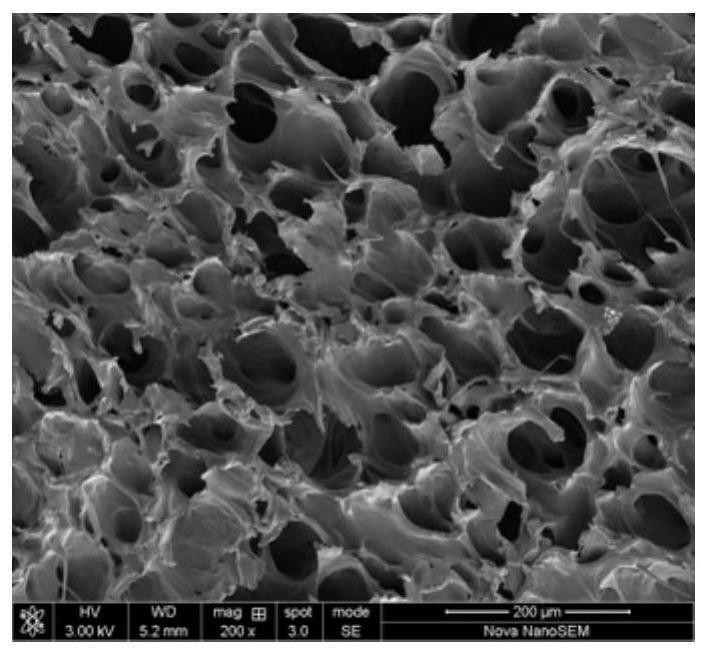

[0045] The SEM image of the internal cross-section ...

Embodiment 2

[0047] A method for preparing a tissue engineering scaffold material by using a degradable synthetic polymer material, comprising the following steps:

[0048] (1) The raw material used is polyglycolide with a crystallinity of 50%, and the flakes are prepared by hot pressing, and then placed in a high-temperature and high-pressure reactor;

[0049] (2) Using supercritical carbon dioxide (scCO 2 ) to replace the gas in the high-temperature and high-pressure reactor;

[0050] (3) Put the high-temperature and high-pressure reactor into an oil bath at 250°C, pressurize it to 30MPa, and saturate it for 1 hour;

[0051] (4) Rapidly cool down the oil bath to 220°C, and saturate the flakes in the reactor for 1 hour;

[0052] (5) According to the set pressure drop curve to release the pressure, the tissue engineering scaffold material can be obtained; the pressure drop curve of the pressure release is as follows: image 3 shown.

[0053] The SEM image of the internal cross-section ...

Embodiment 3

[0055] A method for preparing a tissue engineering scaffold material by using a degradable synthetic polymer material, comprising the following steps:

[0056] (1) The raw material used is polycaprolactone (PCL) powder with a crystallinity of 67%, and the flakes are prepared by hot pressing, and then placed in a high-temperature and high-pressure reactor;

[0057] (2) Using supercritical carbon dioxide (scCO 2 ) to replace the gas in the high-temperature and high-pressure reactor;

[0058] (3) Put the high-temperature and high-pressure reactor into a water bath at 90°C, pressurize it to 30MPa, and saturate it for 1 hour;

[0059] (4) Cool the oil bath to 30°C quickly, and saturate the flakes in the reactor for 1 hour;

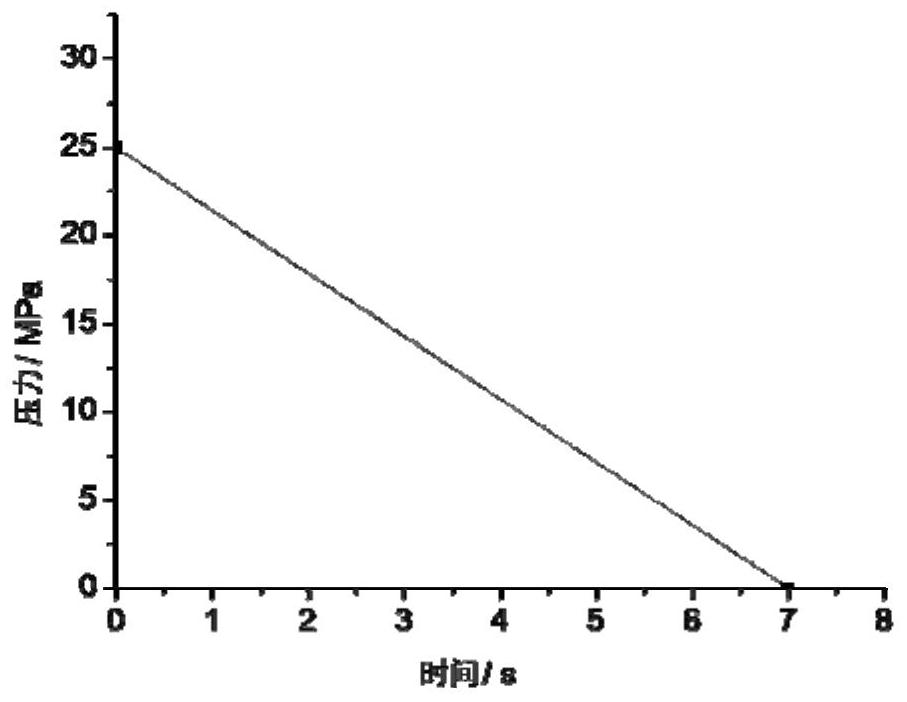

[0060] (5) According to the set pressure drop curve to release the pressure, the tissue engineering scaffold material can be obtained; the pressure drop curve of the pressure release is as follows: Figure 5 shown.

[0061] The SEM image of the internal cro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size distribution | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com