Self-heating heat-pump energy-saving device for lurgi furnace gasification sewage and method for sewage pretreatment with device

A technology of gasifying sewage and energy-saving devices, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., and can solve problems such as high energy consumption, high operating costs, and easy blockage of equipment , to reduce energy consumption and treatment costs, eliminate crystallization and scaling, and achieve obvious energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

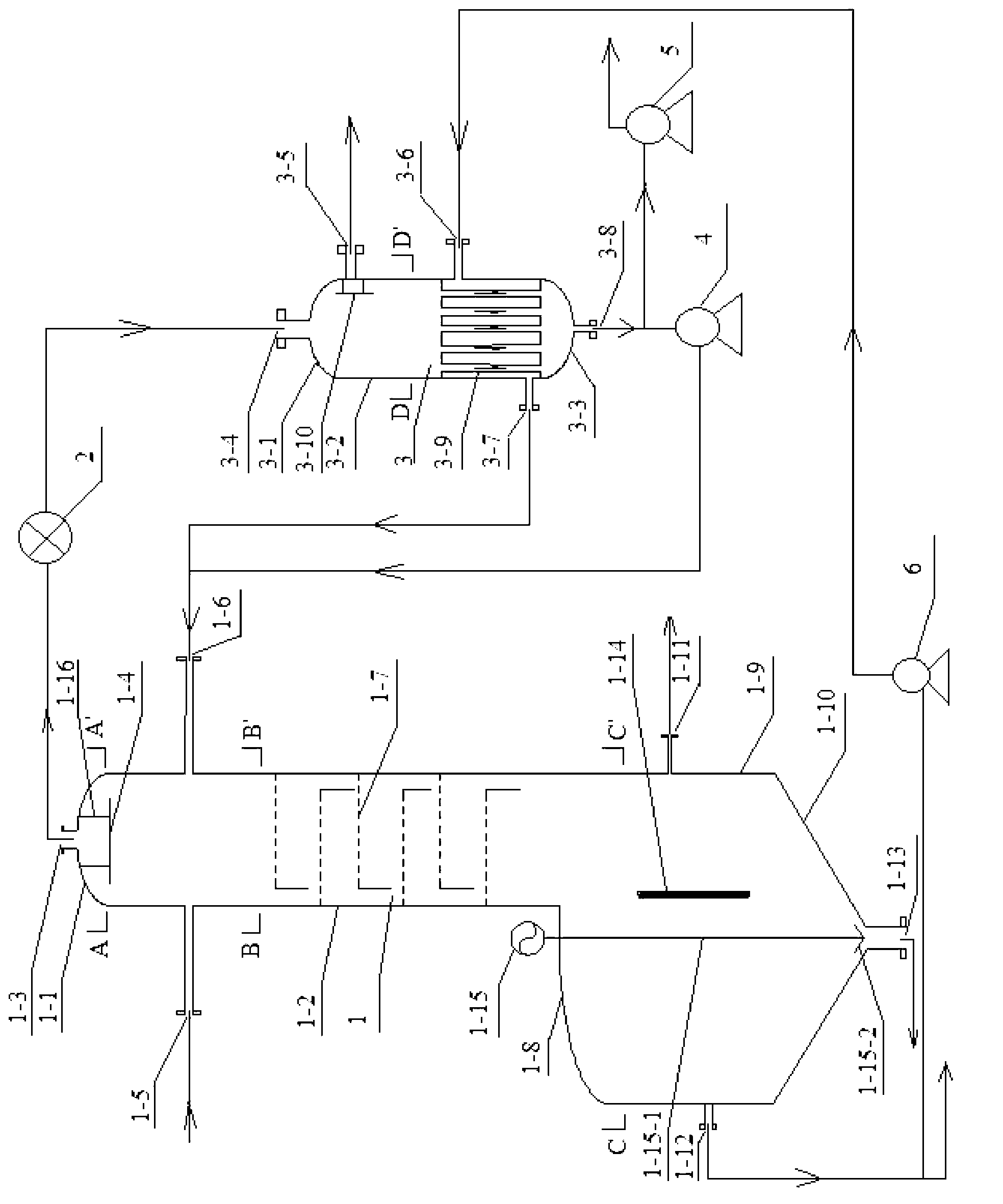

[0011] Specific implementation mode one: combine image 3 In this embodiment, a Lurgi furnace gasification sewage self-heating heat pump energy-saving device includes a vacuum extraction and sedimentation composite tower 1, a vacuum device 2, a heat exchange separation tower 3, a circulation pump 4, an ammonia water pump 5 and a sewage circulation pump 6; The upper part of the extraction and settling compound tower 1 is a vacuum extraction part and the lower part is a settling part. The vacuum extraction part includes an arc-shaped top 1-1, a cylindrical side wall 1-2, a gas phase outlet 1-3 at the top of the tower, and a baffle 1 -4, Lurgi hot sewage inlet 1-5, Lurgi cold sewage inlet 1-6 and several large-pore sieve plates 1-7; tower top gas phase outlet 1-3 is arranged at the center of the arc-shaped top 1-1, folding The baffle 1-4 is suspended below the gas phase outlet 1-3 at the top of the tower, and the baffle 1-4 is fixedly connected with the arc-shaped top 1-1 through...

specific Embodiment approach 2

[0016] Embodiment 2: This embodiment differs from Embodiment 1 in that: the vacuum pumping device 2 is a vacuum pump or a steam extractor. Others are the same as the first embodiment.

specific Embodiment approach 3

[0017] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the distance between the baffle plate 1-4 of the described vacuum extraction and settling compound tower 1 is 0.5m~3 from the tower top gas phase outlet 1-3 1m. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com