Dry quenching furnace having novel exhaust structure

A CDQ furnace and inclined flue technology, which is applied in the field of CDQ, can solve problems such as coke blockage, large gas pressure drop, and partition wall damage that have not been fundamentally solved, so as to improve the operation effect and stability, and eliminate operation The effect of pressure increase, avoiding damage and collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

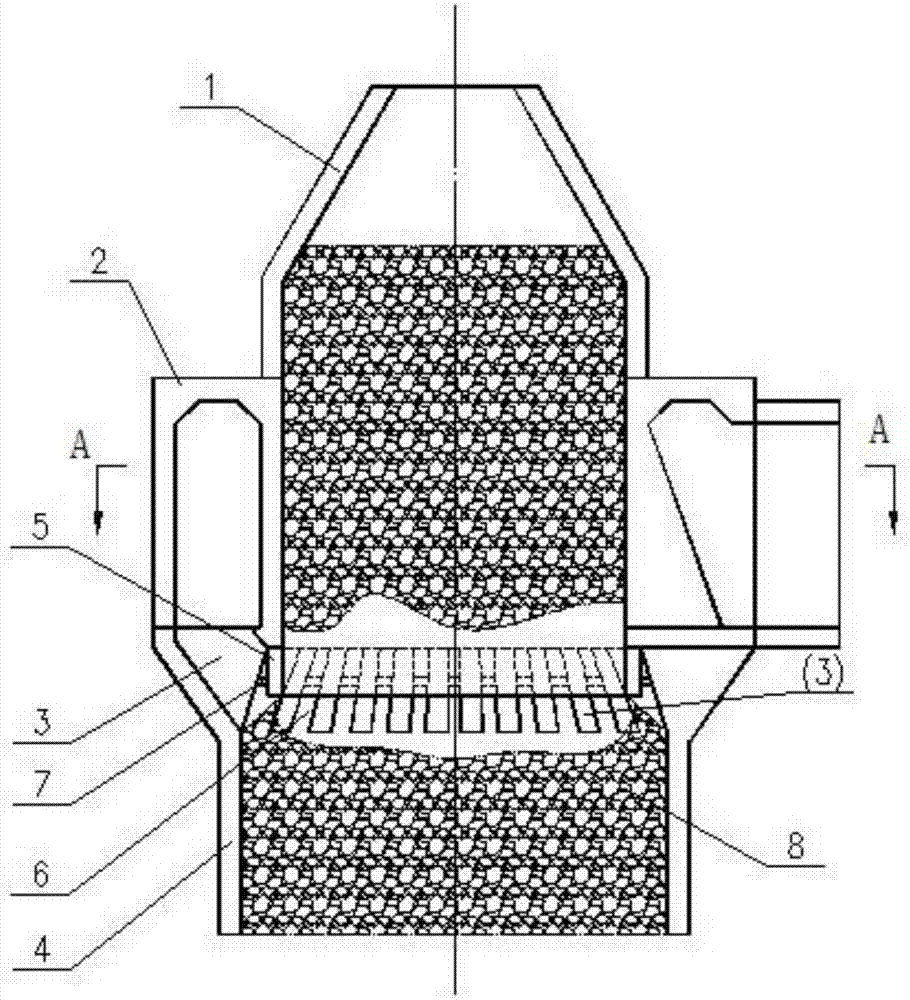

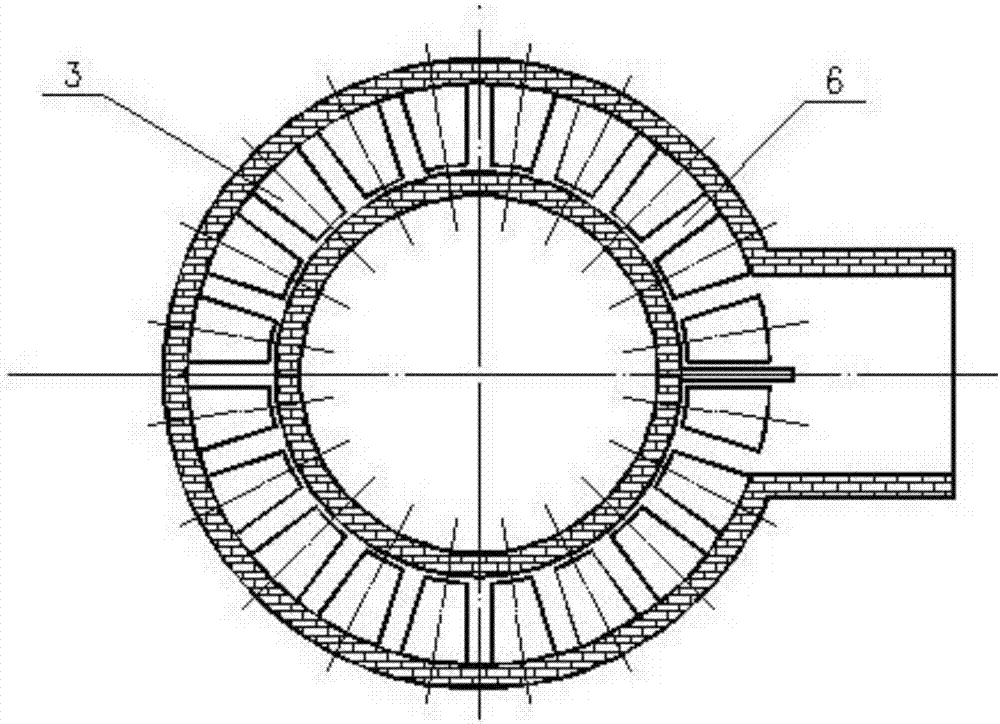

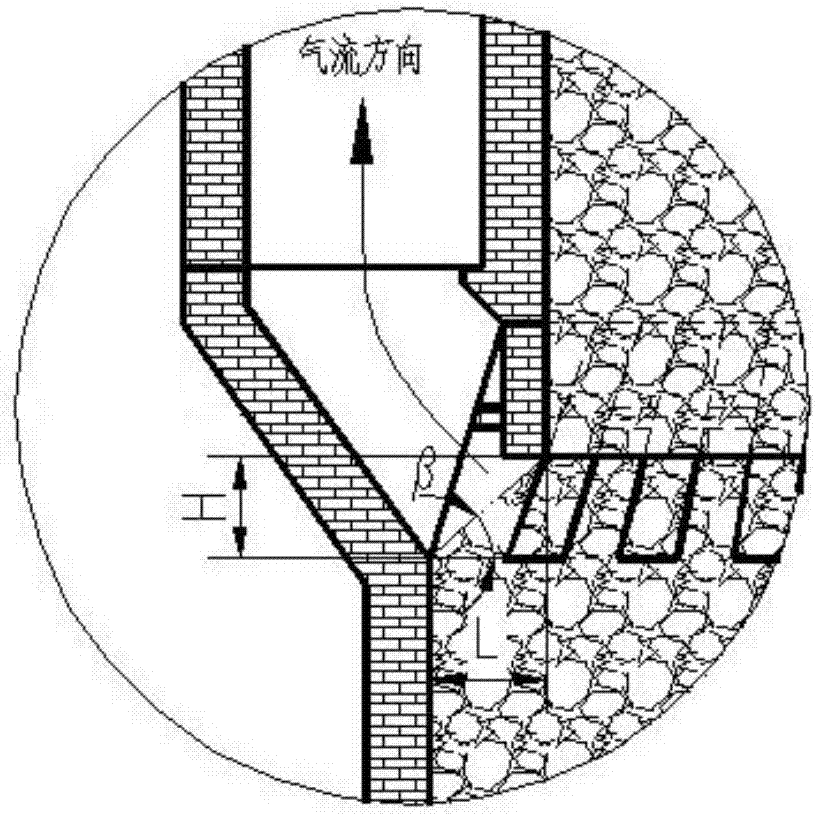

[0023] See figure 1 , a CDQ furnace with a new exhaust structure, including a cooling chamber 4, a pre-storage chamber 1, an inclined flue 3 and an annular air duct 2, and an inclined flue 3 is provided between the cooling chamber 4 and the pre-storage chamber 1 to communicate with the annular air duct 2. The inclined flue 3 is provided with an inclined flue partition wall 6; the diameter of the cooling chamber 4 is larger than that of the pre-storage chamber 1, and the bottom of the pre-storage chamber 1 is provided with an annular coke blocking wall 5, which is connected with the inclined flue A focus blocking wall support 7 is set between the partition walls 6 .

[0024] The horizontal elevation of the bottom of the annular coke blocking wall 5 is higher than the horizontal elevation of the bottom of the inclined flue 3 .

[0025] The vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com