Coagulation filtering method

A filtration method and coagulation technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, special treatment targets, etc., can solve the problems of increasing the amount of discharged water, worsening the turbidity of the treated water, and reducing the water recovery rate. , to achieve the effect of reducing usage and reducing the frequency of regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

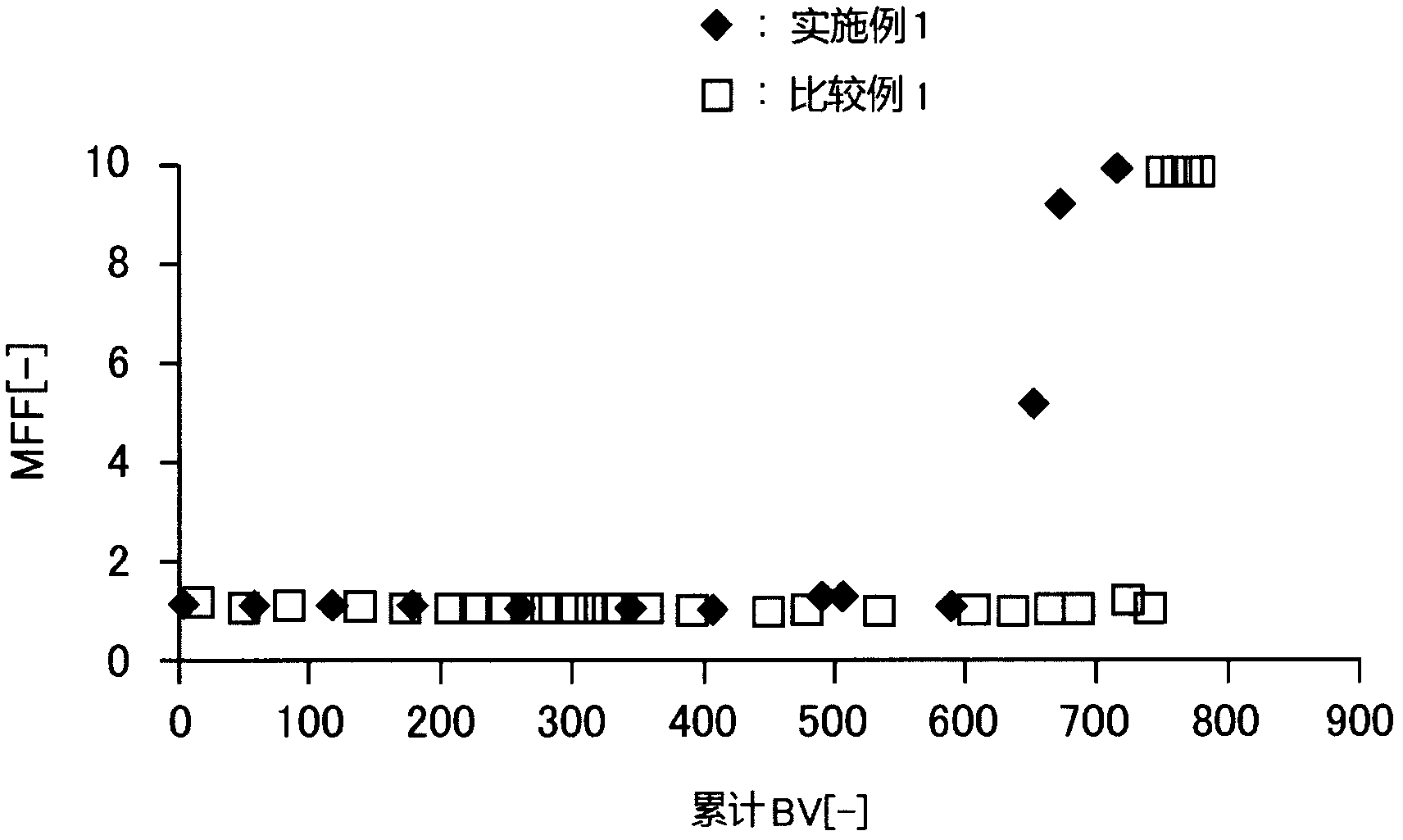

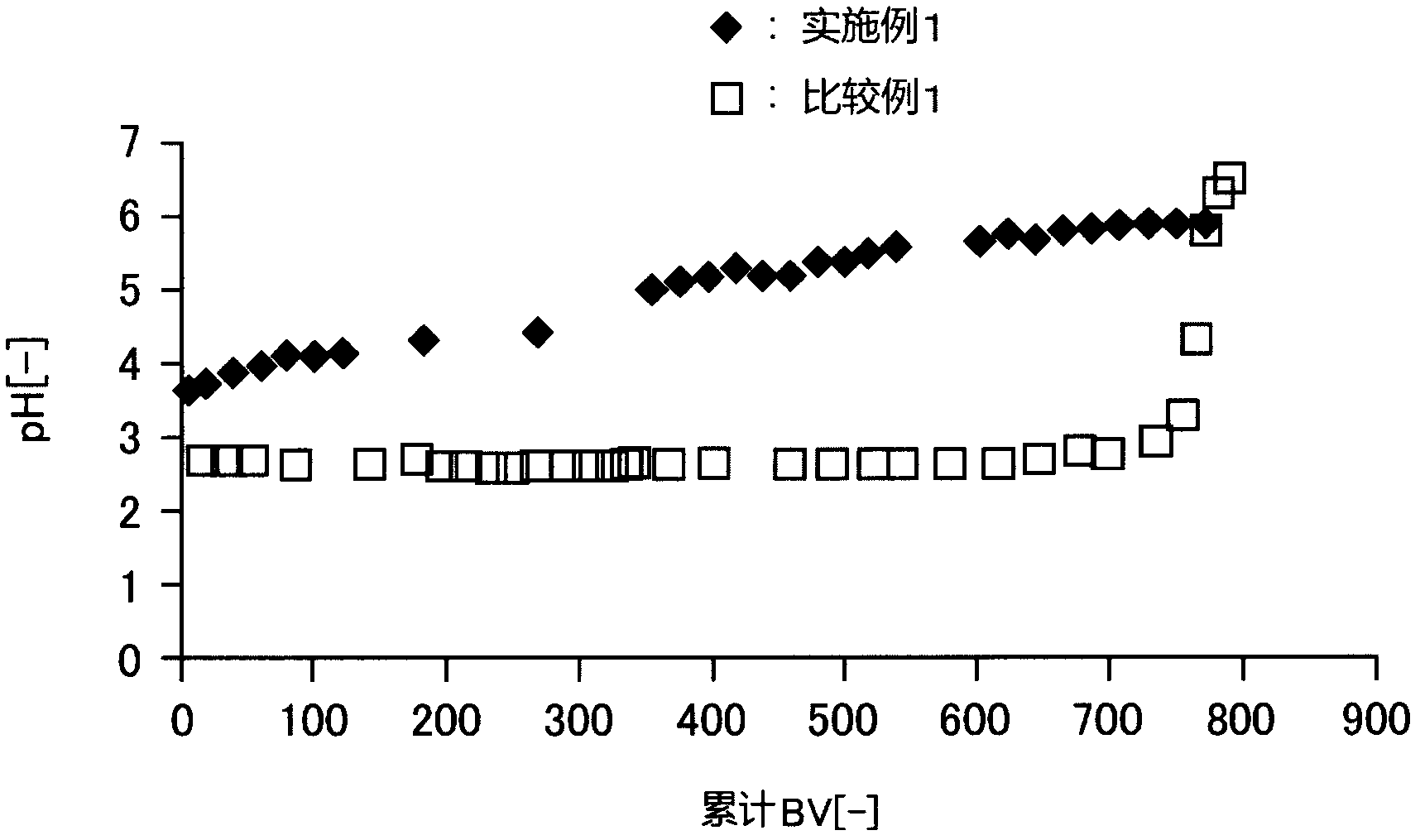

[0041] [Example 1, Comparative Example 1]

[0042] The industrial water of the water quality shown in Table 1 was subjected to the following SS rough separation treatment, and then water was passed into the cation exchange resin column under the following conditions.

[0043] Table 1 Water quality of industrial water

[0044] project

unit

Analysis value

pH

-

7.6

mg / m

37

M base

mg / L

83

SS

mg / L

6.1

Spend

4

Chroma

Spend

6

[0045]

[0046] The coagulation operation was carried out under the conditions of PAC 50 mg / L and coagulation pH 6.5, and the coagulated water was treated by pressurized suspension to roughly separate SS. The pH of the pressurized suspension treated water was 6.5, and the SS concentration was 3.8mg / L.

[0047]

[0048] Example 1: Weakly acidic cationic resin (WC-10, manufactured by Mitsubishi Chemical C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com