Desulfurization and denitration device and technology used for purifying coke oven smoke

A flue gas purification, desulfurization and denitrification technology, applied in the field of coke oven flue gas purification, can solve the problem of high energy consumption, achieve the effects of reducing energy consumption, reducing regeneration frequency, and reducing ammonium sulfate deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

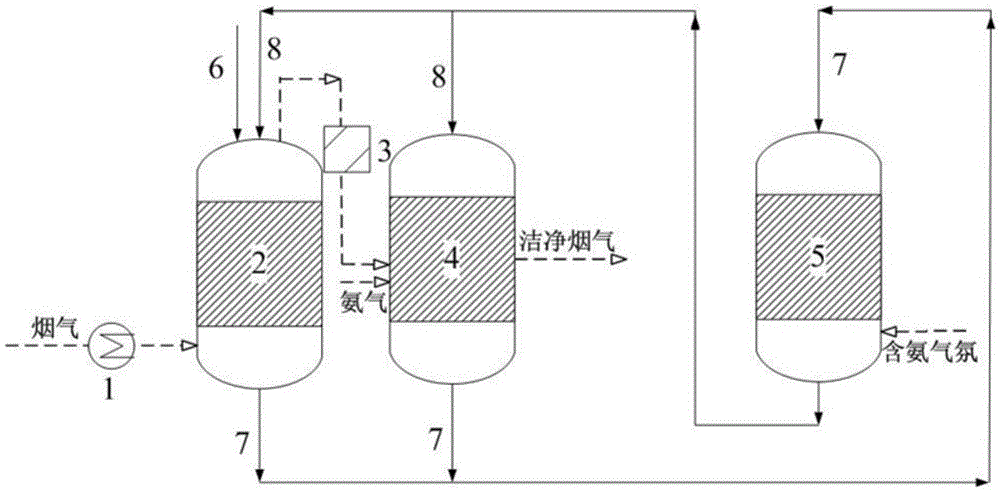

[0052] A desulfurization, denitrification and regeneration device for coke oven flue gas purification, such as figure 1 shown. The device includes a heat exchanger 1, a desulfurization reactor 2, an SCR denitrification reactor 4 and an ammonia regeneration device 5; the desulfurization reactor 2 and the SCR denitration reactor 4 are provided with a carrying device capable of moving downward, and placed in the carrying device There is granular activated coke and / or activated carbon.

[0053] The desulfurization reactor 2 is a desulfurization tower. The carrying device is the transmission device disclosed in CN103894040A. The transmission device includes a hinge and a transmission wheel, and the transmission wheel is connected to the motor; the hinge is provided with several hinge support platforms, and the distance between each hinge support platform should be greater than the height of the hopper; a pair of hinge support platforms on the hinge should be Be highly consistent...

Embodiment 2

[0061] Use the device described in Example 1 to desulfurize and denitrify coke oven flue gas at a temperature of 190°C, and the coke oven flue gas flow rate: 100,000 m 3 / h, water content: 5%, NO x : 500mg / m 3 , SO 2 : 200mg / m 3 , the specific process of desulfurization and denitrification is as follows:

[0062] Active coke is placed on the supporting devices in the desulfurization reactor 2 and the SCR denitration reactor 4 .

[0063] The coke oven flue gas first passes through the heat exchanger to obtain coke oven flue gas at a temperature of 130°C; after heat exchange, the coke oven flue gas enters the desulfurization reactor 2 through the first air inlet at the bottom of the desulfurization reactor 2, Contact desulfurization with active coke countercurrent under certain conditions, fresh active coke and partially regenerated active coke enter the desulfurization reactor 2 through the solid inlet at the top of the tower, and the active coke moves from top to bottom in...

Embodiment 3

[0067] Use the device described in Example 1 to desulfurize and denitrify coke oven flue gas at a temperature of 200°C, and the coke oven flue gas flow rate: 200,000 m 3 / h, water content: 5%, NO x : 800mg / m 3 , SO 2 : 200mg / m 3 , the specific process of desulfurization and denitrification is as follows:

[0068] Activated carbon is placed on the supporting devices in the desulfurization reactor 2 and the SCR denitrification reactor 4 .

[0069] The coke oven flue gas first passes through the heat exchanger to obtain coke oven flue gas at a temperature of 140°C; after heat exchange, the coke oven flue gas enters the desulfurization reactor 2 through the first air inlet at the bottom of the desulfurization reactor 2, desulfurization by countercurrent contact with activated carbon under certain conditions, fresh activated carbon and partially regenerated activated carbon enter the desulfurization reactor 2 through the solid inlet on the top of the tower, and the activated ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com