Catalyst system and method for desulfurization of sulfur-containing hydrocarbon

A technology for catalysts and sulfur-containing hydrocarbons, applied in refining to remove heteroatoms, etc., can solve the problems of desulfurization activity and desulfurization stability, affect the desulfurization effect of sulfur-containing hydrocarbons, and incomplete reduction of active metals, etc., to improve activity And the effect of stability, reduction of pile ratio, and not easy to be lost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

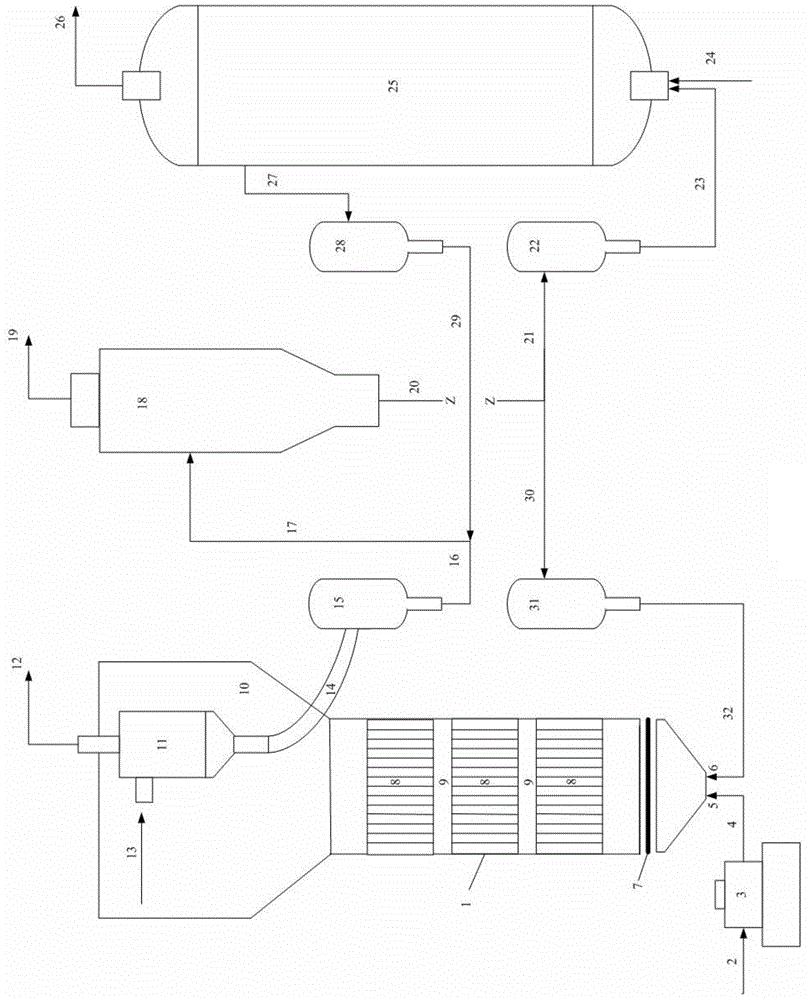

[0063] According to a preferred embodiment of the present invention, preferably, as figure 1 As shown, the method of the present invention is carried out in a device for sulfur-containing hydrocarbon desulfurization, which device includes the sulfur-containing hydrocarbon desulfurization reactor 1, atmosphere replacement and pressure transformation unit and regenerator 25; the sulfur-containing hydrocarbon desulfurization reactor 1 The bottom of the sulfur-containing hydrocarbon desulfurization reactor 1 is provided with an exhaust pipe 12 and a discharge pipe 14; the atmosphere replacement And the pressure transformation unit is provided with reactor receiver 15, reactor feed tank 31, regenerator receiver 28, regenerator feed tank 22, replacement gas inlet pipe (not marked in the figure) and replacement gas discharge pipe 19, Wherein, the atmosphere replacement and pressure transformation unit also includes a lock hopper 18; the reactor receiver 15, the reactor feed tank 31, ...

Embodiment 1

[0079] This example is used to illustrate the catalyst system and the method for desulfurizing sulfur-containing hydrocarbons of the present invention.

[0080](1) Catalyst system (the weight ratio of the desulfurization aid to the active component coating of the structured catalyst is 1:1).

[0081] Preparation of Regular Structure Catalysts: Ni / Al 2 o 3 For the active component coating, it is coated on a cordierite honeycomb carrier (the carrier pore density is 400 holes / square inch, and the porosity is 70%) to obtain a regular structure catalyst, and the nickel content on the active component coating is 80% by weight , Al 2 o 3 The content is 20% by weight. The active component coating content of the catalyst was 25% by weight.

[0082] The desulfurization aid is prepared by the following method:

[0083] Mix 6.07 kg of zinc oxide powder (produced by Beijing Chemical Plant, containing 6.0 kg on a dry basis), 0.32 kg of lanthanum oxide (produced by Sinopharm Group, con...

Embodiment 2

[0090] This example is used to illustrate the catalyst system and the method for desulfurizing sulfur-containing hydrocarbons of the present invention.

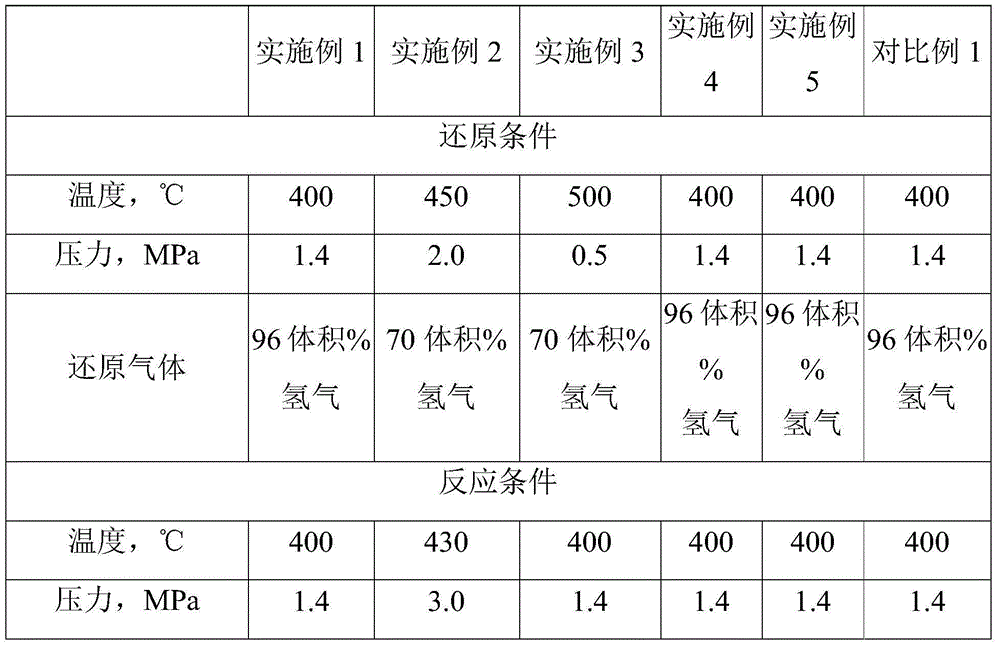

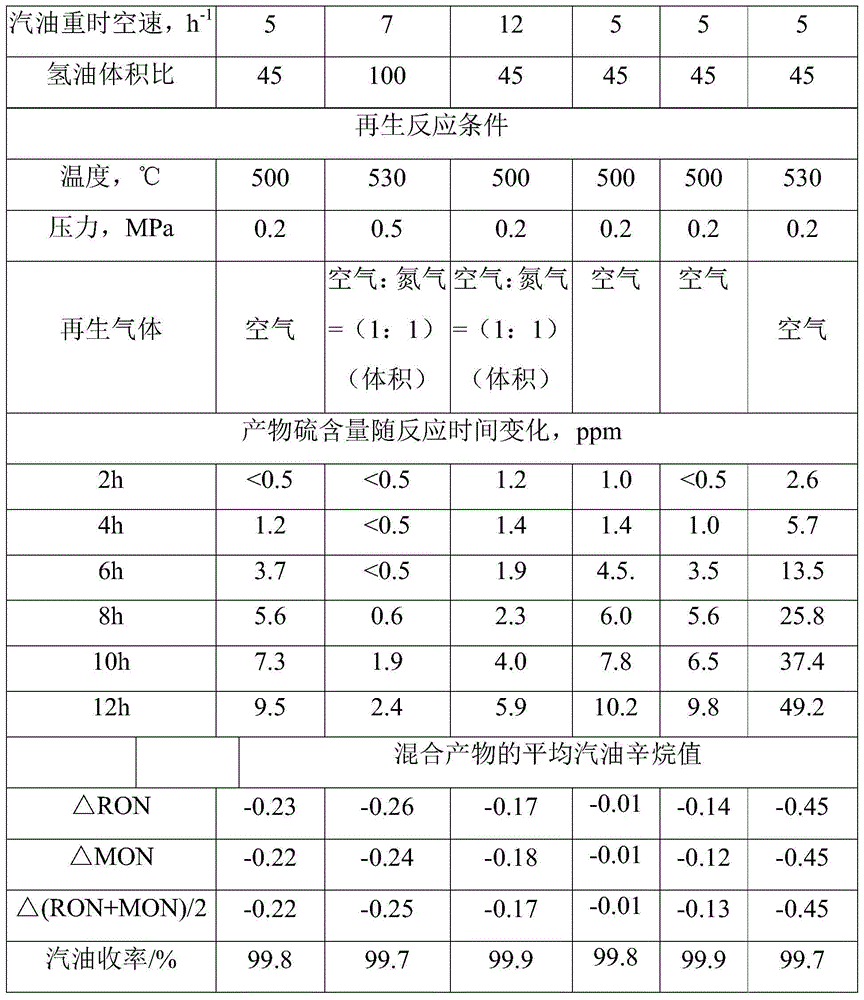

[0091] According to the method of Example 1, the difference is that the reduction in (2): use "400°C" and "containing 70% hydrogen by volume" instead of "450°C" and "containing 96% hydrogen by volume"; desulfurization: use " The temperature is 430℃, the pressure is 3.0MPa, and the gasoline weight hourly space velocity is 7h -1 , the volume ratio of hydrogen to gasoline is 100", replacing "the temperature is 400°C, the pressure is 1.4MPa, and the space velocity of gasoline is 5h -1 , the volume ratio of hydrogen to gasoline is 45". The reaction conditions and reaction results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com